Hi Guys,

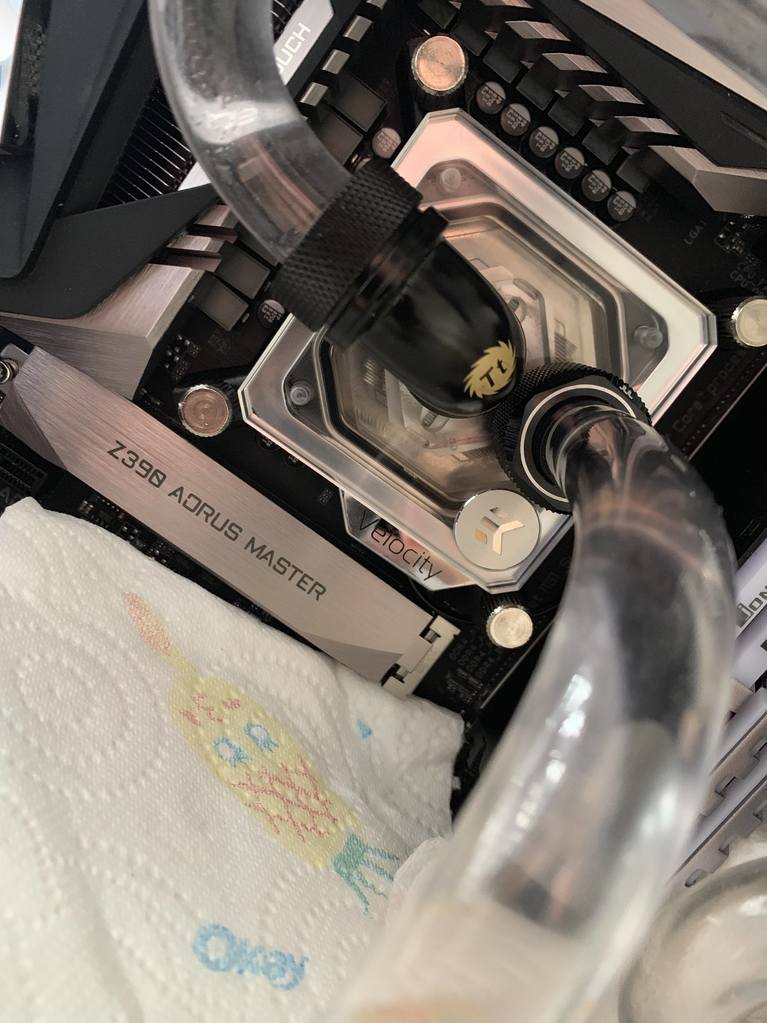

I finally completed my 1st loop.

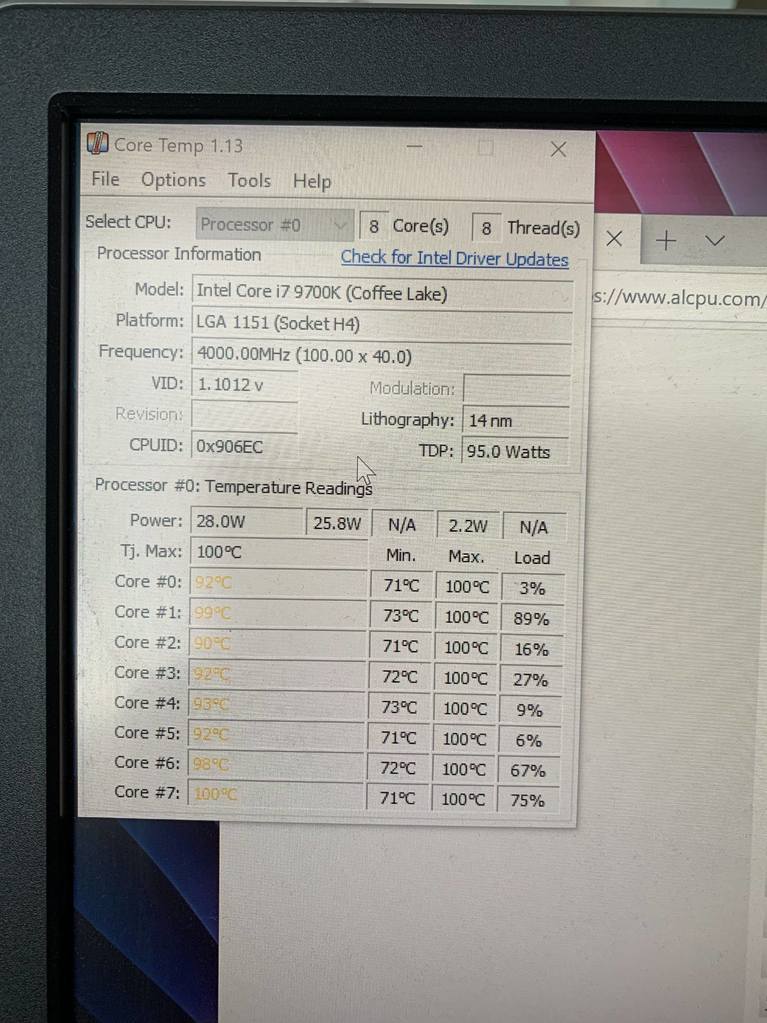

On first boot, the pump wasn't running so it thermal throttled.

