You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

IC Diamond24/Perihelion4gm Giveaway

- Thread starter IC Diamond

- Start date

More options

Thread starter's postsYou've provided data specifying wattage used and contact area. That puts you head and shoulders above the rest of the field in my view, even if your results weren't good. Thank you for the link and for the data.

Was the synthetic die copper or nickel plated copper?

Thank you for testing with the system soldered together, I've been trying to find the courage to solder my cpu to a waterblock for a while now, and that rather puts me off. I'm fairly sure that the liquid pro can perform better, simply as it will wick into the (clean) copper surfaces better than a grease has any realistic chance to. Cleaning up the surface of my waterblock took considerable effort though (I ended up flycutting it which isn't an option for most people), so I'm certain thermal grease will continue to dominate the market.

0.5 K / 120W worse than solder isn't quite negligible, but I think I agree that further progress is going to qualify as diminishing returns. Nicely done regardless, I'll be buying paste from you next time around.

Was the synthetic die copper or nickel plated copper?

Thank you for testing with the system soldered together, I've been trying to find the courage to solder my cpu to a waterblock for a while now, and that rather puts me off. I'm fairly sure that the liquid pro can perform better, simply as it will wick into the (clean) copper surfaces better than a grease has any realistic chance to. Cleaning up the surface of my waterblock took considerable effort though (I ended up flycutting it which isn't an option for most people), so I'm certain thermal grease will continue to dominate the market.

0.5 K / 120W worse than solder isn't quite negligible, but I think I agree that further progress is going to qualify as diminishing returns. Nicely done regardless, I'll be buying paste from you next time around.

Associate

- Joined

- 14 Jan 2011

- Posts

- 85

ON MY HONOR IN EXCHANGE FOR FREE COMPOUND I DO SOLEMNLY SWEAR TO TEST AND POST MY RESULTS

I will be able to test on my i5 2500k, against 2 different thermal compounds. The stuff that comes with the Zalman CNPS9500 range (As I have a 2nd set of it now, unused) and against the Tuniq TX-2 compound that I am currently using.

The cooler in question is the Zalman CNPS 9500A.

I will be able to test on my i5 2500k, against 2 different thermal compounds. The stuff that comes with the Zalman CNPS9500 range (As I have a 2nd set of it now, unused) and against the Tuniq TX-2 compound that I am currently using.

The cooler in question is the Zalman CNPS 9500A.

- Joined

- 7 Dec 2010

- Posts

- 223

You've provided data specifying wattage used and contact area. That puts you head and shoulders above the rest of the field in my view, even if your results weren't good. Thank you for the link and for the data.

1 And Pressure

2 You should see my data on the competition

Was the synthetic die copper or nickel plated copper?

Copper Had to use a blow torch with steel wool to clean and still had to re-lap with my diamond stones 400-800 grit to get it properly clean

Thank you for testing with the system soldered together, I've been trying to find the courage to solder my cpu to a waterblock for a while now, and that rather puts me off. I'm fairly sure that the liquid pro can perform better, simply as it will wick into the (clean) copper surfaces better than a grease has any realistic chance to. Cleaning up the surface of my waterblock took considerable effort though (I ended up flycutting it which isn't an option for most people), so I'm certain thermal grease will continue to dominate the market. There is a company that has an ignitable metal foil as an interface that when you set it off it burns for a few hundredths of a second and welds a nice joint.

0.5 K / 120W worse than solder isn't quite negligible, but I think I agree that further progress is going to qualify as diminishing returns. Nicely done regardless, I'll be buying paste from you next time around.

Last edited:

- Joined

- 7 Dec 2010

- Posts

- 223

First batch gets mailed early next week

Associate

- Joined

- 8 Feb 2011

- Posts

- 284

ON MY HONOR IN EXCHANGE FOR FREE COMPOUND I DO SOLEMNLY SWEAR TO TEST ON MY DADS PC AND POST HIS RESULTS

Lol I'm sure he wont mind lol, mind you i did put some stuff made by AC5 (wasnt AC5 but meant to be made by same people, cant remember wot it was now tho), will be interesting to see if and how better it is?

now to get my post count up to 50!

Please consider me.

Lol I'm sure he wont mind lol, mind you i did put some stuff made by AC5 (wasnt AC5 but meant to be made by same people, cant remember wot it was now tho), will be interesting to see if and how better it is?

now to get my post count up to 50!

Please consider me.

Associate

- Joined

- 28 Nov 2009

- Posts

- 881

- Location

- Manchester

First batch gets mailed early next week

Woot.

Soldato

- Joined

- 9 Oct 2009

- Posts

- 9,258

- Location

- United Kingdom

Yes please Sir,

ON MY HONOR IN EXCHANGE FOR FREE COMPOUND I DO SOLEMNLY SWEAR TO TEST AND POST MY RESULTS

Testing with

i7 920 DO @ 4.2GHz HT & 4.4GHz (No HT) - Titan Fenrir & Artic Silver

GTX 470 @ stock/OC & Gelid Icy Vision Cooler

emailed

ON MY HONOR IN EXCHANGE FOR FREE COMPOUND I DO SOLEMNLY SWEAR TO TEST AND POST MY RESULTS

Testing with

i7 920 DO @ 4.2GHz HT & 4.4GHz (No HT) - Titan Fenrir & Artic Silver

GTX 470 @ stock/OC & Gelid Icy Vision Cooler

emailed

Last edited:

Ignitable foil is a particularly clever idea, I like that.

There's a graph in my thermodynamics lectures taken from an old, but unreferenced, textbook (it isn't recent enough to be using SI at least). It shows thermal resistance against mounting pressure for a range of materials in direct contact with each other, unsurprisingly resistance decreasing with mounting pressure. The unexpected result comes from electroplating copper with nickel; the result is a lower resistance than unplated copper. The porous surface deforms under pressure to give a greater contact fraction and the effect overwhelms the additional cu-ni boundary and increased thickness.

Unfortunately I haven't been able to source a reference that I can link to for this, and I keep forgetting to email my old lecturer to ask. It's stayed with me as an interesting counter argument to lapping, hence my curiosity as to your testing surface.

I fear a lot of nonsense is taken as fact on overclocking boards, so hard data is always very much appreciated. Thanks again

There's a graph in my thermodynamics lectures taken from an old, but unreferenced, textbook (it isn't recent enough to be using SI at least). It shows thermal resistance against mounting pressure for a range of materials in direct contact with each other, unsurprisingly resistance decreasing with mounting pressure. The unexpected result comes from electroplating copper with nickel; the result is a lower resistance than unplated copper. The porous surface deforms under pressure to give a greater contact fraction and the effect overwhelms the additional cu-ni boundary and increased thickness.

Unfortunately I haven't been able to source a reference that I can link to for this, and I keep forgetting to email my old lecturer to ask. It's stayed with me as an interesting counter argument to lapping, hence my curiosity as to your testing surface.

I fear a lot of nonsense is taken as fact on overclocking boards, so hard data is always very much appreciated. Thanks again

Soldato

- Joined

- 9 Dec 2009

- Posts

- 5,330

- Location

- Bristol

Perihelion is a top competitor in user tests to date it is only second to ICD on performance at much lower cost than ICD or comparative competition compounds. It has the same viscosity as ICD for long term reliability minimizing pump/bake out failures so do not discount the advantages on the Perihelion.

Is "bake out" when the TIM turns hard & crusty? I've had this with some thermal compounds & this is the reason why I have stuck with AS5 as it gives me consistent results over time rather than being amazingly cool for a few weeks then temps begin creeping up. My system does run quite warm (low 60s).

Soldato

- Joined

- 6 Jun 2009

- Posts

- 5,460

- Location

- No Mans Land

ON MY HONOR IN EXCHANGE FOR FREE COMPOUND I DO SOLEMNLY SWEAR TO TEST AND POST MY RESULTS

between AS5

between AS5

Soldato

- Joined

- 27 Jan 2003

- Posts

- 5,962

- Location

- Chesterfield, UK

ON MY HONOR IN EXCHANGE FOR FREE COMPOUND I DO SOLEMNLY SWEAR TO TEST AND POST MY RESULTS

I7 920 @ 3.9 GHz - Underwater

I7 920 @ 3.9 GHz - Underwater

- Joined

- 7 Dec 2010

- Posts

- 223

There's a graph in my thermodynamics lectures taken from an old, but unreferenced, textbook (it isn't recent enough to be using SI at least). It shows thermal resistance against mounting pressure for a range of materials in direct contact with each other, unsurprisingly resistance decreasing with mounting pressure. The unexpected result comes from electroplating copper with nickel; the result is a lower resistance than unplated copper. The porous surface deforms under pressure to give a greater contact fraction and the effect overwhelms the additional cu-ni boundary and increased thickness.

Unfortunately I haven't been able to source a reference that I can link to for this, and I keep forgetting to email my old lecturer to ask. It's stayed with me as an interesting counter argument to lapping, hence my curiosity as to your testing surface.

Interesting about the nickel perhaps why Intel coats the IHS? I had always assumed it was for corrosion I will have to look into that some more.

Dead on target IMO with the pressure with all things being equal increased pressure will compensate or improve contact and reduce resistance most.

An often recognized problem is IHS/sink contact is so poor that pressure can not compensate and in many instances IHS edges will be higher than the inside area creating a too large gap that no reasonable pressure con compensate for.

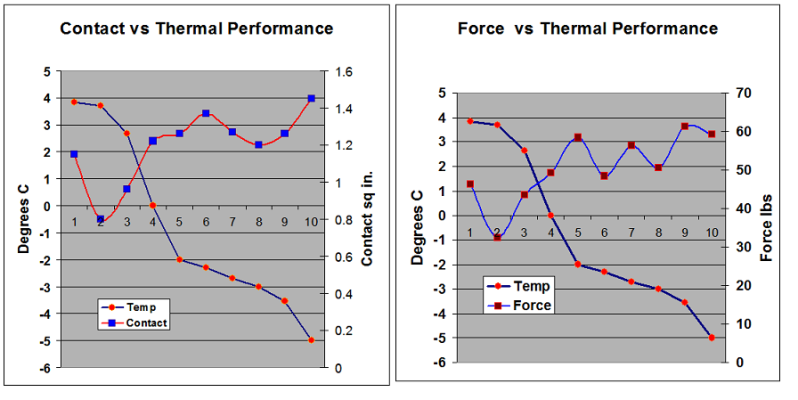

We sampled some end user contact patterns over several forums and as can be noted at least from the samples recorded seems to be a common issue.

Technical/Troubleshooting Note:

As most experienced users understand that when troubleshooting thermal problems there are usually 3 areas of concern.

1.) Pressure

2.) Contact

3.) Application

Taking a thermal measurement on it's own is not enough without a relative basis of comparison. Application and use of thermal compound is a mechanical function though many electronically oriented people tend to attach little importance to mechanical measurements.

Every thermal compound has it's own unique ideal pressure/thermal performance curve. A highly liquid retail compound with great contact resistance will test well at low or moderate pressures as they hit their Bond line thickness (BLT) or average thickness relatively easily but since they are at optimum at these lower pressures adding more pressure fails to yield much of an improvement.

IC Diamond is of a much higher viscosity and has a very different pressure/ performance curve than a more liquid retail compound so at lower pressures and/or contact thermal results maybe equal or less. In paste reviews the major failure is in quantifying the mechanical aspects of what is being tested, are they @ 35lbs and 50% contact area? or 60lbs 60% contact? And how does that relate to multiple thermal/performance pressure curves of different compounds?

Note: 80% of sampled retail sinks were over 50lbs psi

Quantifying mechanical's is not realistic for the individual user but they get around that by observing multiple user results to mentally average a comparison unlike the individual anecdotal test they have a reference point(s) more or less like we are doing here providing samples for comparison.

We generated the attached charts Below from some forum user tests.

What they show is what most know already - that good C/P provides a good thermal result. What it also shows is that IC Diamond performance margins increase with over 50 psi force and with good contact margins are higher. Pressure is dominant and contact will increase with pressure.

Data point # 2 has weak pressure and poor contact resulting in a + 3.7C increase in temps over the liquid paste.

Data point # 10 with great contact and pressure shows a -5C improvement over the more liquid compound.

This is a nontrivial approx 9C spread and pretty well explains why people get different results.

Also observe Point # 6 it has a somewhat lower pressure but a higher contact hence the improved thermal

So to optimize your thermal result, apply enough compound, tighten your sink and do some lapping

- Joined

- 7 Dec 2010

- Posts

- 223

Is "bake out" when the TIM turns hard & crusty? I've had this with some thermal compounds & this is the reason why I have stuck with AS5 as it gives me consistent results over time rather than being amazingly cool for a few weeks then temps begin creeping up. My system does run quite warm (low 60s).

We did some thermal stress testing on IC diamond (ICD) against the more popular retail compounds all failed except ICD in this test.