Associate

Thank you to Parvum Systems, Noctua, ASRock, Silverstone, HyperX and Li-Heat for your support with PARVUM FURIA, i'm very excited to be moving forwards with this!

The time has come for another project, just a little one for me to try new things and push some boundaries. This will actually form part of a piece of work for my Engineering Degree and is being treated as a continuation from PARVUM MATE, implementing the same wild ideas but with a strong focus on power density and spatial efficiency.

So instead of starting with a case cutting it up and then trying to fit the most stuff inside it with an insane waterblock this time i'll start with the internals and work outwards. The waterblock will form the spine eliminating all redundant components along the way to achieve something far more powerful, more refined and much smaller. Every part will be modeled and digitally assembled to ensure no space is wasted, consequently it will be a few more weeks until physical progress is made but work is very much underway.

Intel i7-5820K

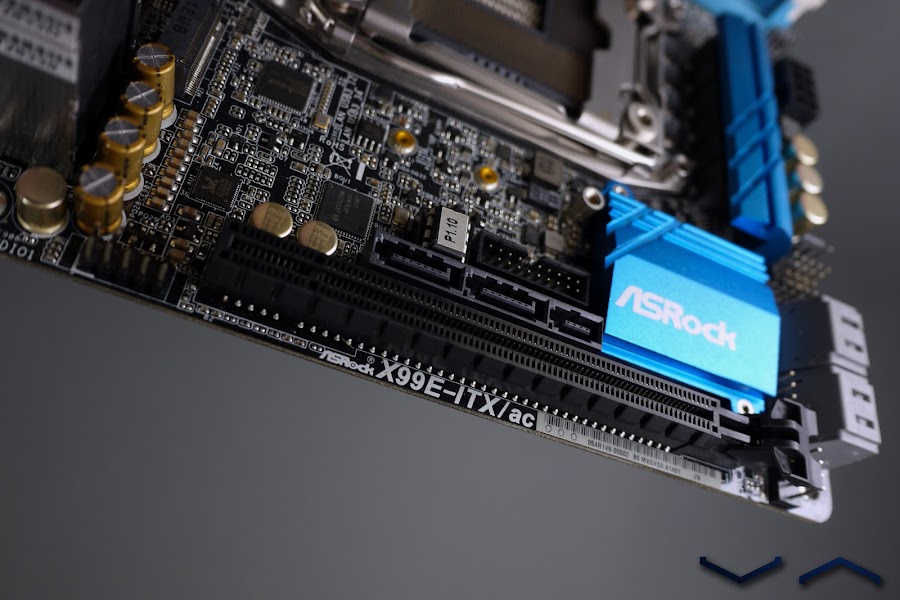

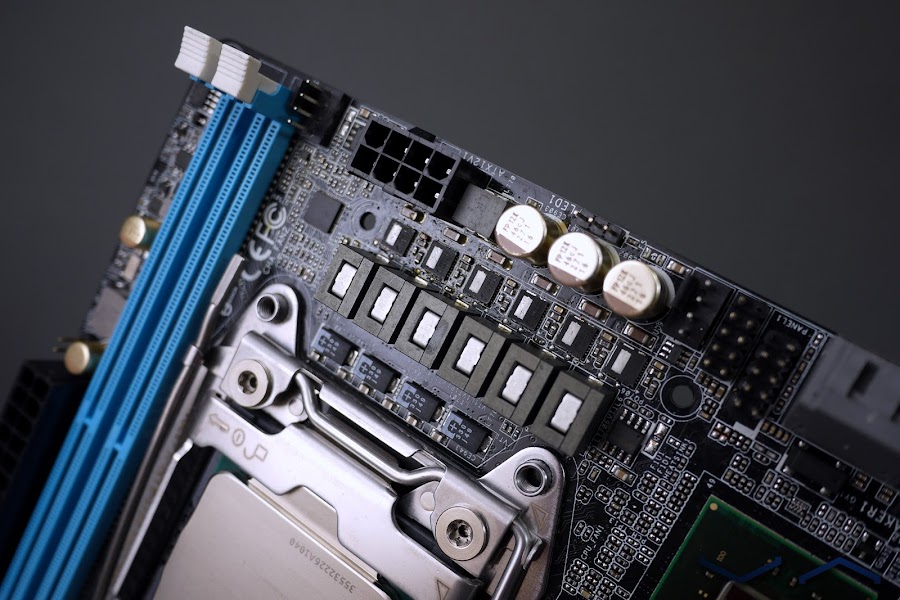

ASRock X99E-ITX/ac

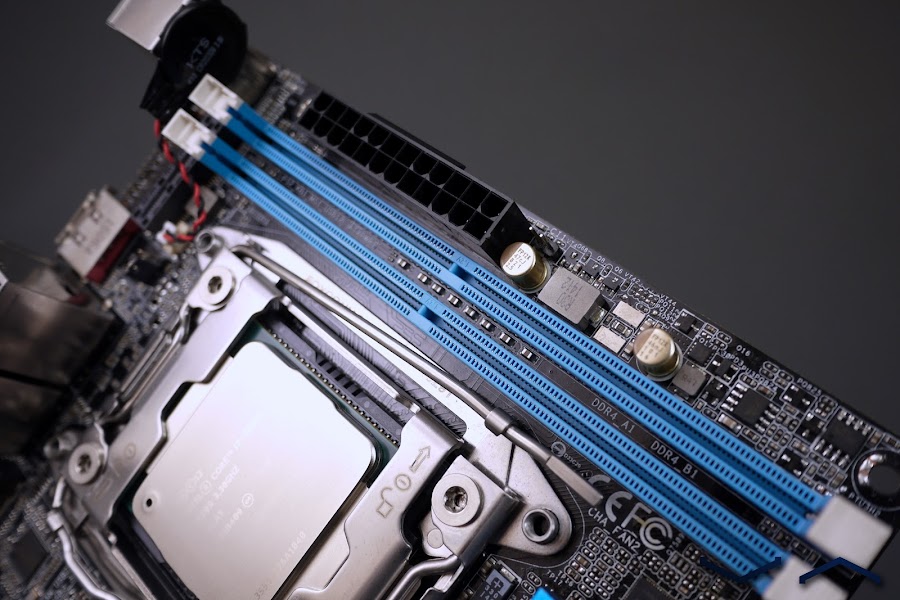

HyperX DDR4

HyperX Predator M.2

AMD Radeon R9 FURY X

Silverstone SX-600G

Noctua NF-A14 iPPC x2

Secretly i'm hoping to pack everything into something not just 30% smaller than MATE (my actual target) but sub 10l with the inclusion of a 280mm rad to keep things as quiet as they can be. So to achieve that more than fancy packaging alone will be needed. Eliminating the need for a 2.5"drive, hence some cables and access to the SATA ports was always going to be a big help to reduce size and increase footprint so an ITX board with M.2 was a must.

