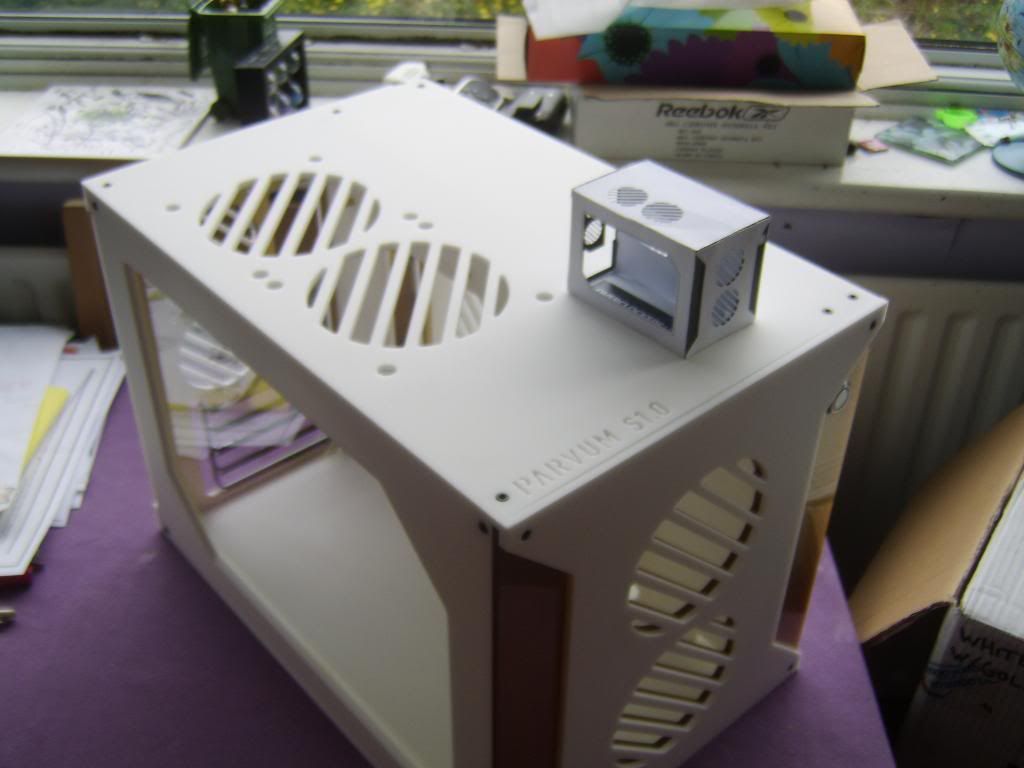

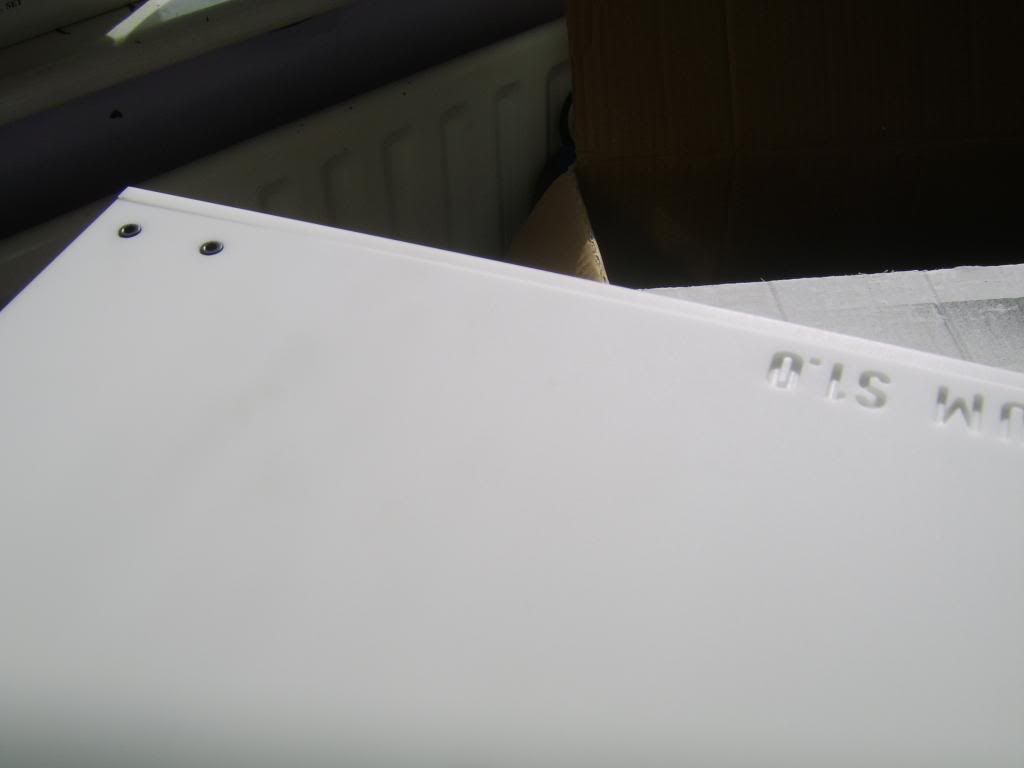

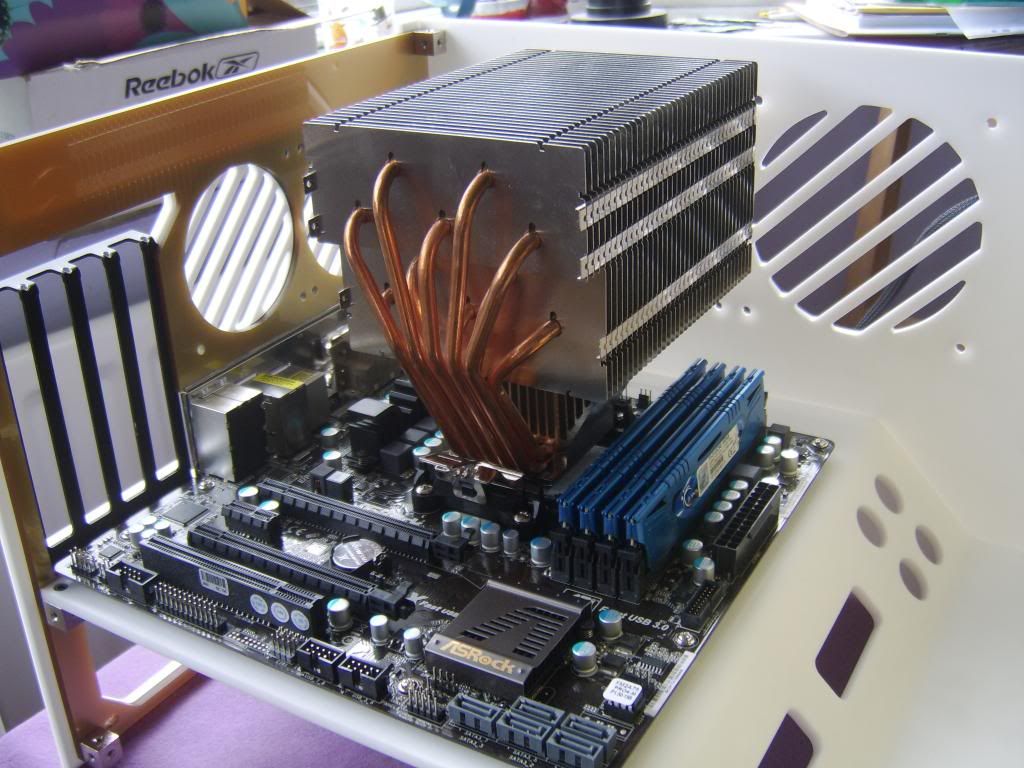

A closer look clearly shows that the Parvum guys are serious about case design, there are a lots of small details that shout quality.

The top panel can be easily alined due to the front being 5mm higher and acts as a guide

