Associate

- Joined

- 21 Aug 2006

- Posts

- 1,908

- Location

- Stafford

Just a quick hi as I have not been on here for some time. Been playing round with a NorthQ Siberian Tiger and been quite impressed.

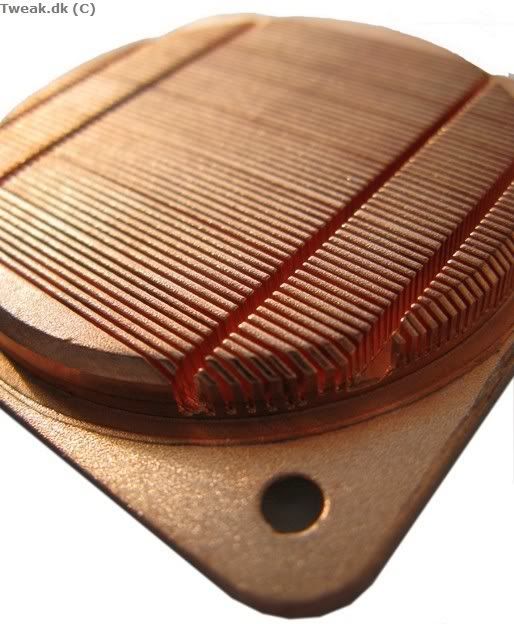

This has led me into the diabolical world of watercooling and being a must do it myself I have started construction of my X-factor water block.

It might not be as pretty as a commercial unit, but at least it is a one off.

Still a long way to go, but it is getting there. Any ideas or thoughts you guys may have may give me some inspiration.

Also can you see any potential problems I may have as I am still 'collecting' all the goodies for my water cooling setup.

This has led me into the diabolical world of watercooling and being a must do it myself I have started construction of my X-factor water block.

It might not be as pretty as a commercial unit, but at least it is a one off.

Still a long way to go, but it is getting there. Any ideas or thoughts you guys may have may give me some inspiration.

Also can you see any potential problems I may have as I am still 'collecting' all the goodies for my water cooling setup.