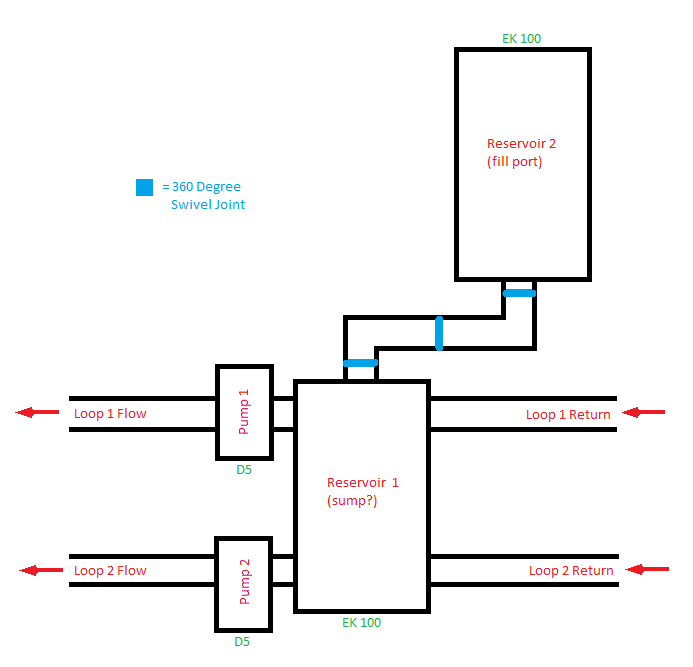

Hey guys. A reservoir is lovely, because it makes filling and bleeding really quick and easy. Well, relatively. A T line is better for flow rate as the water is not being accelerated and decelerated in the reservoir. So here for your viewing pleasure, I propose the following solution.

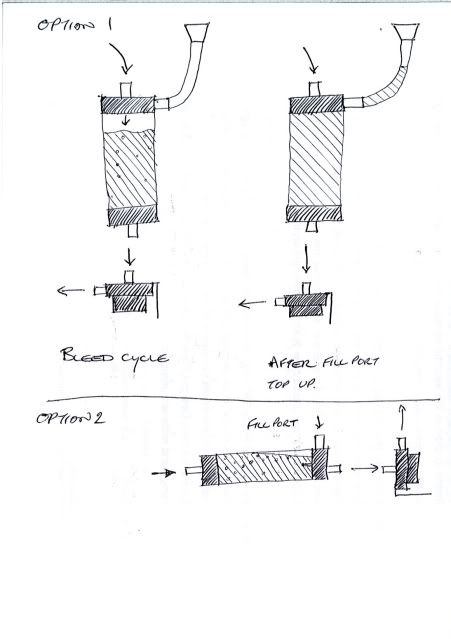

Ideallised of course. In case it isn't immediately obvious, you open the valve while filling and bleeding the system, at which point it behaves like a reservoir normally does. Once bled, you close the valve, and the system proceeds to work just like a T line. It would be wise to have the valve physically above the T, but coming from the middle section. Not quite as shown here, this made for a nicer picture. Dimensions are by eye for the ddc and valve, 11mm tubing, ignored barbs and drew a purely imaginary radiator.

Criticism of concept welcome. Criticism of solid edge + paint also welcome

Ideallised of course. In case it isn't immediately obvious, you open the valve while filling and bleeding the system, at which point it behaves like a reservoir normally does. Once bled, you close the valve, and the system proceeds to work just like a T line. It would be wise to have the valve physically above the T, but coming from the middle section. Not quite as shown here, this made for a nicer picture. Dimensions are by eye for the ddc and valve, 11mm tubing, ignored barbs and drew a purely imaginary radiator.

Criticism of concept welcome. Criticism of solid edge + paint also welcome