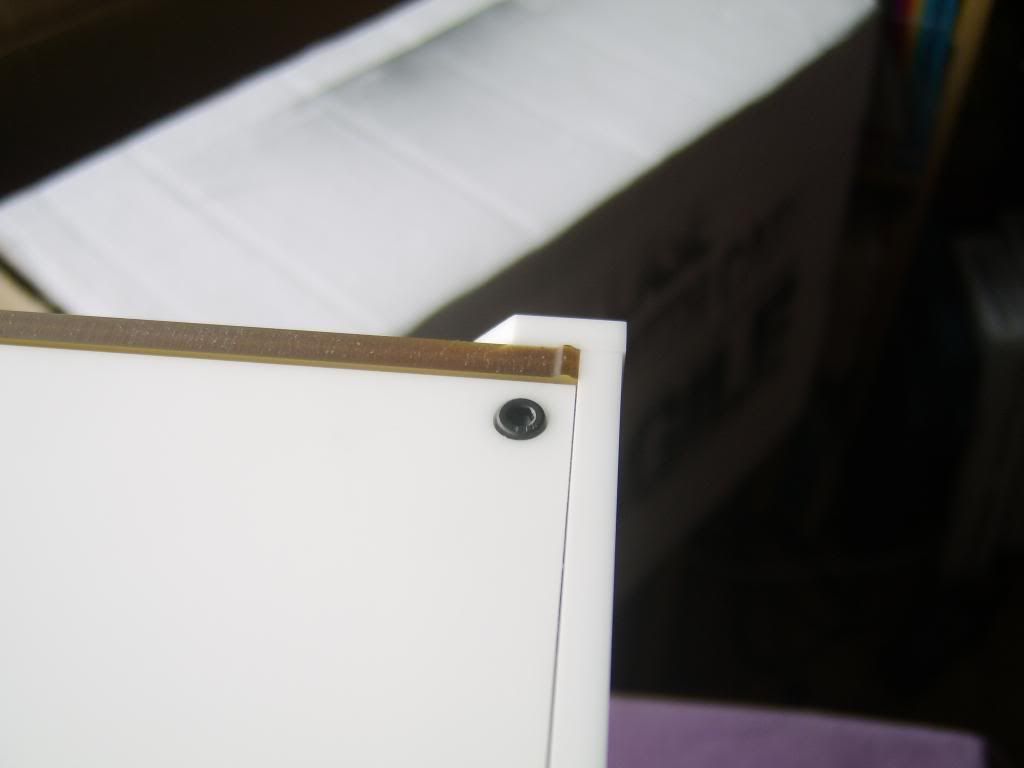

The twin front and back panels so the fan fixing are hidden (shame this isn't also on the roof)

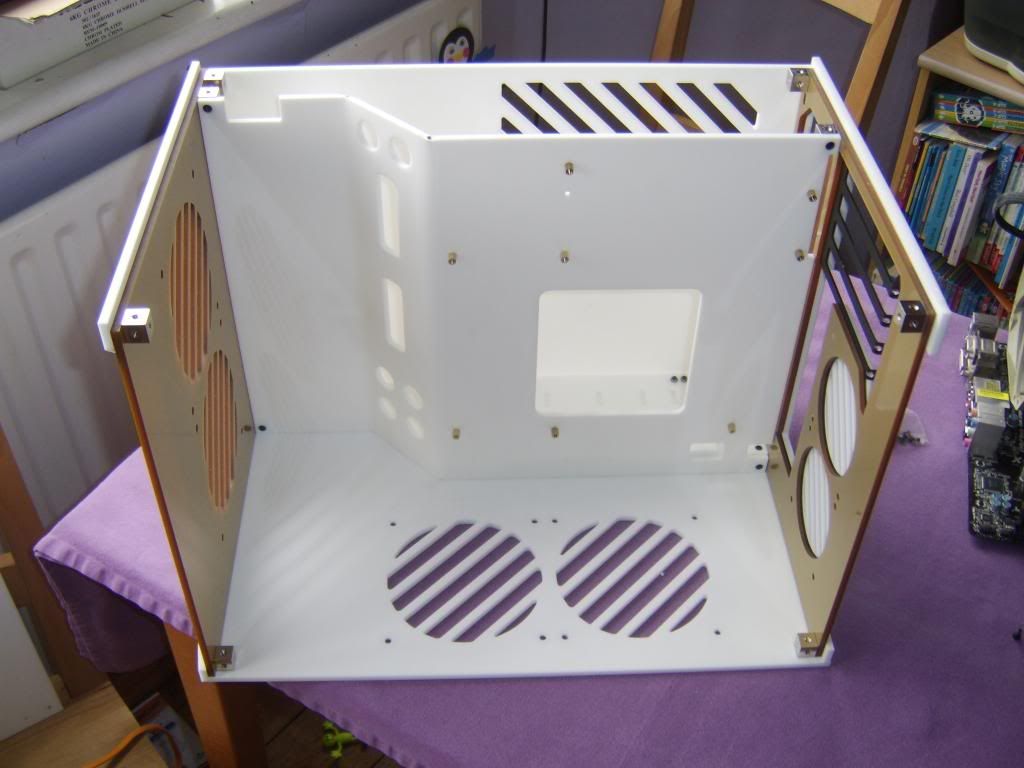

Rounded edges on all the cut outs are a product of the manufacture process, but are still most welcome.

