I'm going on about stress concentration factors on the basis that if the OP buys 40mm square then drills an 8mm hole through it, it's far less certain whether the beam will hole up or not. It's not always intuitive just how much drilling holes weakens a structure.

The youngs modulus of steel doesn't change much with grade.

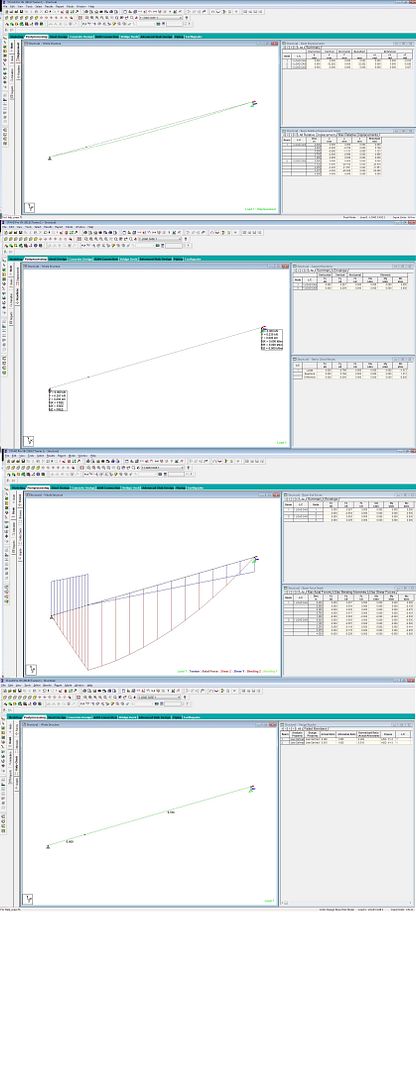

I can do the equations from first principles, they come from considering equibrium of moments and forces through an arbitrary plane in the beam then repeatedly integrating the result. Or cheating a bit and using Macaulay's notation to hide the integration. Or cheating a lot and letting a website draw the pictures for me.

I'm not sure what I've done to put your back up here. I approximated 48g as 500N (err on the side of caution at every step, if you know your theory is inaccurate), but then you took the bending moment to 7 significant figures. Engineers bending theory just isn't accurate enough to justify that. And we both concluded 40x40x5mm for the steel, if there aren't any holes drilled through it. Where's the issue?

The youngs modulus of steel doesn't change much with grade.

I can do the equations from first principles, they come from considering equibrium of moments and forces through an arbitrary plane in the beam then repeatedly integrating the result. Or cheating a bit and using Macaulay's notation to hide the integration. Or cheating a lot and letting a website draw the pictures for me.

I'm not sure what I've done to put your back up here. I approximated 48g as 500N (err on the side of caution at every step, if you know your theory is inaccurate), but then you took the bending moment to 7 significant figures. Engineers bending theory just isn't accurate enough to justify that. And we both concluded 40x40x5mm for the steel, if there aren't any holes drilled through it. Where's the issue?