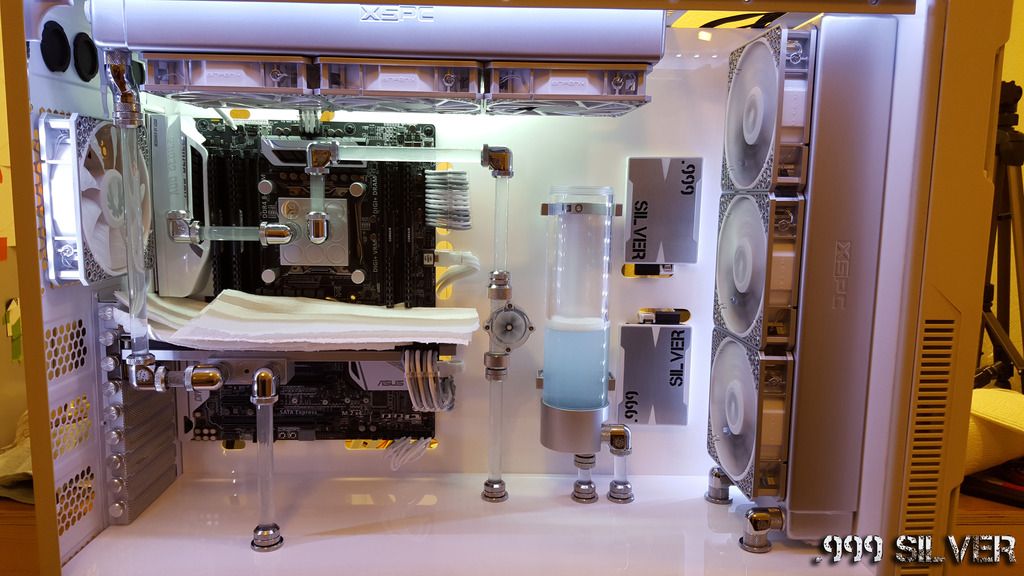

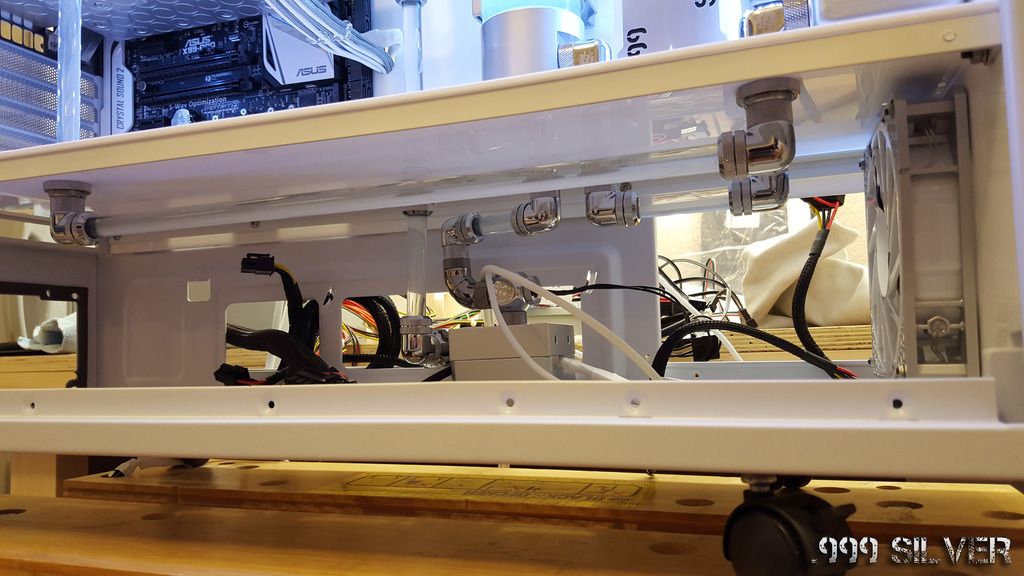

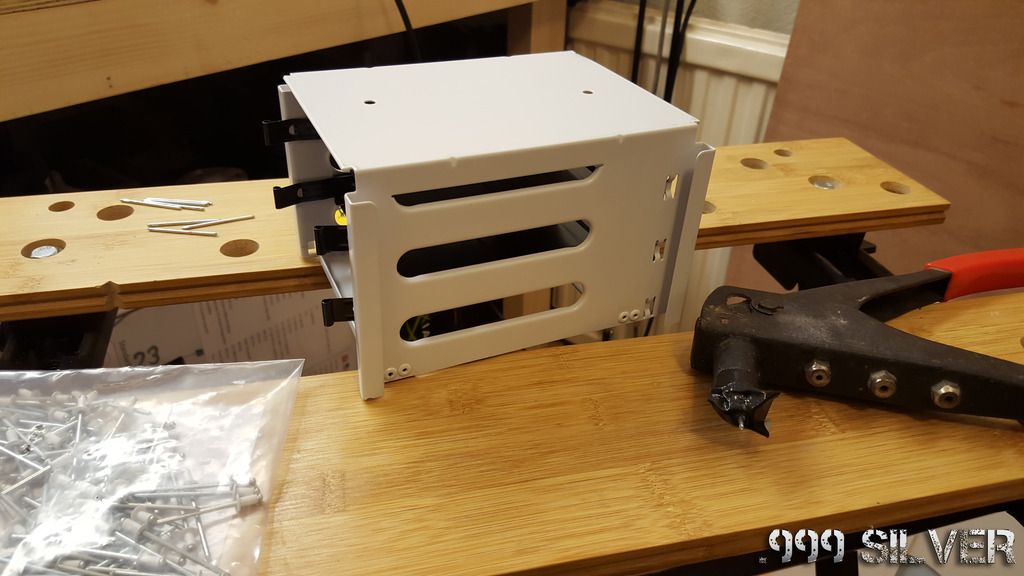

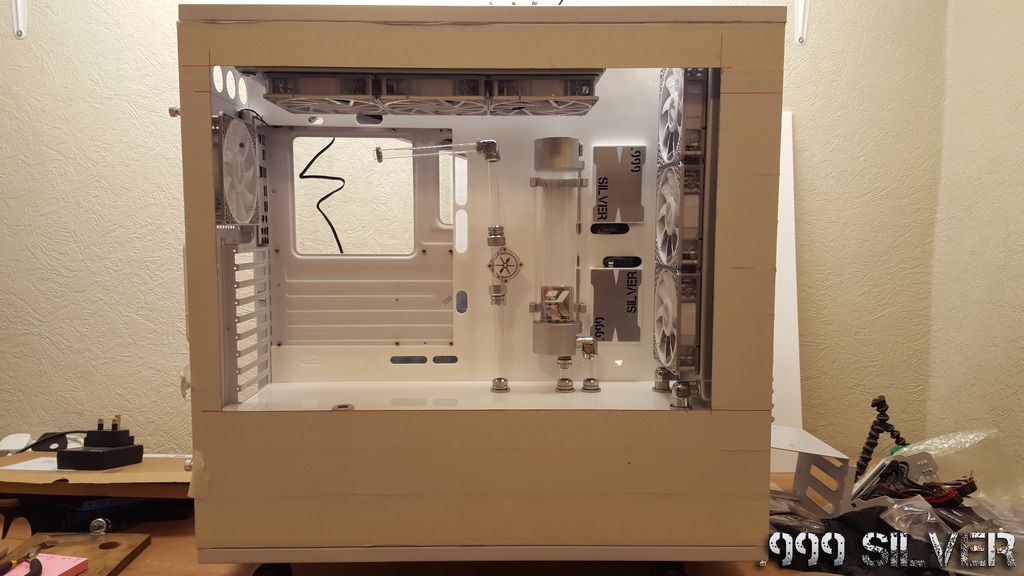

I do like the front look of the case. It looks clean but not boring, in fact it almost has an aggressive touch to it. Can't wait to see those cables fitted

