Ok, so I did some more work.

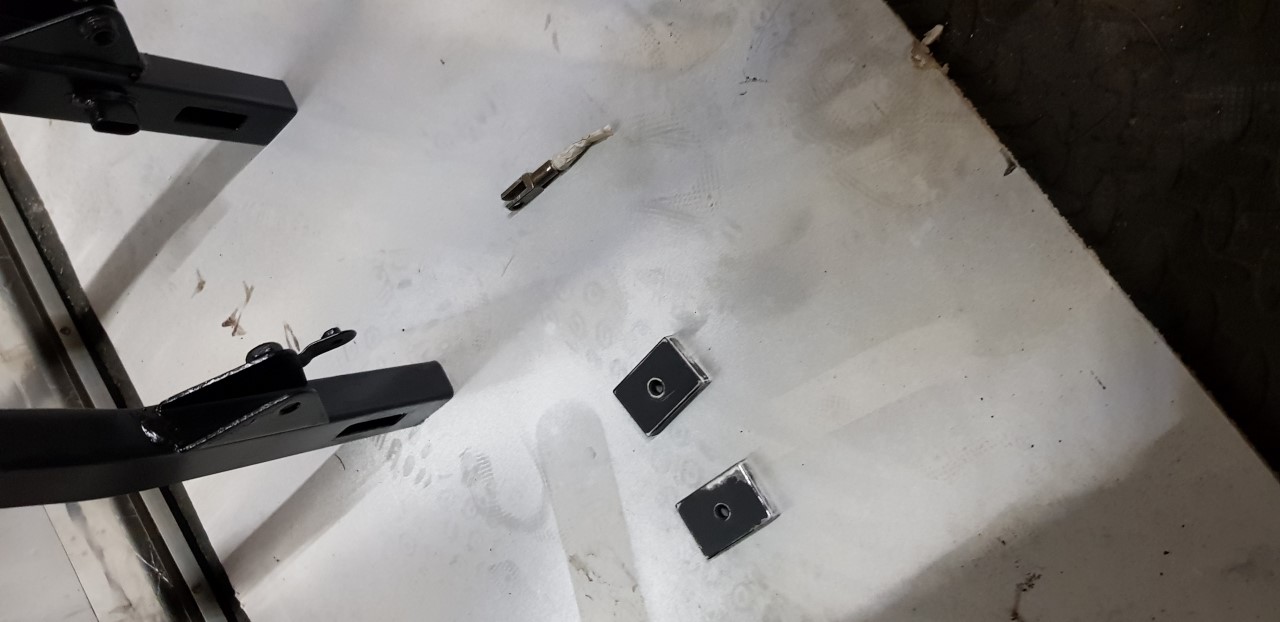

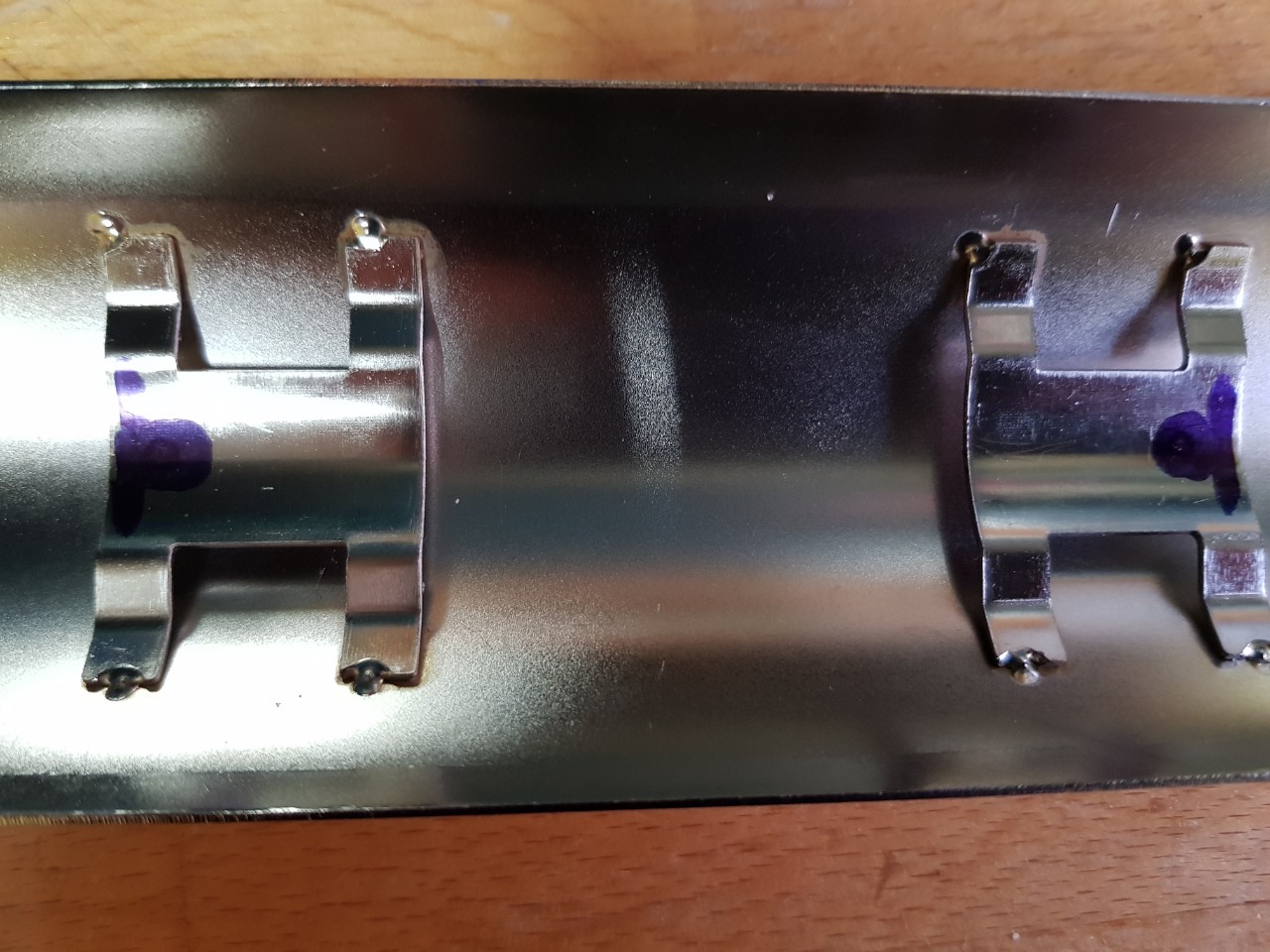

Knocked up a prototype parts tumbler to try and clean up some of the small parts more easily:

Only used some sharp sand I had lying about, and did it for 30 mins.

Parts before they went in:

And, as they came out:

Some parts came out great! The plastic part, and the exhaust bolts were greatly improved. Could do with a little longer, but I think I need to get the sand drier, or wetter and use it for longer to get the best results. I will also look to get some proper media to help with the heavy deposit removal.

Now I know it works, I will make it a little more portable and less cumbersome!

Chain adjuster plates looking a little nicer after their final coat.

Quite happy with that.

