I've added the short intro on the manifold issues as a bit of background into why I decided to change the turbo only a few months after having it on the dyno and being very happy with it.

At the Circuit Days trackday, both Matt and I were sure we could smell some exhaust fumes from under the bonnet when in the carpark but couldn`t find the source anywhere. It was only a slight smell and at speed it disappeared.

Back in the UK I decided to remove the turbo and check the mounting face as everything else seemed OK. As soon as it was removed I realised I had a problem. The manifold has certainly seen a few extreme heat cycles but appeared to be holding up well after the previous repair back in 2015 .Closer internal inspection immediately identified the problem. The inside of the collector looks worse for wear. The steel has cracked badly.

Die grinder to clean the inside and again, it was worse than I initially thought.

I've been contemplating changing the turbo for a couple of years but everytime I think about it, the work required to modify the collector on the manifold made me think it wasnt worth it. The car is quick enough, I won't use more boost, especially in 3rd and 4th so what's the point.

Then this happened and at the same time, I spotted the turbo I've had my eye on come up for sale very cheaply. If that does't scream "This is meant to be !!" I don't know what does

Or maybe I'm just trying to convince myself this is a good idea

Or maybe I'm just trying to convince myself this is a good idea

MANY hours of cutting, grinding and welding later it was repaired in SCH40 Stainless steel ready for the turbo to be fitted.

Not my finest work, but it's strong and will do the job. (There isn't a hole on the bottom right runner, it's just a shadow. )

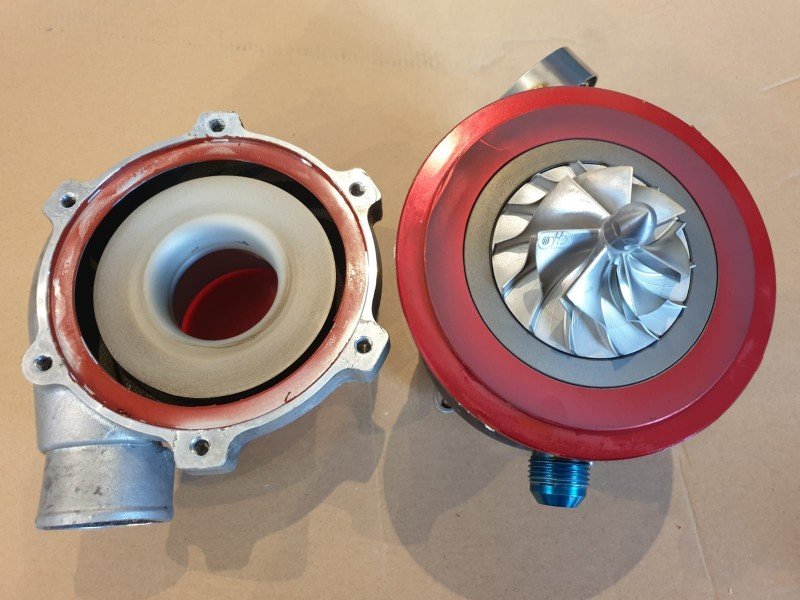

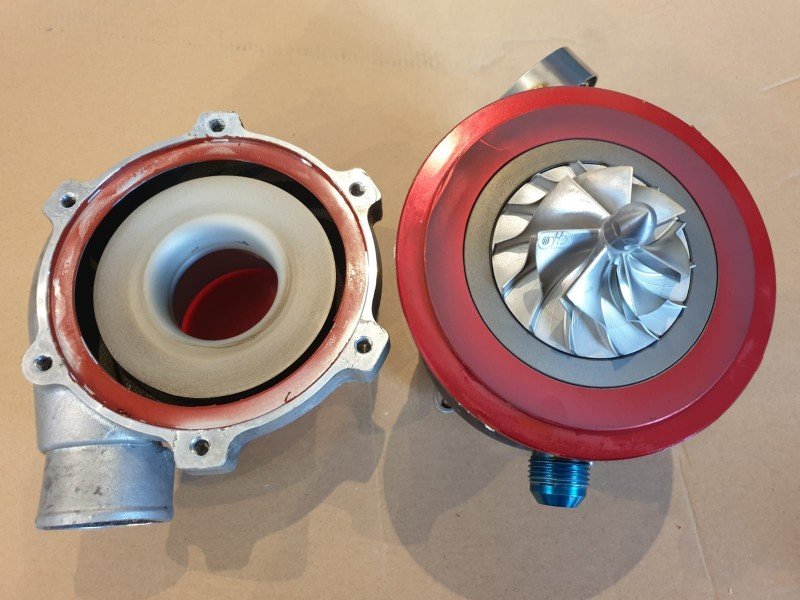

Arrived at EFI-Parts for Chris to map DTAFast S80Pro ECU on the Golf with the new Owen Developments GT2868HTA turbo I'd fitted. This is a used turbo from a BTCC race car. They don't run them until they break, but replace them after a certain amount of hours and fit a new one. That means turbos like this keep popping up on the 2nd hand market. A quick visual inspection showed no signs of wear at all and the play in the bearings was imperceptible.

Splitter removed to allow it to fit on the dyno

Drove in and strapped the Golf down, MAP and knock sensors attached to the engine, AFR in the exhaust.

After one run it was obvious the fibreglass bonnet was flapping around too much so we quickly removed it

I had swapped from the Siemens 630cc injectors to some Bosch 900CC ones. The old ones wouldn't be able to supply sufficient fuel for the new turbo. That meant Chris had to spend a little while tuning the part throttle and off bost area of the tune before any power runs. The DTA fuelling table allows precise injector pulsewidth changes and Chris was able to use this to get a really smooth idle and great low throttle opening response.

