Associate

- Joined

- 10 May 2013

- Posts

- 11

- Location

- in front of the PC

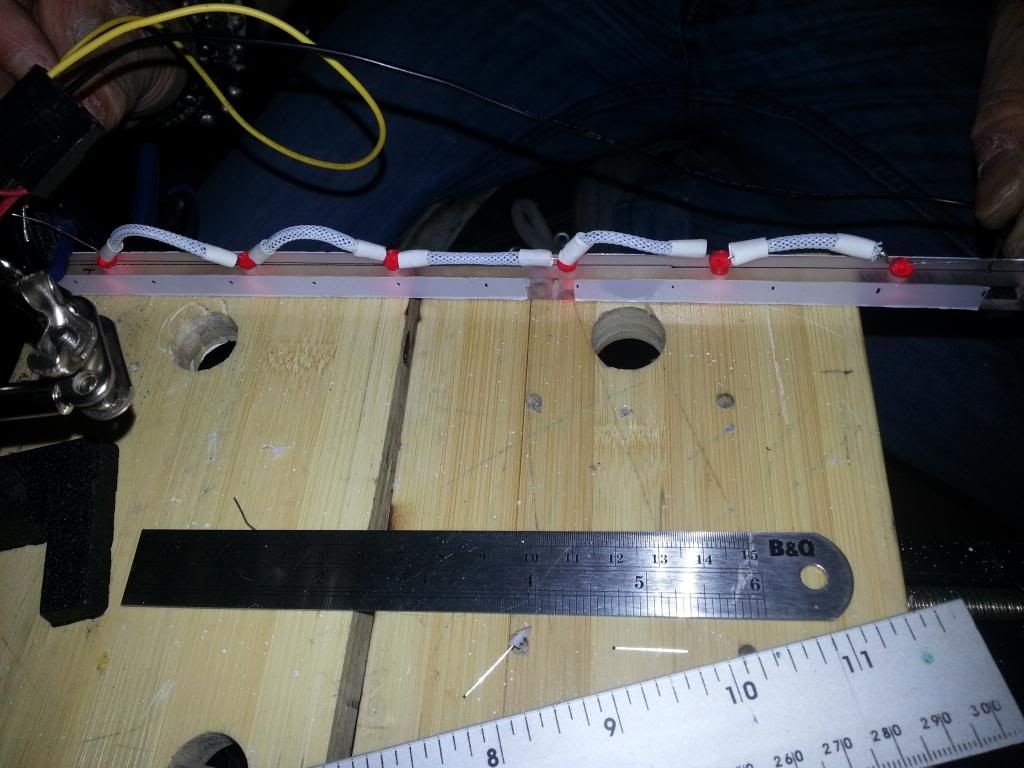

First OF all guys I'm new here so i'd like to say hello and welcome to my log. Feel free to point out all the bad things about my build and ways I can improve it. It is nothing special by a lot of the rigs and builds I have seen on here but having limited tools and crippling arthritis at times things can sometimes go wrong lol.

My daughter has had a pretty rough time of things lately, with trying to find a job, caring for me and my disabilities and the GCSE's fiasco. So in a bid to give her something to smile about I'm hoping to build her a fairly nice rig.

I am hoping to be able to scavenge a few parts that are laying around the house and maybe if I'm lucky a few donations or some things might come from fleabay.

