So my build is nearing completion and to put it bluntly its had its ups and downs and many changes along the way but the short story is: I'm using copper tubing. I've been working with 16mm copper and basically there are a number of problems with using it, main ones are:

Solutions are either I use a boat load of EK fittings (I don't want to do that I prefer the cleaner look) or I use standard plumbing elbows to have nice little neat bends... Plus a few bits hand bent that at accessible. The problem with this is typically you would solder the joints to make them watertight, my question whether in a Nickel/copper full loop would a lead free silver solder cause me corrosion due to the generally high tin content?

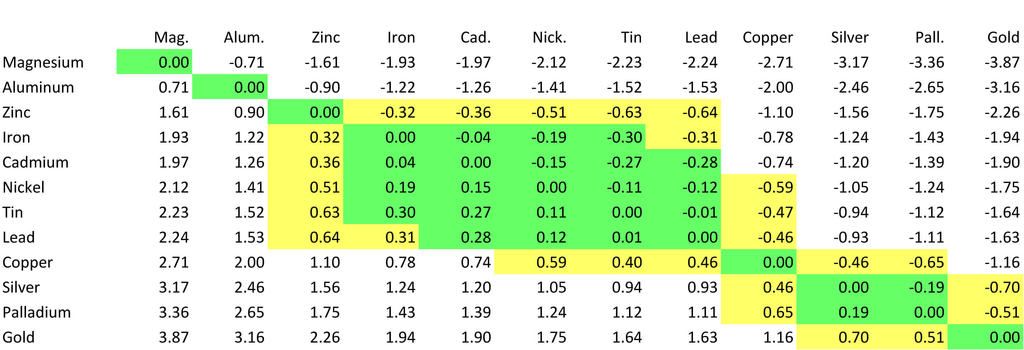

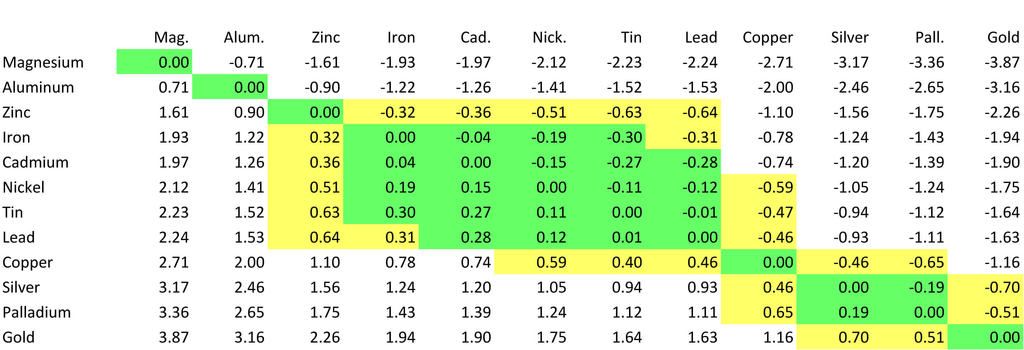

Goes without saying that the guys making rads must solder with something but the question is what? Zero knowledge in this and needless to say with a lot of expensive components I don't want to kill them all... Table below for the index of metals:

My other option is to bond joints with this stuff:

http://www.justforcopper.co.uk/

Has mixed reviews for proper plumbing but potentially in this use its fit for purpose...

Help.

- You can't get it many places and the stuff I've found is 1mm thick, aka very solid to shape/bend

- Given the size and thickness, the tools to bend it do not come in 'small' you cannot get bends tight enough for much of the loop

Solutions are either I use a boat load of EK fittings (I don't want to do that I prefer the cleaner look) or I use standard plumbing elbows to have nice little neat bends... Plus a few bits hand bent that at accessible. The problem with this is typically you would solder the joints to make them watertight, my question whether in a Nickel/copper full loop would a lead free silver solder cause me corrosion due to the generally high tin content?

Goes without saying that the guys making rads must solder with something but the question is what? Zero knowledge in this and needless to say with a lot of expensive components I don't want to kill them all... Table below for the index of metals:

My other option is to bond joints with this stuff:

http://www.justforcopper.co.uk/

Has mixed reviews for proper plumbing but potentially in this use its fit for purpose...

Help.