Associate

- Joined

- 30 Oct 2020

- Posts

- 5

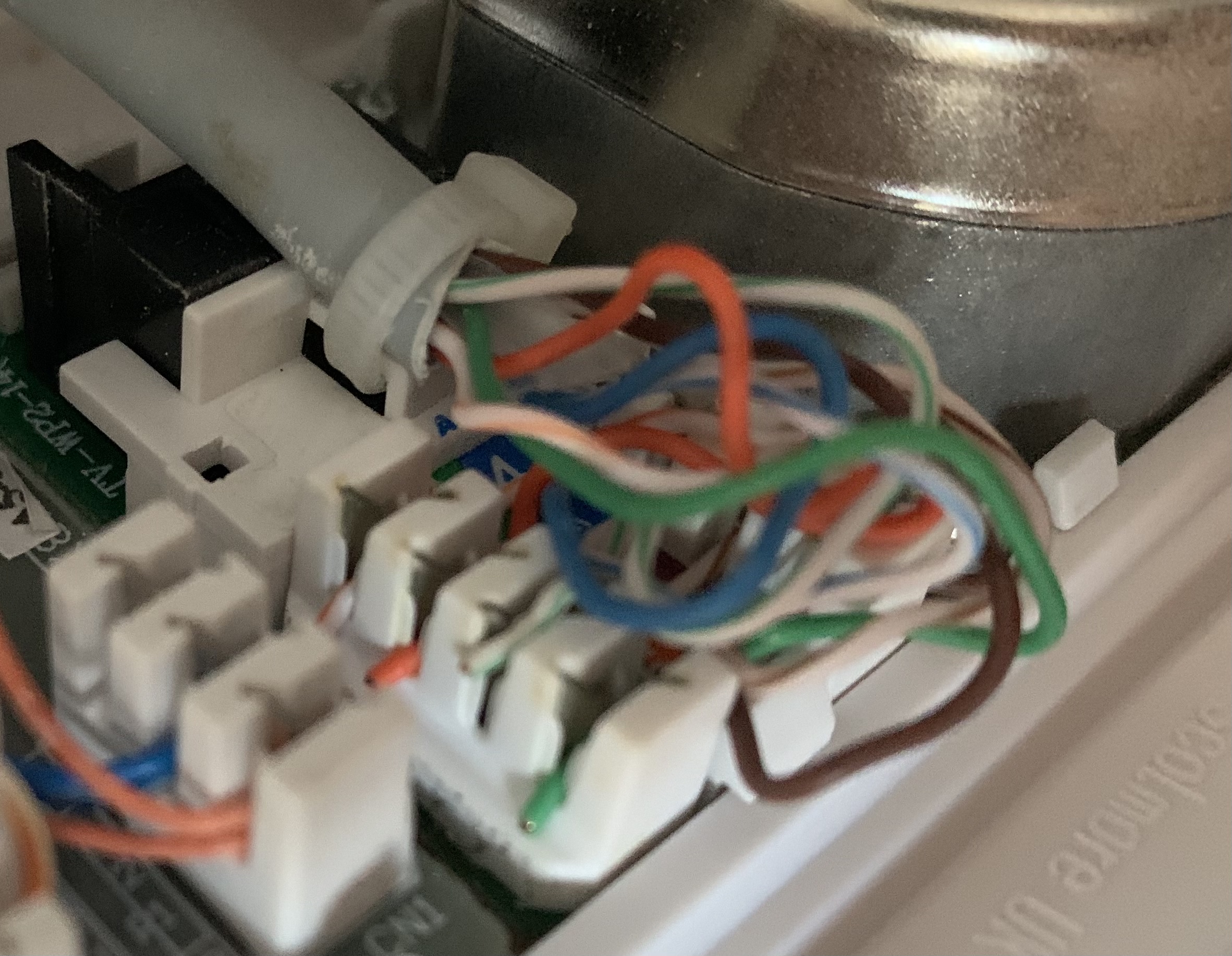

Hi. I’m in a new build house and the builders have run cat 6 cable from a number of different rooms to where the master line comes in. They connected the cables to wall plates but didn’t terminate the other ends. I have terminated them myself with RJ45 connectors. When I connected the tester to it I found a short on each cable. A particular (and different pin) is shorted on each cable. One cable has multiple shorts. I cut and re-terminated the ends 3 or 4 times and it’s always the same pins that are shorted.

Does this mean the problem is with the wall plates that the builders connected? Is it unusual for them to have not connected each plate properly?

Any help most appreciated. Thank you.

Does this mean the problem is with the wall plates that the builders connected? Is it unusual for them to have not connected each plate properly?

Any help most appreciated. Thank you.