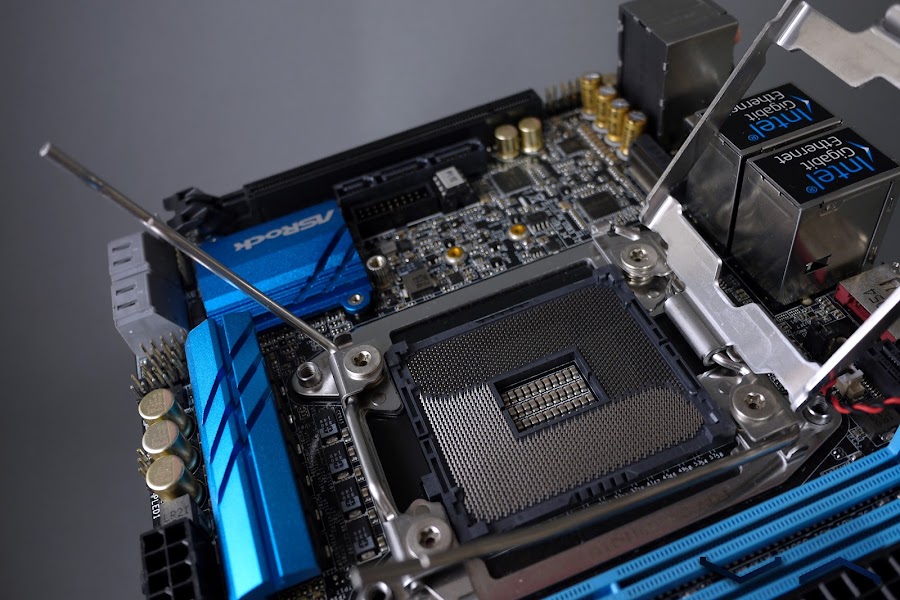

So naturally an X99 board seemed appropriate! Well not exactly, it is very excessive however the unique board layout drew me in. It's rare this side of a workstation board to see memory slots parallel to the PCIe but I have a feeling that will be very useful when it comes to watercooling.

It did also mean a beast of a CPU would be required, for this little build 28 lanes were more than enough so I went for the 5820K with its hexacore glory, I couldn't be more excited for 12 thread ITX.

IDK why, but, dual ethernets!

Also the much needed M.2 slot with all that lovely PCIe bandwidth.

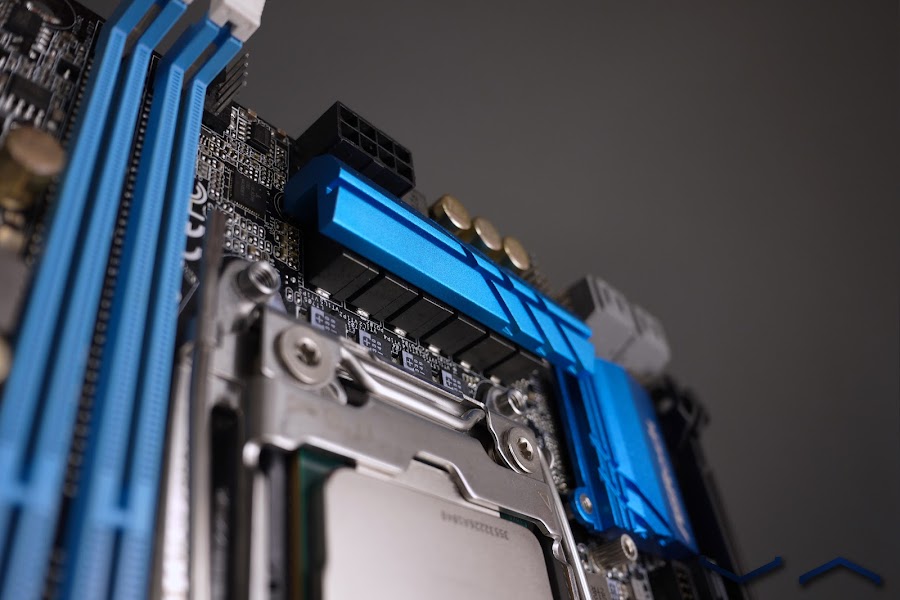

I was overwhelmed with curiosity at what may be under the little heatsinks and the potential of making a little tiny waterblock. It's tight but i'm definitely going to attempt to include the VRM's, chipset and M.2 into the monoblock.

As always the first parts to land in my hands were from Noctua, I can't think of anything better for the task!

I did a few rough dimensioned sketches when deciding which parts to go for and, well a 280mm rad seem like the obvious choice for the layout I have in mind, but now these fans look gigantic! The motherboard will easily fit inside the fan box with room to spare.

Well I think that sets out the theme and objectives of the project, I was unsure at first whether to hide the blue of the board but as it's quickly becoming one of the least popular colour choices i'm going to stick with it! Maybe one day it will be mainstream again like yellow and brown.

JR

time for lots of layers!

time for lots of layers!