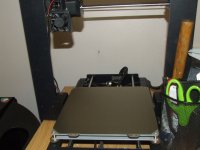

I have Wanhao i3 and prints are always hard to remove, so was thinking about a magnetic build plate as it should be loads easier to remove prints. But then I thought about glass because the prints pop off as the glass cools... So which do you like the best and why?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Glass vs Magnetic build plate?

- Thread starter Phil2008

- Start date

More options

Thread starter's postsSoldato

Depends what you are printing tbh

I have a glass bed at home and then 3/4 of the printers here at work are glass with one magnetic, not everything just pops off of glass, if its got a large contact area and is printed in carbon getting prints off of glass is still a real pita.

I have a glass bed at home and then 3/4 of the printers here at work are glass with one magnetic, not everything just pops off of glass, if its got a large contact area and is printed in carbon getting prints off of glass is still a real pita.

Associate

Magnetic flex PEI (smooth) might be a good in between, stuff sticks well to the smooth surface but you can bend it to release.

Soldato

Having a flexible bed to get jobs off is a must for some, however, unless you have some sort of CR/BL Touch then the repeated removing of the flexible sheet will give you questionable results, the number of people I see on the FB Ender 3 Pro group complaining about uneven beds is shocking, yes glass will solve that, but comes at a price, personally I wouldn't use a flexible bed on my printer at home unless I had some sort of ABL.

Associate

We are talking about the sheet/plate not the bed. The bed not being level is a different issue.Having a flexible bed to get jobs off is a must for some, however, unless you have some sort of CR/BL Touch then the repeated removing of the flexible sheet will give you questionable results, the number of people I see on the FB Ender 3 Pro group complaining about uneven beds is shocking, yes glass will solve that, but comes at a price, personally I wouldn't use a flexible bed on my printer at home unless I had some sort of ABL.

Even if the magnetic flexible sheet/plate had somehow got a bow or something in it from “repeated removing” (which I don’t believe happens) the magnets are really strong and would negate that. The magnets are soo strong they almost take your finger off!

Last edited:

Soldato

We are talking about the sheet/plate not the bed. The bed not being level is a different issue.

Even if the magnetic flexible sheet/plate had somehow got a bow or something in it from “repeated removing” (which I don’t believe happens) the magnets are really strong and would negate that. The magnets are soo strong they almost take your finger off!

Thats not what I'm on about though, if you take that sheet/plate off you are gonna run into level issues, maybe the mag pad that sticks to the hot plate has an airpocket in it or isn't uniform, popping the sheet/plate off could also introduce bits of stringing material if you're not in a clean environment or whatever, IMHO, and I am only 2 months into this 3d printing thing so my experience is limited, glass will always give you better adhesion and first layer consistency vs a mag sheet.

That said, and as I said above, YMMV based on what you are printing and what you are printing with, there is no 'correct' answer full stop, only a 'correct' answer for you based on your variables..

Well guys I have ordered this and I should get it tomorrow. https://www.amazon.co.uk/dp/B08D77KW2G?psc=1&ref=ppx_yo2ov_dt_b_product_details

I have a odd but very effective way of levelling my bed... I have a white wall behind my printer and when I shine a bright torch at it, the light kind of bounces back.. So I adjust the bed until I can just see the torch light underneath the nozzle.

I would have thought the bed would stay level for longer with a flexible sheet, because I tap the scraper with a hammer to get my print off, so the knocking will adjust the level of the bed. So Im hoping with not hammering the bad to get prints off, the bed will stay level for longer.Having a flexible bed to get jobs off is a must for some, however, unless you have some sort of CR/BL Touch then the repeated removing of the flexible sheet will give you questionable results, the number of people I see on the FB Ender 3 Pro group complaining about uneven beds is shocking, yes glass will solve that, but comes at a price, personally I wouldn't use a flexible bed on my printer at home unless I had some sort of ABL.

I have a odd but very effective way of levelling my bed... I have a white wall behind my printer and when I shine a bright torch at it, the light kind of bounces back.. So I adjust the bed until I can just see the torch light underneath the nozzle.

Last edited:

Soldato

I use a glass bed that has a bit of a coating on it. Prints stick great and are always very easy to remove once the bed temp has dropped below 35 degrees. I don't use any other kind of adhesive or release agent and I don't need to use a scraper or any kind of banging/knocking force. The trick is to let the bed cool before trying!

HICTOP Ender 3 pro Glass Bed Double Sided Upgraded Tempered Glass Bed 235x235 for Ender 3 Ender 3 Pro Ender 5 CR-20 Pro 3D printer (235 * 235) : Amazon.co.uk: Business, Industry & Science

Buy HICTOP Ender 3 pro Glass Bed Double Sided Upgraded Tempered Glass Bed 235x235 for Ender 3 Ender 3 Pro Ender 5 CR-20 Pro 3D printer (235 * 235) at Amazon UK. Free delivery on eligible orders.

www.amazon.co.uk

Soldato

A scrapper with a hammer, or using a light to level the bed, I'm not sure which one of those is more cringy lol

Soldato

Glass and pritt stick ftw

A scrapper and a hammer works really well,, as you hit the scrapper with the hammer to get underneath the print and then it normally just pops off. And yeah the light to level the bed is a real odd way of doing it but works really well also.A scrapper with a hammer, or using a light to level the bed, I'm not sure which one of those is more cringy lol

Soldato

PLease tell me you have at least printed a scraper and arent using the metal one that comes with the printers?

Soldato

glass will always give you better adhesion and first layer consistency vs a mag sheet

This is just wrong!

As long as the bed is properly calibrated and Z height set correctly, there should be no difference with adhesion.

It will also depend on what material is being printed, some need a release agent applying first etc

I much prefer using a smooth PEI spring steel sheet for printing PLA over glass, but requires a release agent for printing PTEG. I’ve heard great things about Satin sheets but not got round to buying one yet.

Soldato

This is just wrong!

As long as the bed is properly calibrated and Z height set correctly, there should be no difference with adhesion.

It will also depend on what material is being printed, some need a release agent applying first etc

I much prefer using a smooth PEI spring steel sheet for printing PLA over glass, but requires a release agent for printing PTEG. I’ve heard great things about Satin sheets but not got round to buying one yet.

Well as I said, I'm only a few months into this 3d printing lark, but I have also said, several times, that it depends what model you are printing, as in what sort of bed contact it has, as well as what material you are printing with...

I stick by the consistency comment though given that you don't remove and replace the glass bed like you do the mag sheet.

A plastic scraper would be totally useless getting prints off the bed.. Anyway hopefully now scrapers and hammers will be a thing of the past as the magnetic plate came today and its on. Its Just a shame I haven't anything to print atm.PLease tell me you have at least printed a scraper and arent using the metal one that comes with the printers?

I was a bit worried that it would move about when printing, but the magnet is really strong, I cant move it when its magnetised on. So getting it straight when putting it on is a bit of a pain as it wont slide at all.

Last edited:

Soldato

A plastic scraper would be totally useless getting prints off the bed..

I use a 3d printed one, that way its less likely to damage the print.

Prints can withstand a lot before they get damaged, Im more worried about damaging the build surface then the print. If a print is totally stuck down(no lifting at the corners), then its a right pain to get the prints off and you need a few taps with a hammer to get the scraper underneath the print.. Ive have always used a hammer as its impossible to get the scraper underneath the print withoutI use a 3d printed one, that way its less likely to damage the print.

Last edited:

Soldato

Clearly strong prints that I'm doing lol