Permabanned

- Joined

- 8 Jan 2010

- Posts

- 10,263

- Location

- UK

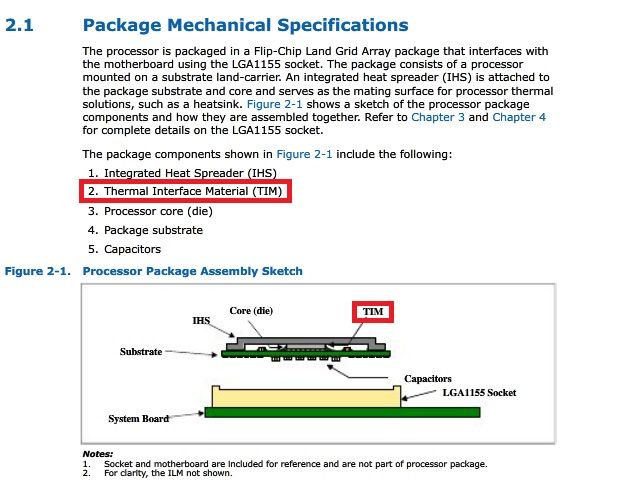

PC enthusiasts with Ivy Bridge engineering samples, and reviewers at large have come to the consensus that Ivy Bridge is a slightly warmer chip than it should be. An investigation by Overclockers.com revealed a possible contributing factor to that. Upon carefully removing the integrated heatspreader (IHS) of an Ivy Bridge Core processor (that steel plate on top of the processor which makes contact with the cooler), the investigator found common thermal paste between the CPU die and the IHS, and along the sides of the die.

In comparison, Intel used flux-less solder to bind the IHS to the core on previous-generation Sandy Bridge Core processors. Attempting to remove IHS off a chip with flux-less solder won't end well, as it could rip the die off the package. On the other hand, the idea behind use of flux-less solder in CPU packages is to improve heat transfer between the die and the IHS. Using thermal paste to do the job results in slightly inferior heat transfer, but removing IHS is safer. One can be sure that making it safe for IHS removal couldn't have been the issue behind switching back to conventional thermal paste, as everything under the IHS isn't user-serviceable anyway, and off limits for them.

http://www.techpowerup.com/forums/showthread.php?t=164858

So based on what evidence we could find from our own investigation, as well as what experience has taught us, Ivy Bridge is running hot when overclocked because of TIM paste between the IHS compared to solder attach used on Sandy Bridge. Why Intel made this choice we aren’t yet sure. We also aren’t sure if they will continue using TIM paste on the Ivy Bridge line, or if this will only be seen on the Engineering Samples like the units sent out for review. However, we’ve put word out again to Intel and are waiting to hear back if they have any further insight or comment to offer. If nothing else, we can hope their reply will again be in good humor… “Secret Sauce” did give us a laugh!

** No hotlinked images - Please re-host without watermarks before replacing ***