After that : blue screen of death "no accessible boot device". I ended up reinstalling windows.

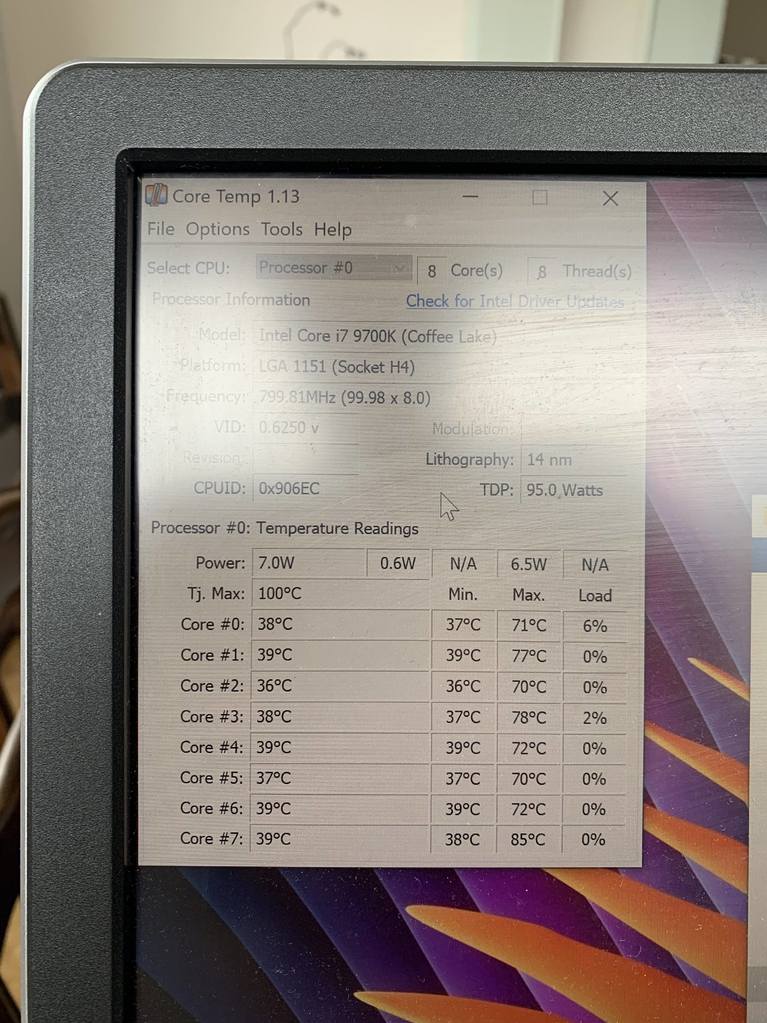

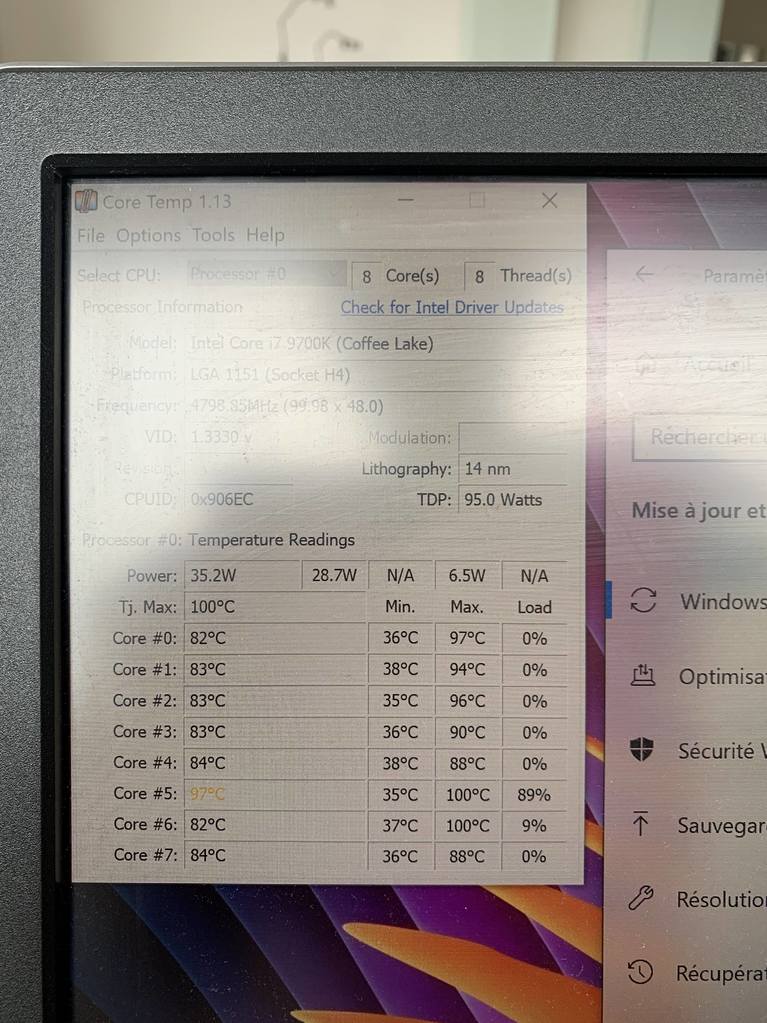

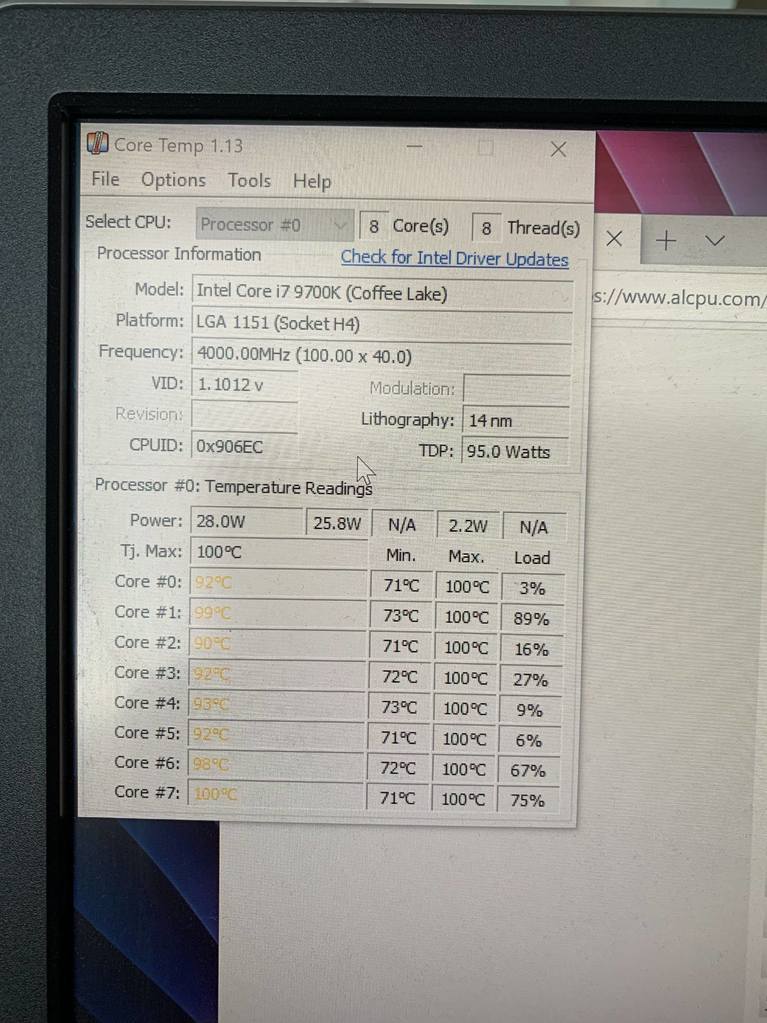

After installing, I immediately installed core temp and here is the result. I think that something is going wrong but I have no idea what...

The pump is definitely working (I see the last micro bubbles traveling), the fans are running, and as far as I know the cpu block is correctly installed.

Any help will be welcome !

Thank you

I finally completed my 1st loop.

On first boot, the pump wasn't running so it thermal throttled.

After that : blue screen of death "no accessible boot device". I ended up reinstalling windows.

After installing, I immediately installed core temp and here is the result. I think that something is going wrong but I have no idea what...

The pump is definitely working (I see the last micro bubbles traveling), the fans are running, and as far as I know the cpu block is correctly installed.

Any help will be welcome !

Thank you