Ok after a couple of busy weeks things have started to move a little bit quicker.

First off i'd like to thank MAYHEMS for the little parcel they sent me.

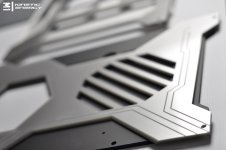

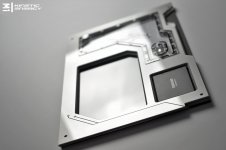

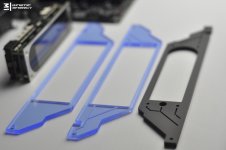

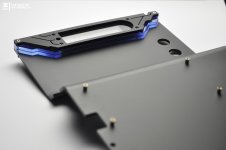

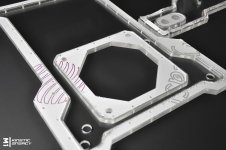

So the last few days ive been polishing the acrylic Reservoirs, now this is not an easy task as ive spent countless hours sanding them up plus re going over the last one i did as i was not happy with how it turned out, anyway thats all finished now. A little tip for those that also want to do this as i done this all by hand no little gadgets to help, once you have finished polishing and buffing and you need to get the polishing residue off, if you use distilled water instead of tap water, when it drys this will dry without leaving streaks or smudges, this is also good for cleaning windows and the likes of car windscreens, plus your hardline tubing after you have cut and chamfered the edges, i just use a small tray filled up with distilled.

Now i just need to tap the screw holes and make up some o-rings and put them together with their lids.

Also this is what Mayhems sent me, i think i have enough dye to last a life time. They also sent me their Havoc 240mm Rad, I wont be using this in this build but i might in a future build, its a nice looking Rad and if you check out the performance online, it is up there with the Best

Thanks for checking this post out, more Updates to follow very soon.