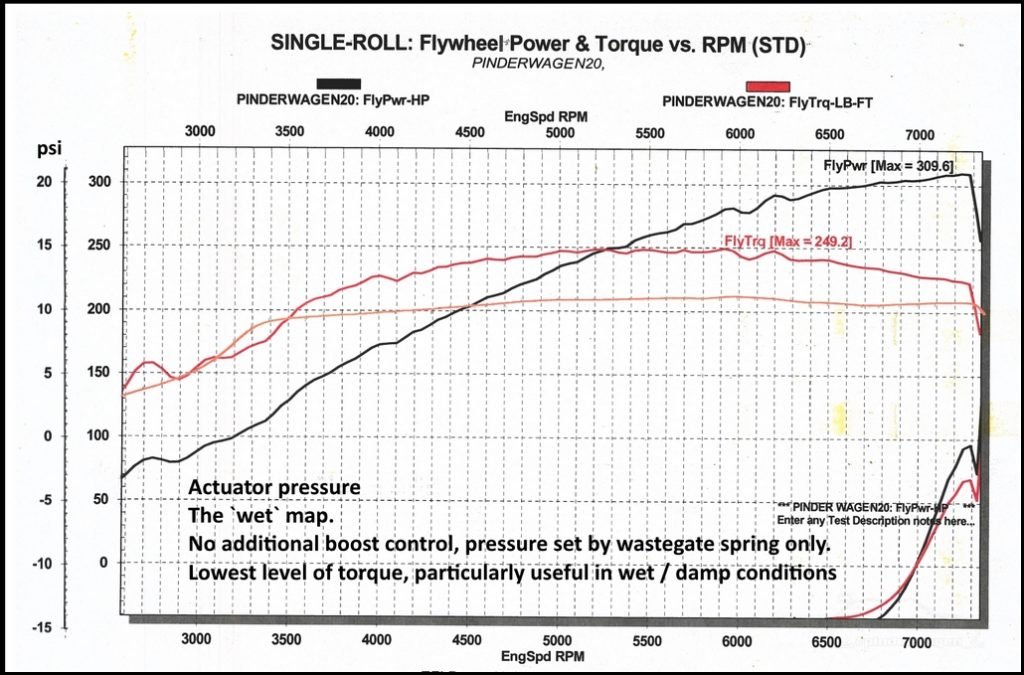

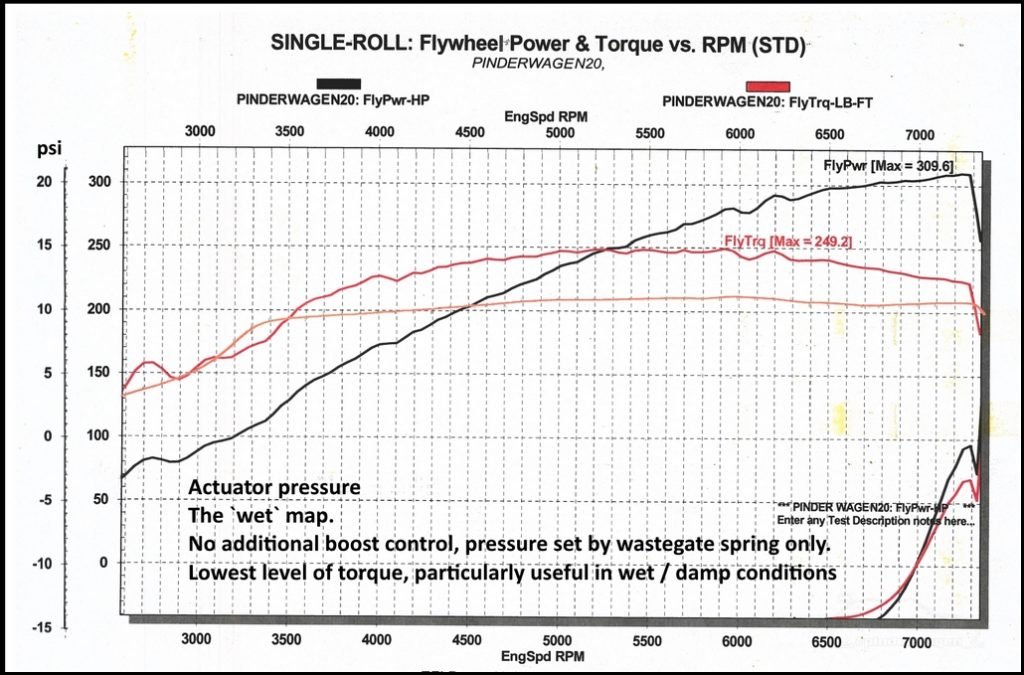

First power run on actuator pressure only and I saw it was reaching 0.75Bar. Hmmm, this was supposed to be a 0.6Bar spring. Nothing I could do on the dyno so I`ll see how it goes, but can always change the spring later if I find it's too much in the wet or low gears.

A very healthy 309 HP, but torque has no assistance so drops away as the revs rise. It's still almost 310HP which is pretty damned good.

