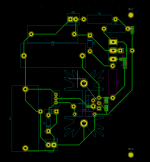

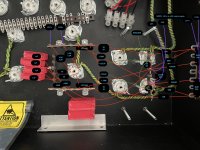

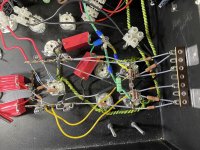

Still waiting on the third back-ordered transformer. Other priorities have got in the way but all 5 power supplies are built point-to-point. Each supply is a RC to RCRC filter with a 1.5mA capacitor bleed to discharge the capacitors and a red LED indicating power on the capacitors. I have some body work todo for mounting points which should be done later today. I've ordered a few additional components to protect the amp power supply from transient voltage spikes (MOVs), an 68 Jule NTC (which helps control inrush current) plus some big polarity protection diodes the polarity sensitive electrolytic caps for each of the power supplies incase they switch off at different speeds. This is possibility given the power supplies for a circlotron are stacked. The neon power switches work nicely, so the next step will be to get the power supplies mounted, connected up and test the startup/shut down without the amp being completed.

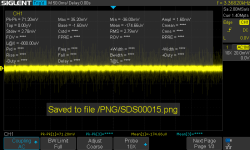

The 117Vac power supply outputs over 170Vdc, this is due to not having any load. However given high DC voltage is extremely dangerous I've also ordered some multimeter clip leads I can clip on before powering up rather than having my hands inside when it's running. Once the low voltage supply transformer arrives, the high voltage will sit on top of the 30Vdc of the low voltage power supply - so 200Vdc. The capacitors in the high voltage supply bleed quite quick (being only two 390uF 350V caps) and the low voltage power supply bleeds slower (two 5600uF 50V caps) and the heater supply has a whopping 30,000uF 25V caps as it's only providing 12.6V. All the supplies have their own transformer secondaries so they are independent and float (this is important).

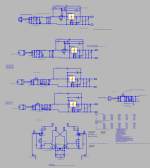

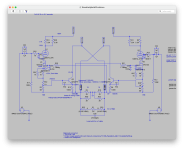

The design of a circlotron is simple - two amps, each side of the speaker/headphone speaker has an amp. If both amps play the same thing then you get zero difference and no current flows through the speaker. If both amps play the same thing but opposite then you get 2x the current flow of a single amp through the speaker - think of it like a seesaw, one amp at the bottom and one amp at the top and the slope of the seesaw is the current flowing - the steeper the slope the more power is being delivered. The same is true for the circlotron. The headphone is the seesaw and the two amps on each side (bridged essentially) are providing that slope.

The complexity of the circlotron is the supply of power. Each amp has it's own power supply that floats to provide the same power regardless of where the amp is on the seesaw. A hybrid (tube+solidstate) circlotron is two power supplies per amp. A high voltage for the tube and a low voltage for the solid-state components. So these two floating power supplies of each amp move up and down with it on the seesaw.

Tubes provide a further complication with heater supplies. They need to be within a certain voltage range of the tube cathode as they are so close over 100V may cause an arc and destroy the tube. This fortunately for our headphone amp can be referenced to ground. The sine wave we create is less than 5V so the cathode will never be more than ±8.3V (5V+12.6/2=8.3V) from the heater voltage - this is because pivot point of the amp is centred around ground..

So if everything is floating how is it a seesaw?

Well the pivot point of seasaw is the same in a circlotron. The centre point of the two amps is connected to ground (zero volts) thus both amps pivot around 0 Volts. The connection go the speaker is connected either side of the pivot point (ground). So the slope always goes through 0 volts in the centre.

Given the amp is connected DIRECTLY to the headphones - the headphones are essentially connected between 200V and the largest signal in the event of two shorted tubes could be 400V. However shorting tubes can be safeguarded by detecting over current - the 12BH7A is 20mA max and shorting occurrs in most tubes either as (a) heater element failure and shorting to the cathode with is not a high voltage issue or (b) if the tubes are run so hard beyond their maximums that metal in the tube vaporises and condenses on the elements causing a short.

This circlotron is a a cathode follower with a emitter follower linked to the cathode, a short will pull up the voltage but it's possible safeguard by limiting with a TVS diode or a pair of Zenner diodes to clamp the maximum voltage. The result would be a limit of say ±5V to the headphones the diodes would open, causing current flow and the fuse in power supply would burn out. A shorted tube is dead anyway and there would be a possibility that you have a very hot BJT transistor for the split second before the fuse blew. The BJT base to emitter voltage could be clamped by a diode to prevent this "max current flow" thus saving the BJT too.

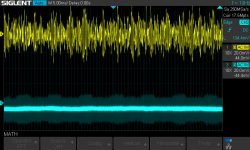

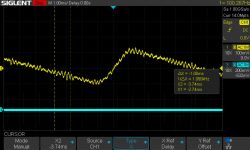

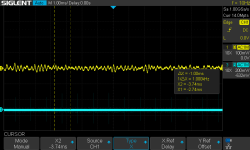

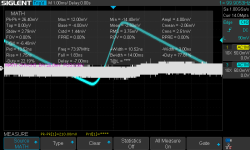

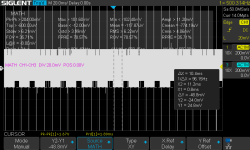

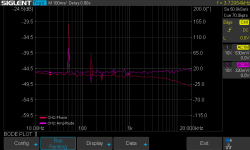

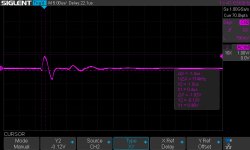

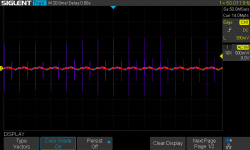

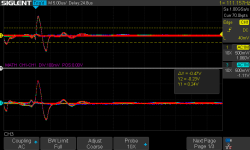

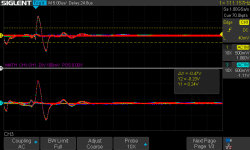

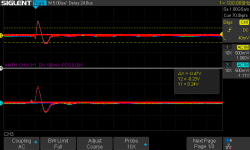

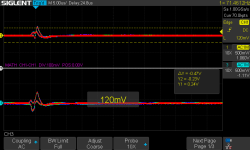

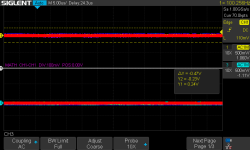

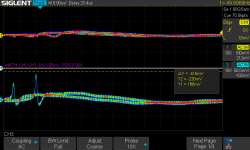

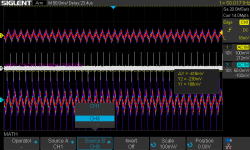

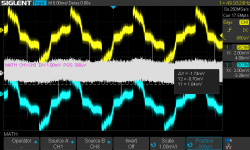

It's also possible to have the mute relay drop and lock should this occur - physically cutting off the amp from the headphones. This mute would be required on startup anyway. For now I will be using a 5W 55 ohm resistor as a speaker substitute to measure and test behaviours. I have a 2W 50ohm speaker for the next step - is there sound etc, although the oscilloscope can show how clean the sound is. After a lot of testing and a few more safety tests.. then I'll add a headphone socket and add the headphones.

This isn't a build from a known and tested schematic.. hence the very experimental approach.. and the fun.

So I hope to be able to get the next chunk of work done this weekend. Enough to power up the tubes whilst I wait for the back ordered transformer to arrive..

I ordered some 1000V multimeter test clip on leads.. that way the multimeter can be connected up before power up without needing to get my fingers and a probe too close.

The 117Vac power supply outputs over 170Vdc, this is due to not having any load. However given high DC voltage is extremely dangerous I've also ordered some multimeter clip leads I can clip on before powering up rather than having my hands inside when it's running. Once the low voltage supply transformer arrives, the high voltage will sit on top of the 30Vdc of the low voltage power supply - so 200Vdc. The capacitors in the high voltage supply bleed quite quick (being only two 390uF 350V caps) and the low voltage power supply bleeds slower (two 5600uF 50V caps) and the heater supply has a whopping 30,000uF 25V caps as it's only providing 12.6V. All the supplies have their own transformer secondaries so they are independent and float (this is important).

