Man of Honour

I've noticed a couple of occasions recently on OcUK where galvanic corrosion has not been pointed out/warned about - So here's a brief snapshot of the issue.

You've spent a lot of money on your new loop, and want to keep it in pristine condition ? - Read on

What is Galvanic Corrosion ?

If you are new to watercooling, galvanic corrosion is not something make up by the PC watercooling industry to force you to buy their specialist fluids,

it has been recognised for hundreds of years effecting things such ships in the early Royal Navy.

I'm no chemist but in very laymans terms it is when very different metals react to each other when in contact via a fluid.This reaction causes one metal to start dissolving.

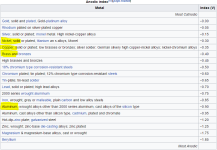

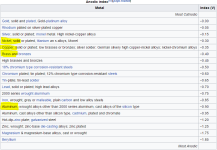

This diagram shows that the most common metals used in watercooling copper,brass and nickel are very similar and will work happily together.

But aluminium is at the other end of the scale so it won't play well with the others.

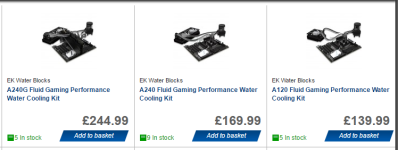

Extreme case of galvanic corrosion on a cpu block in a copper + aluminium loop

How can i prevent it ?

The easiest way to prevent Galvanic corrosion is to avoid aluminium, but you will still need to take precautions.

Do not just use distilled water or anything labelled as pure water/H20 - You still need an additive to help prevent any nasties from growing in your loop.

Additives / Inhibitors will drastically slow down any reactions - but this doesn't mean it will run for years without issues - you will still need to drain and replace your fluids every 12/18 months, or so, to be safe

Even the similar metals copper,nickel and brass will react together over time as they are different metals ( though in this case it is far slower and less extreme than having aluminium in there )

What fluid to use ?

For the sake of recommendations, i will use Mayhems . OcUK stock them and Mayhems are imo the best in the industry - they specialise in fluids.

Mayhems range of fluid and additives

X1 Clear and X1 coloured Premix Watercooling Fluid along with the Aurora 2 range contain multi metal inhibitors and can be used straight out of the bottle.

If you prefer to mix you own, then this is where it gets slightly complicated;

Ultra Pure H20 - This is a base liquid and needs an additive, such as XT-1 Nuke, as it is just 'pure' water.

If adding dyes to Ultra Pure H20, read the description. You are looking for '(GRAS) multi-metal inhibitors'

The Pastel/Aurora/X1 range of colour concentrated dyes have these included

The range just labelled 'Dye' do not have inhibitors so will require XT-1 Nuke

Aluminium

Seems that i've portrayed Aluminium as public enemy number 1, but remember Aluminium alone is not the problem. MIXING with other metals is the issue here.

Aluminium is lighter,cheaper and almost as good as conducting heat as the other metals i've mentioned, it just doesn't like company when watercooling.

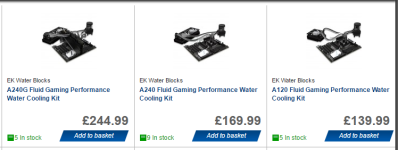

EK have recently released a range of kits, prefixed with an A, that are 100% aluminium parts and i would have no problem recommending them ( just do not add your favourite 360mm copper radiator to the loop ).

EK watercooling kits

Hope i covered some things, and that this might help prevent any mis-haps in the future.

Disclaimer ;

This post is not endorsed by OcUK / Mayhems or EK - just 10 years+ of my own dabbling with watercooling.

Additional info/FAQs

Thanks to ubersonic for these

I run an all copper loop, so i won't be effected ?

I've seen AIOs' with mixed metal parts, how do they do it ?

You've spent a lot of money on your new loop, and want to keep it in pristine condition ? - Read on

What is Galvanic Corrosion ?

If you are new to watercooling, galvanic corrosion is not something make up by the PC watercooling industry to force you to buy their specialist fluids,

it has been recognised for hundreds of years effecting things such ships in the early Royal Navy.

I'm no chemist but in very laymans terms it is when very different metals react to each other when in contact via a fluid.This reaction causes one metal to start dissolving.

This diagram shows that the most common metals used in watercooling copper,brass and nickel are very similar and will work happily together.

But aluminium is at the other end of the scale so it won't play well with the others.

Extreme case of galvanic corrosion on a cpu block in a copper + aluminium loop

How can i prevent it ?

The easiest way to prevent Galvanic corrosion is to avoid aluminium, but you will still need to take precautions.

Do not just use distilled water or anything labelled as pure water/H20 - You still need an additive to help prevent any nasties from growing in your loop.

Additives / Inhibitors will drastically slow down any reactions - but this doesn't mean it will run for years without issues - you will still need to drain and replace your fluids every 12/18 months, or so, to be safe

Even the similar metals copper,nickel and brass will react together over time as they are different metals ( though in this case it is far slower and less extreme than having aluminium in there )

What fluid to use ?

For the sake of recommendations, i will use Mayhems . OcUK stock them and Mayhems are imo the best in the industry - they specialise in fluids.

Mayhems range of fluid and additives

X1 Clear and X1 coloured Premix Watercooling Fluid along with the Aurora 2 range contain multi metal inhibitors and can be used straight out of the bottle.

If you prefer to mix you own, then this is where it gets slightly complicated;

Ultra Pure H20 - This is a base liquid and needs an additive, such as XT-1 Nuke, as it is just 'pure' water.

If adding dyes to Ultra Pure H20, read the description. You are looking for '(GRAS) multi-metal inhibitors'

The Pastel/Aurora/X1 range of colour concentrated dyes have these included

The range just labelled 'Dye' do not have inhibitors so will require XT-1 Nuke

Aluminium

Seems that i've portrayed Aluminium as public enemy number 1, but remember Aluminium alone is not the problem. MIXING with other metals is the issue here.

Aluminium is lighter,cheaper and almost as good as conducting heat as the other metals i've mentioned, it just doesn't like company when watercooling.

EK have recently released a range of kits, prefixed with an A, that are 100% aluminium parts and i would have no problem recommending them ( just do not add your favourite 360mm copper radiator to the loop ).

EK watercooling kits

Hope i covered some things, and that this might help prevent any mis-haps in the future.

Disclaimer ;

This post is not endorsed by OcUK / Mayhems or EK - just 10 years+ of my own dabbling with watercooling.

Additional info/FAQs

Thanks to ubersonic for these

I run an all copper loop, so i won't be effected ?

retailers don't usually seem mention it in specs these days (as most manufacturers don't) but most D5 pumps contain steel (and sometimes aluminium) so people can assume they have an all copper/brass loop when they don't. Secondly, copper/brass radiators are usually soldered together using tin, which as you're chart shows is most of the way to aluminium on the dissimilar metal scale.

I've seen AIOs' with mixed metal parts, how do they do it ?

AIOs, being sealed units can essentially get away with it because they will contain a special coolant that's designed to last for years even with aluminium and copper coexisting.

To put that in perspective, back in the early days of PC water cooling I once ran a mixed copper/alu loop for nearly four years without corrosion, because I used Toyota long life engine coolant which is designed for mixed metal loops and had a 5 year service life lol. Obviously doing that type of stuff isn't really a thing these days (because it would ruin clear blocks/tubing) but in a sealed AIO you can have whatever fluid you want.

Last edited: