Soldato

Aim (primary)

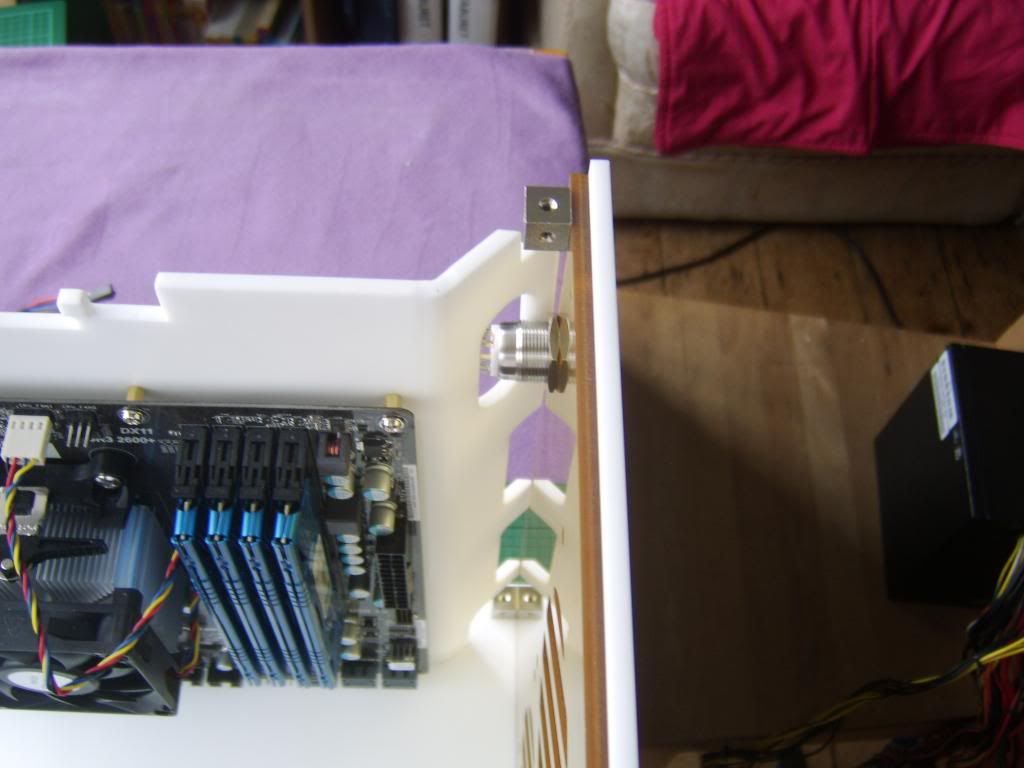

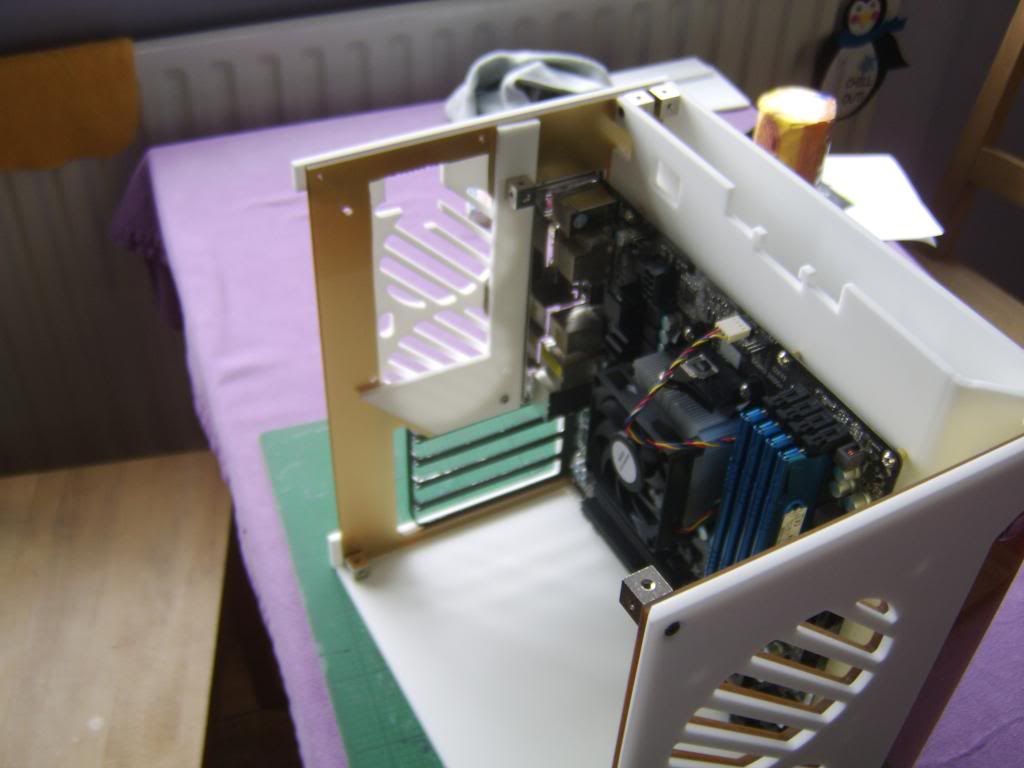

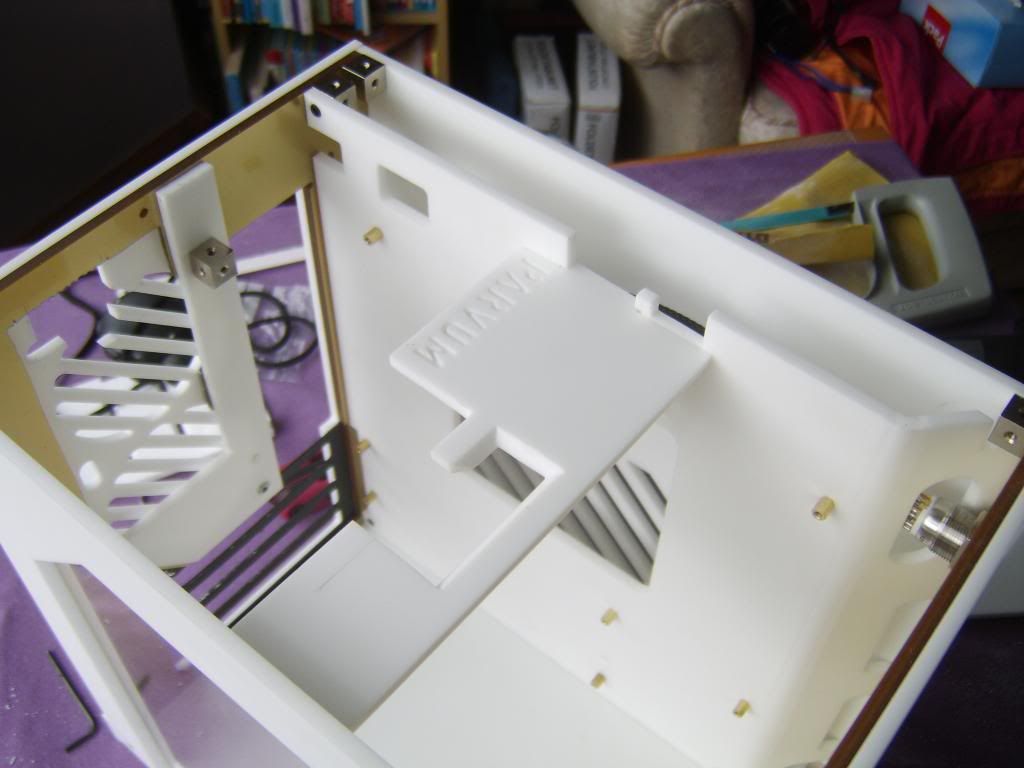

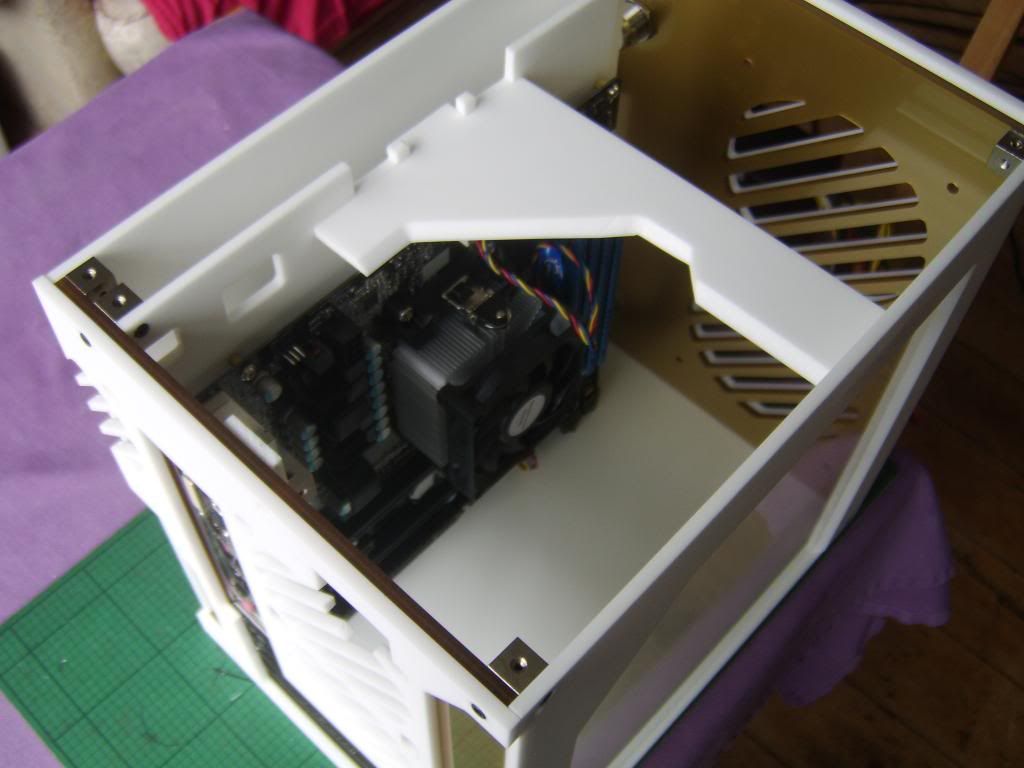

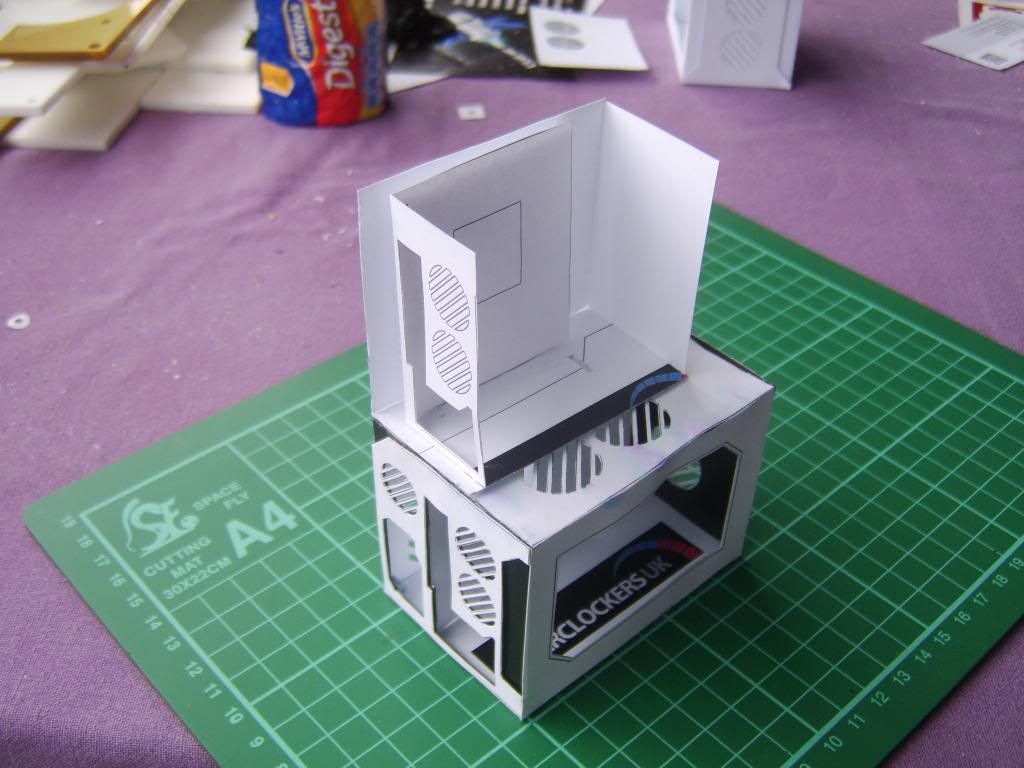

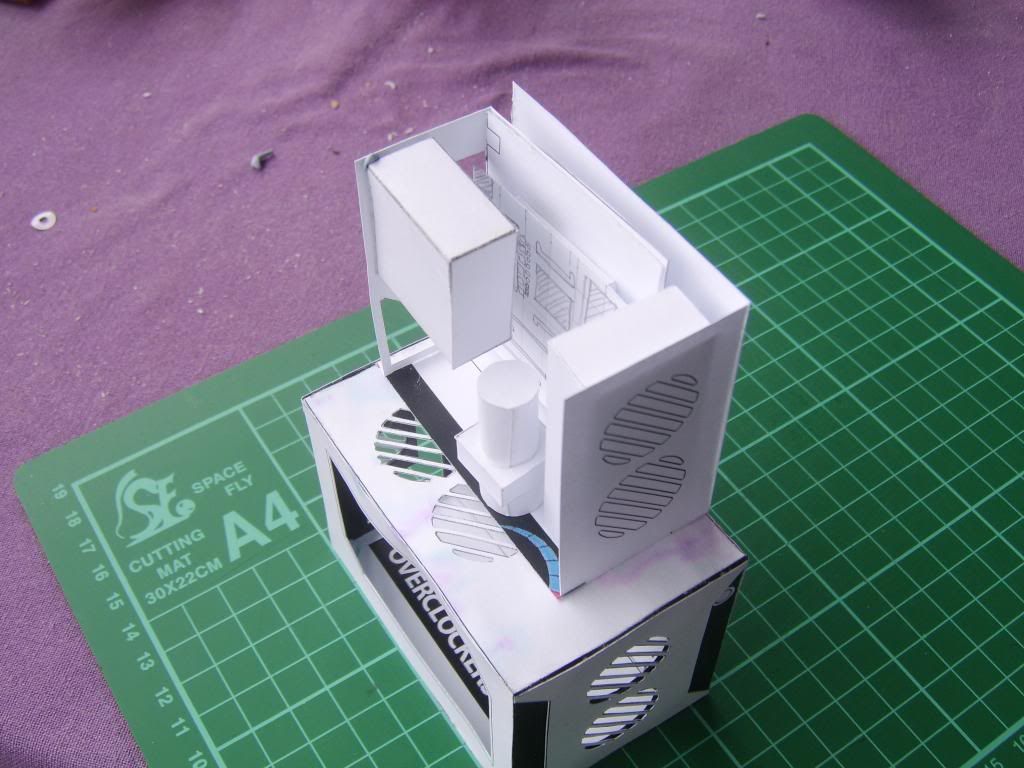

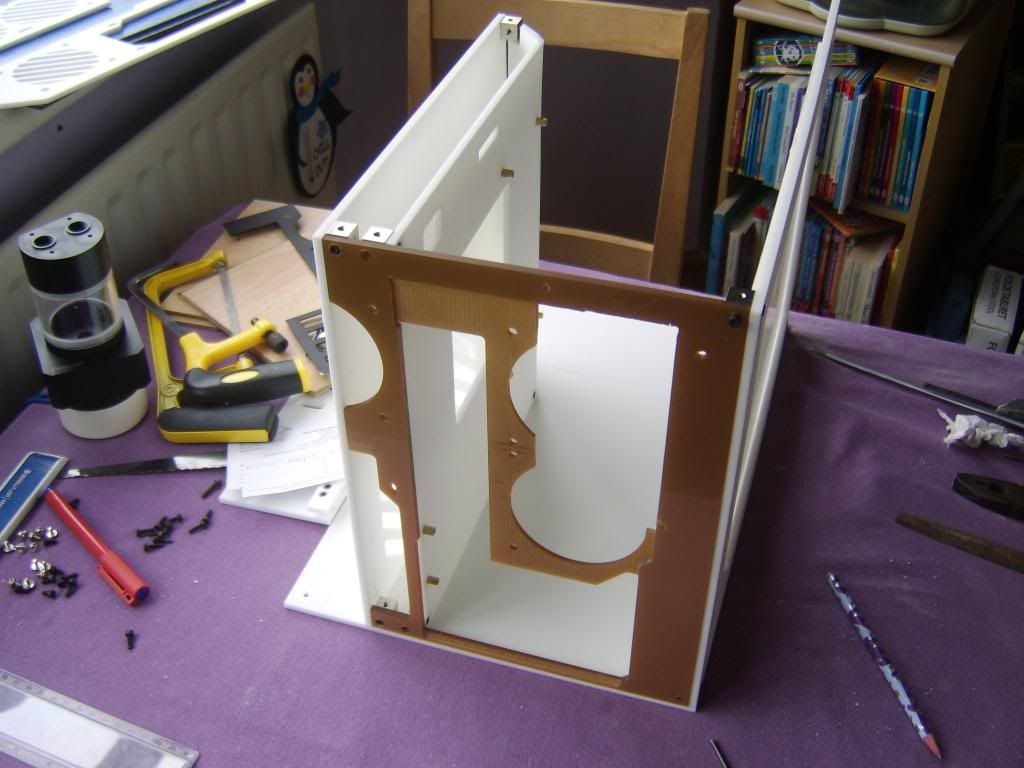

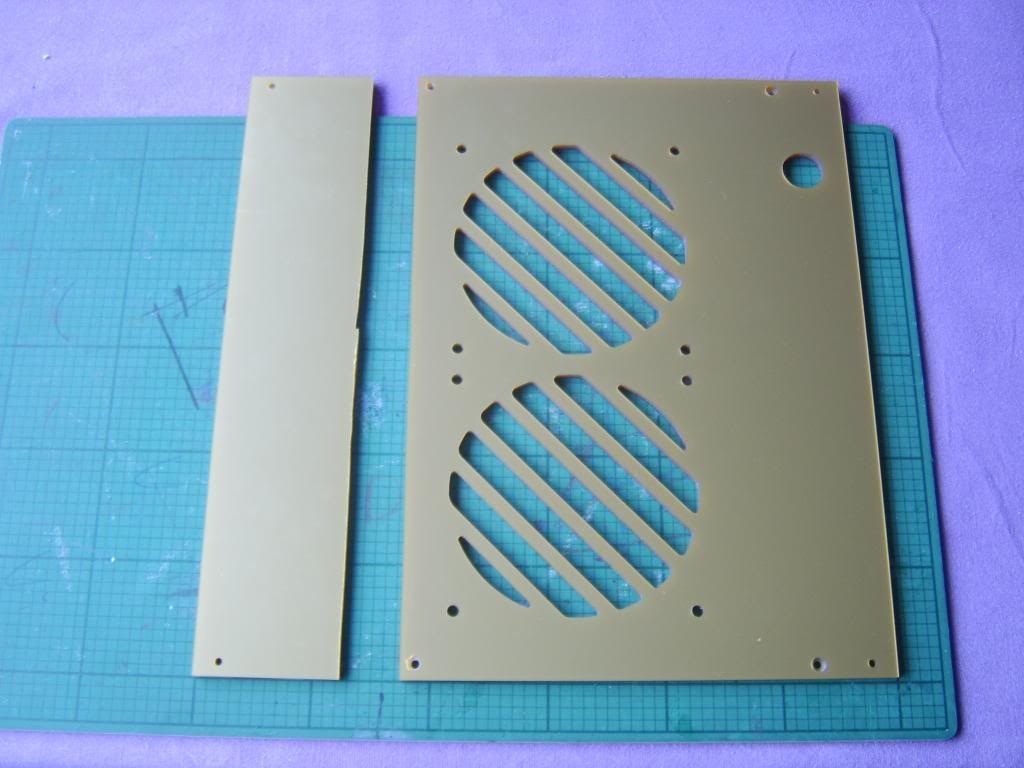

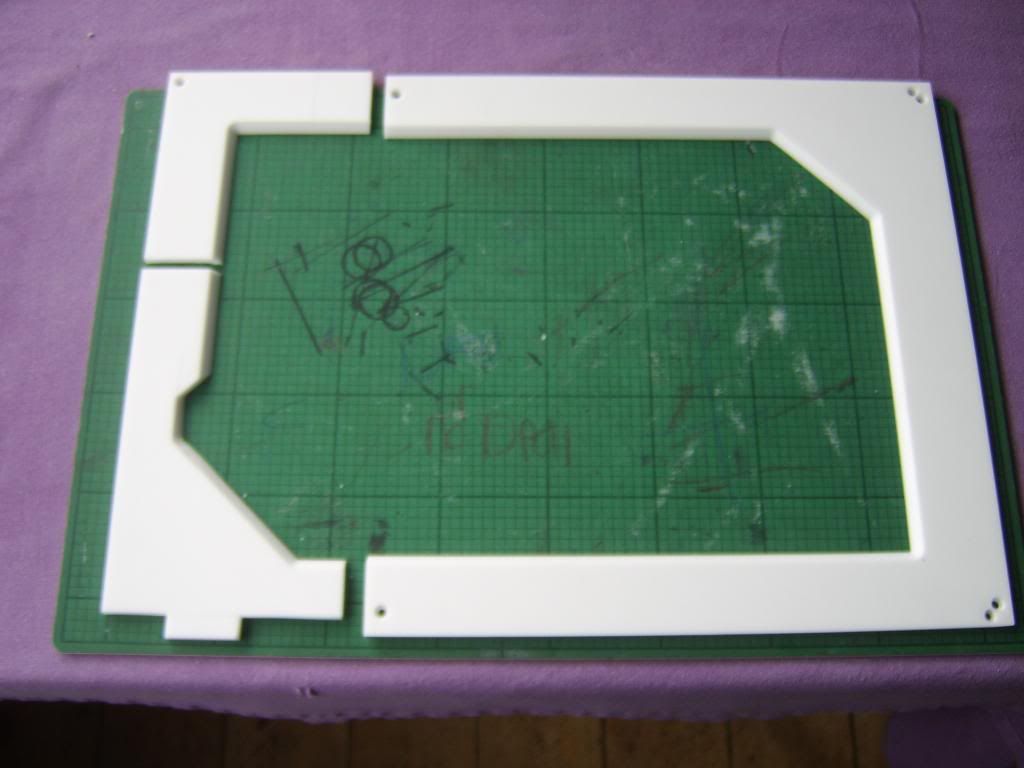

