First time doing a build log

also first time water cooling

hopefully i don't give you the blues

still waiting for the res tube,radiator,

cpu, gpu cooler to arrive

Parts list:

Phanteks Enthoo Primo Full Tower Case - White Edition

Gigabyte X79-UP4

Intel I7 - 4930K

64GB - Crucial Ballistix 1600 VPL Sport

Powercolor Radeon R9 290 PCS+ OC 4096MB GDDR5 PCI-Express Graphics Card

SuperFlower Leadex Platinum 1000W Fully Modular "80 Plus Platinum" Power Supply - White

Water Cooling :

EK Water Blocks EK-D5 Vario X-TOP Incl. Pump - Plexi

EK Water Blocks EK-Supremacy EVO

Aqua Computer kryographics Hawaii for Radeon R9 290X and 290 acrylic glass edition

Phobia Balancer 400 silver nickel

Phobya G-Changer 480 V.2 - Full Copper

Monsoon Hardline Acrylic Tube 3/8 x 1/2 (13mm) 4 Pack - Clear - 4x24”

Monsoon Free Center Hardline 3/8 X 1/2 (13mm) 6 Pack - Blue X2

Parvum Systems F1.0 Performance Pressure Optimised Fan - White X4

Aqua Computer Double Protect Ultra 1l - Blue

Shoggy Sandwich

Modding parts :

4mm triple dense weave Braid in baby blue,Royal Blue and white

heat shrink in same colours as braid Monsoon silicone bending insert

various tools and connectors for making my own custom braid cables

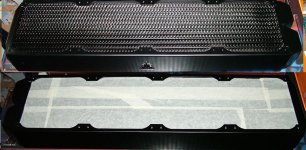

delivery from OverClockers today

some other parts from OC

some of the other parts going into this build

also first time water cooling

hopefully i don't give you the blues

still waiting for the res tube,radiator,

cpu, gpu cooler to arrive

Parts list:

Phanteks Enthoo Primo Full Tower Case - White Edition

Gigabyte X79-UP4

Intel I7 - 4930K

64GB - Crucial Ballistix 1600 VPL Sport

Powercolor Radeon R9 290 PCS+ OC 4096MB GDDR5 PCI-Express Graphics Card

SuperFlower Leadex Platinum 1000W Fully Modular "80 Plus Platinum" Power Supply - White

Water Cooling :

EK Water Blocks EK-D5 Vario X-TOP Incl. Pump - Plexi

EK Water Blocks EK-Supremacy EVO

Aqua Computer kryographics Hawaii for Radeon R9 290X and 290 acrylic glass edition

Phobia Balancer 400 silver nickel

Phobya G-Changer 480 V.2 - Full Copper

Monsoon Hardline Acrylic Tube 3/8 x 1/2 (13mm) 4 Pack - Clear - 4x24”

Monsoon Free Center Hardline 3/8 X 1/2 (13mm) 6 Pack - Blue X2

Parvum Systems F1.0 Performance Pressure Optimised Fan - White X4

Aqua Computer Double Protect Ultra 1l - Blue

Shoggy Sandwich

Modding parts :

4mm triple dense weave Braid in baby blue,Royal Blue and white

heat shrink in same colours as braid Monsoon silicone bending insert

various tools and connectors for making my own custom braid cables

delivery from OverClockers today

some other parts from OC

some of the other parts going into this build

Last edited: