Associate

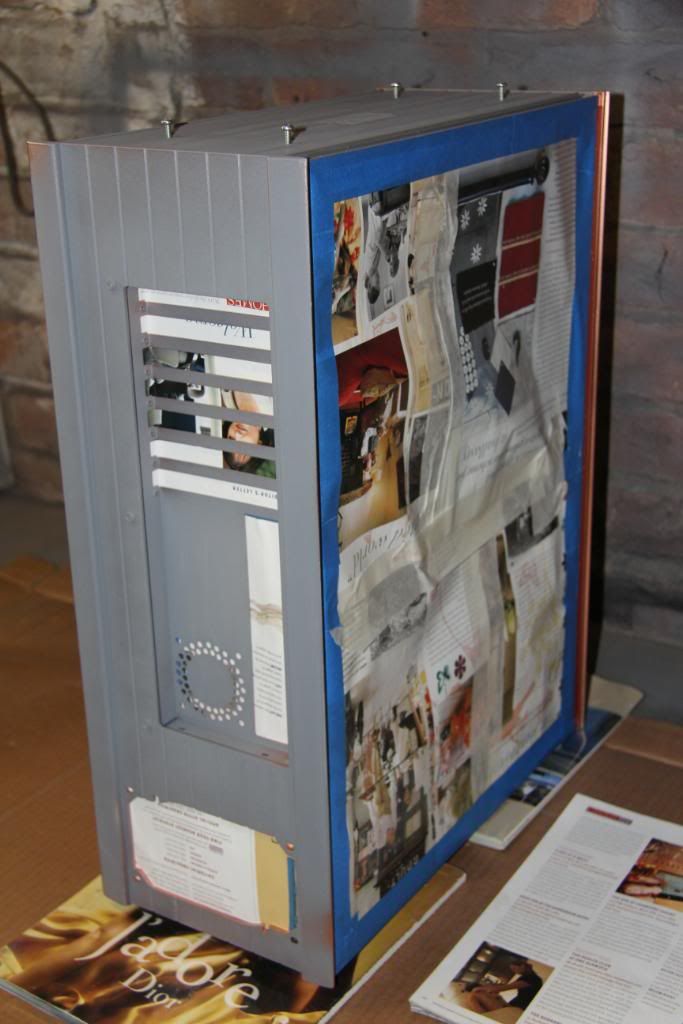

I managed to get my hands on a server case a little while back, and now that Project Modzart is well under way I thought i'd get things started on this one.

Many thanks to all who participated in the thread to choose a name for this Project, and special thanks to Biffa for coming up with the chosen title.

It was a very close run thing with many great suggestions, (all better than my own initial thoughts I hasten to add). So thanks again to all who helped out there.

