Associate

Hey guys! Yes i'm back with another build, but this one isn't for me, I have enough rigs for now, it's for my good friend TJ. He actually got me heavily into tech and PC's when we were growing up and has been enviously watching on my various exploits building insane watercooled rigs and working with Parvum. So now we are working together to build a completely new rig for him with some serious water cooling and pretty insane components for it's size.

I won't be photographing every baby step on this one, just giving a thorough overview of the progress and custom work taking place, as we want to get it completed quite swiftly when we both have the time to work on it.

Parvum Systems R1.0 360

Intel Haswell-E i7-5930K

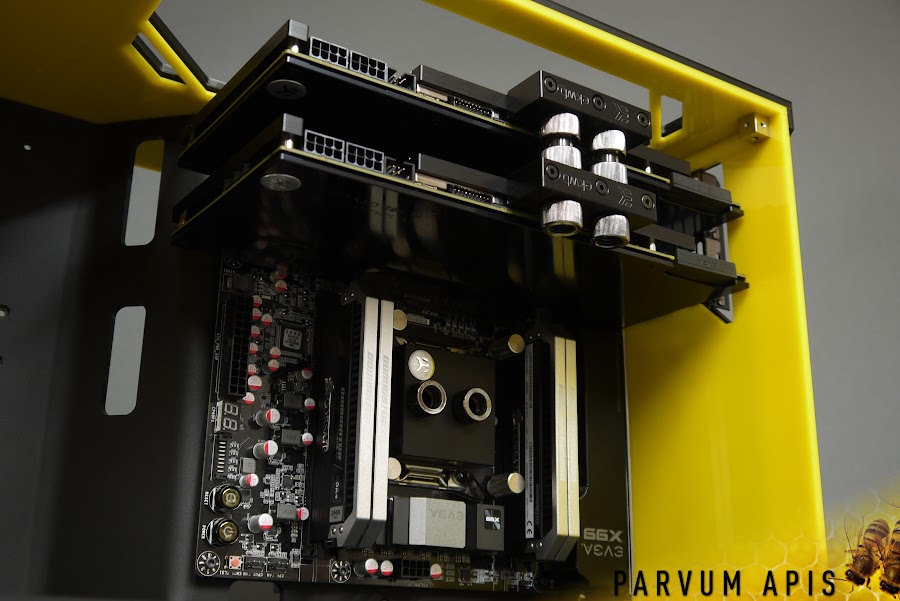

EVGA X99 Micro

EVGA GTX 980 Classified x2

Corsair Dominator Platinum DDR4 4x4GB

Samsung 500GB 840 Evo

EK FC980 Classy Nickel/Acetal x2

EK Supremacy EVO Nickel/Acetal

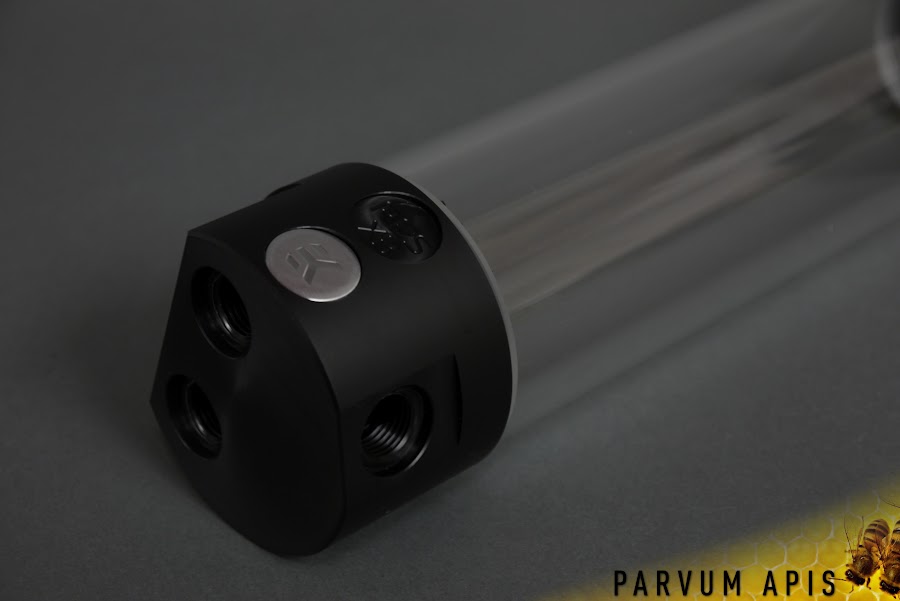

EK D5 REVO Pump Top Acetal

EK RES X3 250 Black Acetal

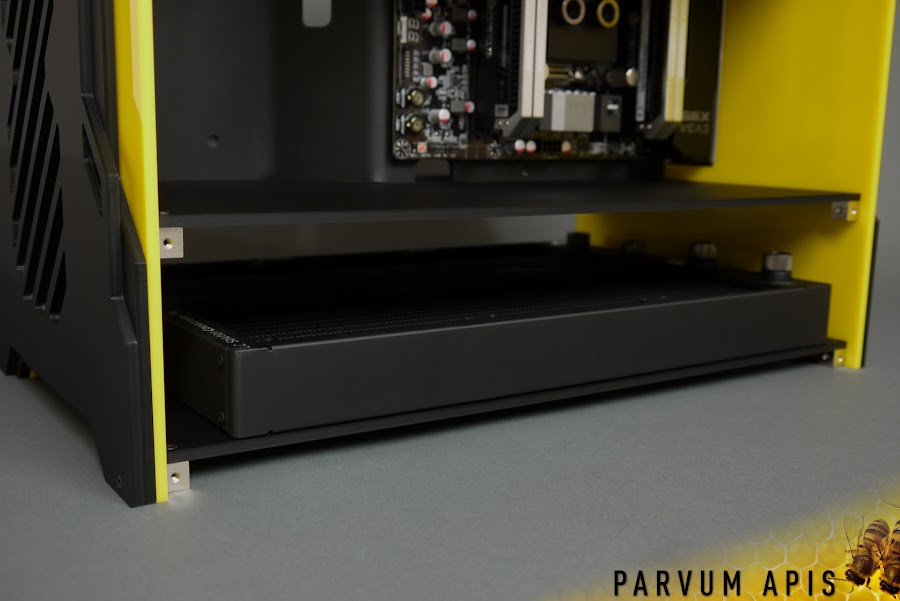

EK CoolStream PE 360 (Triple)

