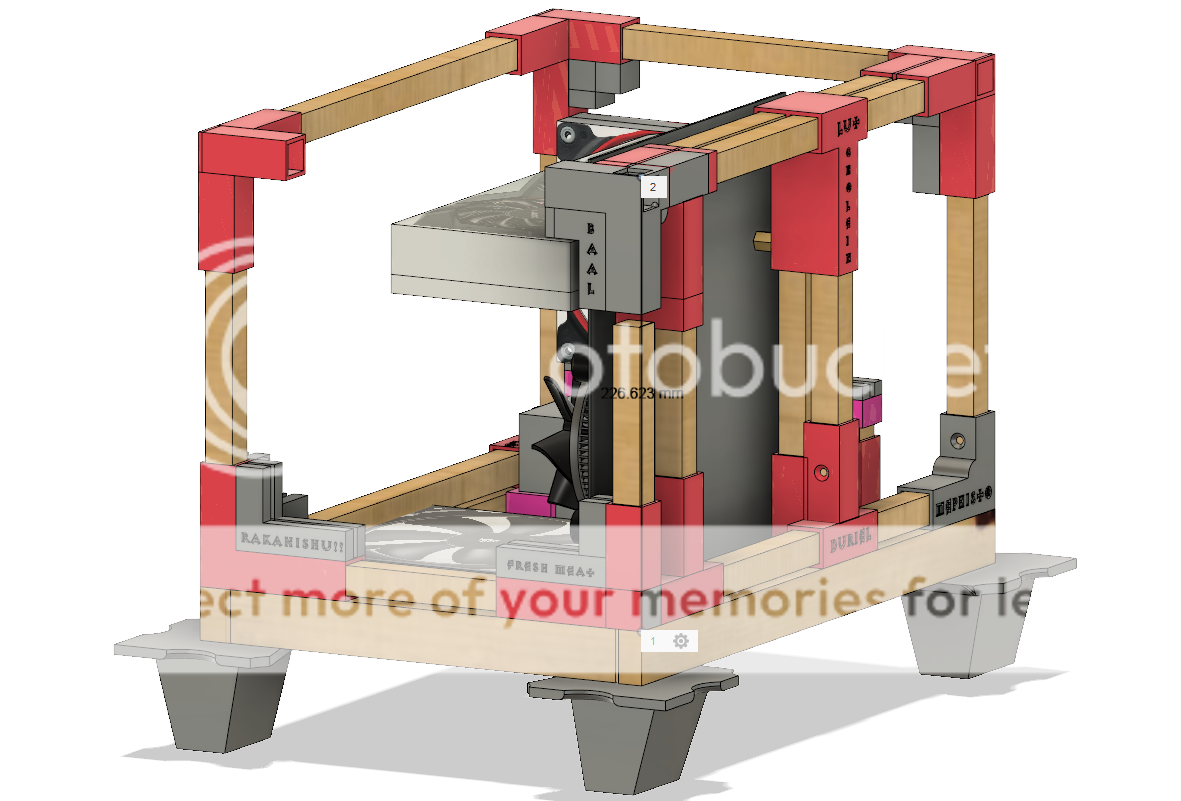

Hello, my project is to create a pc case that looks like a Diablo 3 inventory chest.

The inner frame is a mixture of wood and 3d printed plastic parts.

The outer shell will be 3d printed sanded/smoothed and then moulded and cast in resin.

The components are a mixture of old and new.

Motherboard Asus Micro ATX B85M-G

Processor intel I7 4770

Gigabyte 1660Ti windforce

Sampsung 500SSD

Corsair SF450 Platinum

32 GB corsair DDR3 1600

1 ML140 140mm PWM Premium Magnetic Levitation Fan

1 Air Series™ AF120 Quiet Edition High Airflow 120mm Fan

Challenges

Fusion 360 designing and 3D printing are new to me but I have some experience in 3d modelling.

And I have built my 3 pcs I owned, but never my own case. I also have good experience in miniature modelling and painting. Never done custom cables which I want to do.

I was a bit eager to start and printed some brackets,

But I went back to the drawing board.

The frame now has 2 steps on 3 of the sides so the frame can slide into the outer shell and sit inside the outer shells lip.

Here is a link to the fusion 360 online viewer

https://a360.co/2KaGCRa

Still to do in Modelling:

The fan on the bottom is static 140 mm the one on the side is an airflow fan 120mm.

Any feedback info appreciated.

The inner frame is a mixture of wood and 3d printed plastic parts.

The outer shell will be 3d printed sanded/smoothed and then moulded and cast in resin.

The components are a mixture of old and new.

Motherboard Asus Micro ATX B85M-G

Processor intel I7 4770

Gigabyte 1660Ti windforce

Sampsung 500SSD

Corsair SF450 Platinum

32 GB corsair DDR3 1600

1 ML140 140mm PWM Premium Magnetic Levitation Fan

1 Air Series™ AF120 Quiet Edition High Airflow 120mm Fan

Challenges

- Only use the bottom side and one small side for air flow I/O.

- Keep the size as small as possible with the hardware available.

- Silent

- Medium to good cooling.

- 3D print the case.

Fusion 360 designing and 3D printing are new to me but I have some experience in 3d modelling.

And I have built my 3 pcs I owned, but never my own case. I also have good experience in miniature modelling and painting. Never done custom cables which I want to do.

I was a bit eager to start and printed some brackets,

But I went back to the drawing board.

The frame now has 2 steps on 3 of the sides so the frame can slide into the outer shell and sit inside the outer shells lip.

Here is a link to the fusion 360 online viewer

https://a360.co/2KaGCRa

Still to do in Modelling:

- Model the top part of the chest.

- Re-model the side of the outer shell that hosts the fan and PSU.

- Model the I/O ports that will be attached to the outer shell 2- USB /1 HDMI/ 1 Display port/ 1 Eithernet port. A USB 3 Port will be in one of the key-locks.

- Figure out if I Can easily remove the front side of the outer shell for display.

- 3D printing

- Casting the outer shell

- Custom cables

- Attach Blue LED Strip on the base of the wooden frame.

- Do you see any possible problems in the build?

- Is the cooling sufficient? With the two fans?

The fan on the bottom is static 140 mm the one on the side is an airflow fan 120mm.

Any feedback info appreciated.