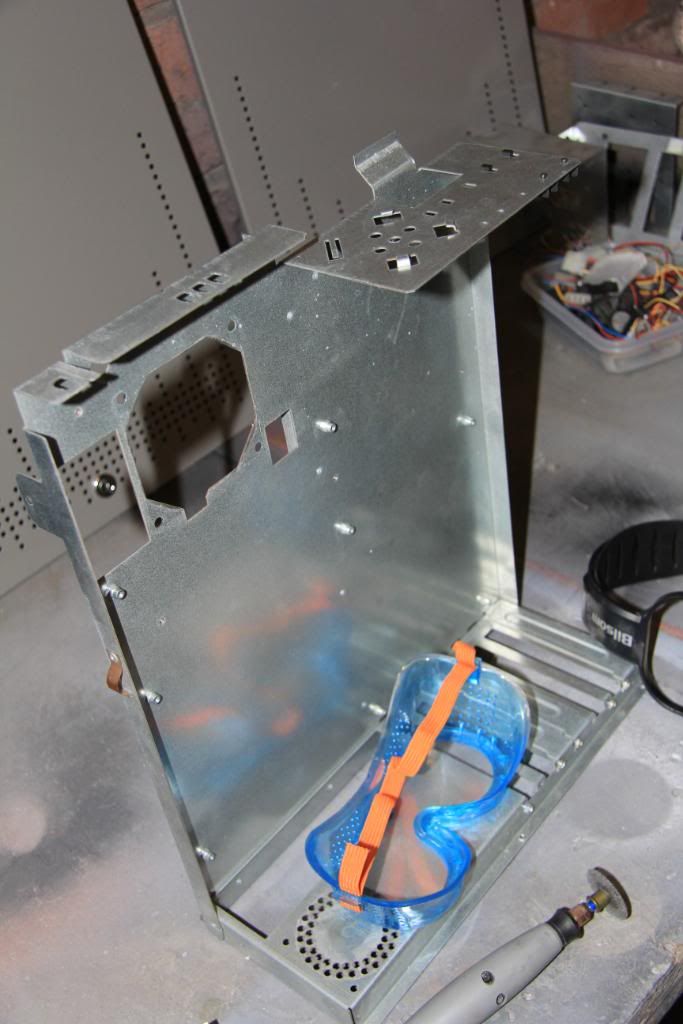

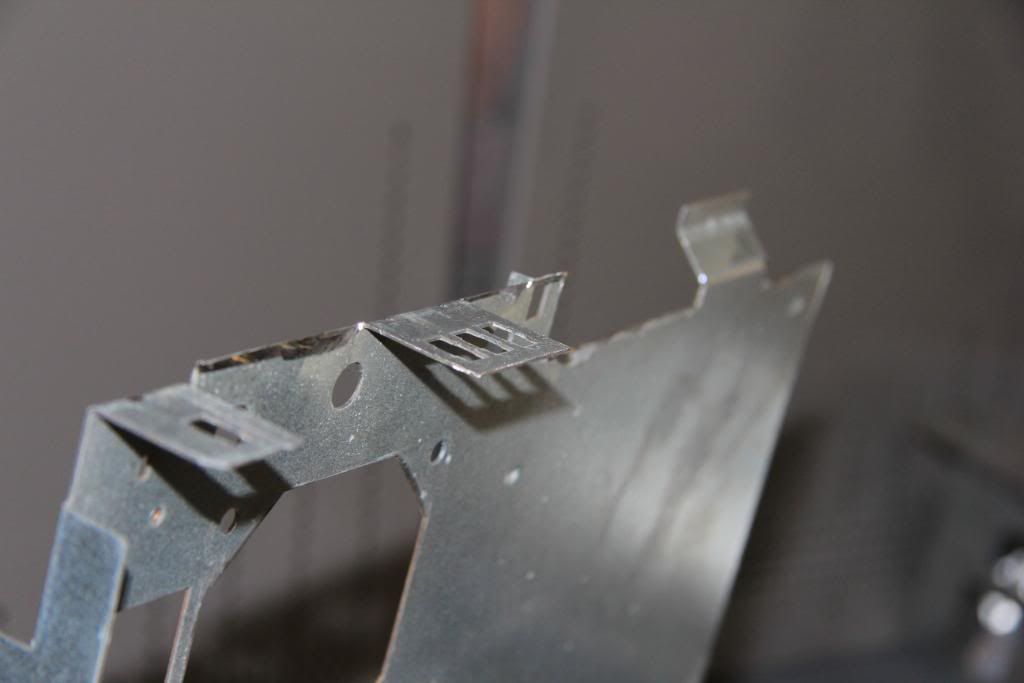

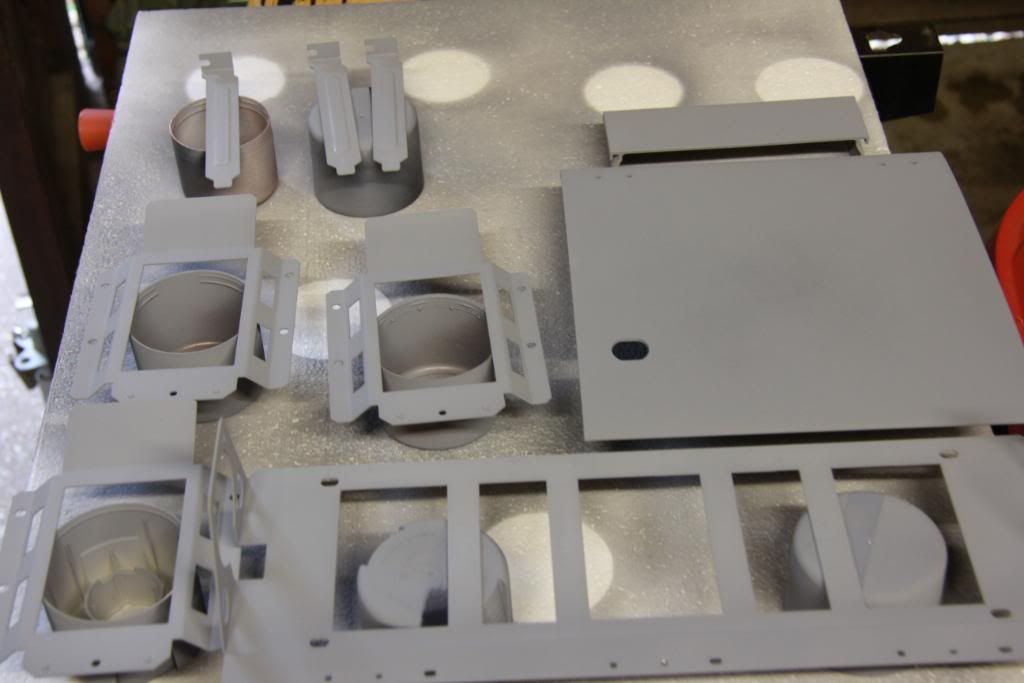

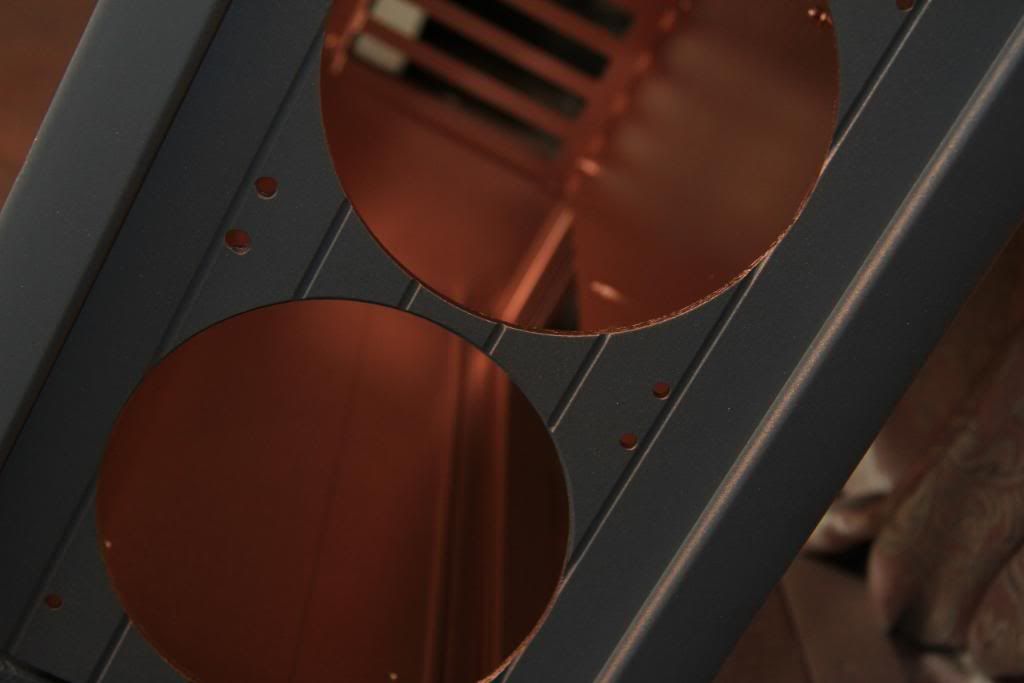

The Case itself is made of 3-4mm steel and is very well built. And when I say very well build I mean you get the impression you could shoot at this thing and there would be very little damage.

