Hey guys,

Pretty sure I am doing something wrong, so wanted to check it out here!

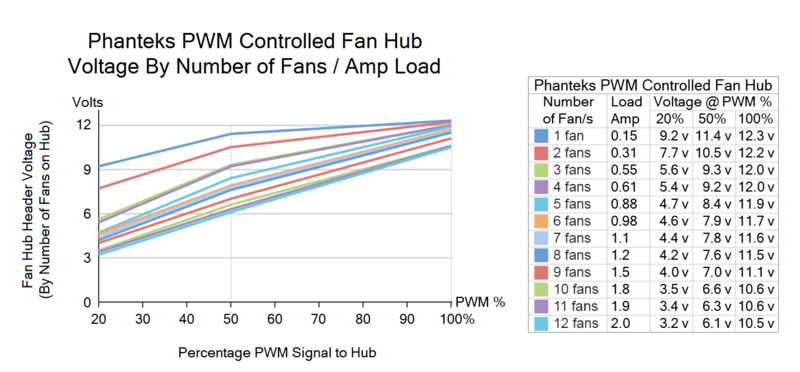

I just finished building a new hard-tube watercooled setup with 2 radiators (top and front) in a Phanteks Enthoo Primo case. The case comes with PWM hub hidden around the back in the cable management area, and some pretty terrible instructions!

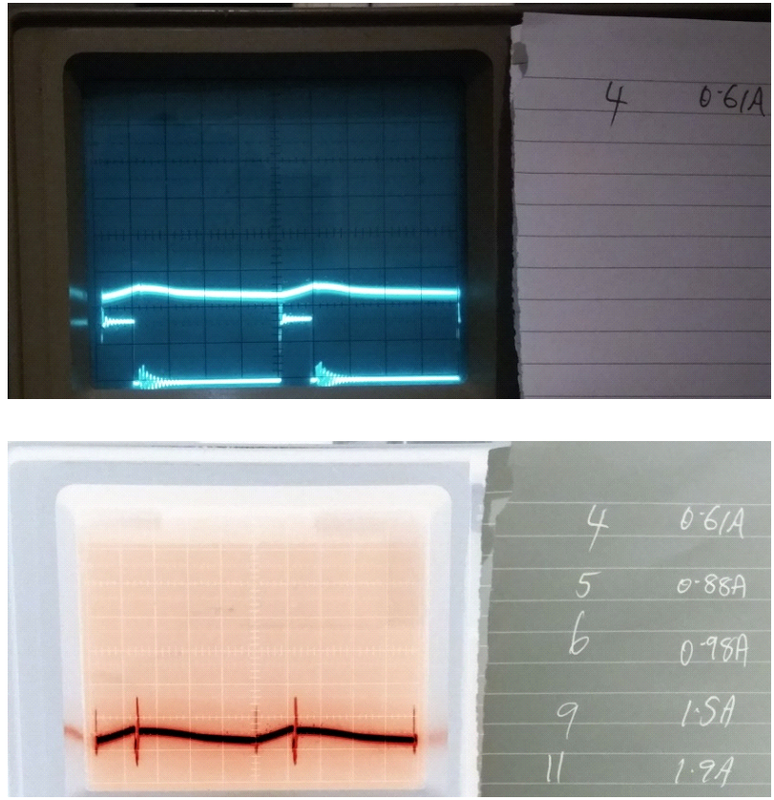

I have connected a 4-pin cable from the CPU Header on the motherboard (MSI X99 SLI Krait Edition) to the indicated connector on the PWM hub. I have also connected the 12v power supply. I have then connected a 3-way splitter to the 3x Vardar fans on the top radiator to another of the PWM hub connectors, and there were 3 case-fans already connected to hub when I got the case (2 of them are at the front, and I am using them to cool the font radiator).

This is how it looks:

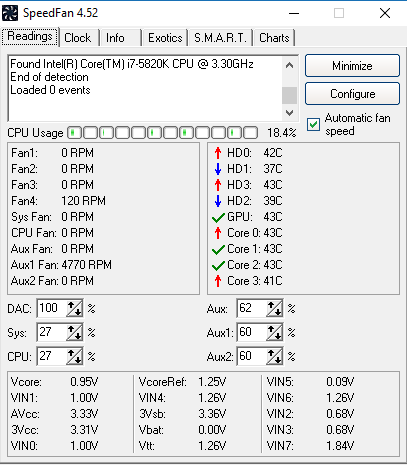

My problem is that the system doesn't seem to detect any CPU fan, just "system" fans as you can see here:

And when the temps are low, rather than reducing the speed of all 3 fans on the top radiator, it just seems to randomly stop one of them, so that 2 of the 3 fans are spinning, and one is idle.

I'm trying to figure out how to connect everything so that I can set a temperature profile that actually works properly! Or is it better to ignore the hub, and just connect everything individually to the motherboard headers?

Thanks for any help, hopefully it made some sense

Cheers, Ori

Pretty sure I am doing something wrong, so wanted to check it out here!

I just finished building a new hard-tube watercooled setup with 2 radiators (top and front) in a Phanteks Enthoo Primo case. The case comes with PWM hub hidden around the back in the cable management area, and some pretty terrible instructions!

I have connected a 4-pin cable from the CPU Header on the motherboard (MSI X99 SLI Krait Edition) to the indicated connector on the PWM hub. I have also connected the 12v power supply. I have then connected a 3-way splitter to the 3x Vardar fans on the top radiator to another of the PWM hub connectors, and there were 3 case-fans already connected to hub when I got the case (2 of them are at the front, and I am using them to cool the font radiator).

This is how it looks:

My problem is that the system doesn't seem to detect any CPU fan, just "system" fans as you can see here:

And when the temps are low, rather than reducing the speed of all 3 fans on the top radiator, it just seems to randomly stop one of them, so that 2 of the 3 fans are spinning, and one is idle.

I'm trying to figure out how to connect everything so that I can set a temperature profile that actually works properly! Or is it better to ignore the hub, and just connect everything individually to the motherboard headers?

Thanks for any help, hopefully it made some sense

Cheers, Ori