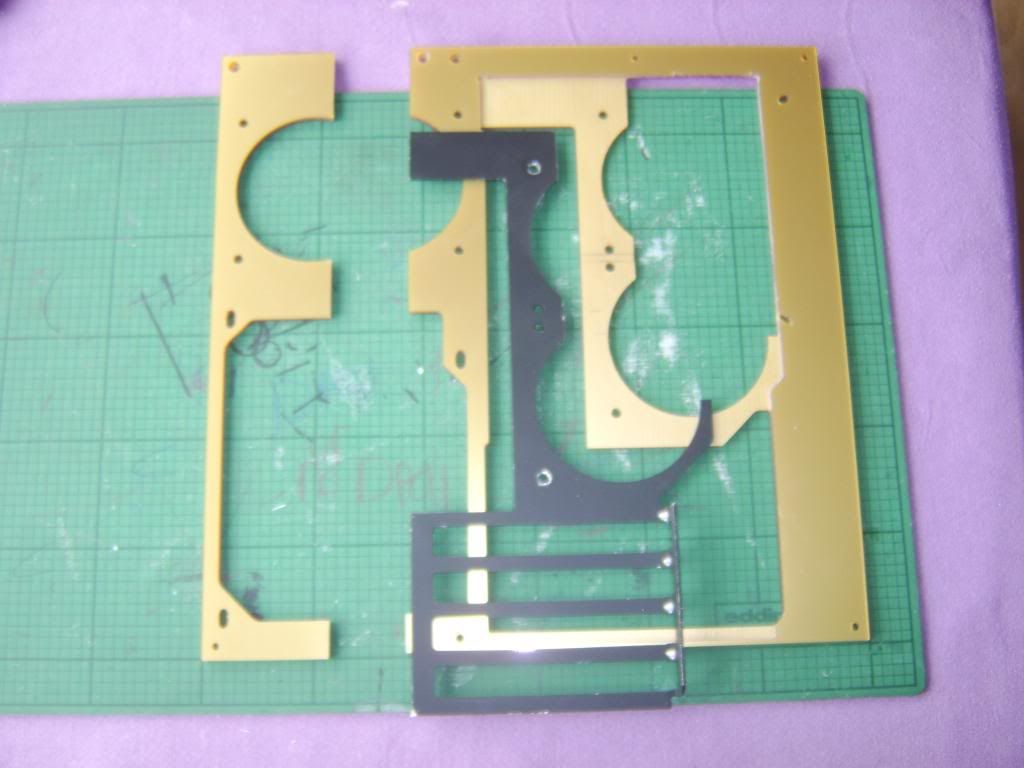

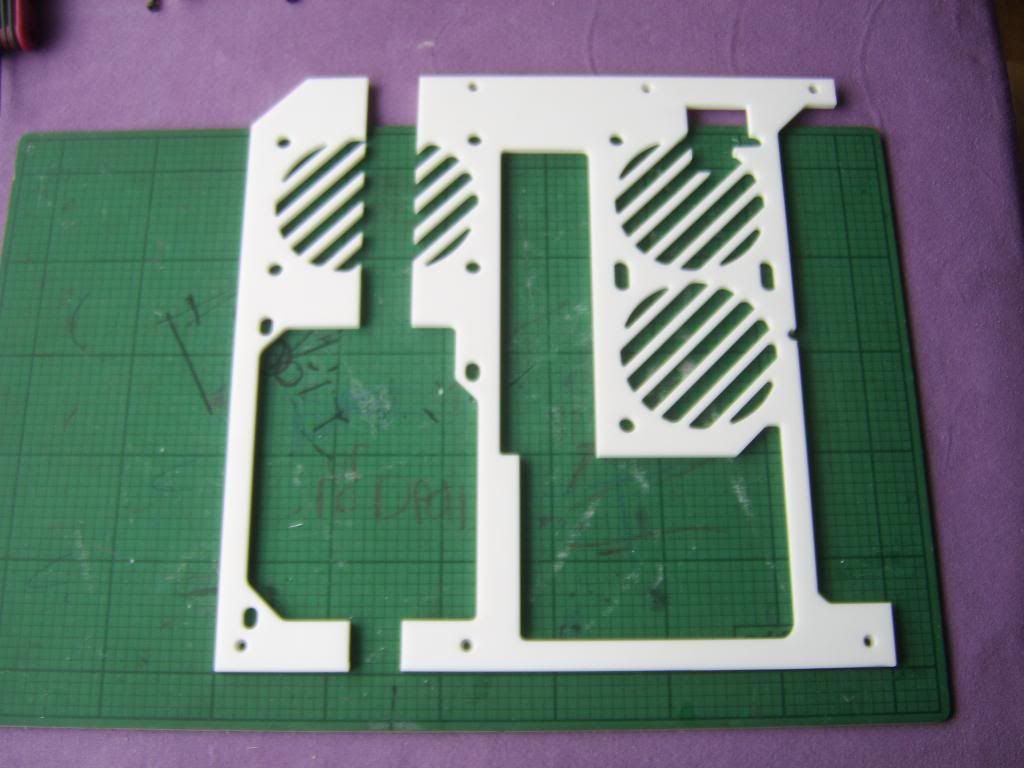

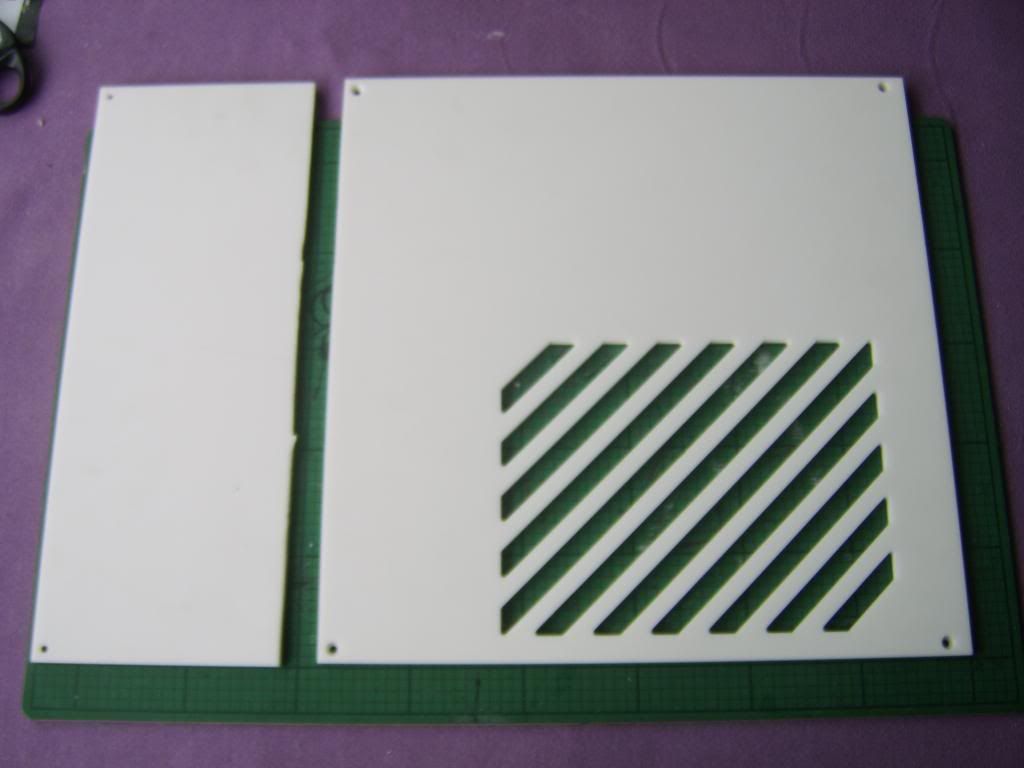

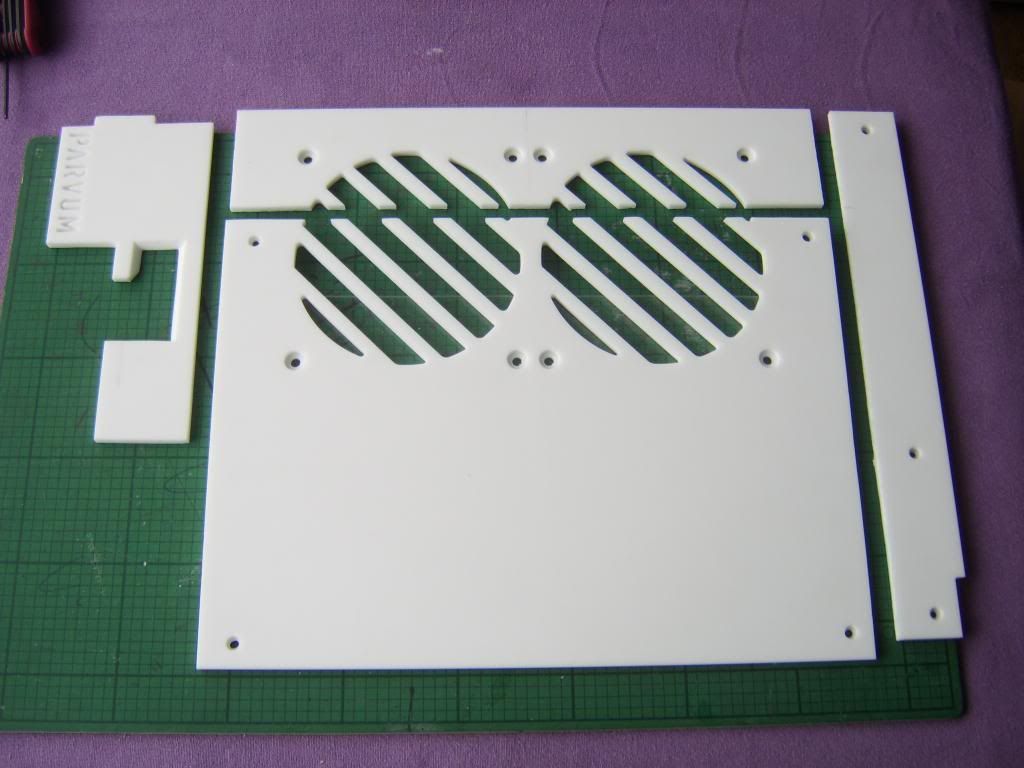

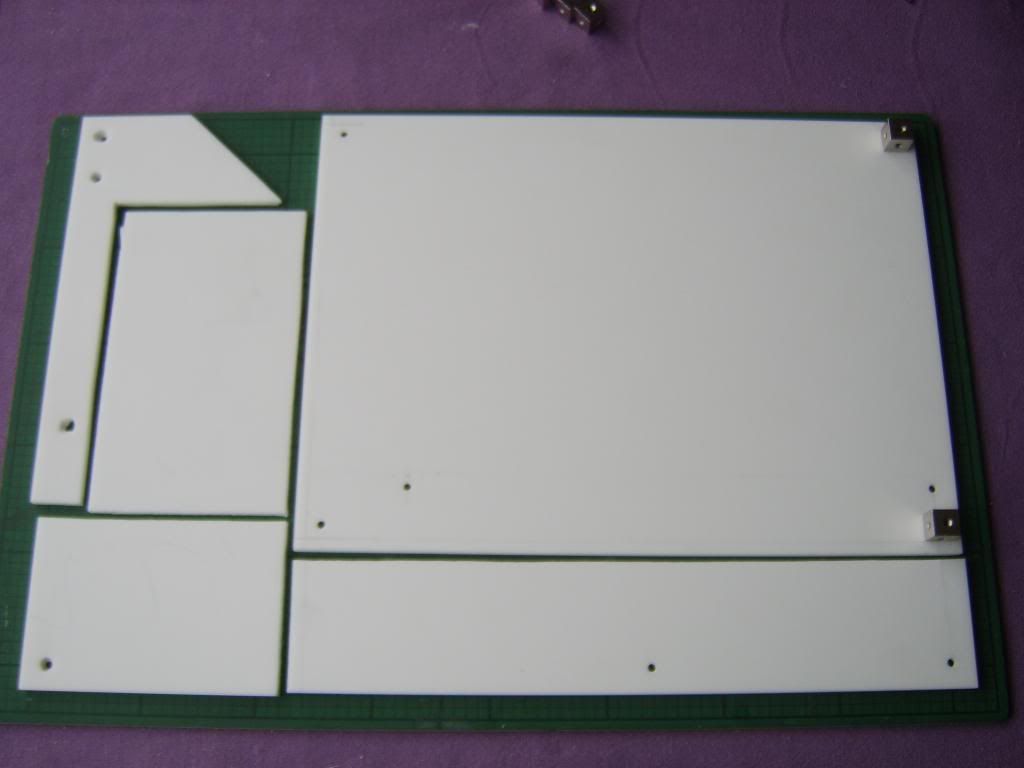

Reduce the size of the Parvum S1.0 case I won to a more manageable 20 litres

But keeping the mATX mobo, full size psu, double rad and duel gpu's.

The secondary aims inclued

Complete the build in less than one week (prevous build logs I've made have dragged on - sorry)

Ok let's start off with some photo's I took a few weeks back and posted in the compertition thread linky