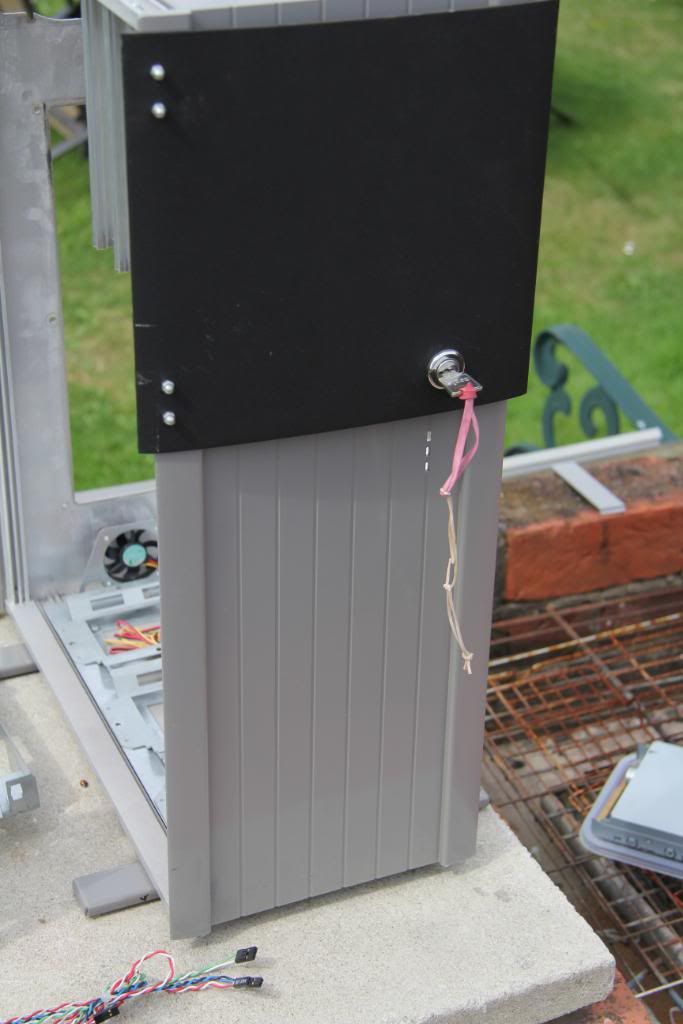

The left hand side panel is lockable, with the right only removable once access is gained to the inside of the case.

