Associate

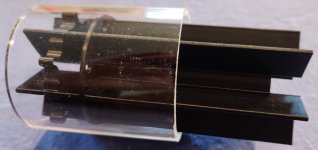

I'm currently building up a system with a loop of 1/2" OD acrylic tubing, with dual D5 pumps and a PrimoChill CTR. The latter has its input via one of the upper side ports, while the output is the central bottom port. After initial filling I'm getting a substantial vortex that sends air down the center of the vertical reservoir and on to the pump.

I haven't gotten all the air out of the system yet, as it gets trapped in the pumps after collecting at the top of the reservoir and then getting drawn in to the pumps again. This video shows the action with only one of the two pumps operating (the left one):

These are PWM pumps, so they are running at full 12V speed from the power supply. I don't want to power up the motherboard until I've finished leak testing and running-in the cooling loop. Much of the advice I've read on this and other forums suggests that running the pump at reduced speed should help. But I'd like to eliminate the vortex even at maximum speed of the pump.

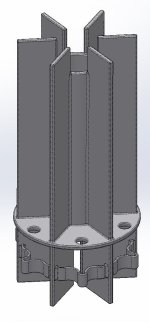

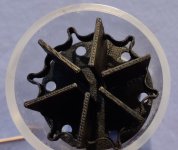

PrimoChill sell a Vortex Killer piece, but only their pump-enabled CTRs have the tapped holes for mounting it. So I designed my own, after studying the topic online. This is about 120mm tall and fits loosely within the acrylic tube of the reservoir, except the six "finger" loops that are supposed to be springs to center it and make sure it doesn't rotate. I've placed an order to get this part 3D printed in ABS/ASA via FDM. It's more complex than it probably needs to be, but that doesn't impact the cost much, and I wanted to make sure it will do the job. BTW, that central hole is blind (a dead end) at the bottom.

It should arrive within 10 days and I'll post an "after" video after I install and test it.

I haven't gotten all the air out of the system yet, as it gets trapped in the pumps after collecting at the top of the reservoir and then getting drawn in to the pumps again. This video shows the action with only one of the two pumps operating (the left one):

These are PWM pumps, so they are running at full 12V speed from the power supply. I don't want to power up the motherboard until I've finished leak testing and running-in the cooling loop. Much of the advice I've read on this and other forums suggests that running the pump at reduced speed should help. But I'd like to eliminate the vortex even at maximum speed of the pump.

PrimoChill sell a Vortex Killer piece, but only their pump-enabled CTRs have the tapped holes for mounting it. So I designed my own, after studying the topic online. This is about 120mm tall and fits loosely within the acrylic tube of the reservoir, except the six "finger" loops that are supposed to be springs to center it and make sure it doesn't rotate. I've placed an order to get this part 3D printed in ABS/ASA via FDM. It's more complex than it probably needs to be, but that doesn't impact the cost much, and I wanted to make sure it will do the job. BTW, that central hole is blind (a dead end) at the bottom.

It should arrive within 10 days and I'll post an "after" video after I install and test it.

Last edited: