Hi all, this will be my first build log, and I probably should have started this earlier to get help, but alas, the build hasnt begun, but I got the case on the 20th June (used but minter - was to big for the original owner and he replaced it after 4 months! and got it for a bargain - Cheers Roman!).

Now I wasnt exactly in the right frame of mind for a new build at the time the case came up, but it was to much to refuse so it all began.

So after much deliberation between AMD and Intel I was pretty much all set for a 965 and the Asus Crosshair IV (man that board looks pretty!). But then the night I got home from work and was going to order the parts, and email came through from ****.co.uk with a sweet deal on a 920. So that was set i7 was going to be it.

So the parts I have waiting to go in that are new, are:

920

Asus P6T Deluxe OC palm edition

OCZ Reaper 6GB (3x2GB) DDR3 16000C9 (2000MHz) Tri-Channel Kit

EK multi res 250

Thermochill PA140.3

The rest will be cannibalised from the rig Im running right now.

Powercolour 5870 flashed to ASUS BIOS with EK HD5870 full cover block

Swiftech MCP655V

EK supreme HF copper top

Antec 1000w True Power Quattro

Black Ice GT stealth 3x120

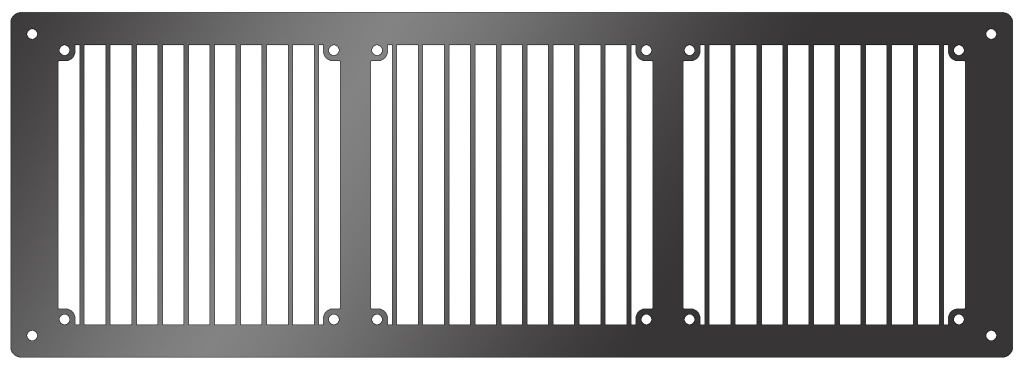

So Im still waiting on my grill to be made, but the PA140.3 is already mounted in the top and Im going to use my Black Ice GT stealth 3x120 aswell, which the holes have been cut ready for it to be mounted in the bottom.