Keep up the excellent work

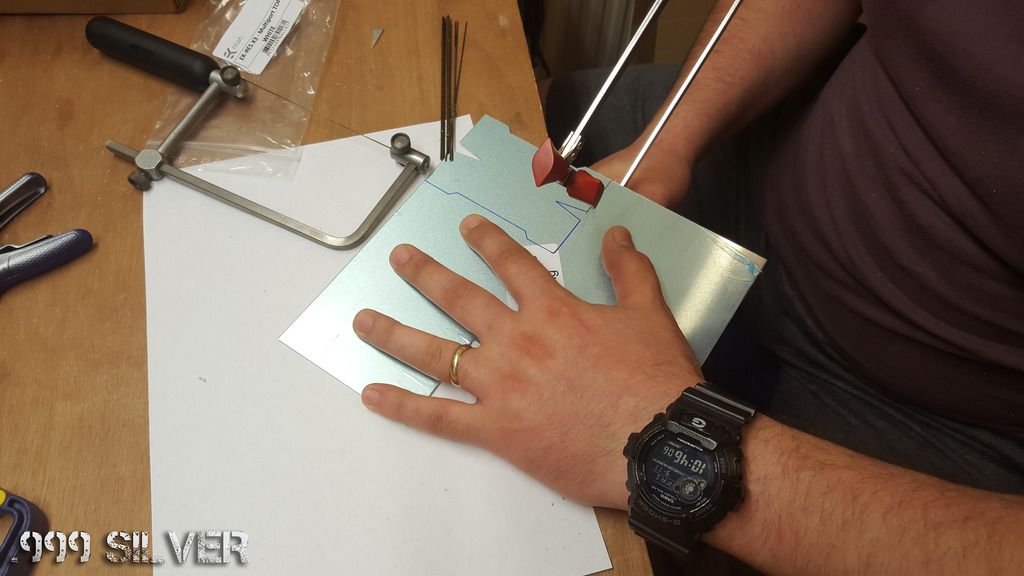

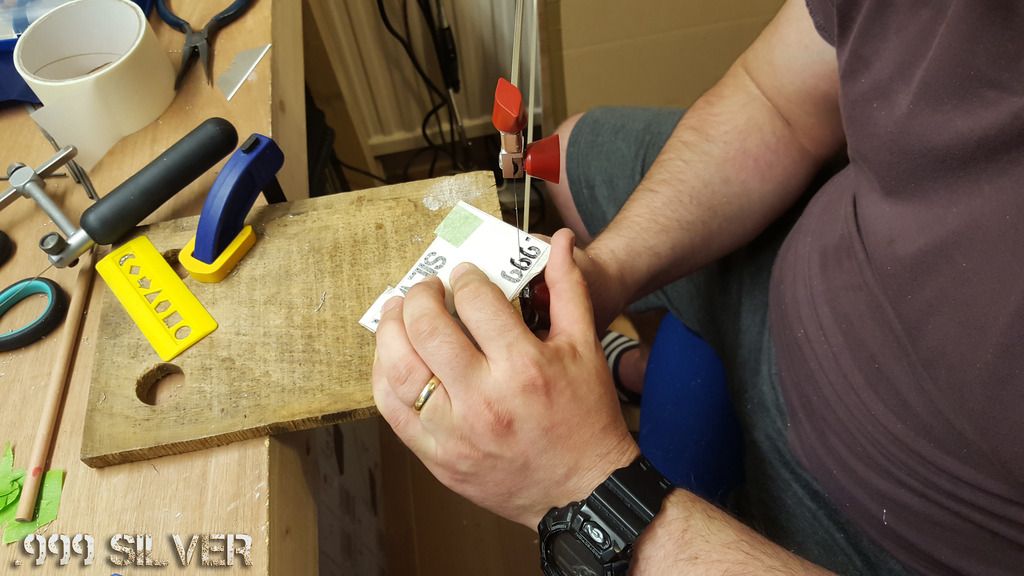

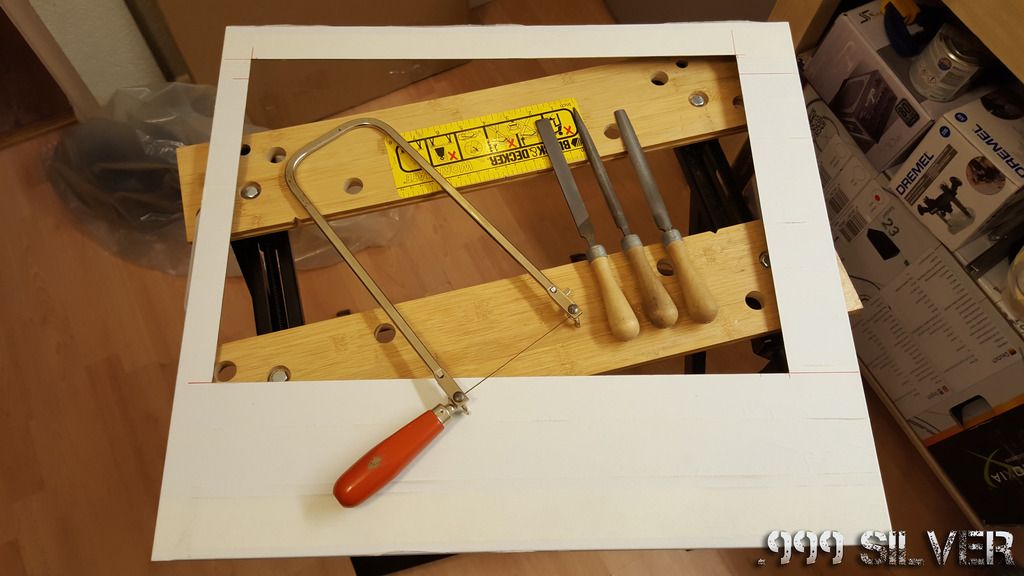

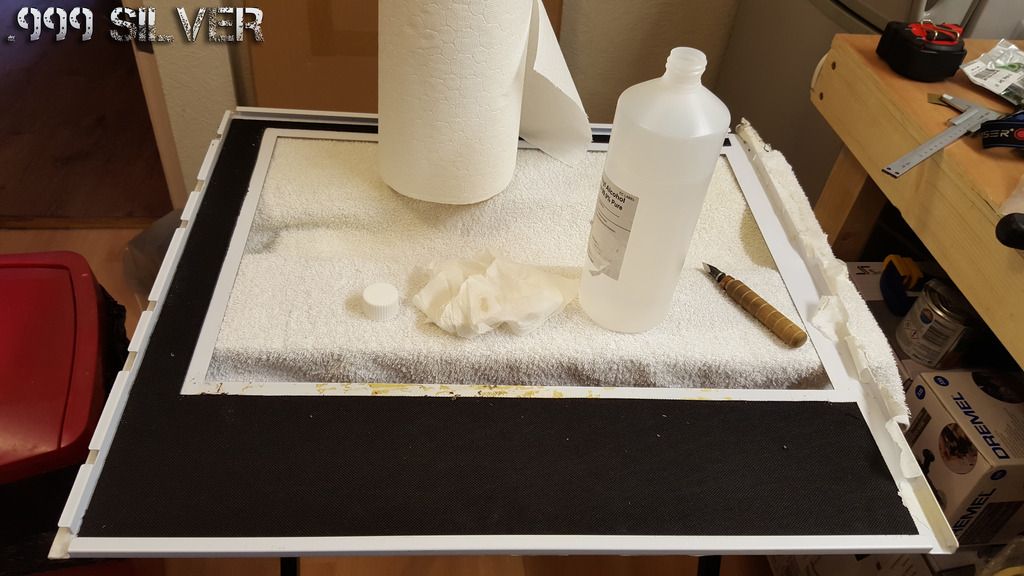

Coming along great, I really like to see your "at work" pics and that you are doing this yourself.

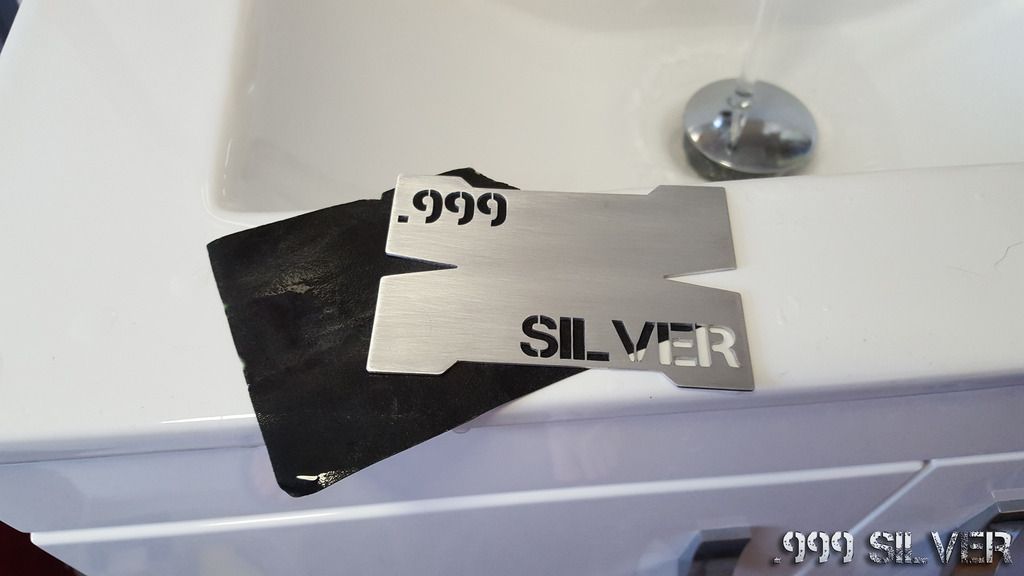

In awe - a true artesan build! The attention to detail is amazing, however i have to say that Nanoxia logo on the front is not to my taste - sorry.

really like this fella build well done.

Thanks for the good words lads, really appreciated

So fingers crossed for that!

So fingers crossed for that!