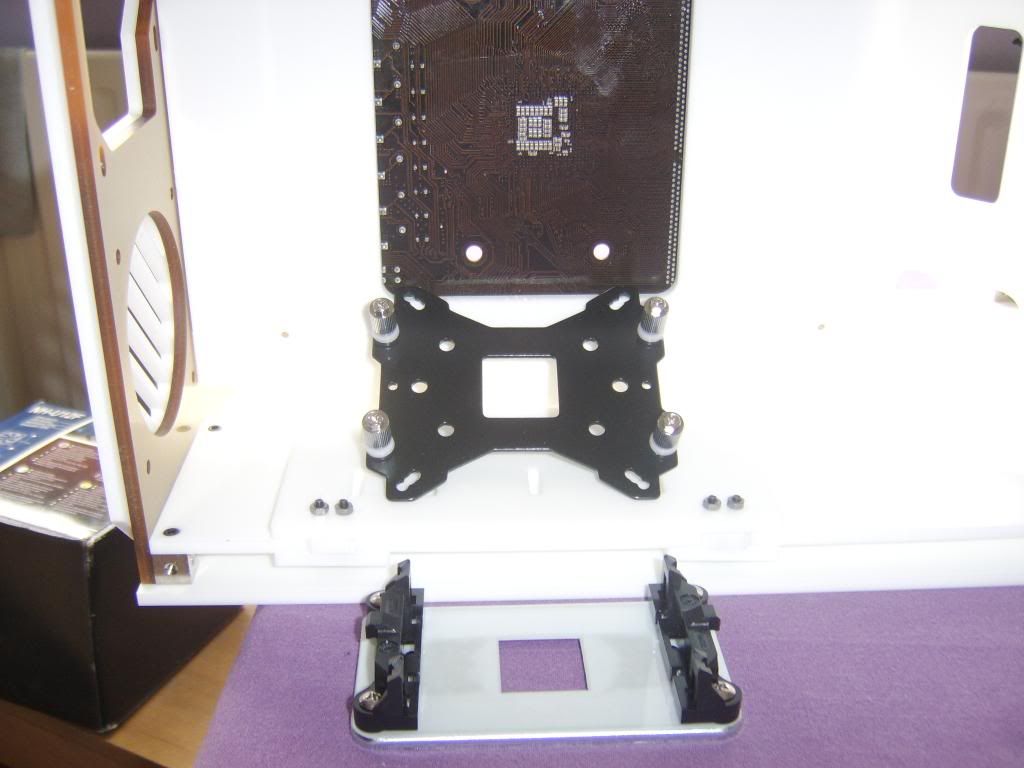

In key areas (mobo tray) larger radius have been used by design, instead of the default tooling generated corner.

The manufacture of an external corner doesn't have this radius - which is perfect to keep the case looking cubic overall

As a design ethos (rounded internal, sharp external) I can't help but want the two sharp corners on the real panel to break the rule.

But understand why they don't. But it's a 1 minute job if you want to change it.