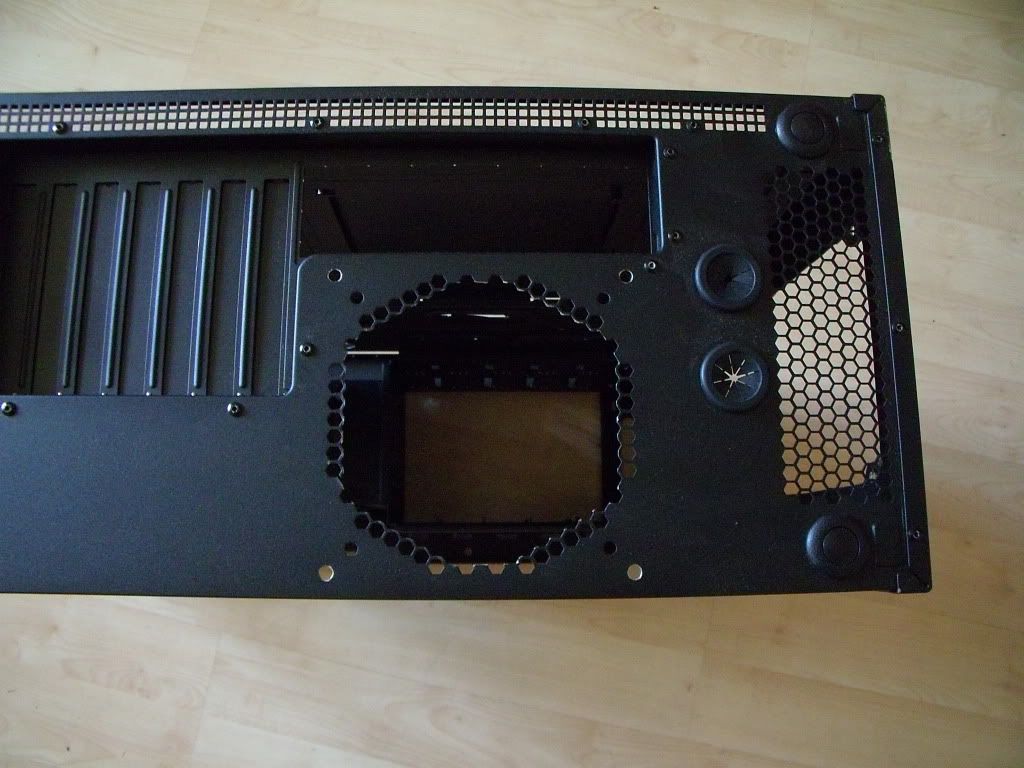

To get the bottom rad mounted I had to cut quite abit from the front aswell to allow space for the PSU, which Im still not sure will fit mounted the right way up yet. Theres 20mm between the 2, so aslong as the cables plugs dont interfere it will be fine.

The fans for the 140.3 are Xigmatek's and the Blackice will use the Yateloons I already have.

So Im waiting on my Grill to be made and then Ill order some new tubing aswell.

But more pics, Sorry about the quality of some, I take some with my poorly tocco.

Heres the bottom with the 3x120 hole cut, Ill take another of it mounted when I do it again, it definetly fits as I drained my loop to check, but now its back on this current rig.

The 140.3 cut out.

I was going to add the lugs for each fan mounting, but it rolled down the original mountings of the stock top, so didnt bother, the grill will take the load just fine, and aslong as I got everything measured right, it will sit a treat.

Heres one with the 140.3 mounted, youll see one screw hole off, as the bloody tape lifted slightly when cutting, but again, Ill redrill it and you wont see it with the grill on.

Bloody battery was dead in my cam at this point so its a blurry pic.

Any hints and tips at this stage? Also, Ill probably throw in a BigNG as Im sick of using the fan controller, I always forget to crank them up before launching a game.

The goal is obviously to hit atleast 4.0 and aiming for 4.4.

Now I wasnt exactly in the right frame of mind for a new build at the time the case came up, but it was to much to refuse so it all began.

So after much deliberation between AMD and Intel I was pretty much all set for a 965 and the Asus Crosshair IV (man that board looks pretty!). But then the night I got home from work and was going to order the parts, and email came through from ****.co.uk with a sweet deal on a 920. So that was set i7 was going to be it.

So the parts I have waiting to go in that are new, are:

920

Asus P6T Deluxe OC palm edition

OCZ Reaper 6GB (3x2GB) DDR3 16000C9 (2000MHz) Tri-Channel Kit

EK multi res 250

Thermochill PA140.3

The rest will be cannibalised from the rig Im running right now.

Powercolour 5870 flashed to ASUS BIOS with EK HD5870 full cover block

Swiftech MCP655V

EK supreme HF copper top

Antec 1000w True Power Quattro

Black Ice GT stealth 3x120

So Im still waiting on my grill to be made, but the PA140.3 is already mounted in the top and Im going to use my Black Ice GT stealth 3x120 aswell, which the holes have been cut ready for it to be mounted in the bottom.

To get the bottom rad mounted I had to cut quite abit from the front aswell to allow space for the PSU, which Im still not sure will fit mounted the right way up yet. Theres 20mm between the 2, so aslong as the cables plugs dont interfere it will be fine.

The fans for the 140.3 are Xigmatek's and the Blackice will use the Yateloons I already have.

So Im waiting on my Grill to be made and then Ill order some new tubing aswell.

But more pics, Sorry about the quality of some, I take some with my poorly tocco.

Heres the bottom with the 3x120 hole cut, Ill take another of it mounted when I do it again, it definetly fits as I drained my loop to check, but now its back on this current rig.

The 140.3 cut out.

I was going to add the lugs for each fan mounting, but it rolled down the original mountings of the stock top, so didnt bother, the grill will take the load just fine, and aslong as I got everything measured right, it will sit a treat.

Heres one with the 140.3 mounted, youll see one screw hole off, as the bloody tape lifted slightly when cutting, but again, Ill redrill it and you wont see it with the grill on.

Bloody battery was dead in my cam at this point so its a blurry pic.

Any hints and tips at this stage? Also, Ill probably throw in a BigNG as Im sick of using the fan controller, I always forget to crank them up before launching a game.

The goal is obviously to hit atleast 4.0 and aiming for 4.4.