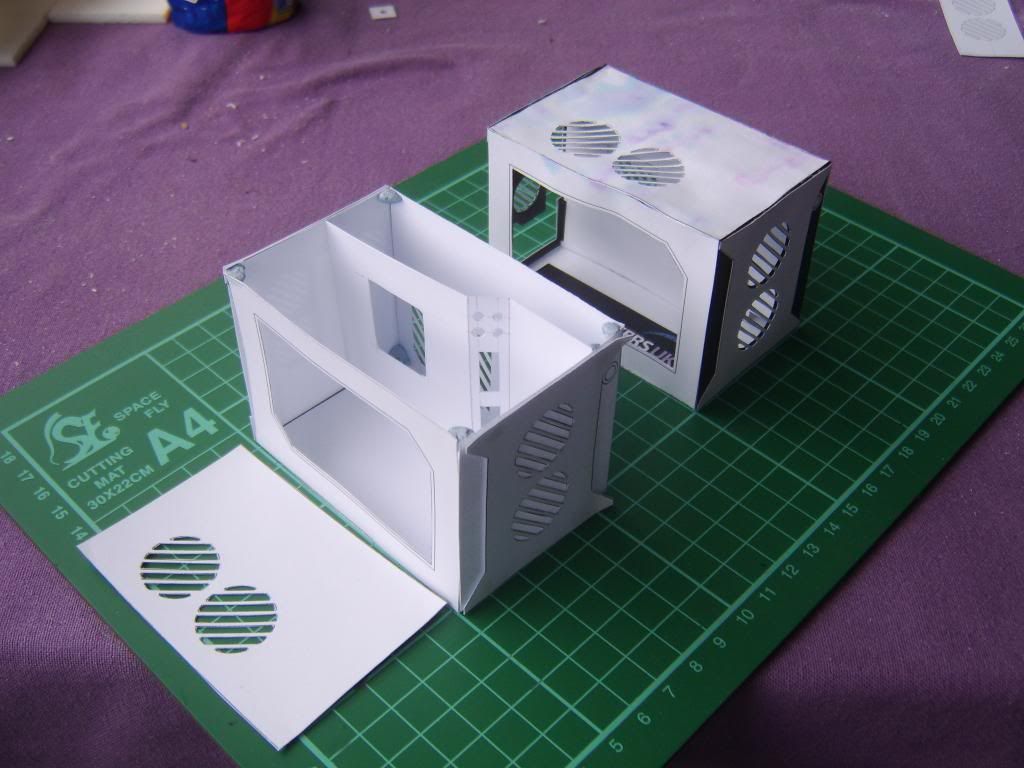

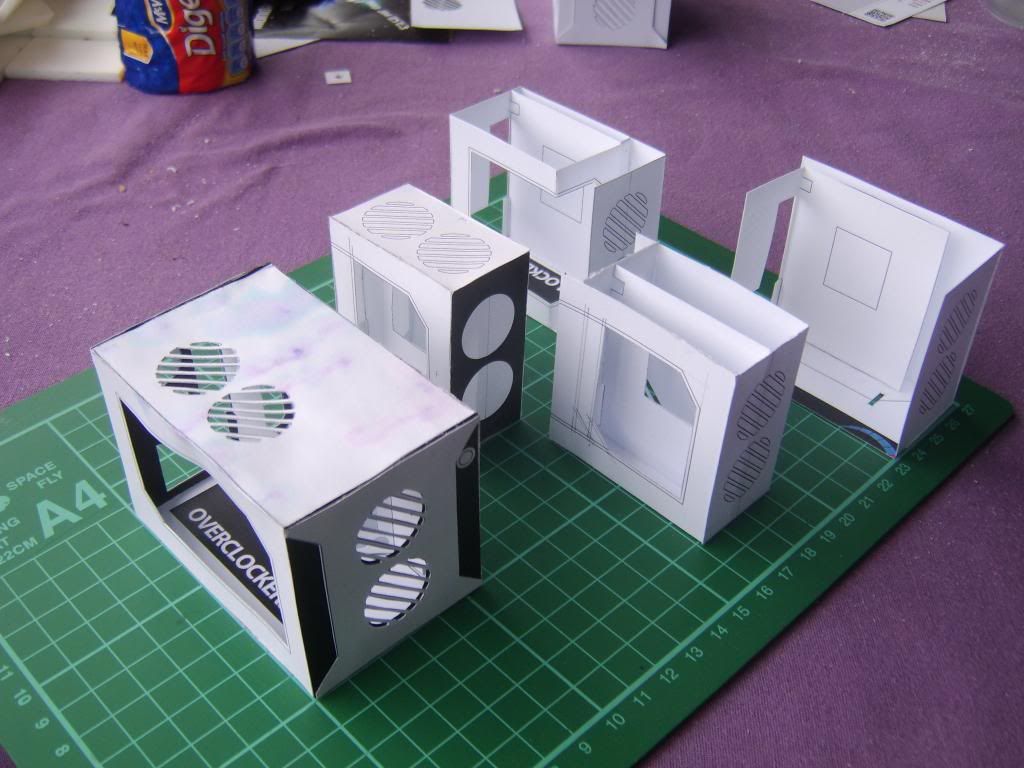

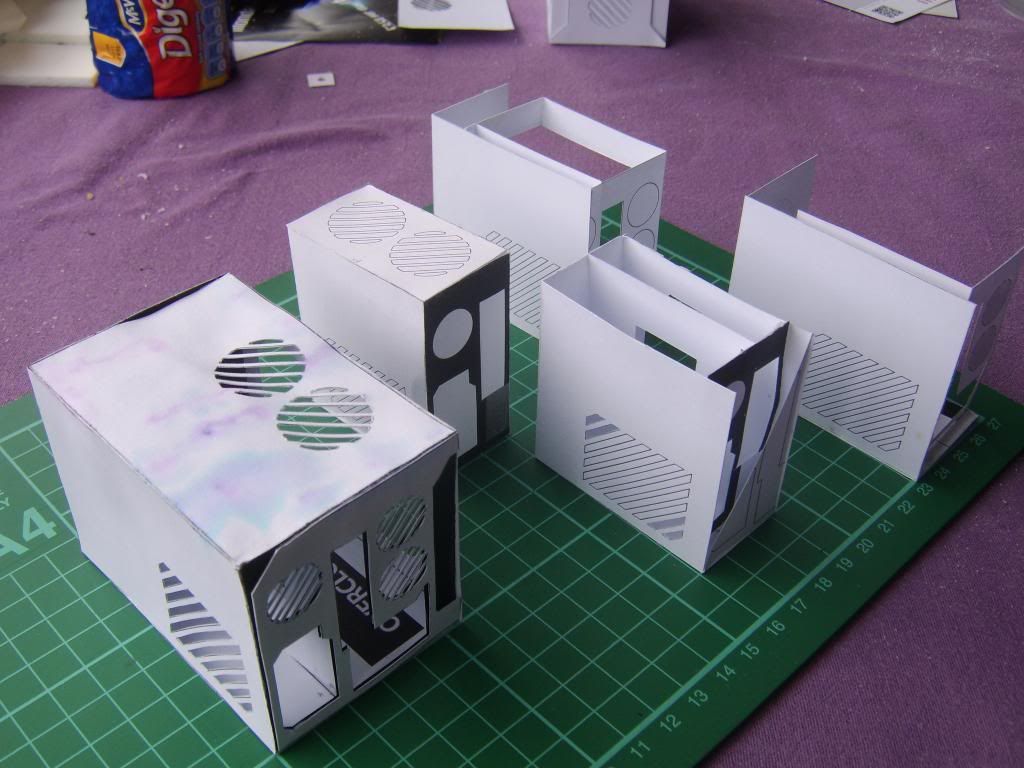

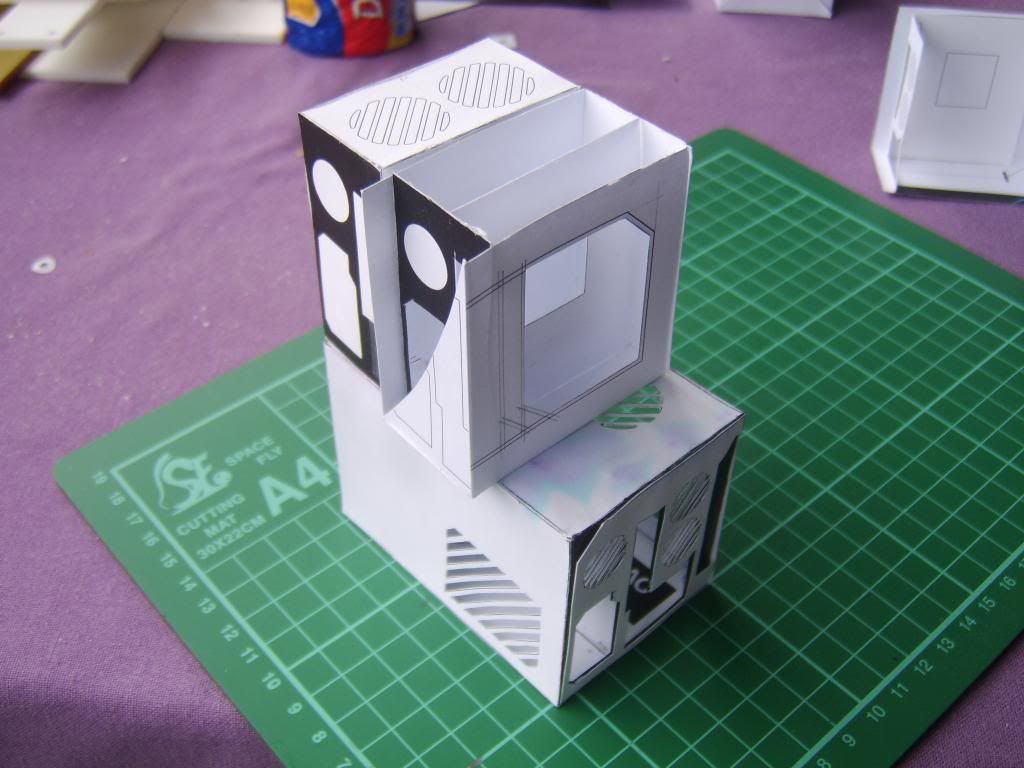

The S1.0 is quite big for a SFF Matx case (35L). Shown here with a PC Design Labs QMicra V2 (29L cube), and Silverstone TJ08B-E (30L)

Reduce the size of the Parvum S1.0 case I won to a more manageable 20 litres

But keeping the mATX mobo, full size psu, double rad and duel gpu's.