EK HD Adapter 10/12mm Black Nickel x28

Corsair SP120 Performance Edition PWM x8

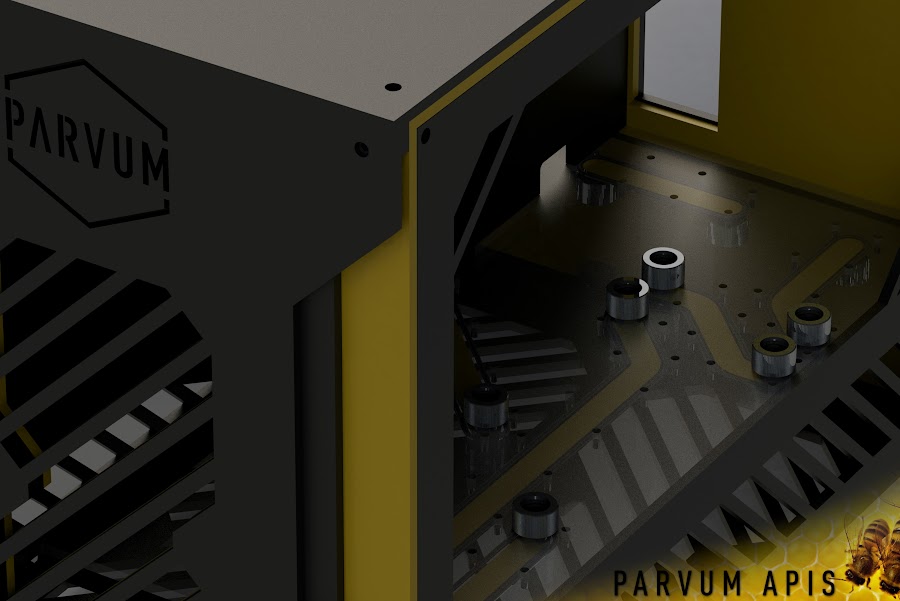

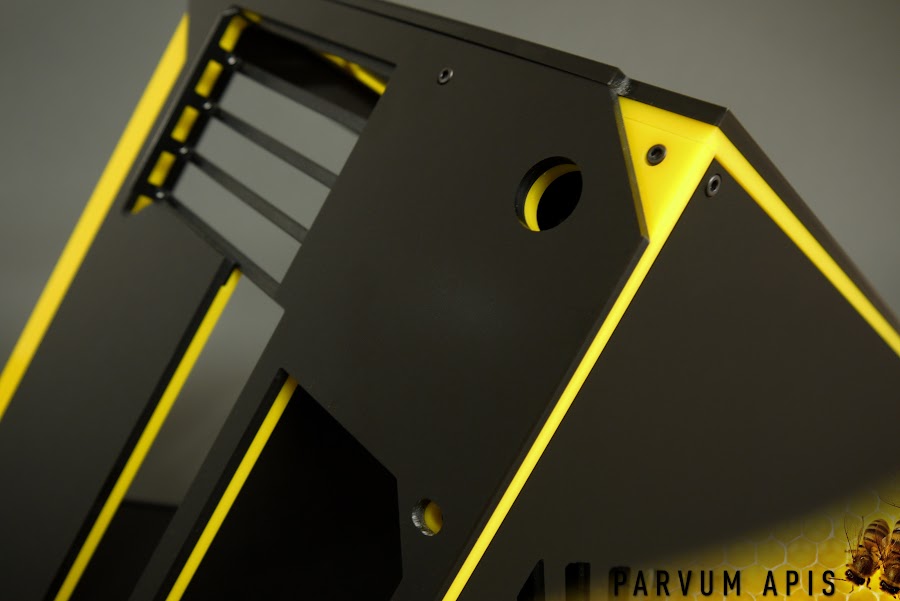

We spent a long time discussing the case, we established very early on that it had to be black and yellow which suited the neutral components very well. Everything had to be visible in an appropriate hierarchy making an inverted platform inevitable. The as of yet unreleased Parvum R1.0 seemed like a great starting point but despite only 3 existing in the world a more exclusive platform was demanded! Following a huge circle of deciding between an inverted S2.0 360 and an R1.0, the R1.0 360 was born.

As a nod to the L1.0's subtle side vents which break up the pedestal we chose to also and a fine strip of slats to both side panels which hopefully will discretely reveal the radiators and fans lurking beneath them.

GPU window of course, why else go to the trouble of an invert.

