Man of Honour

The best bed material I've found for PETg is blue tape and glue stick and bed around 60°c.

Works a treat and once finished remove the part and use warm water to clean glue residue off the print.

Even prusa recommend glue stick on PEI sheet with PETg.

I noticed Rigid.ink recommend the same, not sure exactly what the Ender's bed material is but it was almost impossible to remove. Gone back to trying to glass again to see if I can figure it out

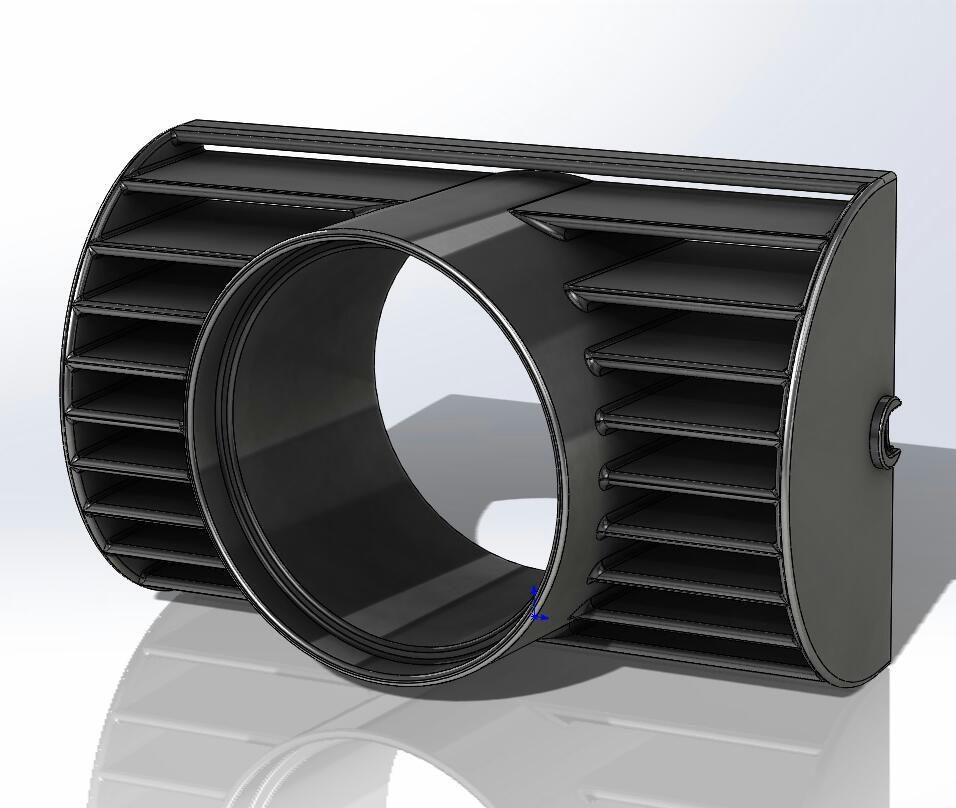

I'm quite happy to post a vent over to you if that's any easier also.

I'm quite happy to post a vent over to you if that's any easier also.