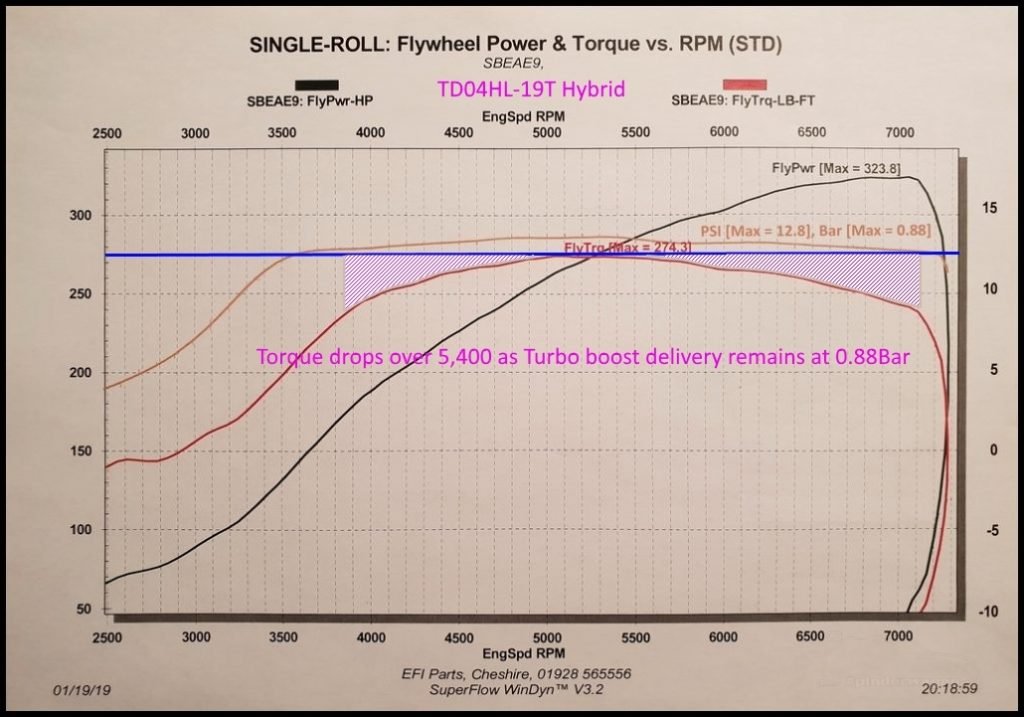

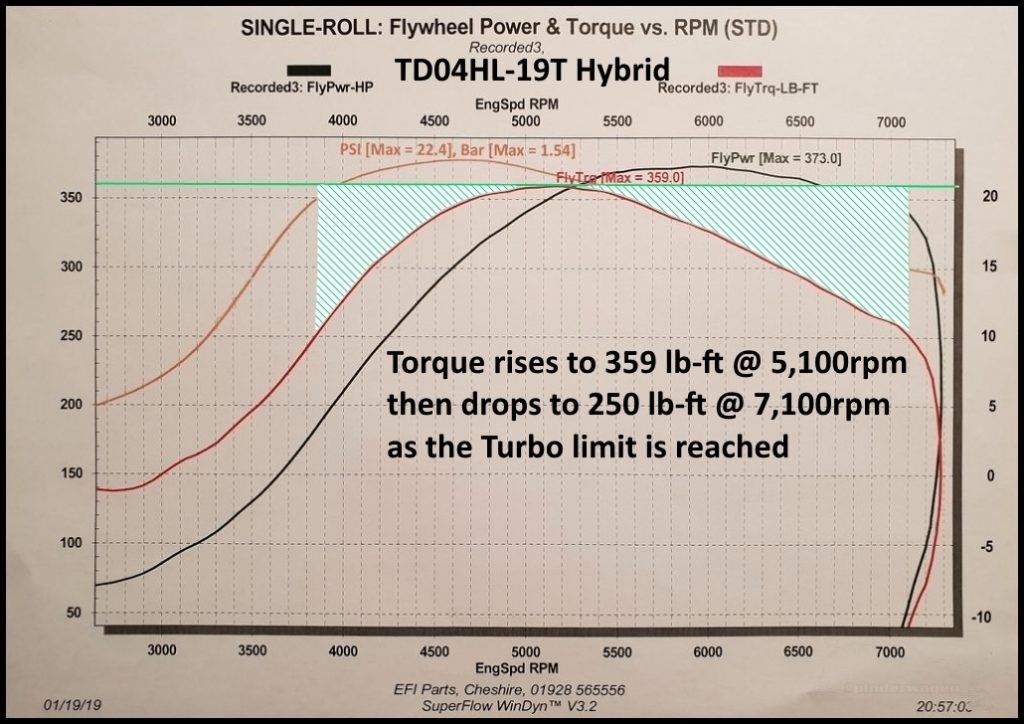

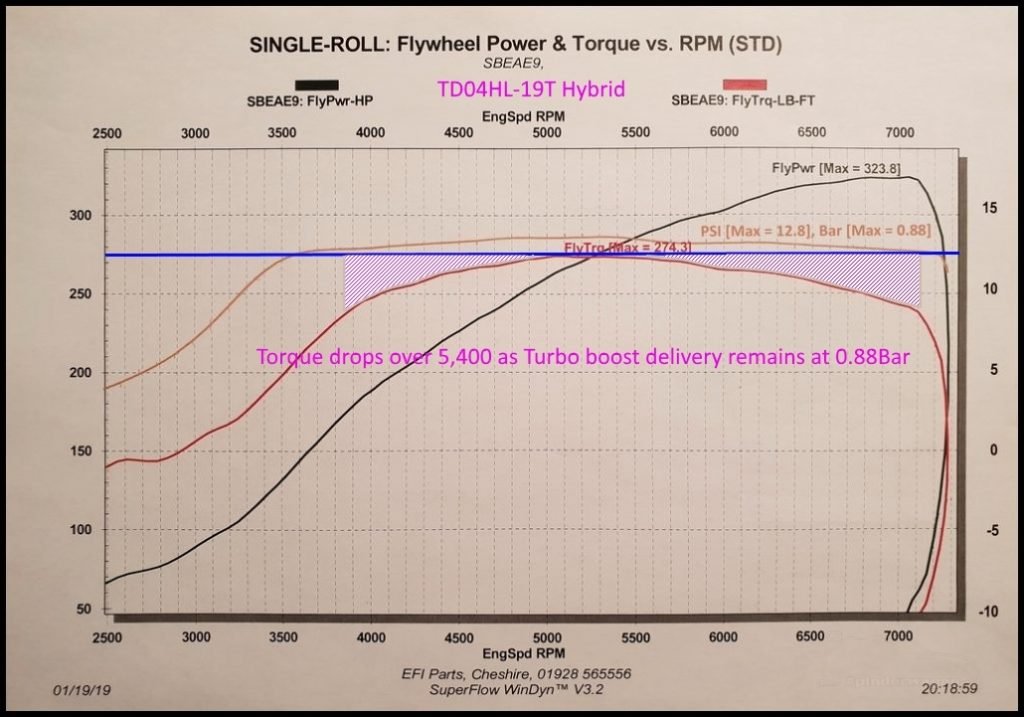

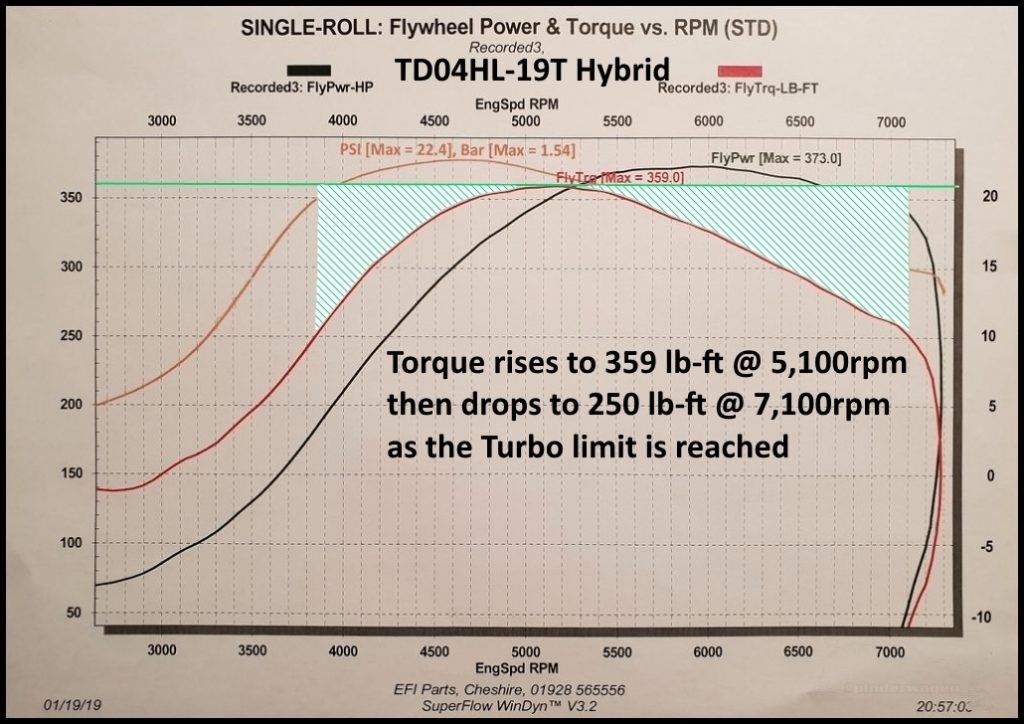

The plot below is a previous dyno runs with the identical engine but on the TD04HL-19T. We didn`t spend a great deal of time tuning the torque delivery on the dyno and as can be seen on the plot below, it tapers from 275 lb-ft to 240 lb-ft at redline.

What I did find was 275 lb-ft never broke traction and was reliable

I showed Chris this old plot and explained how driveable it had been and even peak torque didn't break traction (or CV's !) Chris used this as a limit for the new map and said he wouldn't exceed 280 lb-ft and slightly less would be preferable.