Cheeky rear power button, later in the build it will become apparent why it ended up here.

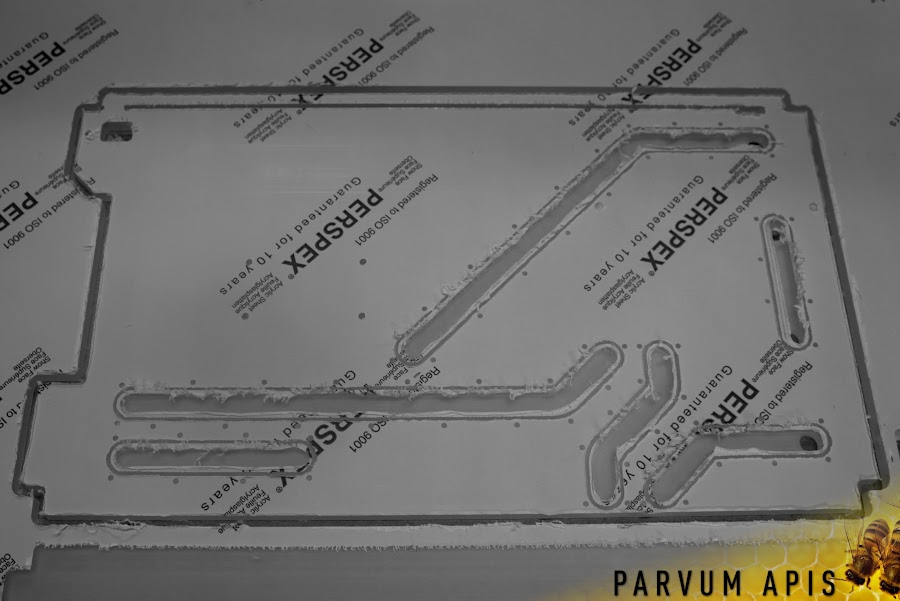

The relatively shallow height of the main chamber meant there wasn't room to take the conventional Parvum HDD bracket approach. Instead all of the drives will be mounted directly to the motherboard tray, not quite as modular but hopefully neater.

Finally what it's all about! It occurred to me a while ago that the S2.0 was the exact width of two radiators hence why the R1.0 was created, this takes that a little further by adding two 360mm radiators side-by-side. Quite unique for what is still a relatively compact mATX rig. I really love the wider aspect ratio it brings to the window leaving lots of room for pumps and reservoirs ahead of the graphics cards.

I'll be back very soon with the first test fitting then it's on to design the loop.

JR

Last edited:

Nice build by the way

Nice build by the way