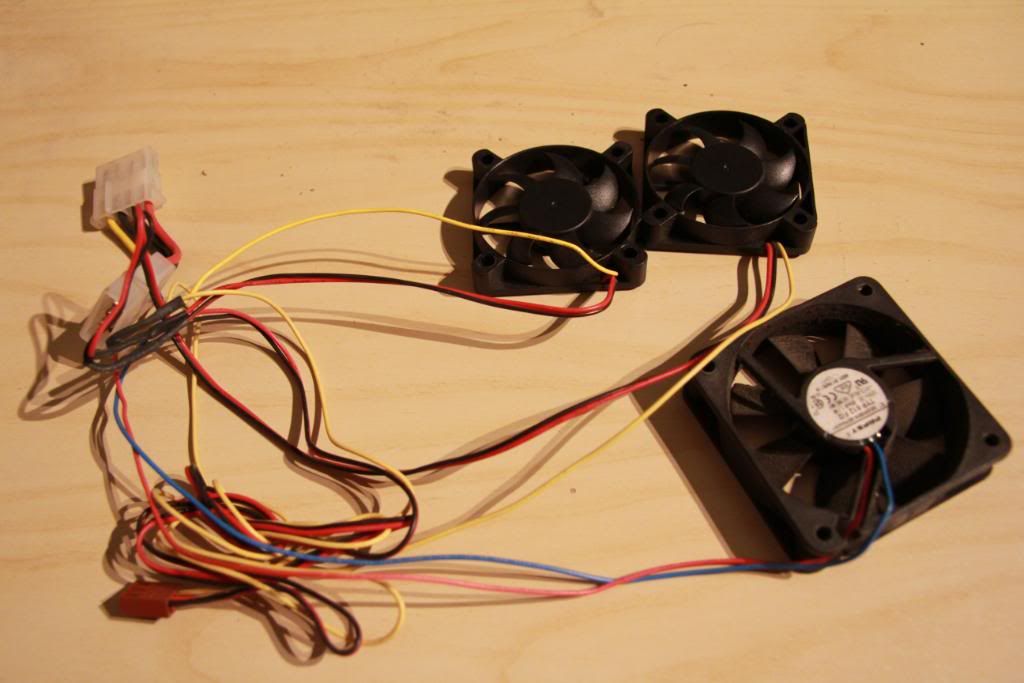

The case has removable sides, a fully removable Mobo tray and ample cable management round the back. There is an HDD rack for 3 HDDs in the front, and room for 3 more in the base of the case.

The front of the case sports a heavy duty steel door, again lockable and pretty tough.

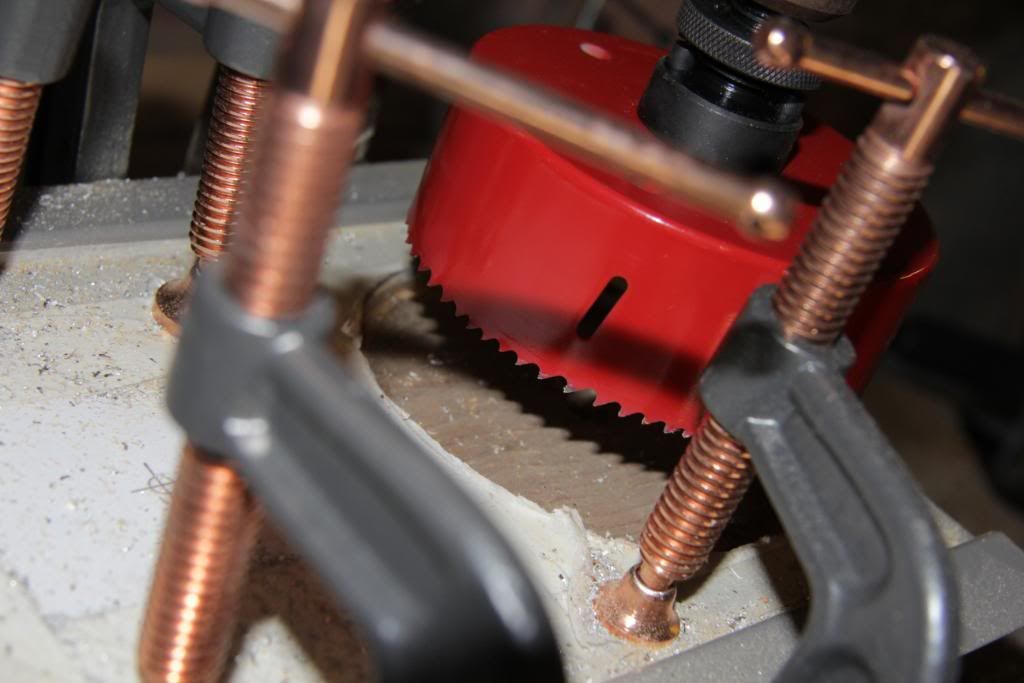

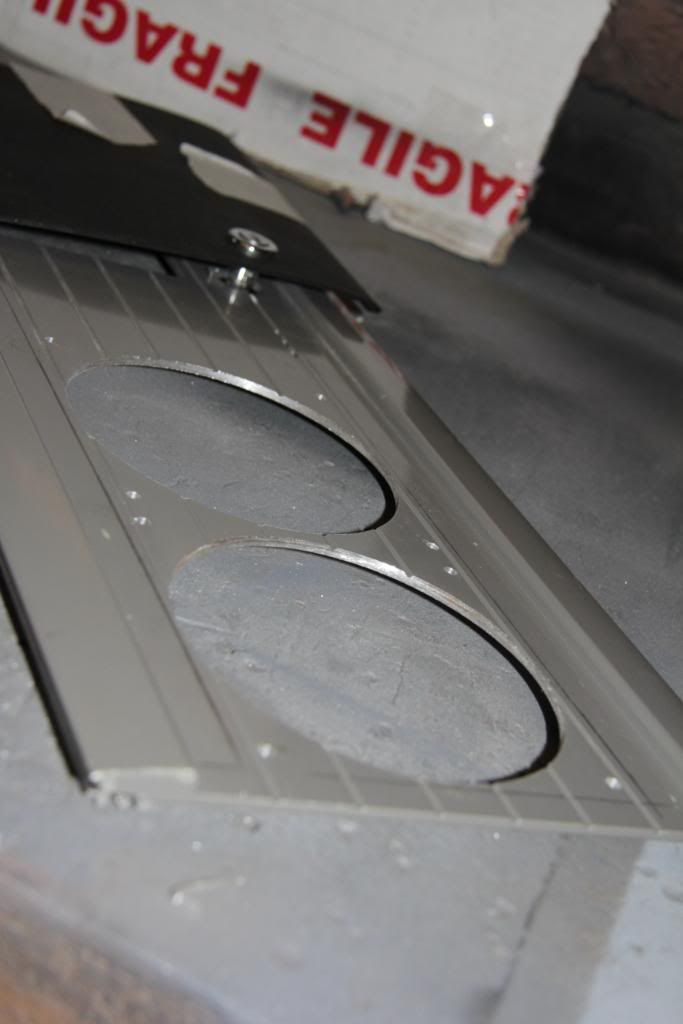

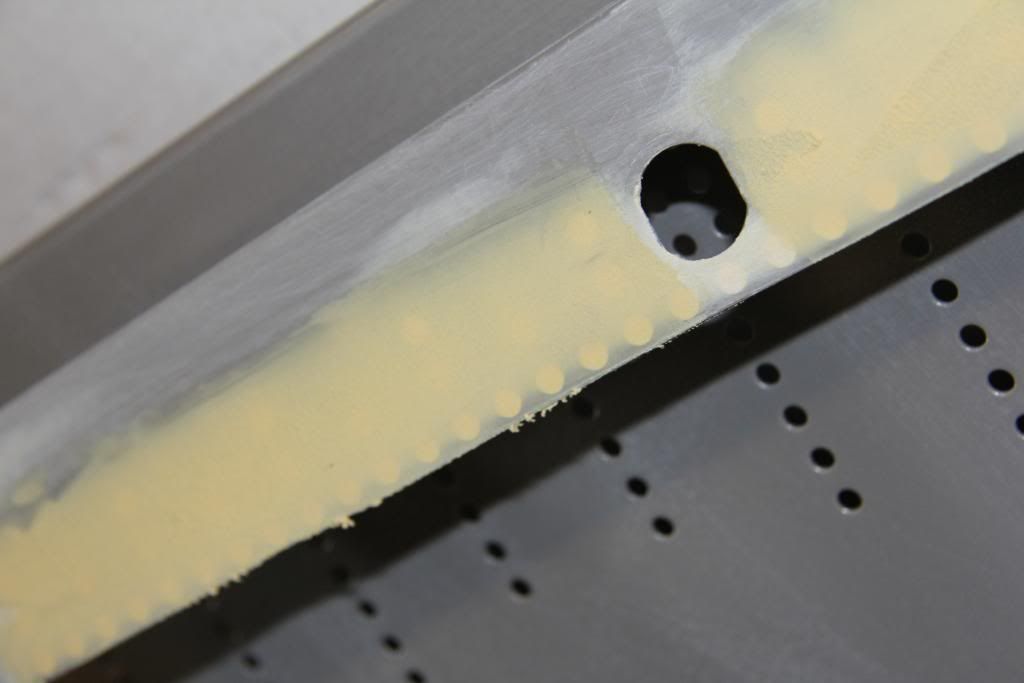

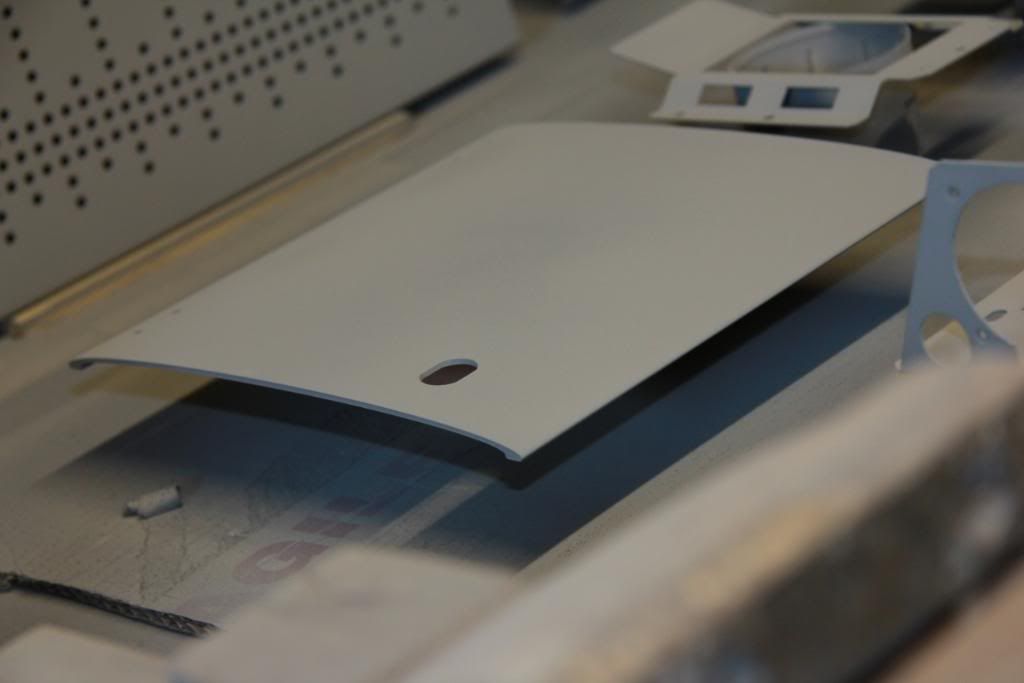

All internal stripped out and ready for work to start.

Many thanks to all who participated in the thread to choose a name for this Project, and special thanks to Biffa for coming up with the chosen title.

It was a very close run thing with many great suggestions, (all better than my own initial thoughts I hasten to add). So thanks again to all who helped out there.

The Case itself is made of 3-4mm steel and is very well built. And when I say very well build I mean you get the impression you could shoot at this thing and there would be very little damage.

The left hand side panel is lockable, with the right only removable once access is gained to the inside of the case.

The case has removable sides, a fully removable Mobo tray and ample cable management round the back. There is an HDD rack for 3 HDDs in the front, and room for 3 more in the base of the case.

The front of the case sports a heavy duty steel door, again lockable and pretty tough.

All internal stripped out and ready for work to start.