The design of a circlotron is simple - two amps, each side of the speaker/headphone speaker has an amp. If both amps play the same thing then you get zero difference and no current flows through the speaker. If both amps play the same thing but opposite then you get 2x the current flow of a single amp through the speaker - think of it like a seesaw, one amp at the bottom and one amp at the top and the slope of the seesaw is the current flowing - the steeper the slope the more power is being delivered. The same is true for the circlotron. The headphone is the seesaw and the two amps on each side (bridged essentially) are providing that slope.

The complexity of the circlotron is the supply of power. Each amp has it's own power supply that floats to provide the same power regardless of where the amp is on the seesaw. A hybrid (tube+solidstate) circlotron is two power supplies per amp. A high voltage for the tube and a low voltage for the solid-state components. So these two floating power supplies of each amp move up and down with it on the seesaw.

Tubes provide a further complication with heater supplies. They need to be within a certain voltage range of the tube cathode as they are so close over 100V may cause an arc and destroy the tube. This fortunately for our headphone amp can be referenced to ground. The sine wave we create is less than 5V so the cathode will never be more than ±8.3V (5V+12.6/2=8.3V) from the heater voltage - this is because pivot point of the amp is centred around ground..

So if everything is floating how is it a seesaw?

Well the pivot point of seasaw is the same in a circlotron. The centre point of the two amps is connected to ground (zero volts) thus both amps pivot around 0 Volts. The connection go the speaker is connected either side of the pivot point (ground). So the slope always goes through 0 volts in the centre.

Given the amp is connected DIRECTLY to the headphones - the headphones are essentially connected between 200V and the largest signal in the event of two shorted tubes could be 400V. However shorting tubes can be safeguarded by detecting over current - the 12BH7A is 20mA max and shorting occurrs in most tubes either as (a) heater element failure and shorting to the cathode with is not a high voltage issue or (b) if the tubes are run so hard beyond their maximums that metal in the tube vaporises and condenses on the elements causing a short.

This circlotron is a a cathode follower with a emitter follower linked to the cathode, a short will pull up the voltage but it's possible safeguard by limiting with a TVS diode or a pair of Zenner diodes to clamp the maximum voltage. The result would be a limit of say ±5V to the headphones the diodes would open, causing current flow and the fuse in power supply would burn out. A shorted tube is dead anyway and there would be a possibility that you have a very hot BJT transistor for the split second before the fuse blew. The BJT base to emitter voltage could be clamped by a diode to prevent this "max current flow" thus saving the BJT too.

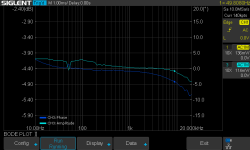

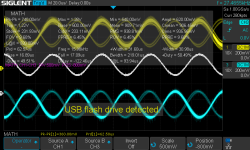

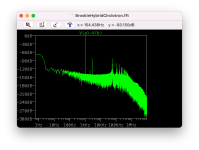

It's also possible to have the mute relay drop and lock should this occur - physically cutting off the amp from the headphones. This mute would be required on startup anyway. For now I will be using a 5W 55 ohm resistor as a speaker substitute to measure and test behaviours. I have a 2W 50ohm speaker for the next step - is there sound etc, although the oscilloscope can show how clean the sound is. After a lot of testing and a few more safety tests.. then I'll add a headphone socket and add the headphones.

This isn't a build from a known and tested schematic.. hence the very experimental approach.. and the fun.

So I hope to be able to get the next chunk of work done this weekend. Enough to power up the tubes whilst I wait for the back ordered transformer to arrive..

I ordered some 1000V multimeter test clip on leads.. that way the multimeter can be connected up before power up without needing to get my fingers and a probe too close.

Last edited:

so far that will be a 7 week backorder for something 10 days.. Go, go, go Global economy!

so far that will be a 7 week backorder for something 10 days.. Go, go, go Global economy!