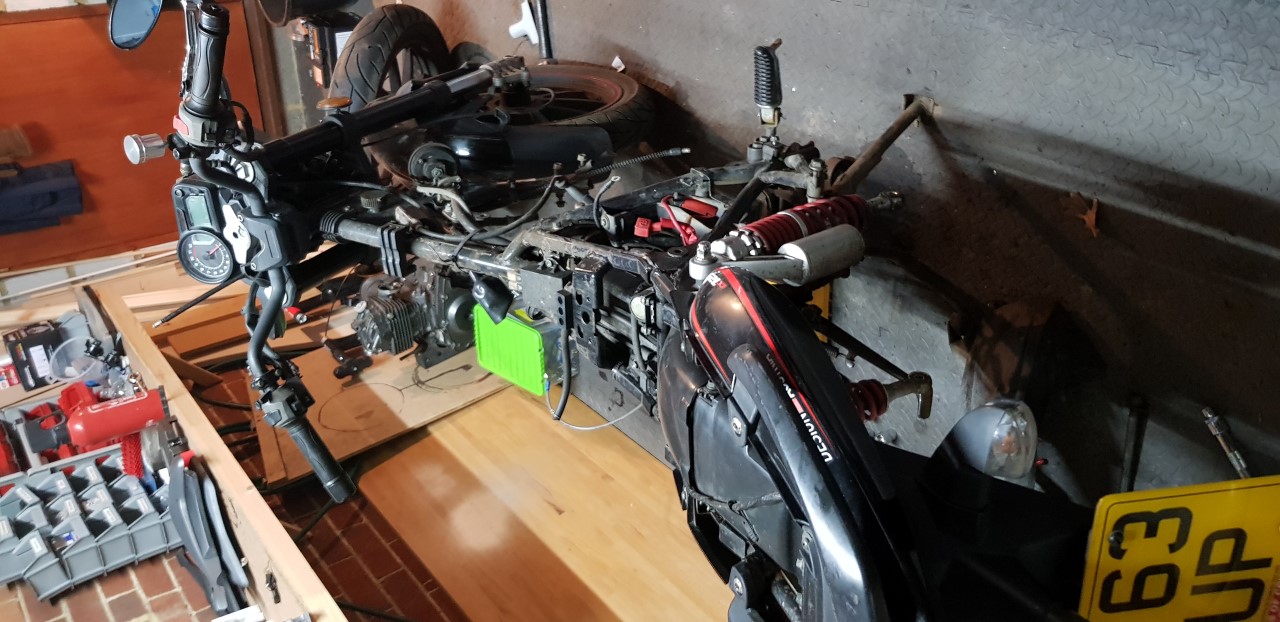

Rear wheel is looking a little cleaner, and ready to go back on the bike. Debating masking up the disk, and treating/painting the centre black to make it look bit neater if I get around to it.

Needed to pull the caliper off the mount to tidy it up. Mount first, will get around to the caliper later.

Cleaning up the mount.

Will paint it shortly.

Got to tidy up this lot next:

Any tips on cleaners for brake hoses?

Exhaust is all done. Not sure I am going to keep it this colour, but it should protect it at least!

Did the same cleaning treatment to the chainstay protector. I also got a bunch of new stainless washers to replace the rusted ones shown in the tumbling parts, as they were way too far gone to be saved.

Got to clean up the under arch plastics too:

