Not exactly a progress update but I thought it might amuse people. My PSU (Nesteq Xzero) that I currently plan to use in the new case helpfully uses non-standard 6-pin molex connectors for the modular power leads (molex and SATA). Can't find them available as they're a different pattern to the 6-pin PCI-E shells so I need to get them off to make new sleeved cables when the time comes. Wouldn't budge with the pin extractors rammed in as hard as I could so I ended up giving the cable a good yank with a "what's the worst that could happen?!" attitude.

Turns out that the worst that can happen is the glue suddenly gives (explains why it was difficult) and the pin is fired out of the hole with the sharp wings (that stop it going to far into the hole) ploughing two furrows diagonally across my thumb. The yellow wire is now red

Plasters are hopeless - don't stick to fingerprints and don't flex. Gorilla Glue (form of superglue with knobs on), however, works wonders. Have a useable thumb again

Turns out that the worst that can happen is the glue suddenly gives (explains why it was difficult) and the pin is fired out of the hole with the sharp wings (that stop it going to far into the hole) ploughing two furrows diagonally across my thumb. The yellow wire is now red

Plasters are hopeless - don't stick to fingerprints and don't flex. Gorilla Glue (form of superglue with knobs on), however, works wonders. Have a useable thumb again

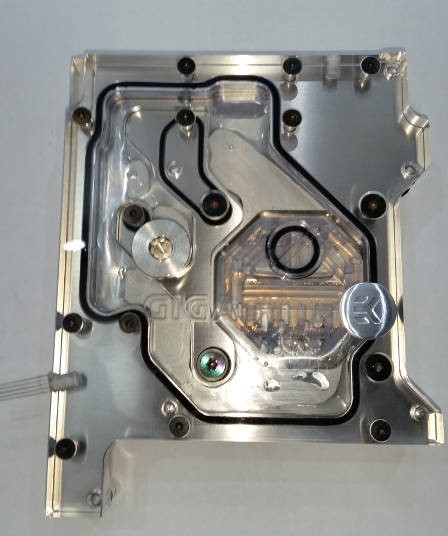

Without wishing to be prematurely blazé it wasn't as difficult as I thought it was going to be. The really thin (and sharp) razor seems to be the key. Most of it it just sliced through, it was just the one 'ear' that I had to keep working on. Found the best thing to clean off the black mastic was a fingernail. IPA and methanol didn't touch it.

Without wishing to be prematurely blazé it wasn't as difficult as I thought it was going to be. The really thin (and sharp) razor seems to be the key. Most of it it just sliced through, it was just the one 'ear' that I had to keep working on. Found the best thing to clean off the black mastic was a fingernail. IPA and methanol didn't touch it.

*blink* *blink*

*blink* *blink*

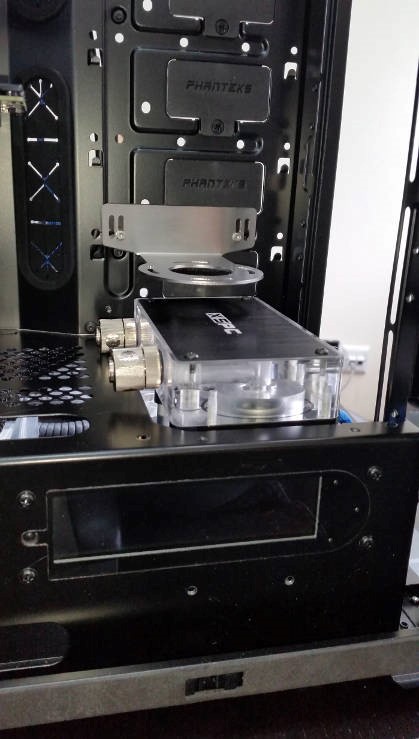

Will try to post some progress of mounting the bottom half of the Aquaero and the flow meter in the meantime.

Will try to post some progress of mounting the bottom half of the Aquaero and the flow meter in the meantime.