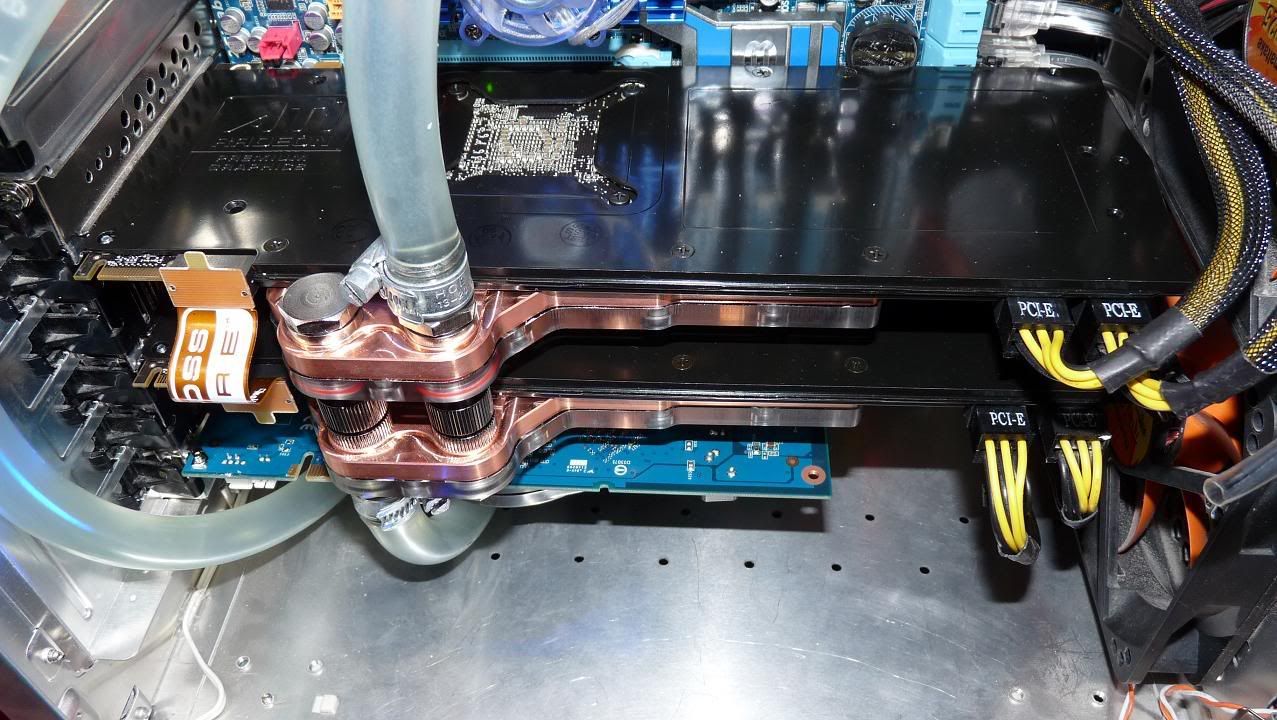

Putting the cards in parallel means the flow through each one will be lower, but the pump acts on a lower peripheral resistance so the flow rate overall in the loop will be higher. The cpu block in particular will appreciate the higher flow. However if the parallel sections aren't identical it gets much more difficult, as one side will tend to starve the other of flow. This is why the sketch shows flow into the bottom card and out the top rather than both in and out on one block.

If the fill and drain pipe are connected to one point, you just have one line which you can use for either. When draining you need a means of letting air in really, if there's only one tube you have to give it a different route in. The multioption has four holes, best performance will be bottom hole going to pump and top hole coming from loop, fill and drain on the other two. Easiest will be using the top for fill line, base for drain, but performance will suffer a bit.

If you put the drain line elsewhere using a T, say near the pump at the base (the lower the better for a drain line really) then you block up one of the holes in the res. Alternatively you could mount it horizontally so a drain line on the side still lets all the liquid out but when working the flow is still straight through. These all seemed too bewildering when I set out, which is a large part of why I chose the combined pump/res and put the drain line elsewhere.

Description of reservoir arrangements above was crap, have a picture

To muddy the water further, you don't need a reservoir at all. A T line before the pump with a longish tube running up to a fill port essentially is a reservoir, you just have to pour water in more frequently while filling it. From this perspective the horizontal reservoir is just a bulge in the tube which happens to be where the T line goes.

If the fill and drain pipe are connected to one point, you just have one line which you can use for either. When draining you need a means of letting air in really, if there's only one tube you have to give it a different route in. The multioption has four holes, best performance will be bottom hole going to pump and top hole coming from loop, fill and drain on the other two. Easiest will be using the top for fill line, base for drain, but performance will suffer a bit.

If you put the drain line elsewhere using a T, say near the pump at the base (the lower the better for a drain line really) then you block up one of the holes in the res. Alternatively you could mount it horizontally so a drain line on the side still lets all the liquid out but when working the flow is still straight through. These all seemed too bewildering when I set out, which is a large part of why I chose the combined pump/res and put the drain line elsewhere.

Description of reservoir arrangements above was crap, have a picture

To muddy the water further, you don't need a reservoir at all. A T line before the pump with a longish tube running up to a fill port essentially is a reservoir, you just have to pour water in more frequently while filling it. From this perspective the horizontal reservoir is just a bulge in the tube which happens to be where the T line goes.

Last edited:

.

. .

.

lol.

lol. .

.