This is why I drive across to Liverpool for the mapping. They are plenty dynos nearer to me but Alex (DTA) recommended him and I can see why. He knows what I want and why and doesn't try and talk you into accepting something you don't want. He understands my boost delivery preference of raising the boost to maintain torque rather than just getting whatever the turbo can give.

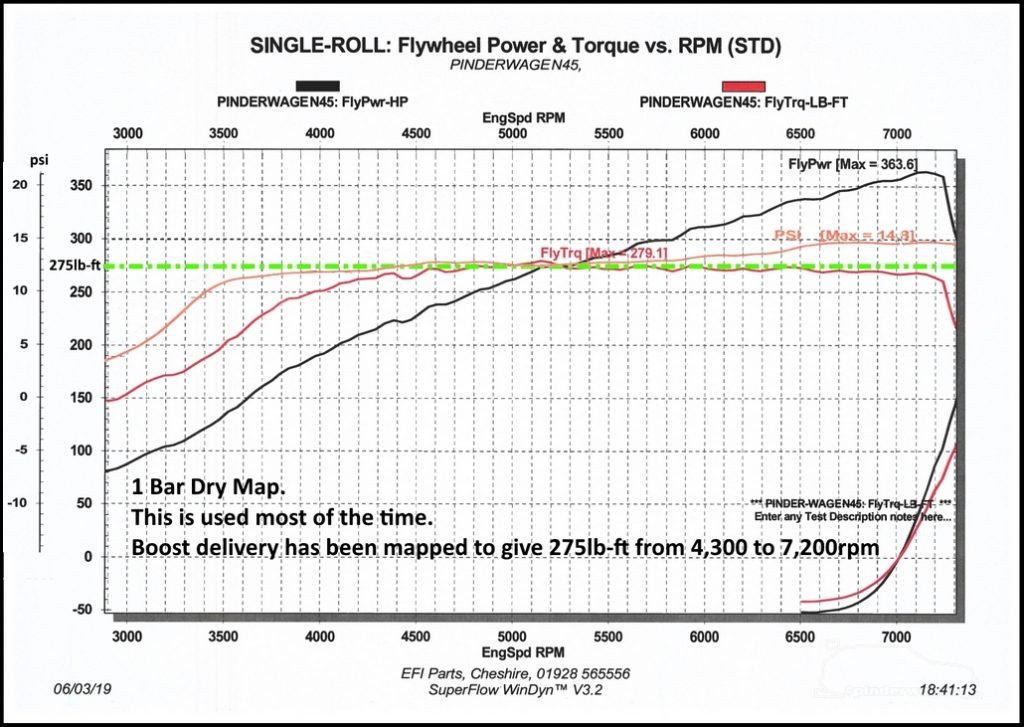

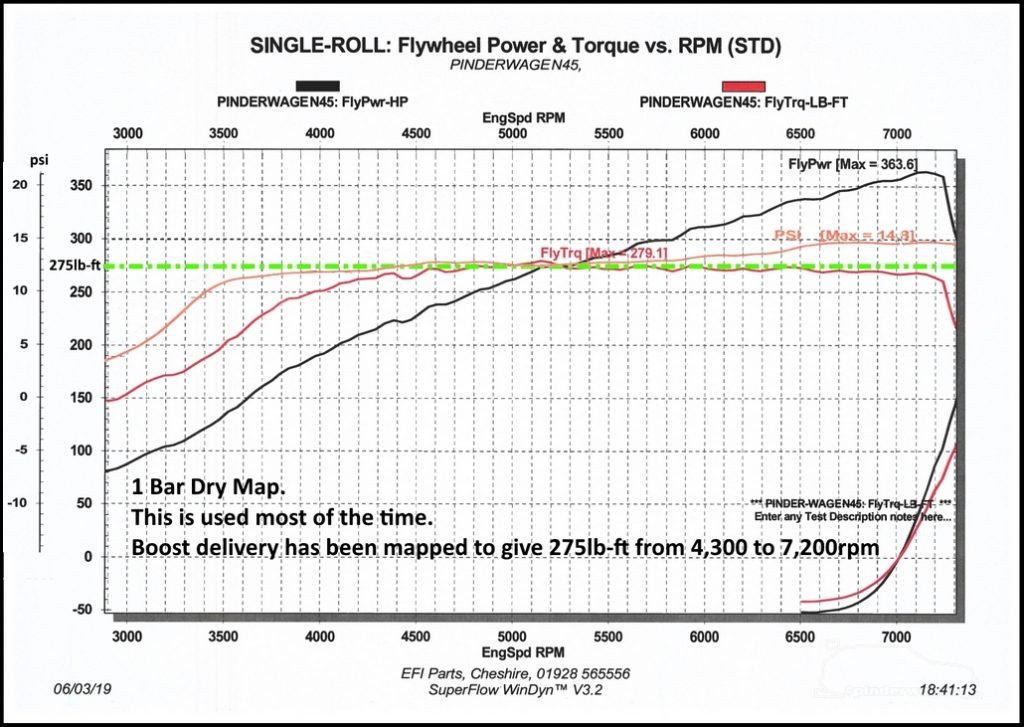

We upped the duty cycle on the boost control table in the ECU and within only a few pulls we had a map where the torque was the same as the old Turbo, but it held rock solid all the way to redline. This will make it very driveable with such a linear power delivery.