The secondary aims inclued

Complete the build in less than one week (prevous build logs I've made have dragged on - sorry)

Ok let's start off with some photo's I took a few weeks back and posted in the compertition thread linky

The S1.0 is quite big for a SFF Matx case (35L). Shown here with a PC Design Labs QMicra V2 (29L cube), and Silverstone TJ08B-E (30L)

Last edited:

)

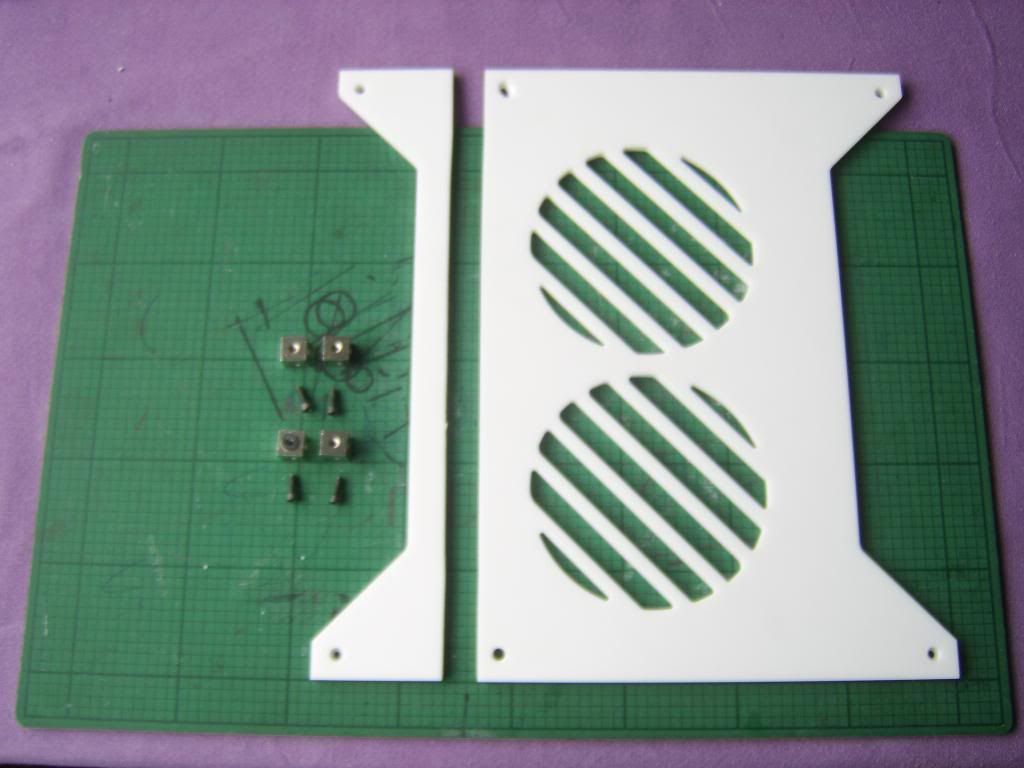

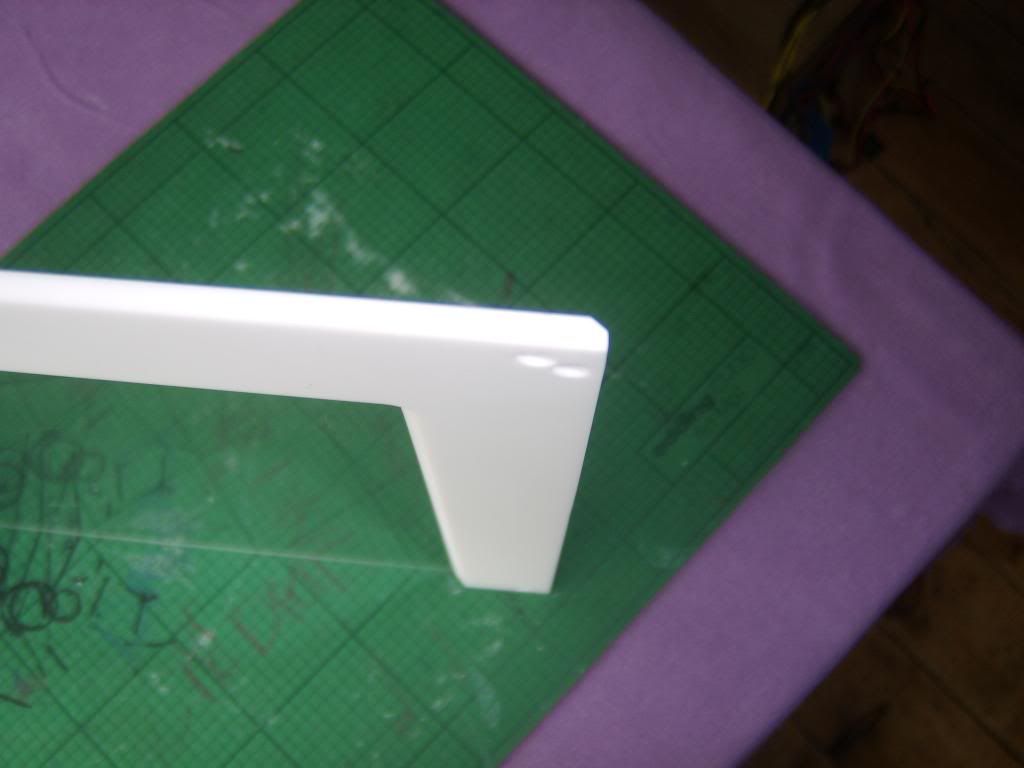

) too much acrylic dust so I wasn't a happy bunny.

too much acrylic dust so I wasn't a happy bunny.

- and thanks

- and thanks