Following on from selling off the dreaded chinese 125, I have been looking for a while for an old Japanese 125 to use what I learnt and have a nicer bike! I was falling over cheap YBR and CBF types which just looked too dull. I was not keen on spending much more than £500 because, well, no real reason, it just seemed a small enough amount to spend on a weekend rebuild project

I found a 2005 CBR 125R RS5 for sale quite near by for £810. It looked a bit cooler than other bikes in the budget, and after a quick HPI it came up as a CAT C in 2006! So I told the owner the bad news, beat him down on price, and we agreed on £650 with a full tank of fuel and new tyres.

I drove it home, broke the gear selector being ham footed, had to limp on a bit in 1st gear, then pull over and ask a nice man called Dave for an allan key so I could re-fit it (a bit tighter this time..)

It was otherwise a nice (if not slightly nervy) 30+ mile ride home avoiding motorways trying to get used to the bike, the weather, and the fact the clocks were almost bouncing out of the cockpit on any bump or jolt.

Made it back, parked it up, and have since been starting to pull it to bits where needed, and will update you with progress as I go.

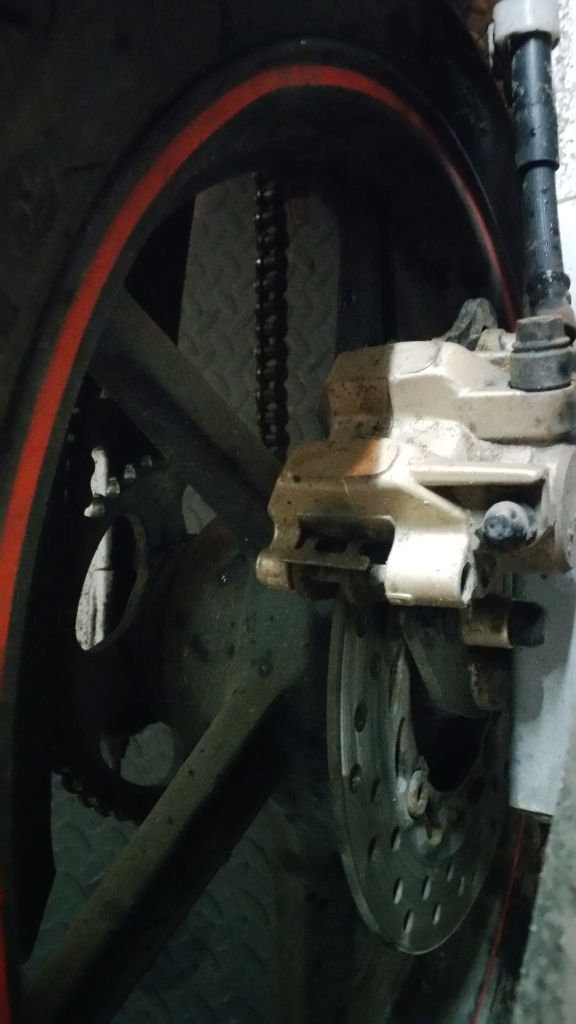

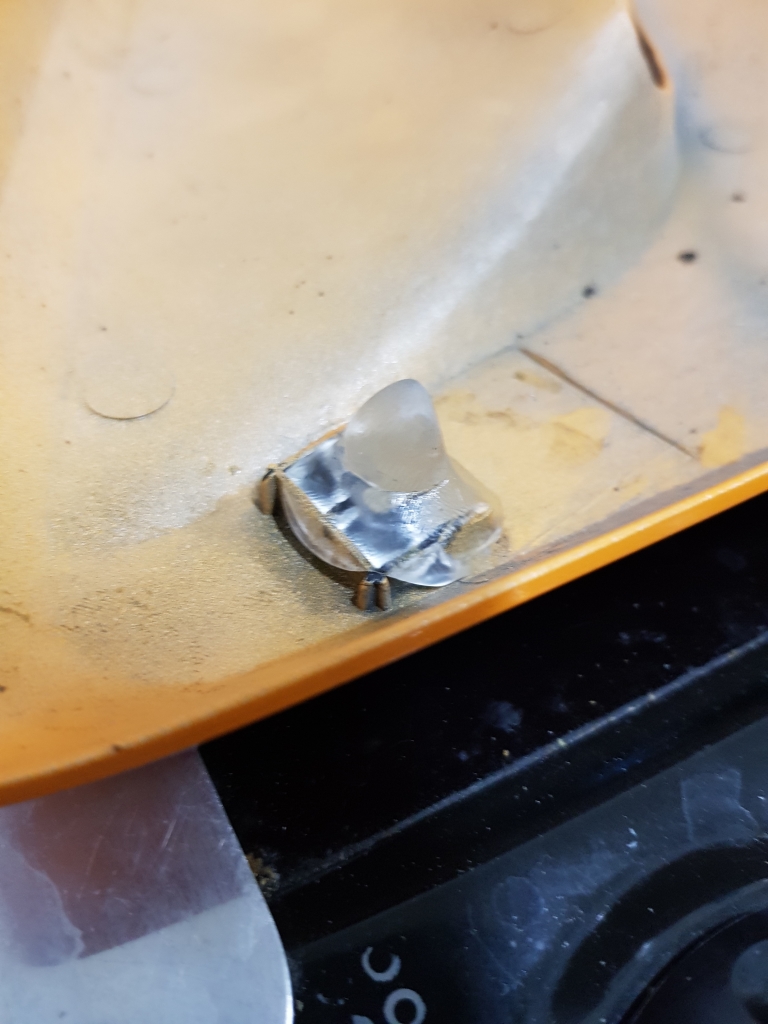

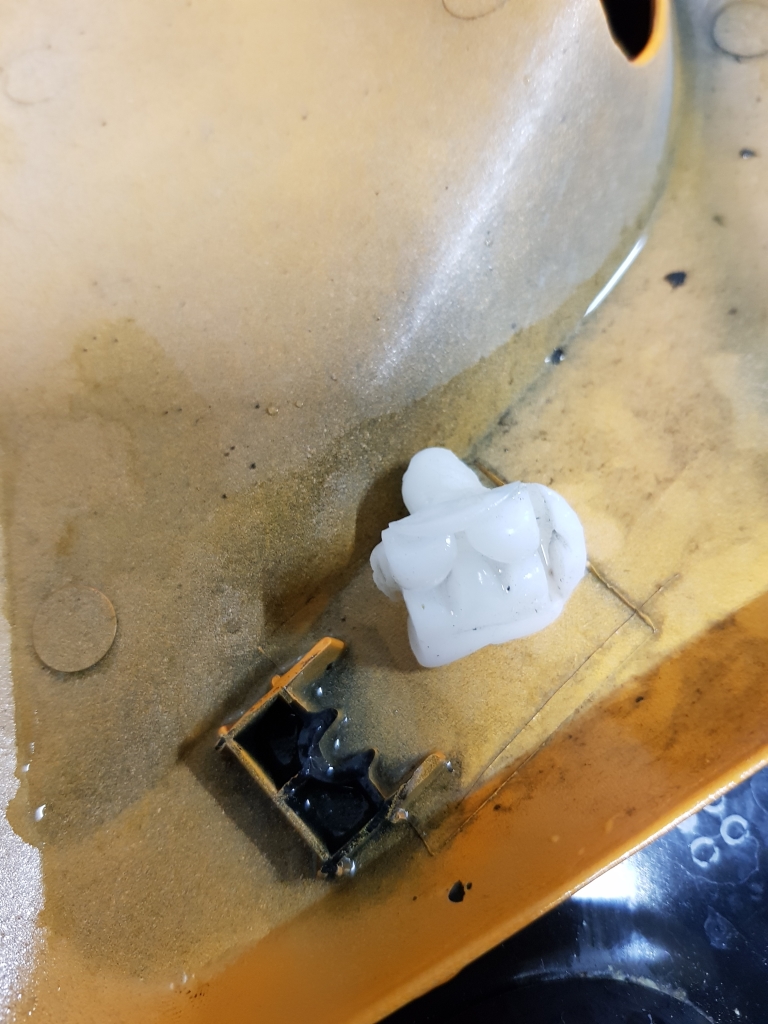

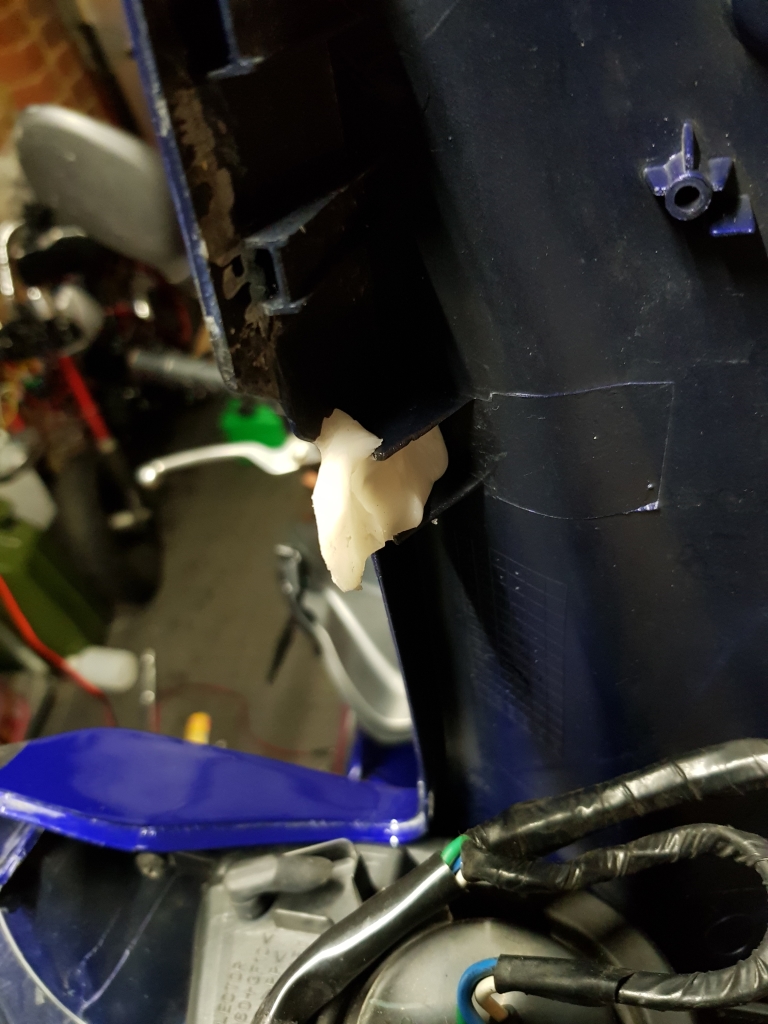

Plan is to service it, find any broken bits, fix/replace them, clean it up, upgrade a few bits to make it look smart, and then ride the thing a lot

I found a 2005 CBR 125R RS5 for sale quite near by for £810. It looked a bit cooler than other bikes in the budget, and after a quick HPI it came up as a CAT C in 2006! So I told the owner the bad news, beat him down on price, and we agreed on £650 with a full tank of fuel and new tyres.

I drove it home, broke the gear selector being ham footed, had to limp on a bit in 1st gear, then pull over and ask a nice man called Dave for an allan key so I could re-fit it (a bit tighter this time..)

It was otherwise a nice (if not slightly nervy) 30+ mile ride home avoiding motorways trying to get used to the bike, the weather, and the fact the clocks were almost bouncing out of the cockpit on any bump or jolt.

Made it back, parked it up, and have since been starting to pull it to bits where needed, and will update you with progress as I go.

Plan is to service it, find any broken bits, fix/replace them, clean it up, upgrade a few bits to make it look smart, and then ride the thing a lot

Last edited: