I'm just about to start a new computer build and just want to check a question about waster cooling before I start anything because I'm a newbie to it. If I want to build my own reservoir out of some stainless or aluminium pipe to sit outside the case, cpu cooler and rad have copper in, so am I right in thinking as long as I don't ground the res to the case I shouldn't have any problems as there wouldn't be a complete circuit?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Galvanic Corrosion

- Thread starter joemo13

- Start date

More options

Thread starter's postsSoldato

- Joined

- 14 Sep 2010

- Posts

- 2,909

- Location

- Port Talbot - Wales

Make the res out of perspex, then sleeve it in aluminium...

That way the loop itself only has one metal actually in contact with the liquid

That said, how about the fixings? they're not copper are they..?

That way the loop itself only has one metal actually in contact with the liquid

That said, how about the fixings? they're not copper are they..?

Soldato

- Joined

- 31 May 2006

- Posts

- 7,564

- Location

- West London

Mixed metal loop just need the right coolant.

Unless its has dis-simular metals in direct contact like the old swiftech GTX.

Thats just asking for trouble.

Building your own is imho not really for a noobie, not sure why you want a 'pipe' reservoir

But if you have the skills there are a few here that have, and will happily offer advice.

Money puzzles, project HUSH is a good place to start.

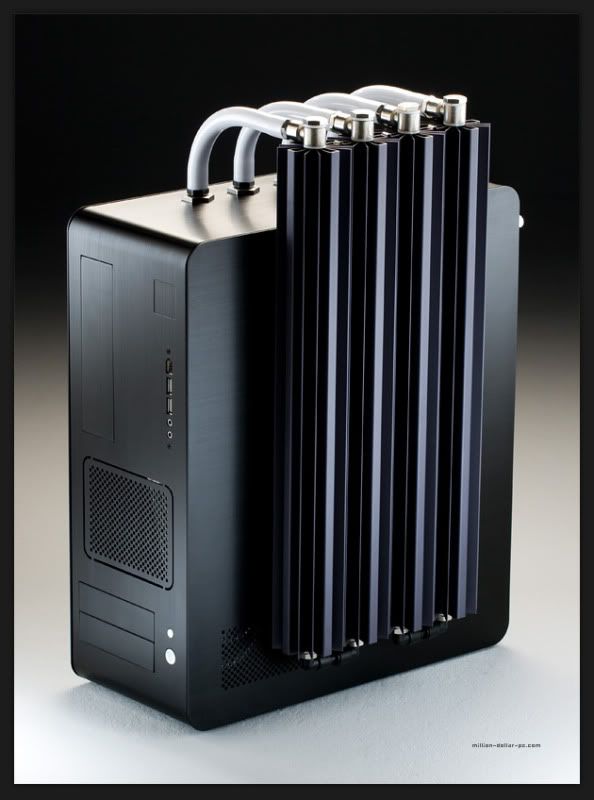

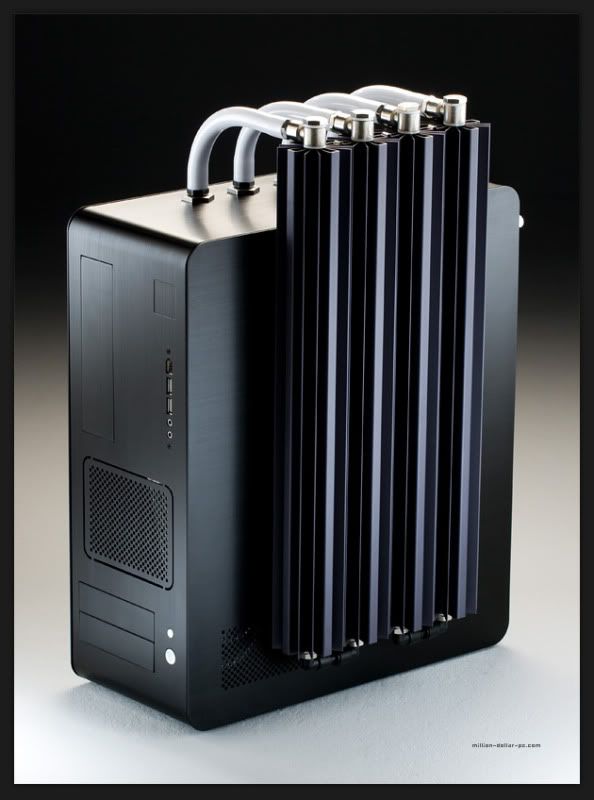

Pictures many help with bubo questions - all are external RAD's which it what I think you ment, so....

Are you looking to do something like this (this has a mixed metal passive loop)

or this (home made rad box for a AV system - fan assisted all copper/brass)

or this (modified commercial passive water loop - mine and mixed metal)

or this (commercial passive free standing rad - mixed metal)

or this (home made, radient panel rad - mine all copper/brass)

Unless its has dis-simular metals in direct contact like the old swiftech GTX.

Thats just asking for trouble.

Building your own is imho not really for a noobie, not sure why you want a 'pipe' reservoir

But if you have the skills there are a few here that have, and will happily offer advice.

Money puzzles, project HUSH is a good place to start.

Pictures many help with bubo questions - all are external RAD's which it what I think you ment, so....

Are you looking to do something like this (this has a mixed metal passive loop)

or this (home made rad box for a AV system - fan assisted all copper/brass)

or this (modified commercial passive water loop - mine and mixed metal)

or this (commercial passive free standing rad - mixed metal)

or this (home made, radient panel rad - mine all copper/brass)

Last edited:

Thanks for the replies, I was thinking of something similar to the XSPC passive radiator. I can get some large bore pipe that would be wide enough for free and just seal the ends with some spare sheet and then cover the outside in corrugated sheet. I wanted it outside the box just for looks, there will also be a normal radiator in the loop to do most of the cooling.

To stop corrosion is there any special paints/coatings that could be used?

To stop corrosion is there any special paints/coatings that could be used?

Soldato

- Joined

- 31 May 2006

- Posts

- 7,564

- Location

- West London

You mean "XSPC 150/250mm Passive Aluminium Reservoir"

If you could get the tube anodized that would help

Or an marine grade paint for the inside would also stop the collant 'touching' the metal.

But will reduce heat transfer.

your biggest issue if fitting barbs

A 2 or 3mm metal plate can be tapped with a G1/4 thread

Or you could just weld them on.

If you could get the tube anodized that would help

Or an marine grade paint for the inside would also stop the collant 'touching' the metal.

But will reduce heat transfer.

your biggest issue if fitting barbs

A 2 or 3mm metal plate can be tapped with a G1/4 thread

Or you could just weld them on.

Yes, I meant reservoir but for some reason radiator poped into my head.

Welding is no problem so I would go that way, do you have a build log for the radient panel rad you made? I might just go down the copper pipe route if it is safer!

Welding is no problem so I would go that way, do you have a build log for the radient panel rad you made? I might just go down the copper pipe route if it is safer!

Associate

- Joined

- 7 Apr 2010

- Posts

- 89

I ran a mixed system copper blocks with Aluminium Radiator and Reservoir for years without issue. Used distilled (not deionised)water with anti corrosion additive. The Aluminium parts were anodized though and I think this was key. I got a scratch in the finish after sometime and at that particular spot corrosion started to happen fairly quickly. So I would not recommend bare Aluminium.

As shadowscotland says there is no problem with mixed metals in loops, You just need a corrosion inhibitor in your coolant.

Antifreeze will serve this purpose very well. 10 - 15 % mix is plenty

My sons system we made has a cast iron / aluminium pump, aluminium radiator, copper blocks and pipes.

This has been running for the past 4-5 years with out a hitch

Antifreeze will serve this purpose very well. 10 - 15 % mix is plenty

My sons system we made has a cast iron / aluminium pump, aluminium radiator, copper blocks and pipes.

This has been running for the past 4-5 years with out a hitch

Soldato

- Joined

- 31 May 2006

- Posts

- 7,564

- Location

- West London

, do you have a build log for the radient panel rad you made? I might just go down the copper pipe route if it is safer!

The panels are skirting heaters - and are made with the copper tube inside.

The 'barbs' were made from the connectors more on it here