Chris commented the engine felt very 'numb' to timing. By that he meant that even with a swing of 4 degrees advance or retard, the power was virtually unchanged. He'd never come across an engine that behaved quite like this. It was also incredibly resistant to knock, it needed a large timing swing to detect any detonation.

This gave him a large window in which to tune for low EGT's without any chance of knock. All in the name of increased reliability which is what I explained was top of my list. Headline figures are OK to talk about in the pub, but they don't actually mean anything, driveability and reliability are far more important to me.

Only a small increase in boost pressure from 0-75 to 0.95 bar, rising to 1bar above 6,400rpm gives us an almost horizontal torque curve at our self imposed limit of 275lb-ft

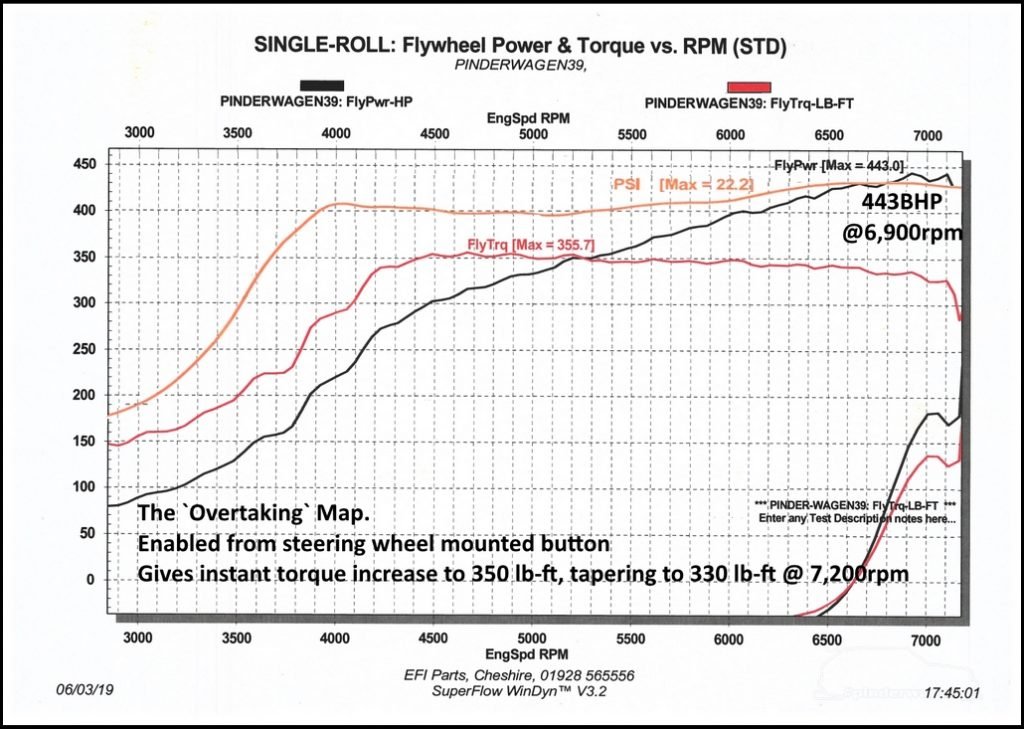

Now it was time to open up the Turbo, but again we looked at the dyno from last time. Peak torque was 359 lb-ft, but this dropped away quickly as the TD04 couldn't maintain that level. This gave a big `push` when pressed but started feeling breathless at the top and as torque dropped to the standard dry map level. What it did show was then when I deployed this torque in 4th, 5th or 6th when the Golf was in a straight line and I wanted to catch / pass something quick, the drivetrain could cope.

It's the CV's and then the gearbox that will fail on mine. The next upgrade is changing to the heavier and stronger 02M gearbox. I could fit that, but it doesn't address the CV's which are the weakest point already. Without new hubs, bigger bearings and some custom CV joints I can't do anything about that. Hence the car being mapped in the most sympathetic way possible to the existing hardware.

For a road car, you'd want more midrange but we mapped out that thump in the back when you put your foot down. I'd guess it would be going on for 400lb-ft if we wound up the boost between 4,500 to 6,000. Obviously that's only going to end up with broken bits if I try that on track with slicks.

TD04Plot from Jan.

Discussed with Chris that 360lb-ft should be the absolute maximum we aimed for and just under would be ideal.

Upping the boost and we immediately hit 400 HP !!

FOUR HUNDRED Horsepower. That's crackers.

Increasing the duty cycle on the boost solenoid and we soon started seeing more power, but the torque fell away as the revs rose.

