Commissario

My Prusa MINI+ was delivered on Friday and of course, it's been running almost continually since.

How do these look?

Is that what I should expect from first and last layers?

Remember these pictures are close up and with the light angled to show most detail.

First layer

Last layer

Sides are pretty good

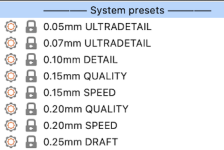

This is the clip, I printed at 0.15 and 40%.

Printed using Prusament PLA

How do these look?

Is that what I should expect from first and last layers?

Remember these pictures are close up and with the light angled to show most detail.

First layer

Last layer

Sides are pretty good

This is the clip, I printed at 0.15 and 40%.

Printed using Prusament PLA