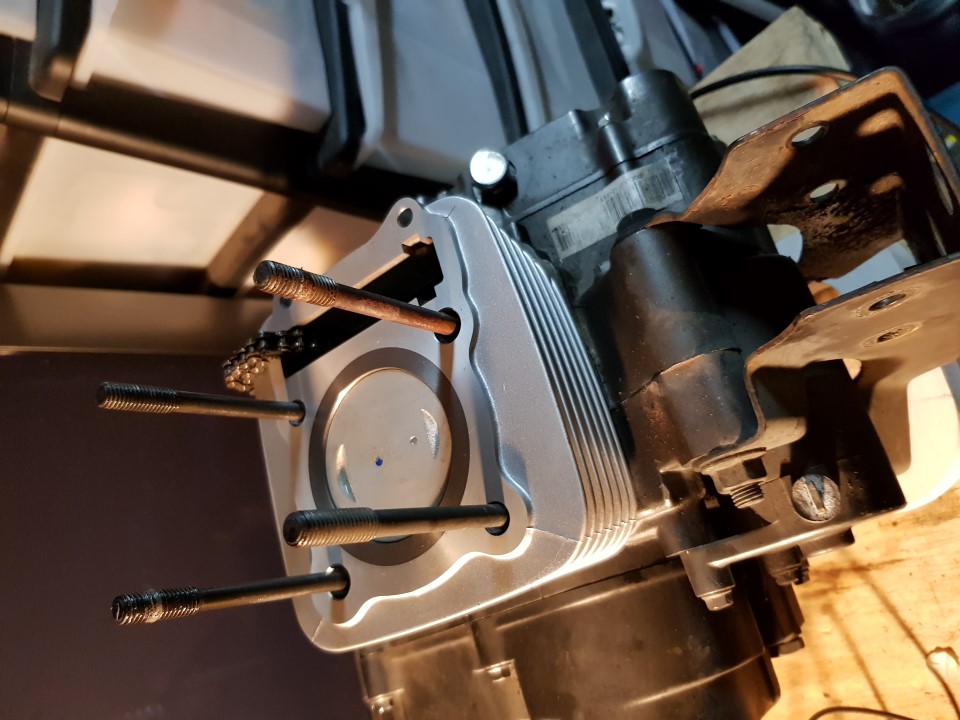

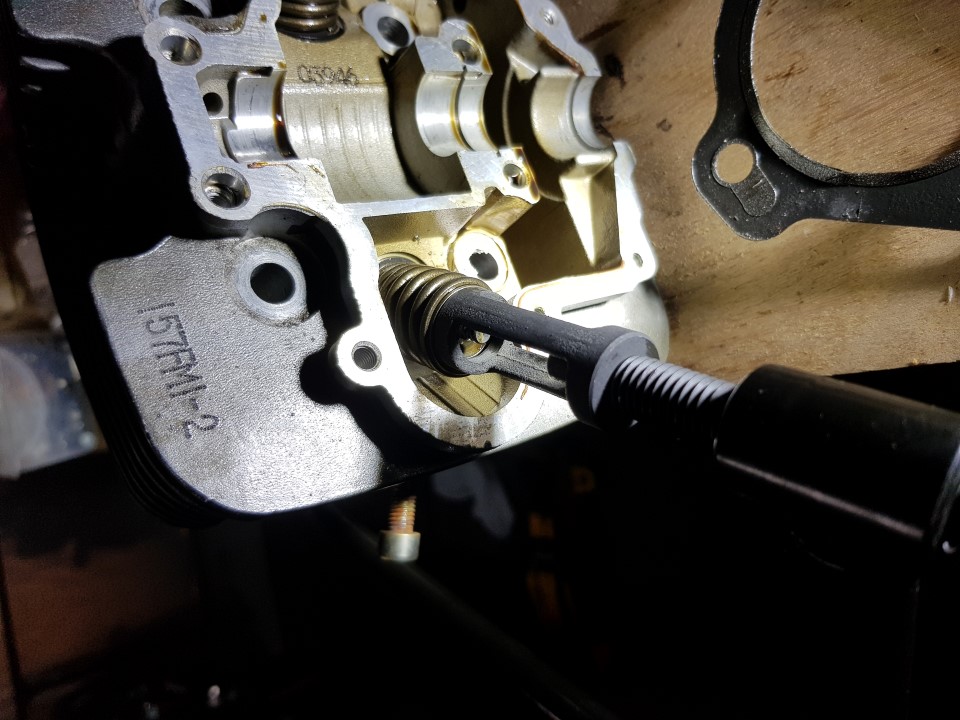

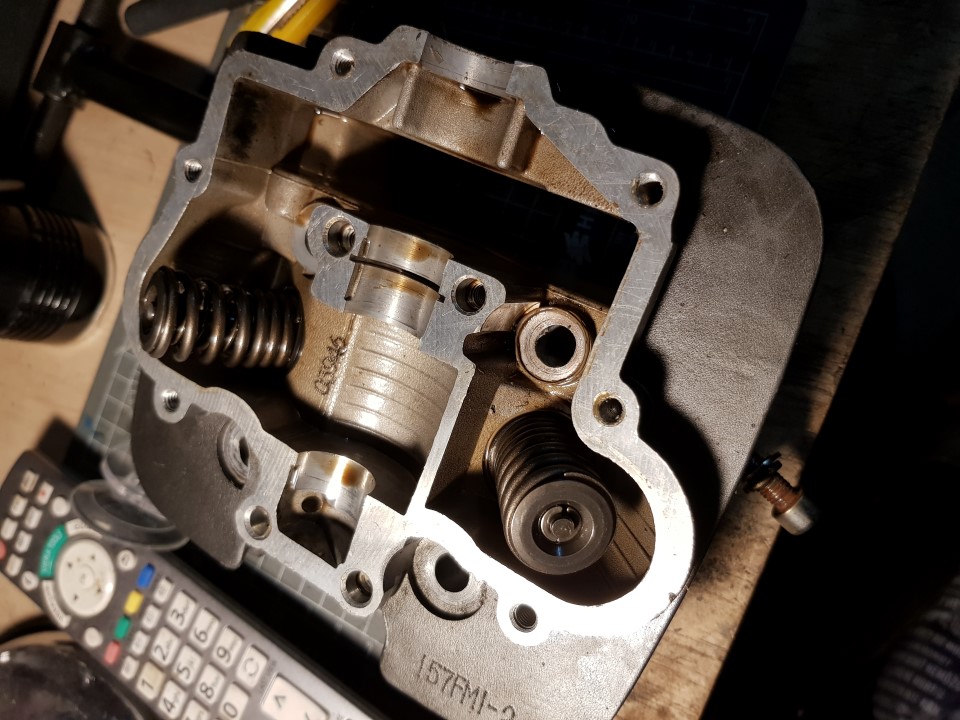

I have the new valves, grinding paste, waiting for the grinding dowel to turn up also.

I also have had to order a valve tool, as it was not working too well with my G-clamp method!