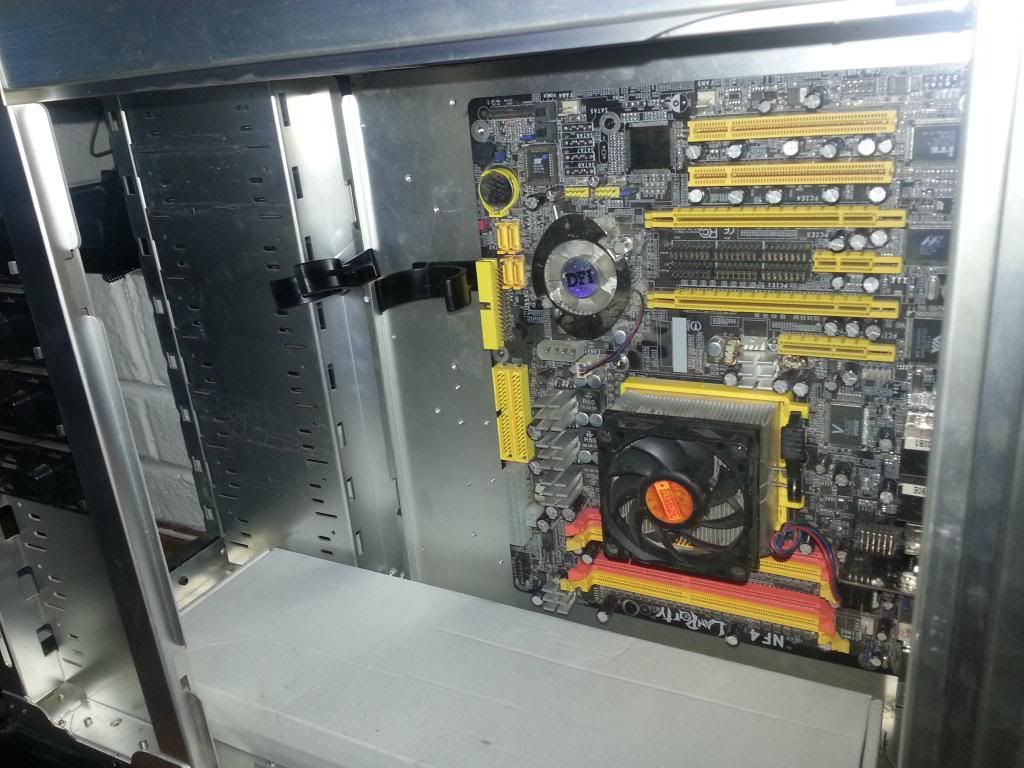

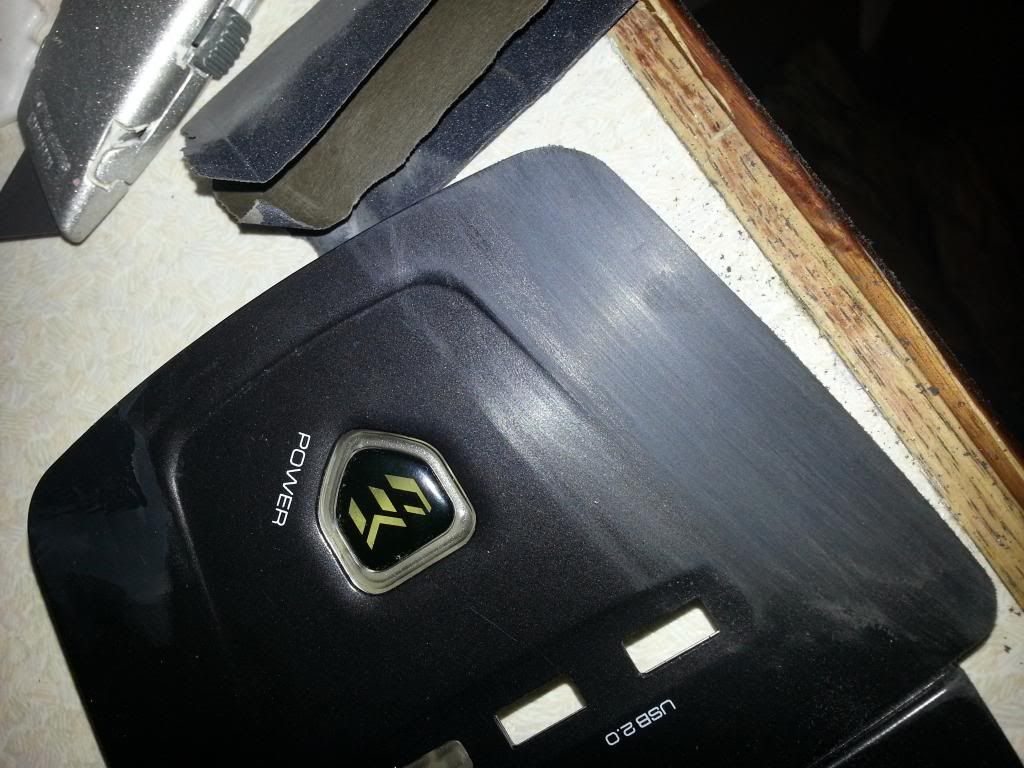

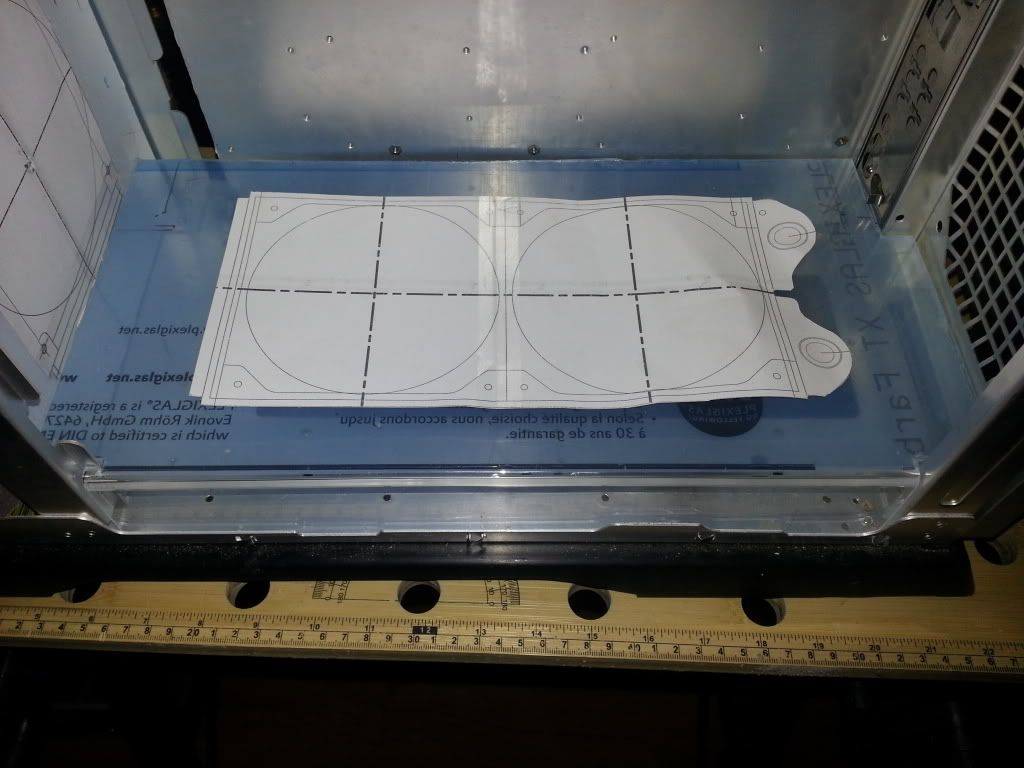

