Associate

- Joined

- 25 Oct 2005

- Posts

- 384

Hi All,

I though it may be interesting to some and useful to me to document a build I am working on. It started as a bit of a distraction during lock down and I'm slowly pulling it together, learning as I go.

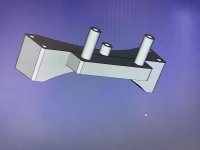

It's an O11D XL build, so nothing revolutionary there, but it'll be a custom over powered water cooling loop with custom cabling / cable management, lots of RGB and I'll be 3D printing bits to help along the way - None of which I have any experience in at all (bar a bit of 3d printing). I always start project with incredibly high expectations and lofty ideas and then try to battle my way through them! the plan is for a nice, clean hardline loop and cabling. So it'll be fun to show what I'm doing, hopefully you'll be able to help when I get stuck and even better someone may see something they like / want advice on.

System as it stands:

AMD 5800XT

MSI RX 5700XT Gaming X

4 x 8GB Corsair Vengeance RGB

MSI Tomahawk x570

Phanteks AMP 750w

For the watercooling set up I currently have an alphacool AIO but going to be:

EKWB PE 360

Alphacool XT45 360

XSPC TX360

Aquacomputer Ultitube 150 / D5 next pump combo

Alphacool GPX block

EKWB Velocity CPU block

EKWB Vertical mount

Aquacomputer Octo & Farbwerk for fan / rgb control. I have a load of black / atomic green MDPC cable sleeving.

I'll add some photos of where I am.

Cheers, Mike

I though it may be interesting to some and useful to me to document a build I am working on. It started as a bit of a distraction during lock down and I'm slowly pulling it together, learning as I go.

It's an O11D XL build, so nothing revolutionary there, but it'll be a custom over powered water cooling loop with custom cabling / cable management, lots of RGB and I'll be 3D printing bits to help along the way - None of which I have any experience in at all (bar a bit of 3d printing). I always start project with incredibly high expectations and lofty ideas and then try to battle my way through them! the plan is for a nice, clean hardline loop and cabling. So it'll be fun to show what I'm doing, hopefully you'll be able to help when I get stuck and even better someone may see something they like / want advice on.

System as it stands:

AMD 5800XT

MSI RX 5700XT Gaming X

4 x 8GB Corsair Vengeance RGB

MSI Tomahawk x570

Phanteks AMP 750w

For the watercooling set up I currently have an alphacool AIO but going to be:

EKWB PE 360

Alphacool XT45 360

XSPC TX360

Aquacomputer Ultitube 150 / D5 next pump combo

Alphacool GPX block

EKWB Velocity CPU block

EKWB Vertical mount

Aquacomputer Octo & Farbwerk for fan / rgb control. I have a load of black / atomic green MDPC cable sleeving.

I'll add some photos of where I am.

Cheers, Mike