Soldato

Hey all, first time in about a decade I am doing a full on project and finally moving away from my old lovely custom tj-07, you can find the first refit of that here https://forums.overclockers.co.uk/threads/project-magus-refit.18272137/ Since then it had a new rad in the front (hdd's moved to a server) and gpu changes etc but nothing major.

New project is going to be in a Lian Li PC-011 Dynamic in white.

First time I will be spray painting things myself.

3 x 360 rads, UV strips, RGB Fans/CPU Block/RAM/Motherboard.

UV coolant, helix reservoir, clear tubing, black fittings, shiny backplates etc.

Wanted to move away from my red/black/white highlights color scheme, and avoid some of the main trends of RGB rainbow puke on everything. I still love UV.

I decided I really liked the UV Purple coolant from mayhems, then couldn't think of anything to go with it except for green due to "The Joker". Thus, the scheme for this was born.

My plan is to spray the fans blades and housing, one fluorescent green, one fluorescent purple. Not sure which way round yet. Leaving gaps where the LED's go on the two sets of fans that are RGB. Spray the outer housing on the rads in a metal effect to hopefully get them reflective a bit.

UV lighting on all the time since I couldn't find good strips which connected via anything other than molex.

RGB, on mobo/cpu/ram probably linked to system data like load/temp unless they are too bright and over bearing in which case I might put some strips in the roof for this effect through the vents.

Fan RGB set to react to music/sound depending on how that works in modern software, and preferably flashing white, although that might change once i get it set up and can see what options look like etc.

Rear side panel and top I am spraying black, as I want the outside largely black, just the internals outlined in white. I am currently approaching artists I know to get someone to do some fancy joker related design on the rear side panel - if anyone is an artist and would like to be commissioned to do this, let me know. Etching something on the glass panel is also an option.

IF a full cover block gets released for the mobo, then I will get that later, I also have the blocks for WC on the RAM due to getting them basically for free with an order but I expect to not use them due to RGB on the RAM i have.

Hardware:

r9 3900x

Asus Crosshair VIII wifi

32GB Corsair Vengeance RGB 3200 c16

512gb Corsair mp510 force M.2ssd

2TB Intel 660p m.2 ssd

2 x EVGA 980ti SC (going to see how they run and then maybe upgrade them, prices will come down in mean time )

)

Silverstone 1500w PSU

Cable mod extension set in white.

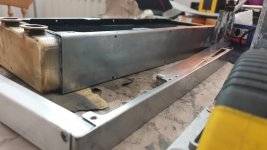

2 x thermochil 360 rads

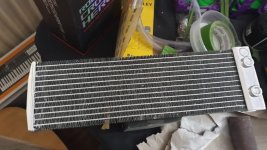

1 x EK slim 360 rad

(one fat and one slim 240 rads spare if i need the space)

Laing d5 pwm pump in monsoon MMRS casing in black

Alphacool Eisbecher helix res - green

EK-Scalar Dual 3-Slot Graphics Card Link Connector - Plexi

EK Supremacy EVO RGB Plexi/nickel

EK FC blocks and backplates in Nickel/acetel

EK compression fittings in black

Corsair COmmander Pro

Corsair RGB Fan Controller

Lamptron FlexLight Standard - 60 LEDs - UV

Clear soft tubing

Mayhems UV Purple Coolant

3 x Corsair SP120 RGB (side)

3 x Alpenfohn wingboost 3 120 white (top)

3 x Noiseblocker NB-Eloop white 120 (bottom)

Spray paint, primer etc

Parts will be arriving this coming week and I will be doing a test of the hardware to check it all works and fits etc, then spraying things, testing them, then water cooling it all. I expect it to take me 1-3 weeks depending on how lazy I am/how quickly spraying things takes and how long it takes to clean all the water bits that I am re using.

Any productive input is welcome, or if you are london based and have an amazing idea you think you can do on the project, hit me up.

New project is going to be in a Lian Li PC-011 Dynamic in white.

First time I will be spray painting things myself.

3 x 360 rads, UV strips, RGB Fans/CPU Block/RAM/Motherboard.

UV coolant, helix reservoir, clear tubing, black fittings, shiny backplates etc.

Wanted to move away from my red/black/white highlights color scheme, and avoid some of the main trends of RGB rainbow puke on everything. I still love UV.

I decided I really liked the UV Purple coolant from mayhems, then couldn't think of anything to go with it except for green due to "The Joker". Thus, the scheme for this was born.

My plan is to spray the fans blades and housing, one fluorescent green, one fluorescent purple. Not sure which way round yet. Leaving gaps where the LED's go on the two sets of fans that are RGB. Spray the outer housing on the rads in a metal effect to hopefully get them reflective a bit.

UV lighting on all the time since I couldn't find good strips which connected via anything other than molex.

RGB, on mobo/cpu/ram probably linked to system data like load/temp unless they are too bright and over bearing in which case I might put some strips in the roof for this effect through the vents.

Fan RGB set to react to music/sound depending on how that works in modern software, and preferably flashing white, although that might change once i get it set up and can see what options look like etc.

Rear side panel and top I am spraying black, as I want the outside largely black, just the internals outlined in white. I am currently approaching artists I know to get someone to do some fancy joker related design on the rear side panel - if anyone is an artist and would like to be commissioned to do this, let me know. Etching something on the glass panel is also an option.

IF a full cover block gets released for the mobo, then I will get that later, I also have the blocks for WC on the RAM due to getting them basically for free with an order but I expect to not use them due to RGB on the RAM i have.

Hardware:

r9 3900x

Asus Crosshair VIII wifi

32GB Corsair Vengeance RGB 3200 c16

512gb Corsair mp510 force M.2ssd

2TB Intel 660p m.2 ssd

2 x EVGA 980ti SC (going to see how they run and then maybe upgrade them, prices will come down in mean time

)

)Silverstone 1500w PSU

Cable mod extension set in white.

2 x thermochil 360 rads

1 x EK slim 360 rad

(one fat and one slim 240 rads spare if i need the space)

Laing d5 pwm pump in monsoon MMRS casing in black

Alphacool Eisbecher helix res - green

EK-Scalar Dual 3-Slot Graphics Card Link Connector - Plexi

EK Supremacy EVO RGB Plexi/nickel

EK FC blocks and backplates in Nickel/acetel

EK compression fittings in black

Corsair COmmander Pro

Corsair RGB Fan Controller

Lamptron FlexLight Standard - 60 LEDs - UV

Clear soft tubing

Mayhems UV Purple Coolant

3 x Corsair SP120 RGB (side)

3 x Alpenfohn wingboost 3 120 white (top)

3 x Noiseblocker NB-Eloop white 120 (bottom)

Spray paint, primer etc

Parts will be arriving this coming week and I will be doing a test of the hardware to check it all works and fits etc, then spraying things, testing them, then water cooling it all. I expect it to take me 1-3 weeks depending on how lazy I am/how quickly spraying things takes and how long it takes to clean all the water bits that I am re using.

Any productive input is welcome, or if you are london based and have an amazing idea you think you can do on the project, hit me up.