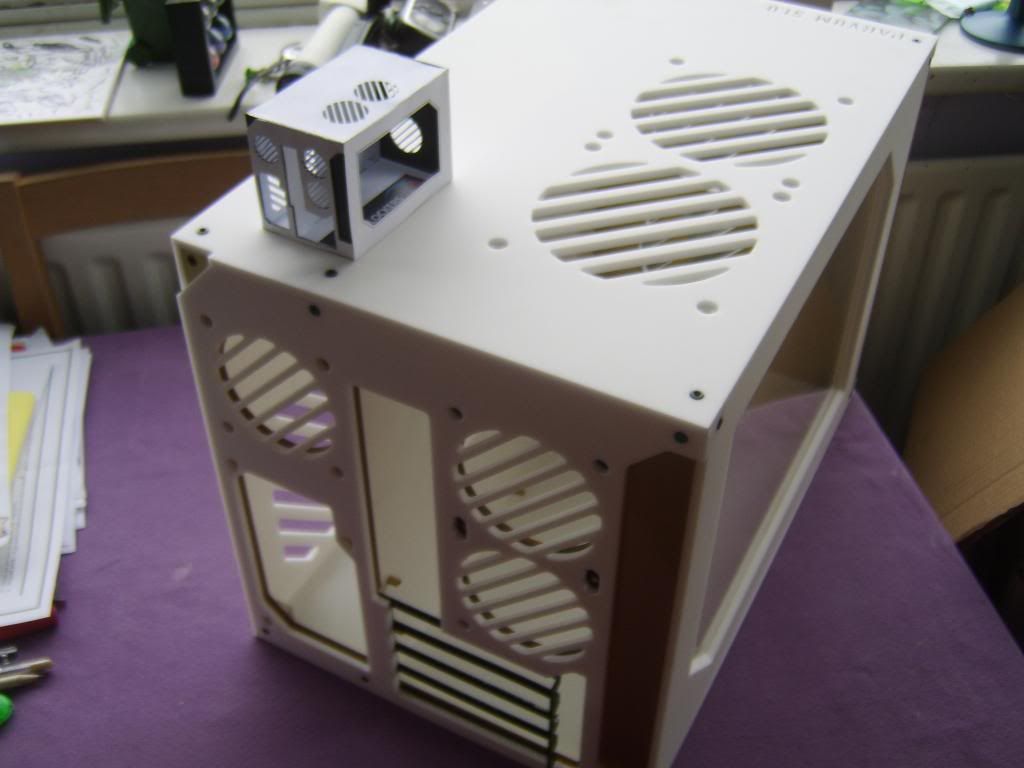

This shot also shows the largest defect of the case - poor paintwork (or lack of primer/prep)

A large chip of paint the size of a fingernail is also missing from the metal insert (but it not visible when fully build)

Again it's an easy mod but shouldn't really need doing on a +£100 case.

The incorrect positioned window and scratches to the inside of the window most likely happened at OcUK HQ

As there are not on the op shots but are on ace's 5th April post (well the tape can be seen in the wrong place anyway)

Again an easy reposition I hope, but the scratches are annoying and show how easy a Perspex window is to damage (as with any case)

Swarf - again an easy fix but shows it's a small business finding its feet.

Non perfect edges - For a flexible panel with limited fixing I actually think even getting this close to flat is excellent

I needed to glue the total length of my model to get it to sit true and that's just not an option with a fully modular case.

The gap in the second shot is the only one on the whole case - every other junction is perfect, even this one is within .5mm tolerance

It's just the nature of a butt joint - if it's not perfect on very close inspection it shows.