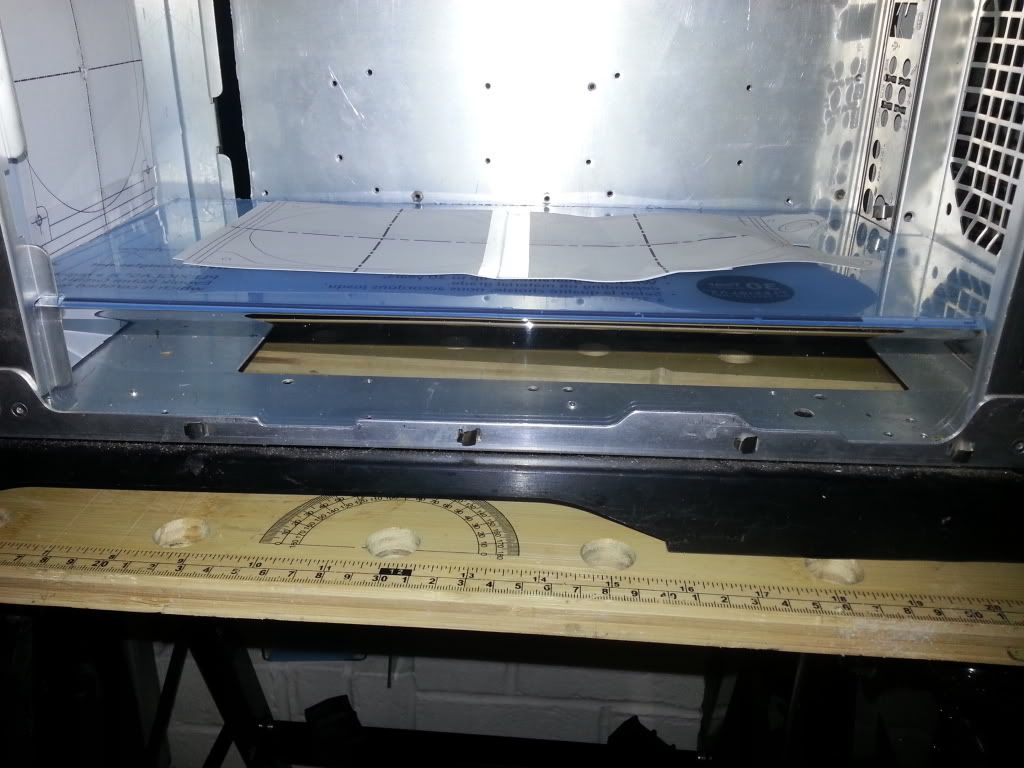

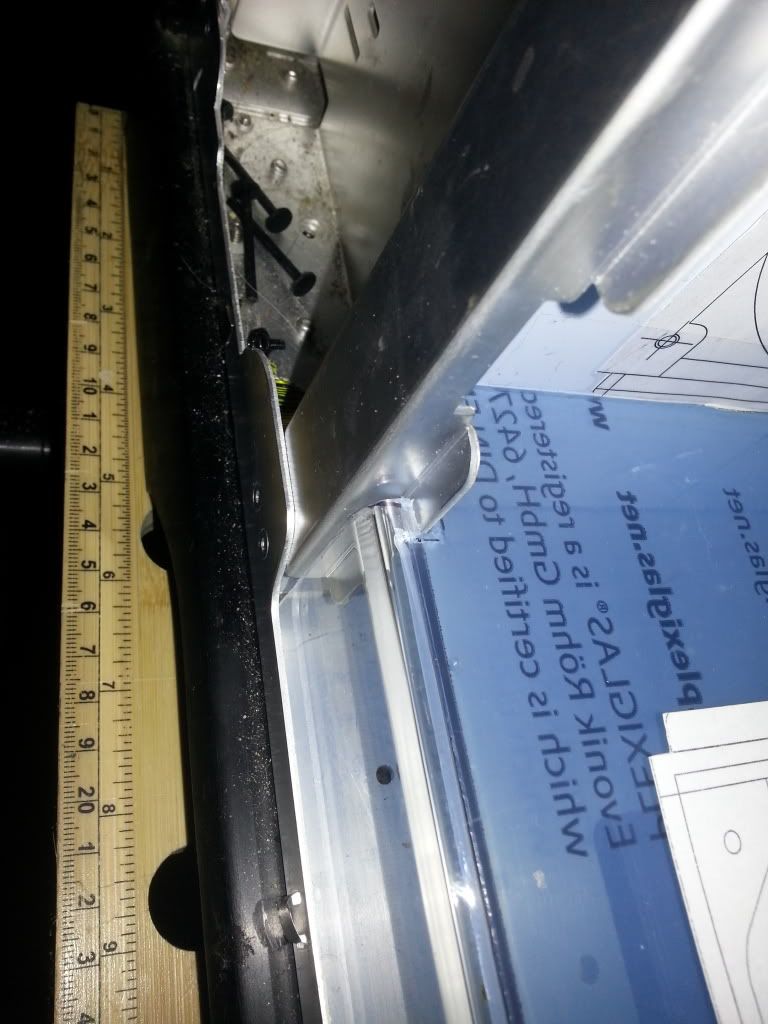

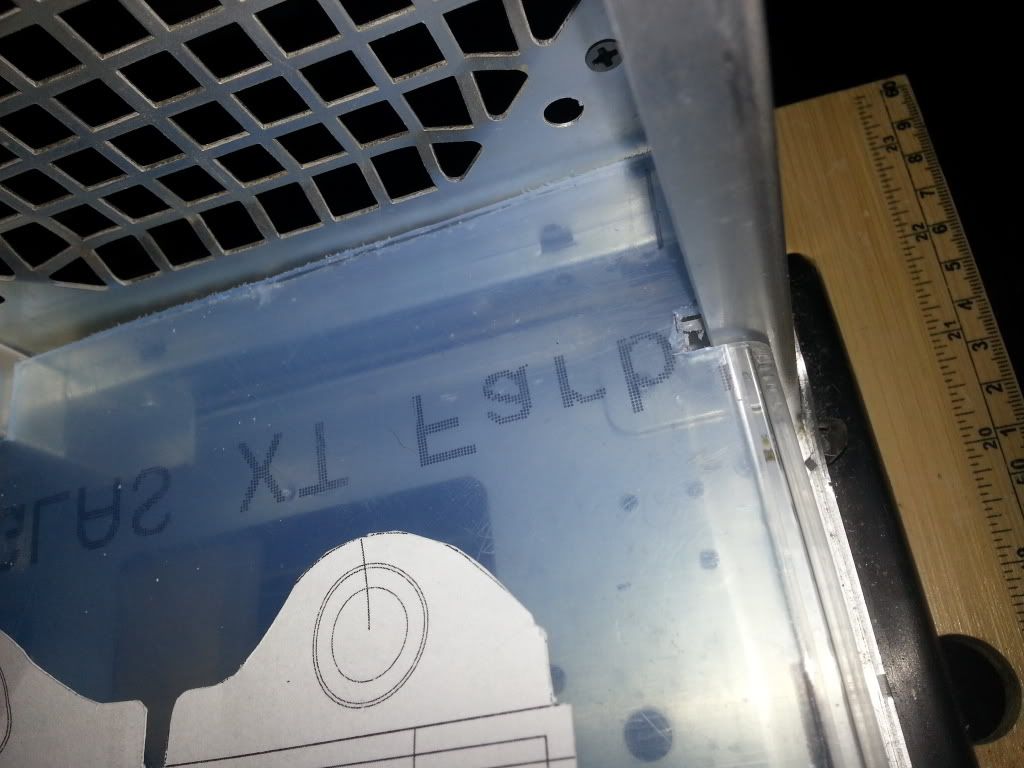

