Thought I'd use my newly found free time to get back to a hobby of mine. Building PCs. Although this time I'll be realising a dream of building a case from scratch.

Edit:

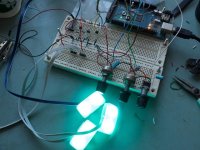

Most recent picture:

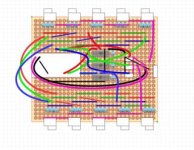

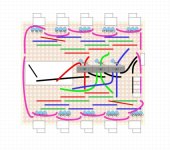

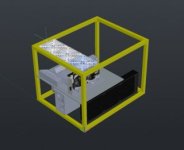

Here's the latest CAD

Sponsored by:

The issue I had was not being able to find a case that could fit both the 420mm and 360mm rads I have. Well, there are cases out there that will do it, but just not perfect, and fairly pricey. So I figured if I'm going to spend a load of money on a case I may as well build it myself.

The plan is:

- 420mm rad with push/pull for the CPU

- 360mm rad with push/pull for the GPU

- 3 X 120mm fans for exhaust top back.

=============================================

Edit: Specs:

Current specs are as follows:

7800X - hopefully with an overclock once this gets done.

Gigabyte X299 AORUS Ultra Gaming Pro

32gb Corsair Vengeance LPX 2666Mhz

AMD Vega56

Samsung 960 250GB NVME

Samsung SM951 250GB NVME

Antec AX1200

Asus Xonar DX Sound Card (maybe, I've got it in a box somewhere so may as well use it).

The watercooling plan is as follows...

CPU Loop:

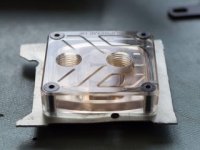

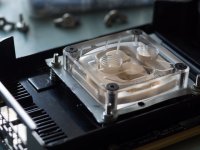

Block: EK Supreme HF

Rad: 420mm EK Coolstream XTC 55mm

Fans: 6 x Gelid Silent 14

Pump: EK DCP 2.2

Res: 150mm Tube (This may change depending on where they end up being mounted)

GPU Loop:

Block: EK Supreme HF with custom mounting bracket.

Rad: 360mm Generic approx 25mm thick. I've had it for years and it's a trooper.

Fans: 6 x Gelid Silent 12

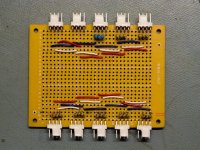

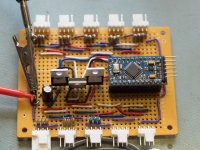

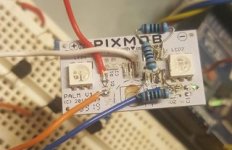

Pump: D4 with custom speed controller (because it's so damn loud!)

Res: 150mm Tube (This may change depending on where they end up being mounted)

=============================================

Might go RGB on the exhaust fans. Undecided on that one.

I've put together some other provisional CAD for the layout. Will make adjustments as I go. Just trying to get a feel for the space usage of the larger components.

Overall dimensions will be around 500mm x 400mm x 400mm. I've already ordered the wrong lengths of extrusion as I was originally planning 600 x 400 x 500 but it just seemed a little too large.

The plan is to use 2020 ali extrusion for the majority of the frame. Having a lower and upper section. Lower section will house the PSU, rads, HDDs and pump. The upper section will house the mobo and GPU. Might do something interesting with reservoirs in the empty space.

Also considering RGB options as the plan is to have the upper section visible from at least two sides with either tempered glass or acrylic. The lower section will have some obstruction, either total blackout or a mesh with back lighting.

The pace of this build will be dictated by delivery timescales! Watch this space.

Hardware specs are from my current PC so nothing crazy. This is more about the case than the performance.

Edit:

Most recent picture:

Here's the latest CAD

Sponsored by:

The issue I had was not being able to find a case that could fit both the 420mm and 360mm rads I have. Well, there are cases out there that will do it, but just not perfect, and fairly pricey. So I figured if I'm going to spend a load of money on a case I may as well build it myself.

The plan is:

- 420mm rad with push/pull for the CPU

- 360mm rad with push/pull for the GPU

- 3 X 120mm fans for exhaust top back.

=============================================

Edit: Specs:

Current specs are as follows:

7800X - hopefully with an overclock once this gets done.

Gigabyte X299 AORUS Ultra Gaming Pro

32gb Corsair Vengeance LPX 2666Mhz

AMD Vega56

Samsung 960 250GB NVME

Samsung SM951 250GB NVME

Antec AX1200

Asus Xonar DX Sound Card (maybe, I've got it in a box somewhere so may as well use it).

The watercooling plan is as follows...

CPU Loop:

Block: EK Supreme HF

Rad: 420mm EK Coolstream XTC 55mm

Fans: 6 x Gelid Silent 14

Pump: EK DCP 2.2

Res: 150mm Tube (This may change depending on where they end up being mounted)

GPU Loop:

Block: EK Supreme HF with custom mounting bracket.

Rad: 360mm Generic approx 25mm thick. I've had it for years and it's a trooper.

Fans: 6 x Gelid Silent 12

Pump: D4 with custom speed controller (because it's so damn loud!)

Res: 150mm Tube (This may change depending on where they end up being mounted)

=============================================

Might go RGB on the exhaust fans. Undecided on that one.

I've put together some other provisional CAD for the layout. Will make adjustments as I go. Just trying to get a feel for the space usage of the larger components.

Overall dimensions will be around 500mm x 400mm x 400mm. I've already ordered the wrong lengths of extrusion as I was originally planning 600 x 400 x 500 but it just seemed a little too large.

The plan is to use 2020 ali extrusion for the majority of the frame. Having a lower and upper section. Lower section will house the PSU, rads, HDDs and pump. The upper section will house the mobo and GPU. Might do something interesting with reservoirs in the empty space.

Also considering RGB options as the plan is to have the upper section visible from at least two sides with either tempered glass or acrylic. The lower section will have some obstruction, either total blackout or a mesh with back lighting.

The pace of this build will be dictated by delivery timescales! Watch this space.

Hardware specs are from my current PC so nothing crazy. This is more about the case than the performance.

Last edited:

.

.