- Joined

- 10 Dec 2017

- Posts

- 49

Time for some time consuming but neccecary stuff

All the harddrives and ssd custom cables have been done. Some small fixes to be made still but it's all there and it works

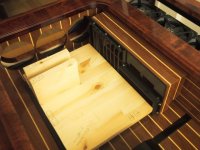

My custom stand for it all if anyone forgot

Not a fun cable to make:S

All done just gonna tuck it a bit and the cables will flow perfectly

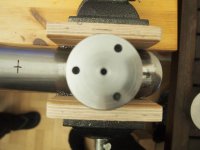

And yeah the key ignition is up and running!

All the harddrives and ssd custom cables have been done. Some small fixes to be made still but it's all there and it works

My custom stand for it all if anyone forgot

Not a fun cable to make:S

All done just gonna tuck it a bit and the cables will flow perfectly

And yeah the key ignition is up and running!

) and theeen another molex end made for the pumps. But all in all it worked well and 10 components running off 1 cable seems very efficient and clean so I'm happy.

) and theeen another molex end made for the pumps. But all in all it worked well and 10 components running off 1 cable seems very efficient and clean so I'm happy.