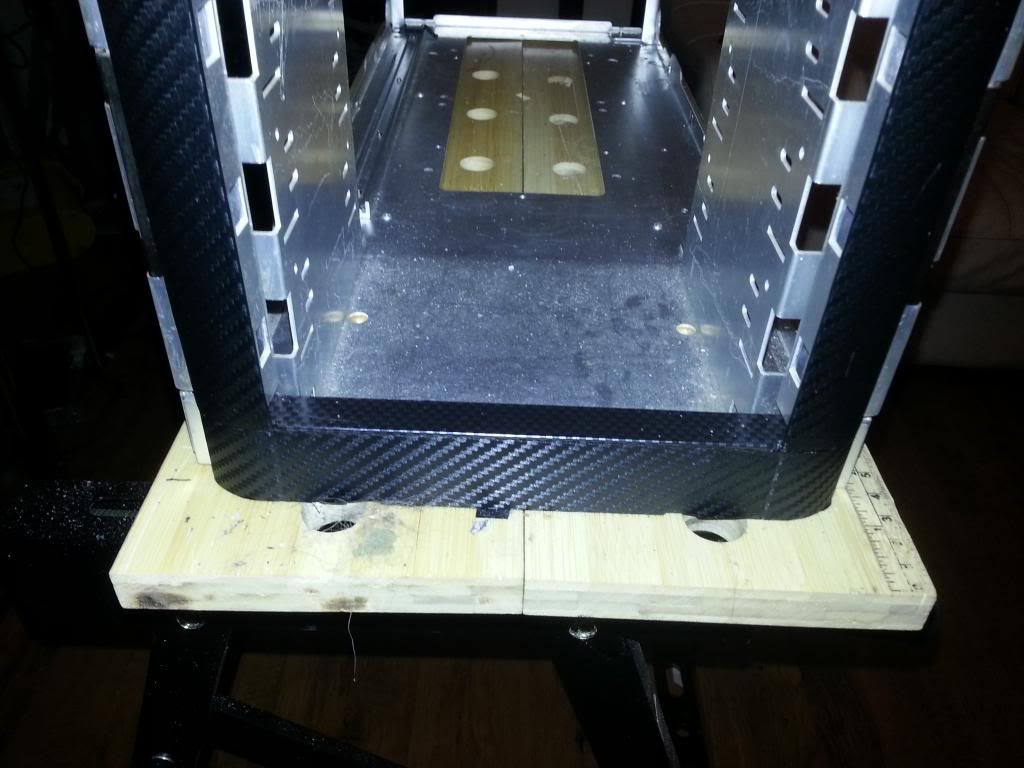

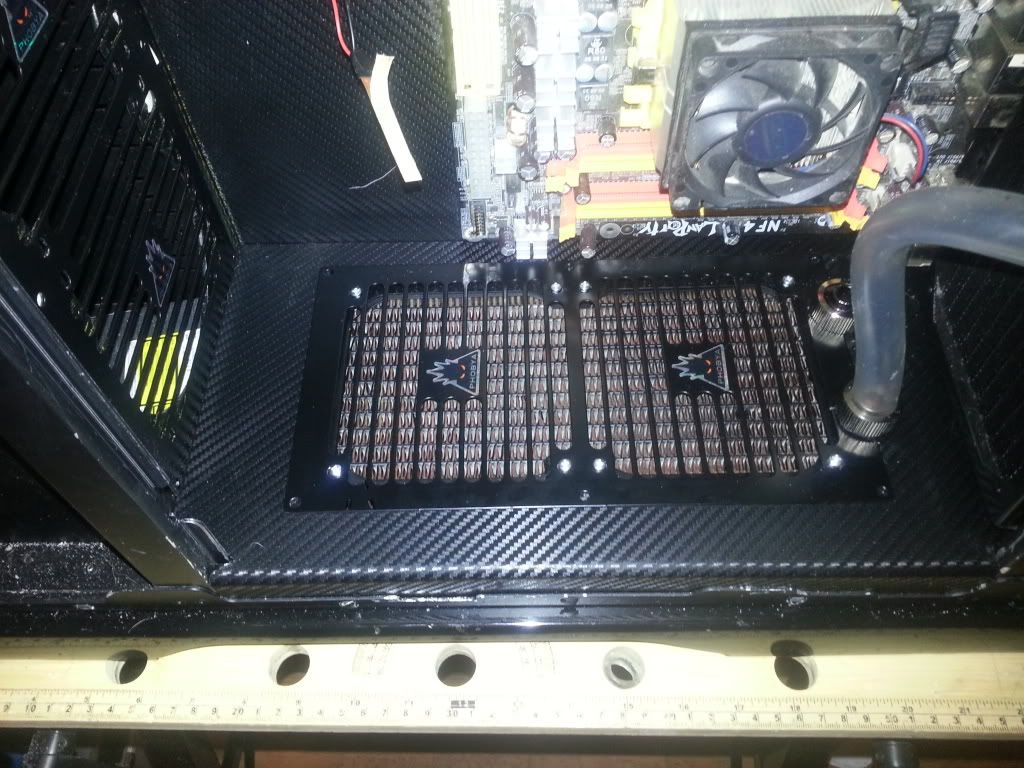