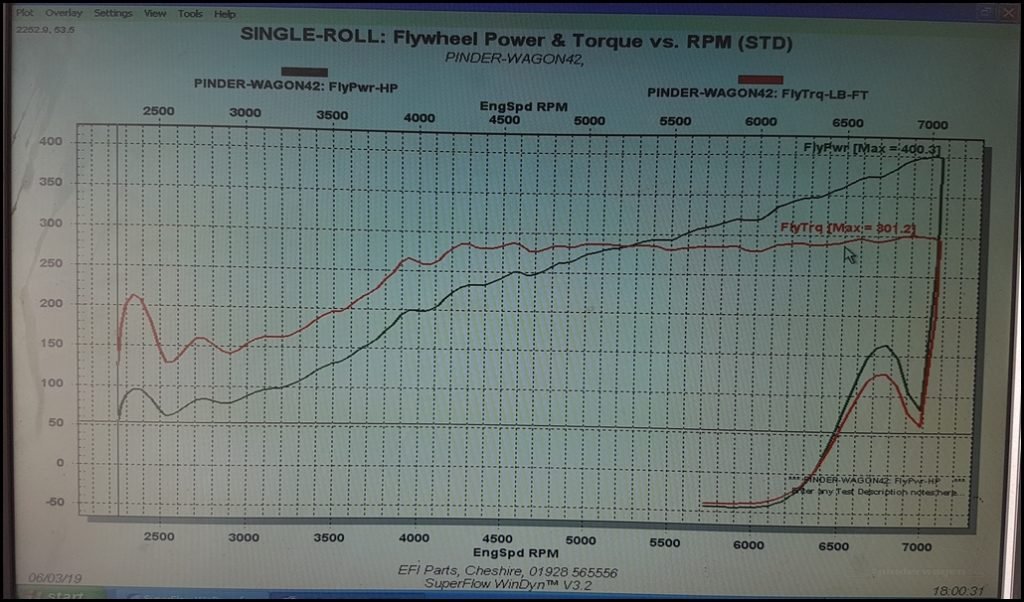

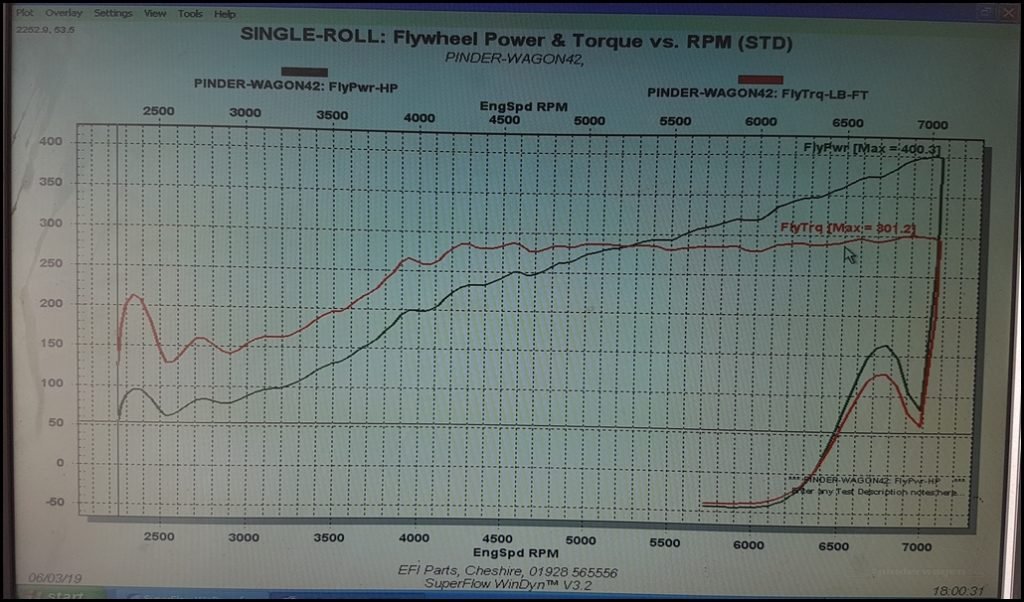

This plot shows a couple of pulls, torque too high at 378 lb-ft but dropped to 300 at redline. This is the shape you often see on turbo car dyno plots although they often have a more exaggerated torque hump in the middle.

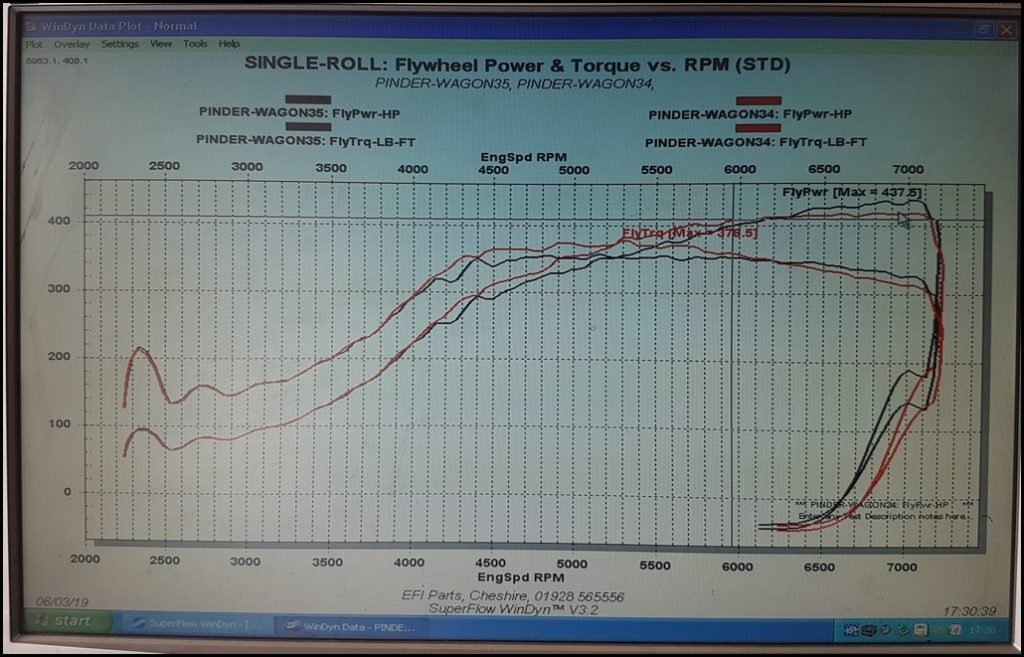

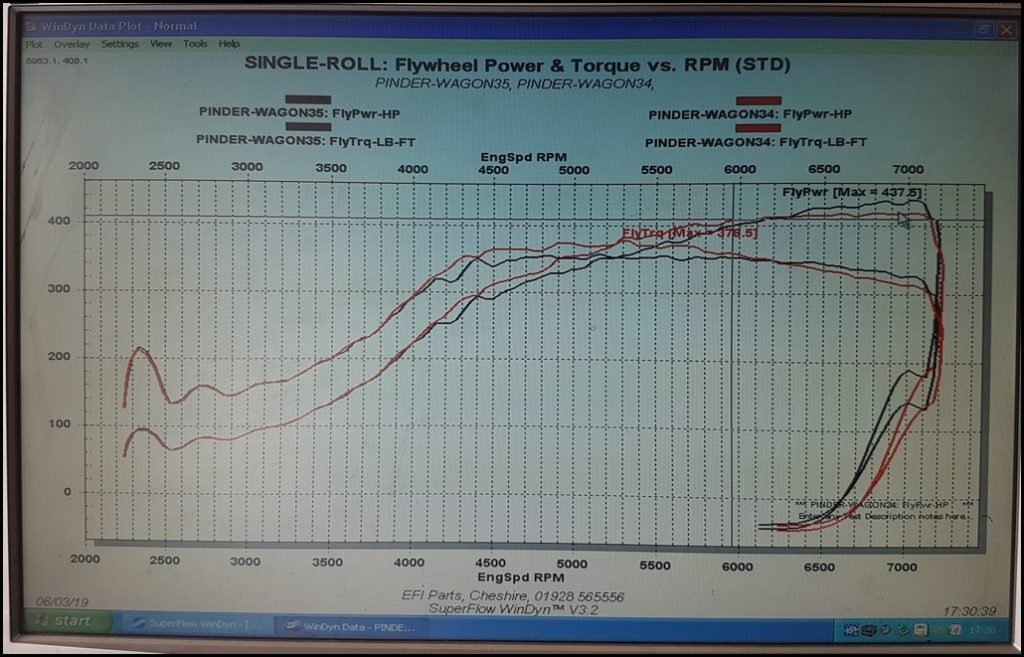

A bit of tweaking and we saw a much better torque delivery and we hit 440HP at the same time !