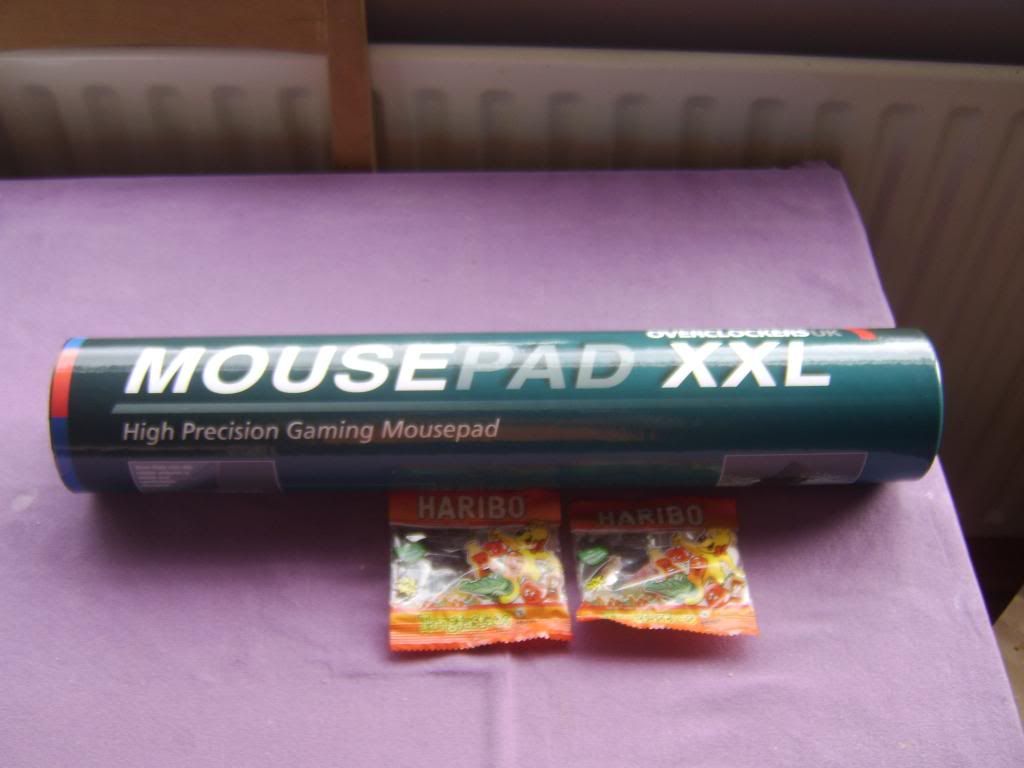

The whole case could have done with a clean tbh - but then it's not factory fresh so can't blame Parvum

To many haribo in the OcUK office leads to sticky fingers ;0

It's possible the 'gold' isn't used as a stock colour due to chipping - again only a minor issue

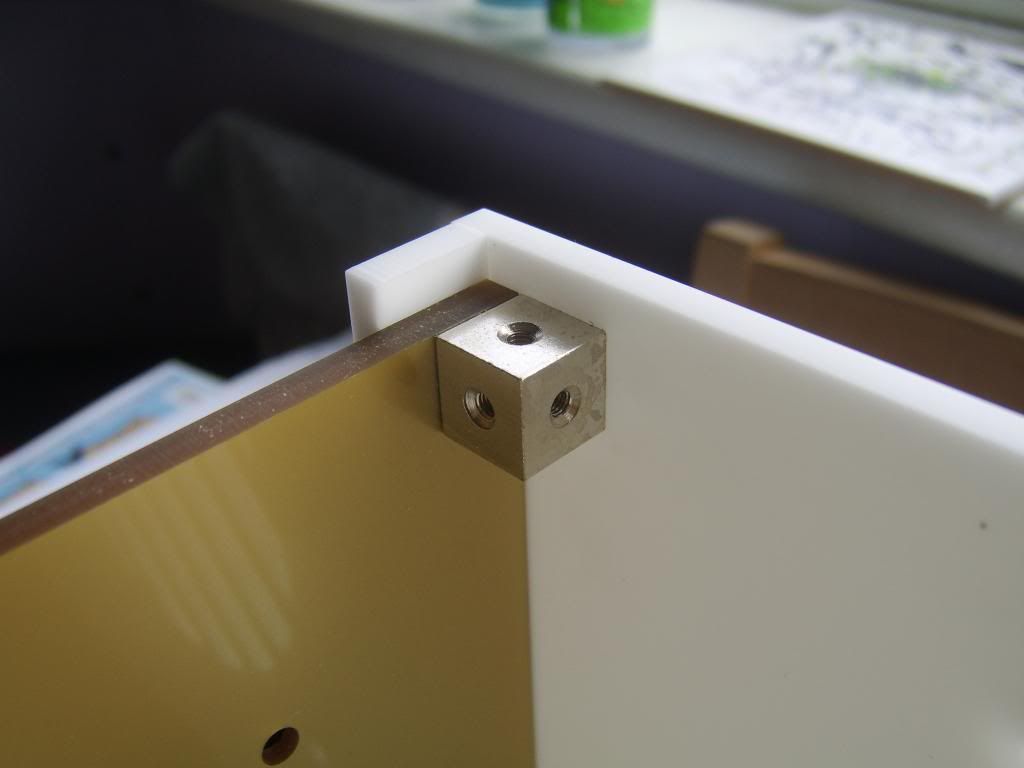

Apart for the paint work this might be my biggest issue - uneven screw levels.

Some are rebated, most are flush, some are proud.

The picture is of a corner so three different panels but even on the same panel there are +1mm depth differences.

Again some careful hand drilling will sort this but it's my biggest disappointment.

Another small niggle is a black marker was used to mark the bend of the mid panel - the black mark is visible when fully built.

Again an easy fix - clean or file off - but imho use a pencil or clean off the pen prior to building the case.

The following small machining errors I quite like, they make the case a one off, human, non mass produced

My personal taste is more Wabi-sabi (beauty that is imperfect, impermanent, and incomplete) that slavishly trying for glossy mag perfect.