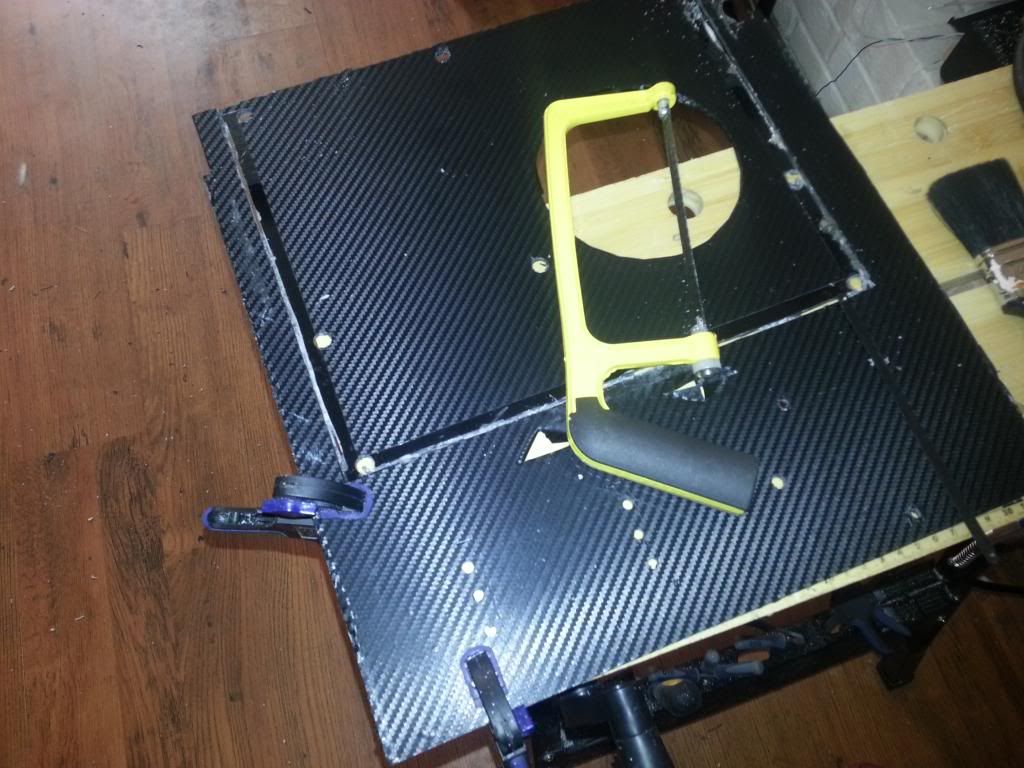

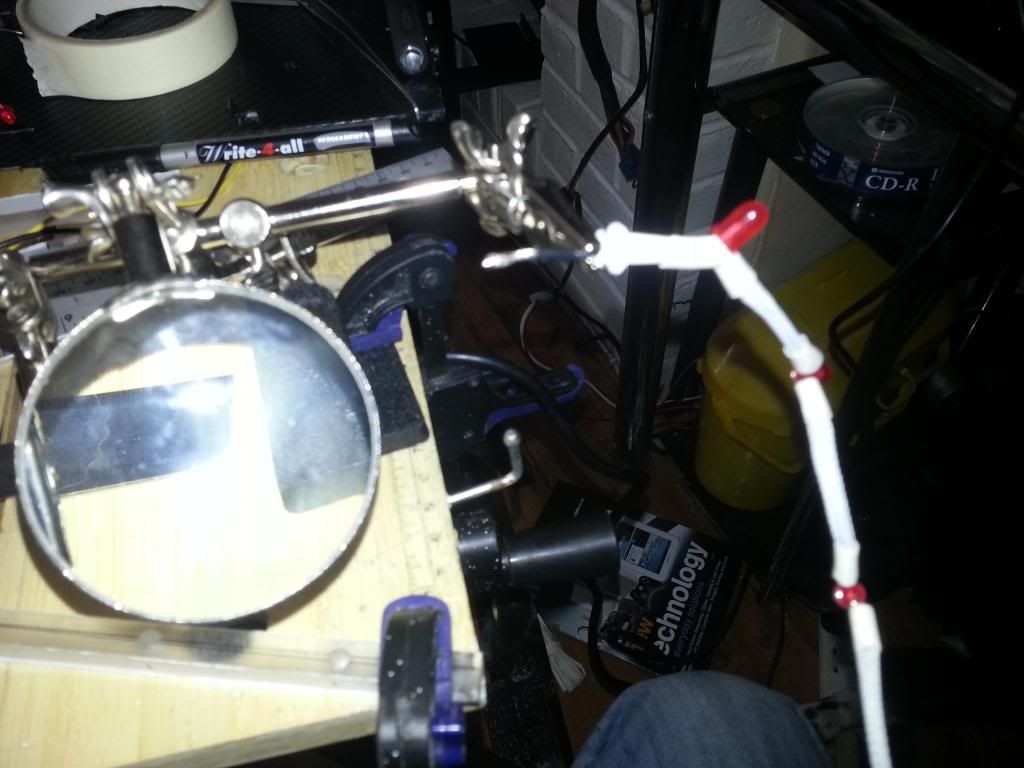

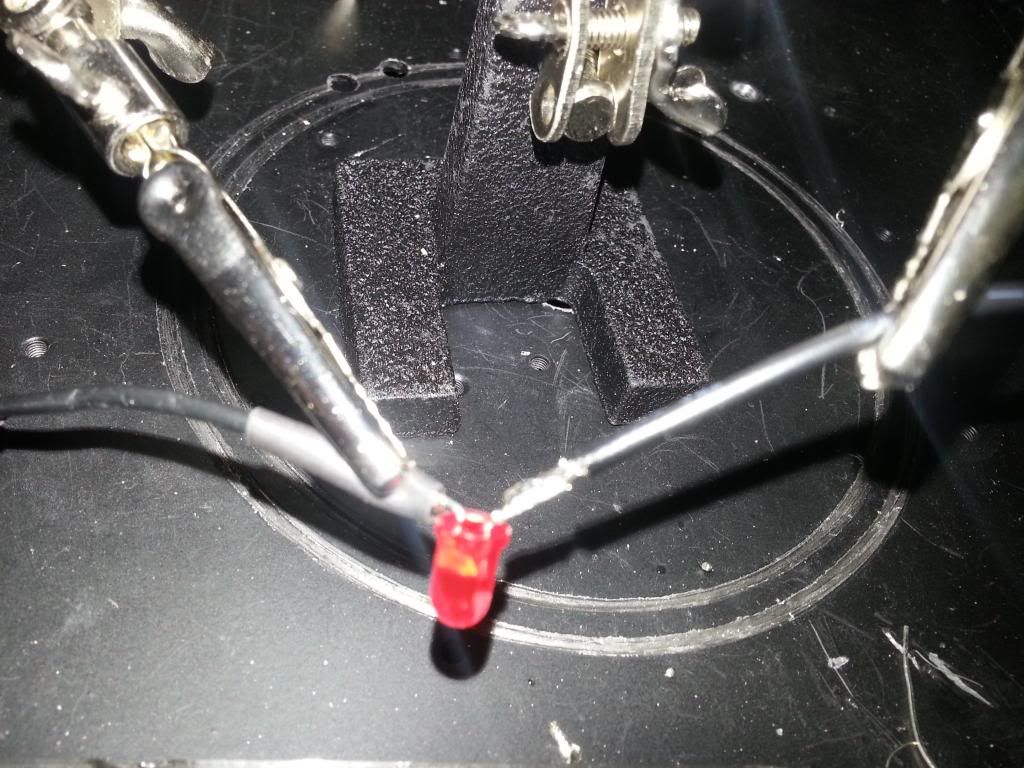