Torque drops off right at the top end but we felt this was acceptable. The fuel pump was starting to struggle to supply enough fuel and rather than push it we settled on this final map.

EGT`s are mid 700's and just over 820°C once it hits 1.5Bar. The lower dry map saw them sat at 760°C to 780°C for the entire pull.

Plugs removed after the final run showed excellent fuelling.

I`m not just happy, I'm bloody ecstatic.

If we had just tuned for maximum power we would have easily passed 450HP, but that's missing the point. I'm struggling with drivetrain reliability as it is. Not in a straight line, but when on high power and going over kerbs or big bumps on track. The wheel spinning up when in the air then landing causes a shock load through the CV's and driveshafts which breaks CV's instantly.

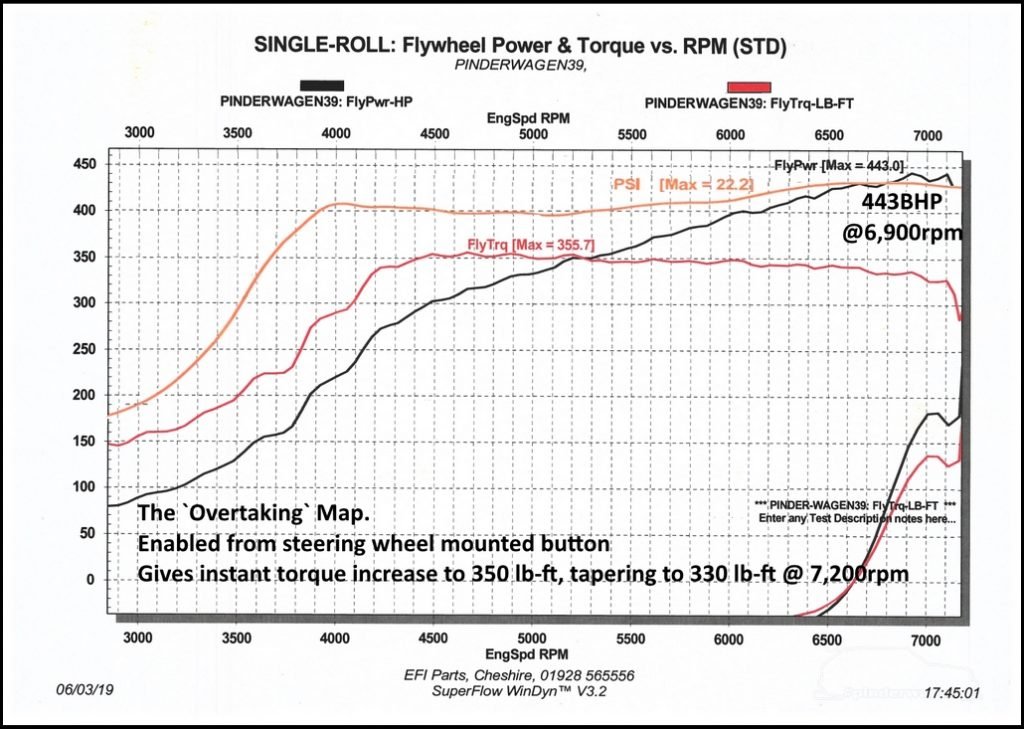

By not going over the 'safe' 280 lb-ft limit for normal dry running and keeping that level, I'm hopeful this will aid longevity. I don't use the overtaking button often and when I do it is usually in 5th or 6th. Having run 355 lb-ft last with no ill effects this year, that was chosen as our limit for this map.

The engine isn't making any more torque than with the old turbo, the difference is this one is efficient enough to maintain that all the way to the Redline which is why the power figure is so much more.

Time will tell if it's too much or not.

Since this dyno session I did a trackday in the wet at Bedford. The power delivery is simply amazing, it really feels like a big capacity n/a car with loads of power. The 1.5Bar map is just ballistic and the car really picks up and accelerates hard when engaged.

This pull from 60mph to just short of 140mph shows how relentless it is but as the delivery is so linear it never breaks traction even in the pouring rain which is exactly what I hoped it would be like.

Throttle response is excellent and even in the conditions experienced at Bedford, I was able to adjust the throttle pedal with what feels like almost instant response.

I'm back at the Nurburgring in July with DNEvents for a 2 day exclusive trackday which will give me a proper test of just how quick and driveable it is

.

.

At the Circuit Days trackday, both Matt and I were sure we could smell some exhaust fumes from under the bonnet when in the carpark but couldn`t find the source anywhere. It was only a slight smell and at speed it disappeared.

Back in the UK I decided to remove the turbo and check the mounting face as everything else seemed OK. As soon as it was removed I realised I had a problem. The manifold has certainly seen a few extreme heat cycles but appeared to be holding up well after the previous repair back in 2015 .Closer internal inspection immediately identified the problem. The inside of the collector looks worse for wear. The steel has cracked badly.

Die grinder to clean the inside and again, it was worse than I initially thought.

I've been contemplating changing the turbo for a couple of years but everytime I think about it, the work required to modify the collector on the manifold made me think it wasnt worth it. The car is quick enough, I won't use more boost, especially in 3rd and 4th so what's the point.

Then this happened and at the same time, I spotted the turbo I've had my eye on come up for sale very cheaply. If that does't scream "This is meant to be !!" I don't know what does

MANY hours of cutting, grinding and welding later it was repaired in SCH40 Stainless steel ready for the turbo to be fitted.

Not my finest work, but it's strong and will do the job. (There isn't a hole on the bottom right runner, it's just a shadow. )

Arrived at EFI-Parts for Chris to map DTAFast S80Pro ECU on the Golf with the new Owen Developments GT2868HTA turbo I'd fitted. This is a used turbo from a BTCC race car. They don't run them until they break, but replace them after a certain amount of hours and fit a new one. That means turbos like this keep popping up on the 2nd hand market. A quick visual inspection showed no signs of wear at all and the play in the bearings was imperceptible.

Splitter removed to allow it to fit on the dyno

Drove in and strapped the Golf down, MAP and knock sensors attached to the engine, AFR in the exhaust.

