Associate

- Joined

- 7 Jul 2010

- Posts

- 18

Hi OCUK,

I'm not sure if this quite a build log, but I wanted to share my progress with my latest build. I know I like my context when sharing a build, so I'll do my best to not go waffling on.

This has been going since Oct 2017 when I decided, after much thinking, that I wanted to build a smaller PC. At the time I had been involved with strike action at work, so money was a bit tight. I couldnt afford to build a entriely new rig, so made the decision to re-house my current setup and bought a Mastercase Pro 3 to see if I could make it work.

I started a new job shortly after that, and finding free time to do the build became a bit harder, so progress slowed. I chipped away at the mod, and after a number of external things holding me up (disadvantages of doing things on the cheap sometimes) I finally managed to get it 90% built ready for my event AtomLAN 41 in August this year. I then moved into my first house, etc, and this is where we are today (Still sorting out that free time

Parts:

CPU: 4790K

Mobo: Asus Z97-Pro WiFi ac

RAM: Corsair Vengence Pro 16GB

GPU: 980ti Hydrocopper

SSD: Crucial M4 256gb

HDD: WD black 1TB, WD Green 3TB

PSU: Focus Plus Gold 750w

Cable + Connectors: Pexon PC's

Sleeve: Telios

Cooling:

CPU EK Supremacy EVO

Pump: EK-XRES 100 D5

Rads: EK 280 XTC, Blackice GTS 240

Controller: Commander Pro

Fans: Areocool Dead Silence 120/140 Blue

Temp Sensor: Aquacomputer G1/4 straight through, Alphacool Eiszapfen G1/4 plug

To start, I got home to the new case, ripped it out of the case and got some cardboard out to see what was happening. I had already bought a second hand EK rad to go with the Blackice I had from my old LANBOY build. Now that has been around quite a while. Still not much better at taking photos

A quick look at the new Pro 3 vs the current TJ-07

I grabbed some cardboard and started brainstorming

I wanted to get a feel for what I wanted to do, so hooked up the fans and spent more time thinking about it. One thing I did know - those blue LED's would have to change.

I ordered some diffused white LED's and got to replacing all of the LED's on the fans.

Getting there

Apparently the 120 and 140 Areocool DS's are made differently. The LED's are placed facing different ways which gives a different effect between fans. Not a major thing, just having them next to each other they look a bit odd. The white LED's I used are the same brightness.

Before/After

Full Set

Whilst this was happening I had drawn up a few parts on the PC, from my CAD (Cardboard Aided Design) and the parts I had that were not in use in my PC, including a D5 EK pump/res that I had bought in anticipation (thanks to el2k) .

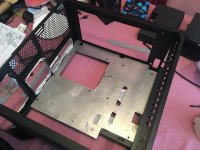

The first parts came back from the laser and went onto the case to test for fit.

The PSU bracket was one of the things I had worked out I would need fairly early on in the CAD process, as I needed to move the PSU over ~10mm.

Pump/Res to Rad mount

A while later, a second (or third) hand GPU from another BT member (thanks keenan) had arrived, so I took the opportunity to partially strip my rig to test fit some of the parts in the case

Throwing the Mobo and GPU in the case proved it was going to work, with only a couple of tight places.

Mobo to HDD cage clearance

Mobo to PSU clearance

HDD to pin header was always going to be close, and I had had the idea of 90deg headers, which also looked like they were good to go

I put the old rig back together and got back to the CAD

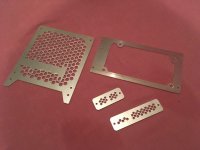

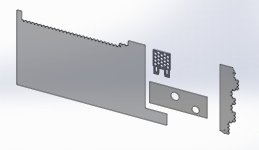

I had already decided that I liked the hex mesh on the case and had made the pump/res mount and Mobo tray passthroughs to suit. With the midplate back in and the Mobo now properly bent to suit, I thought it would look cool to have the Mobo sort of punch through the midplate.

I got back to the PC, and spent quite a while thinking about what I wanted to do. Hexagons did become a bit of a thing - I do have a fondness for polygons. After a lot of head scratching, this is what I had. Mobo Tray, Midplate, Front panel and there is a new bracket for the PSU as I gave it another 2mm clearance (12mm total)

and some acrylic parts to match, including a new swirl plate for the D5 res

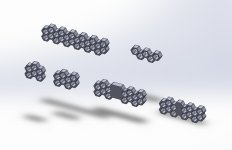

I also wanted to give hex cable combs a go - so drew a few up to see how they would come out

With those files at various different friends for cutting, I turned to sorting the case out to fit the PSU. A larger hole was cut and I modified a hole punch to pull a boss in the sheet metal to allow it to take a thread.

The holes came out well, only needing a touch up of paint on the metal that had been stretched