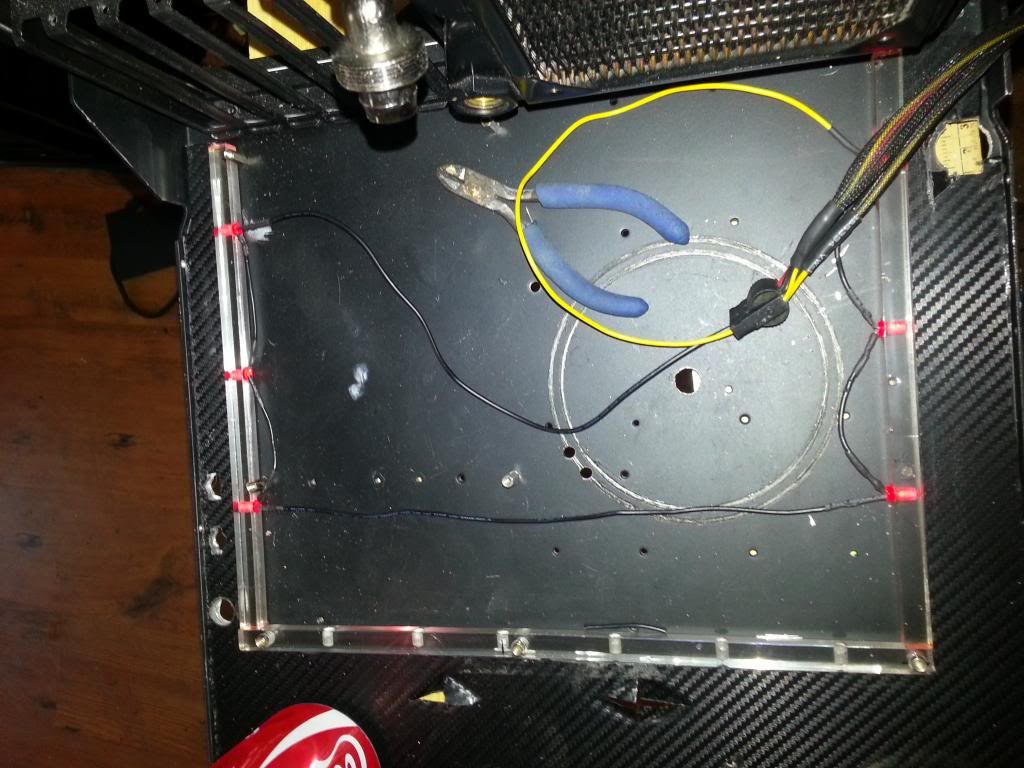

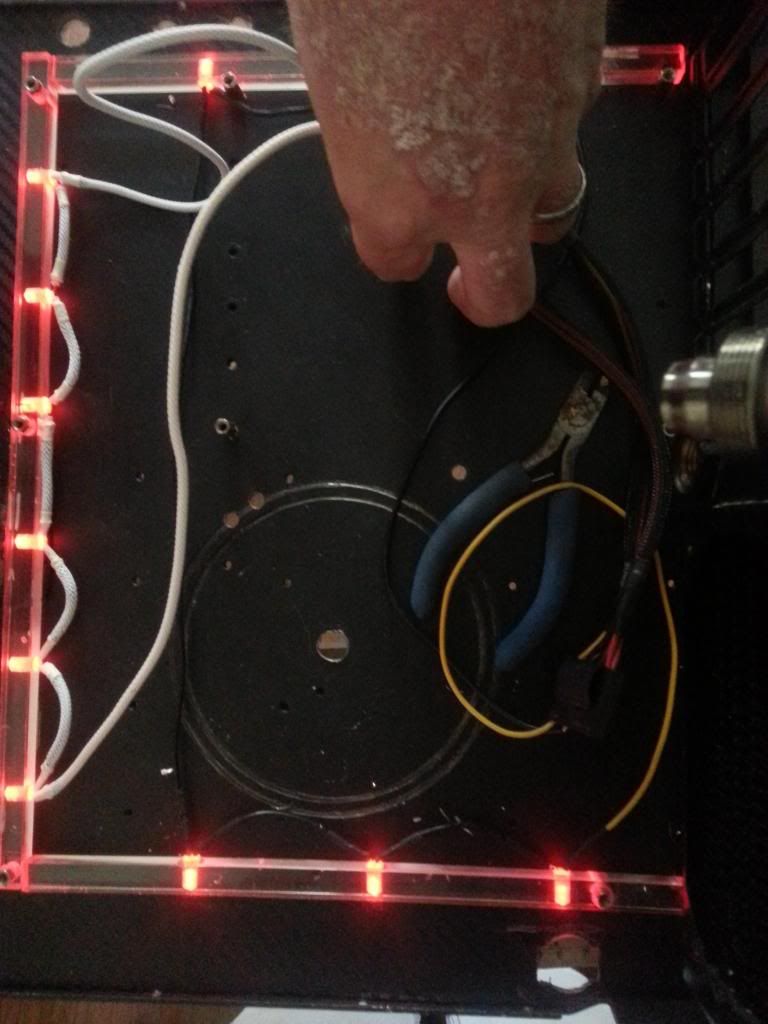

I will be basing this build around a Coolermaster Staker 832 Nvidia Edition that was donated to me by Stuart over at Wabsys in Wakefield, W Yorks.