After one run it was obvious the fibreglass bonnet was flapping around too much so we quickly removed it

I had swapped from the Siemens 630cc injectors to some Bosch 900CC ones. The old ones wouldn't be able to supply sufficient fuel for the new turbo. That meant Chris had to spend a little while tuning the part throttle and off bost area of the tune before any power runs. The DTA fuelling table allows precise injector pulsewidth changes and Chris was able to use this to get a really smooth idle and great low throttle opening response.

First power run on actuator pressure only and I saw it was reaching 0.75Bar. Hmmm, this was supposed to be a 0.6Bar spring. Nothing I could do on the dyno so I`ll see how it goes, but can always change the spring later if I find it's too much in the wet or low gears.

A very healthy 309 HP, but torque has no assistance so drops away as the revs rise. It's still almost 310HP which is pretty damned good.

The plot below is a previous dyno runs with the identical engine but on the TD04HL-19T. We didn`t spend a great deal of time tuning the torque delivery on the dyno and as can be seen on the plot below, it tapers from 275 lb-ft to 240 lb-ft at redline.

What I did find was 275 lb-ft never broke traction and was reliable

I showed Chris this old plot and explained how driveable it had been and even peak torque didn't break traction (or CV's !) Chris used this as a limit for the new map and said he wouldn't exceed 280 lb-ft and slightly less would be preferable.

This is why I drive across to Liverpool for the mapping. They are plenty dynos nearer to me but Alex (DTA) recommended him and I can see why. He knows what I want and why and doesn't try and talk you into accepting something you don't want. He understands my boost delivery preference of raising the boost to maintain torque rather than just getting whatever the turbo can give.

We upped the duty cycle on the boost control table in the ECU and within only a few pulls we had a map where the torque was the same as the old Turbo, but it held rock solid all the way to redline. This will make it very driveable with such a linear power delivery.

Chris commented the engine felt very 'numb' to timing. By that he meant that even with a swing of 4 degrees advance or retard, the power was virtually unchanged. He'd never come across an engine that behaved quite like this. It was also incredibly resistant to knock, it needed a large timing swing to detect any detonation.

This gave him a large window in which to tune for low EGT's without any chance of knock. All in the name of increased reliability which is what I explained was top of my list. Headline figures are OK to talk about in the pub, but they don't actually mean anything, driveability and reliability are far more important to me.

Only a small increase in boost pressure from 0-75 to 0.95 bar, rising to 1bar above 6,400rpm gives us an almost horizontal torque curve at our self imposed limit of 275lb-ft

Now it was time to open up the Turbo, but again we looked at the dyno from last time. Peak torque was 359 lb-ft, but this dropped away quickly as the TD04 couldn't maintain that level. This gave a big `push` when pressed but started feeling breathless at the top and as torque dropped to the standard dry map level. What it did show was then when I deployed this torque in 4th, 5th or 6th when the Golf was in a straight line and I wanted to catch / pass something quick, the drivetrain could cope.

It's the CV's and then the gearbox that will fail on mine. The next upgrade is changing to the heavier and stronger 02M gearbox. I could fit that, but it doesn't address the CV's which are the weakest point already. Without new hubs, bigger bearings and some custom CV joints I can't do anything about that. Hence the car being mapped in the most sympathetic way possible to the existing hardware.

For a road car, you'd want more midrange but we mapped out that thump in the back when you put your foot down. I'd guess it would be going on for 400lb-ft if we wound up the boost between 4,500 to 6,000. Obviously that's only going to end up with broken bits if I try that on track with slicks.

TD04Plot from Jan.

Discussed with Chris that 360lb-ft should be the absolute maximum we aimed for and just under would be ideal.

Upping the boost and we immediately hit 400 HP !!

FOUR HUNDRED Horsepower. That's crackers.

Increasing the duty cycle on the boost solenoid and we soon started seeing more power, but the torque fell away as the revs rose.

This plot shows a couple of pulls, torque too high at 378 lb-ft but dropped to 300 at redline. This is the shape you often see on turbo car dyno plots although they often have a more exaggerated torque hump in the middle.

A bit of tweaking and we saw a much better torque delivery and we hit 440HP at the same time !

Torque drops off right at the top end but we felt this was acceptable. The fuel pump was starting to struggle to supply enough fuel and rather than push it we settled on this final map.

EGT`s are mid 700's and just over 820°C once it hits 1.5Bar. The lower dry map saw them sat at 760°C to 780°C for the entire pull.

Plugs removed after the final run showed excellent fuelling.

I`m not just happy, I'm bloody ecstatic.

If we had just tuned for maximum power we would have easily passed 450HP, but that's missing the point. I'm struggling with drivetrain reliability as it is. Not in a straight line, but when on high power and going over kerbs or big bumps on track. The wheel spinning up when in the air then landing causes a shock load through the CV's and driveshafts which breaks CV's instantly.

By not going over the 'safe' 280 lb-ft limit for normal dry running and keeping that level, I'm hopeful this will aid longevity. I don't use the overtaking button often and when I do it is usually in 5th or 6th. Having run 355 lb-ft last with no ill effects this year, that was chosen as our limit for this map.

The engine isn't making any more torque than with the old turbo, the difference is this one is efficient enough to maintain that all the way to the Redline which is why the power figure is so much more.

Time will tell if it's too much or not.

Since this dyno session I did a trackday in the wet at Bedford. The power delivery is simply amazing, it really feels like a big capacity n/a car with loads of power. The 1.5Bar map is just ballistic and the car really picks up and accelerates hard when engaged.

This pull from 60mph to just short of 140mph shows how relentless it is but as the delivery is so linear it never breaks traction even in the pouring rain which is exactly what I hoped it would be like.

Throttle response is excellent and even in the conditions experienced at Bedford, I was able to adjust the throttle pedal with what feels like almost instant response.

I'm back at the Nurburgring in July with DNEvents for a 2 day exclusive trackday which will give me a proper test of just how quick and driveable it is

Last edited:

I see you know my good friend Kev too! Chris at EFI is a legend, I've only been there once as it's quite a trek for me, but I sure enjoyed it there and know many many people that go there. Well over 400bhp at 1.5bar is incredible, that turbo has some serious flow for a 28!

I see you know my good friend Kev too! Chris at EFI is a legend, I've only been there once as it's quite a trek for me, but I sure enjoyed it there and know many many people that go there. Well over 400bhp at 1.5bar is incredible, that turbo has some serious flow for a 28!