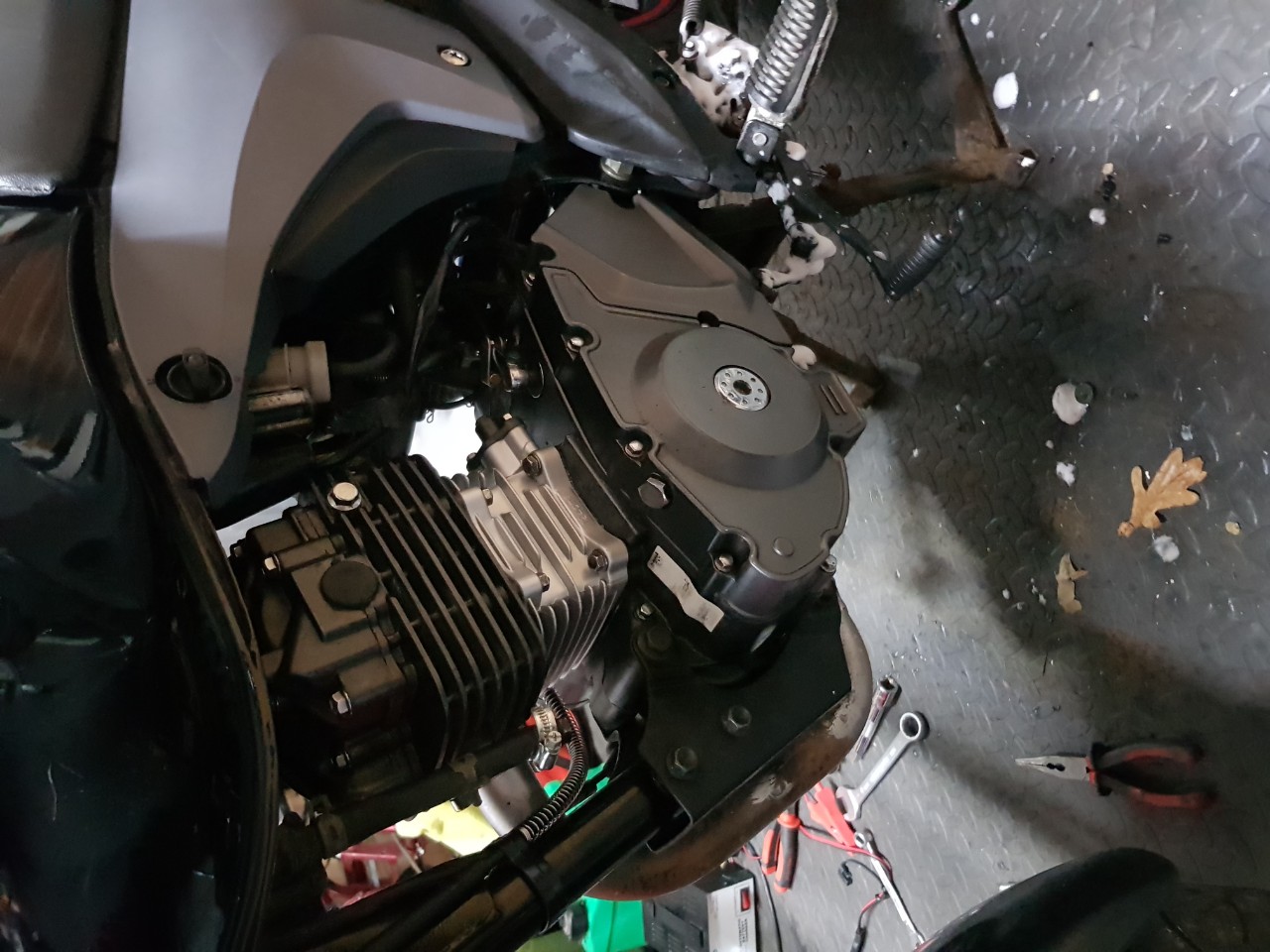

I had a problem with getting the right piston, I stupidly ordered the older suzuki spec piston with a domed top. Had to change this for the flat top modern one, which means the piston rings don't fit! So ordered new piston rings specific to the new piston. Lesson learned there. Only actual physical problem I have had with the engine so far is the removal/replacement of a location dowel. Cant get it out of the old cylinder, and can I cannot find the specific replacement. The two I ordered supposedly for this engine are too small and flop about

I am told I can rebuild without the problem one if needed, but I would like to get one to be sure all is ok.

Hopefully by the weekend the engine will be able to go back in, and I can do a quick tidy-up on the rest of the frame/parts and test ride it.