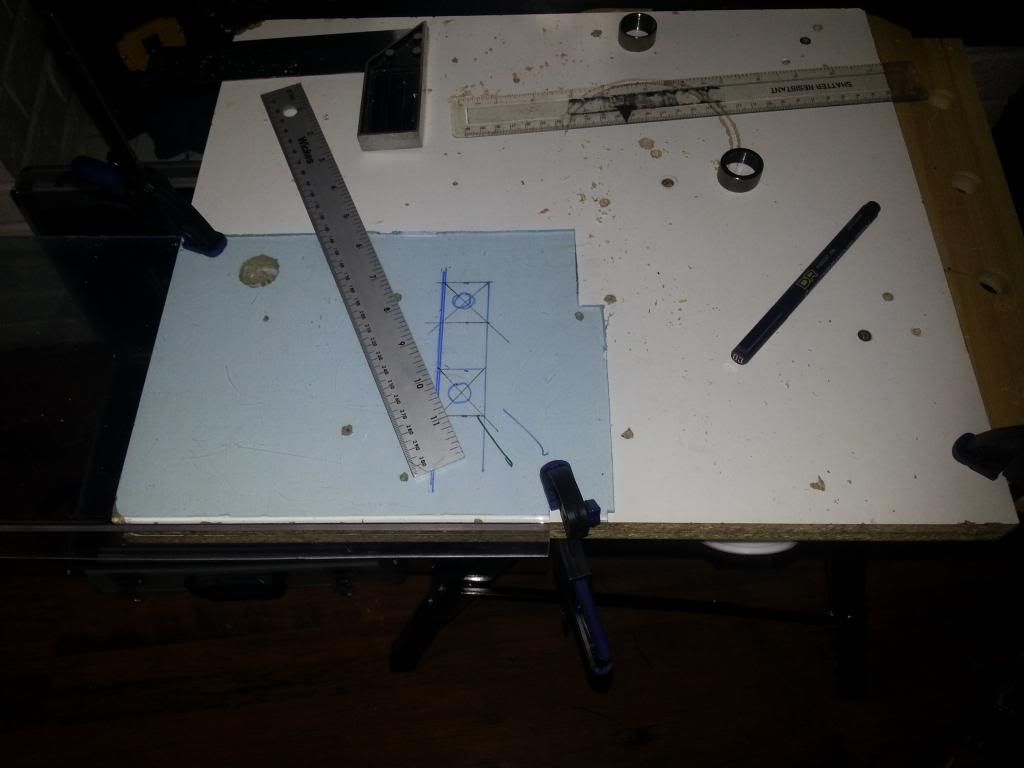

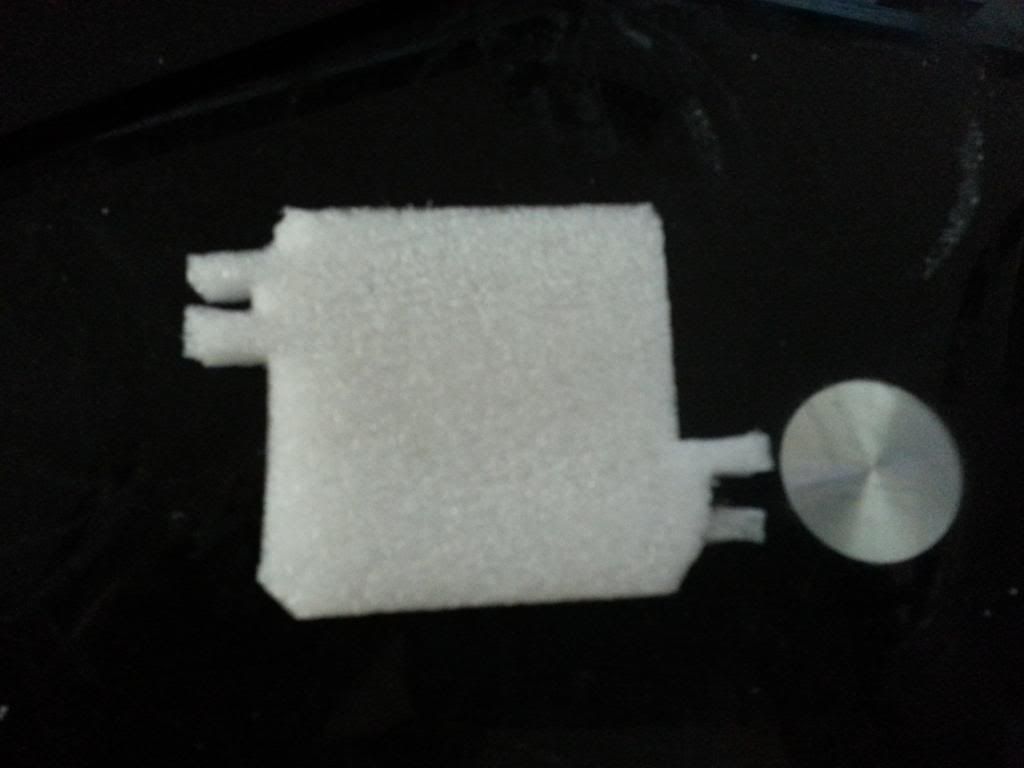

Well here we go the starting case pics..... as soon as I have more info and some ideas have been drwan up I will post them here for to all laugh about ermmm I mean read.

My daughter has had a pretty rough time of things lately, with trying to find a job, caring for me and my disabilities and the GCSE's fiasco. So in a bid to give her something to smile about I'm hoping to build her a fairly nice rig.

I am hoping to be able to scavenge a few parts that are laying around the house and maybe if I'm lucky a few donations or some things might come from fleabay.

I will be basing this build around a Coolermaster Staker 832 Nvidia Edition that was donated to me by Stuart over at Wabsys in Wakefield, W Yorks.

Well here we go the starting case pics..... as soon as I have more info and some ideas have been drwan up I will post them here for to all laugh about ermmm I mean read.

Last edited: