Associate

- Joined

- 11 Dec 2012

- Posts

- 90

Hey guys,

For a long time i've been wanting to make a small pc for the tv so when i saw the announcement of the Intel NUC/Bit-tech competition i thought i would send in a design and see how it goes. Sadly I didn't get picked for the competition but in the true spirit of modding i bought all the parts instead so i can still make a case.

Background:

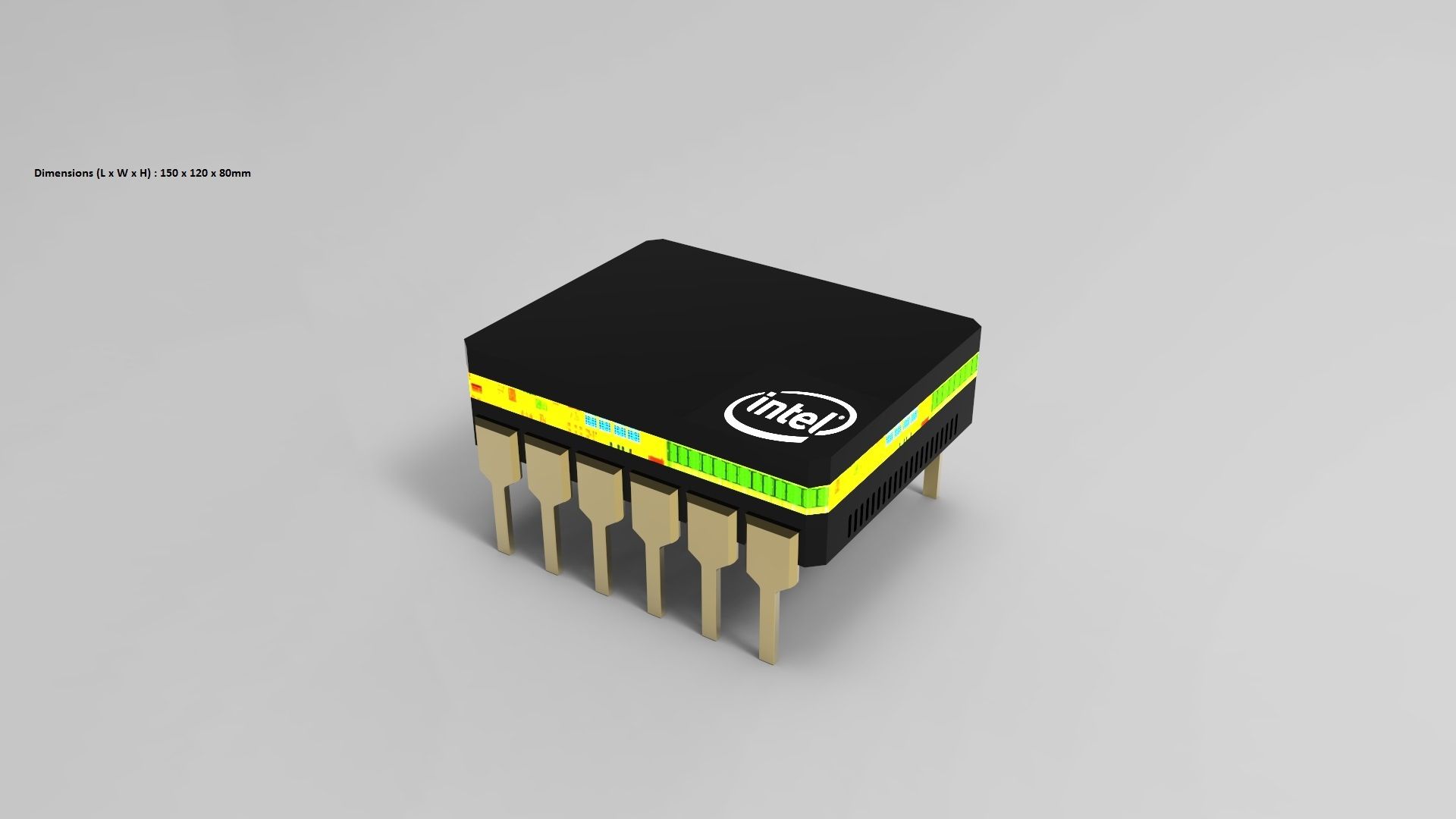

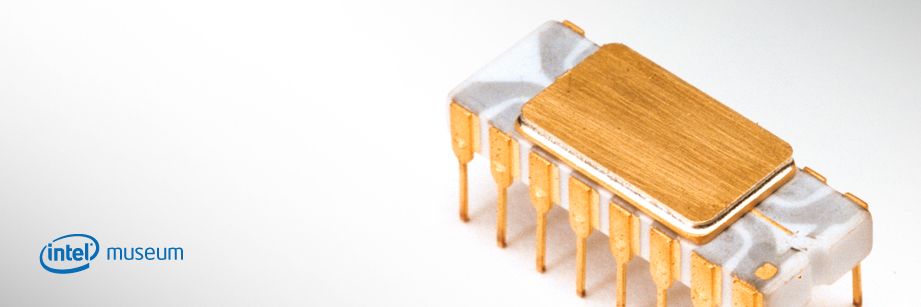

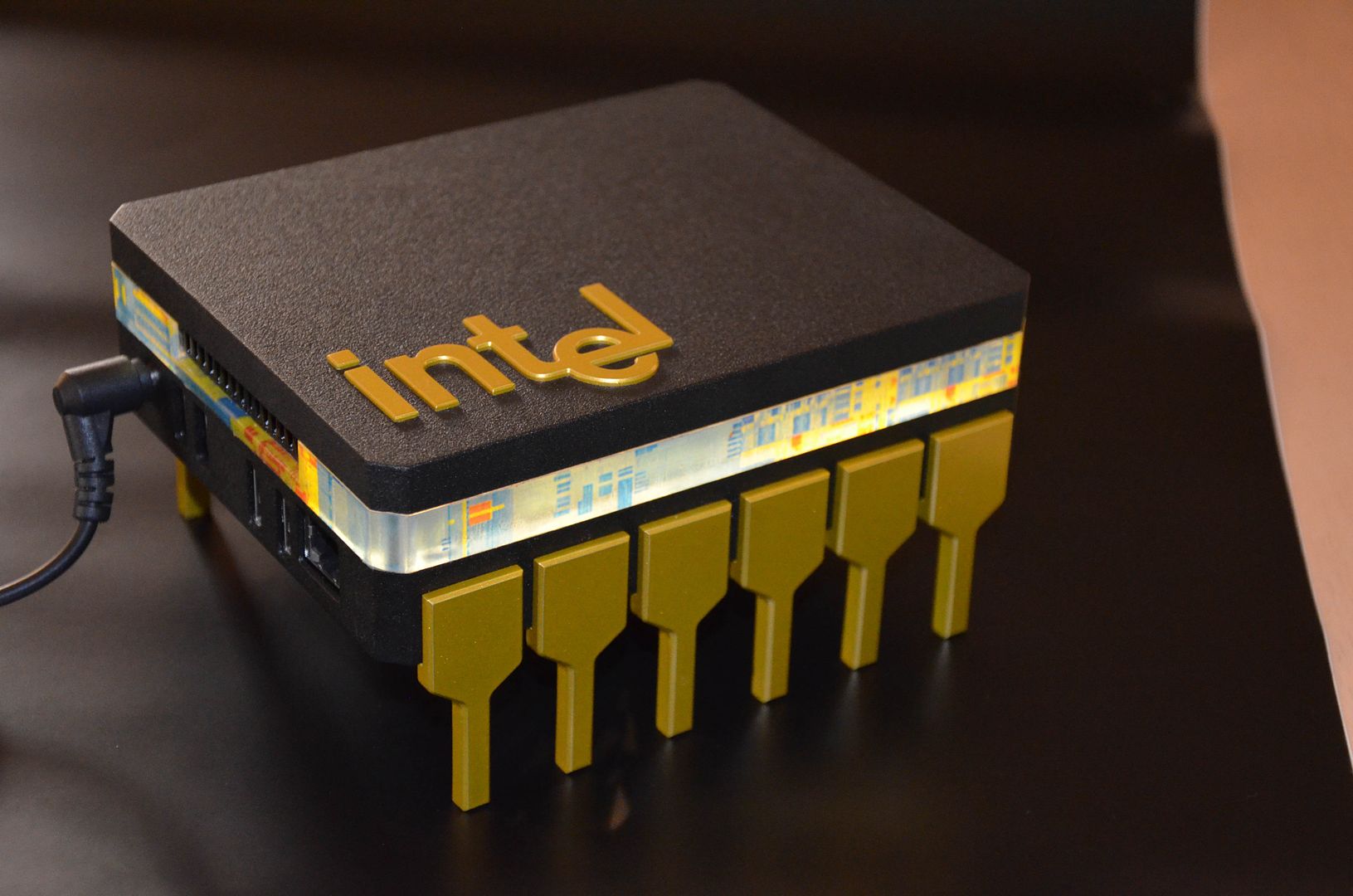

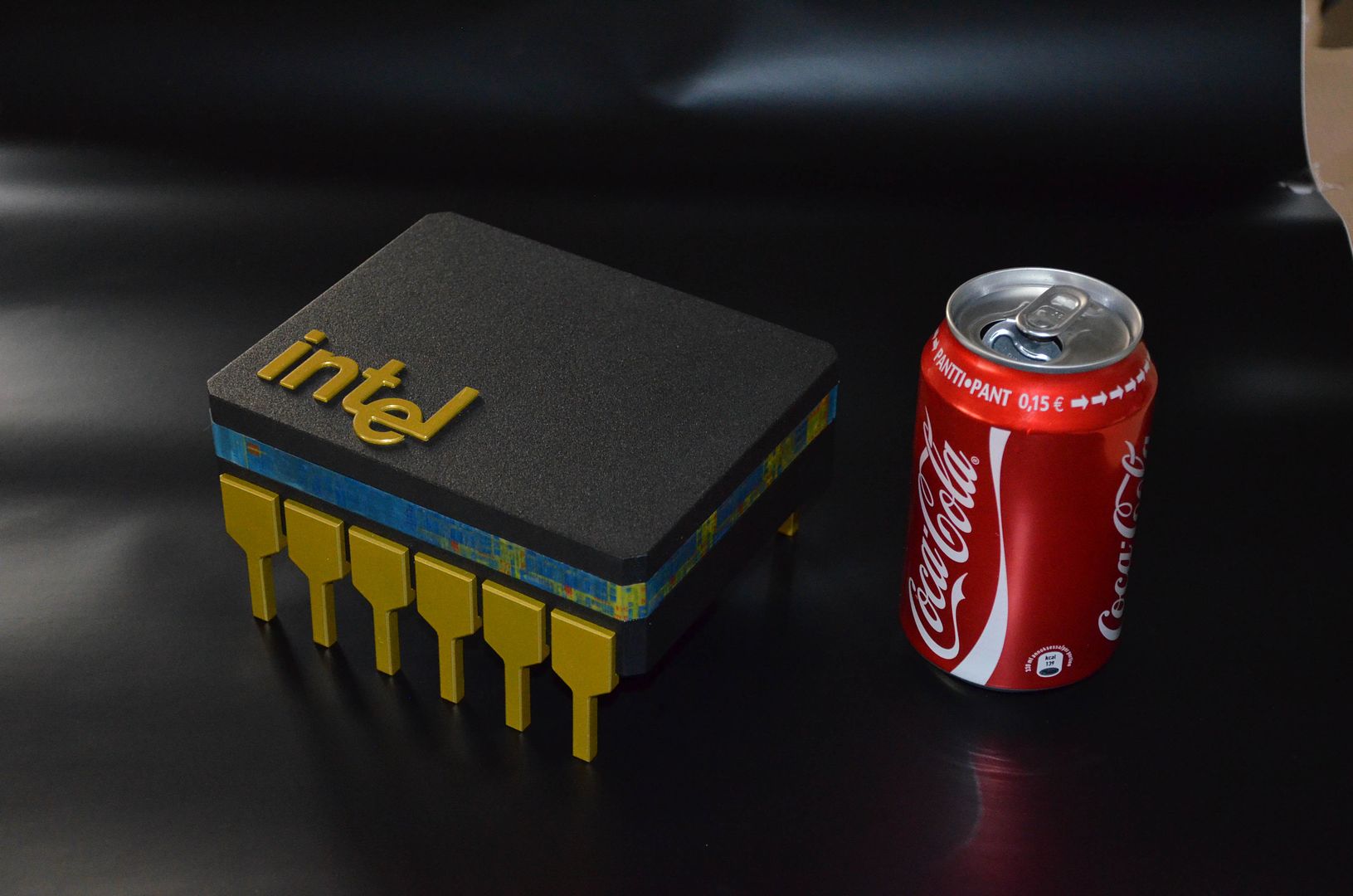

When i first saw the Intel NUC and its small size i knew it would be perfect for my needs. When thinking of a design for the competition i started looking at Intel's old microprocessors and what they meant for the general public back in the days. These nuc motherboards are a bit of the same in my mind seeing they are quite powerful for their very small form factor. Anyways, enough of that

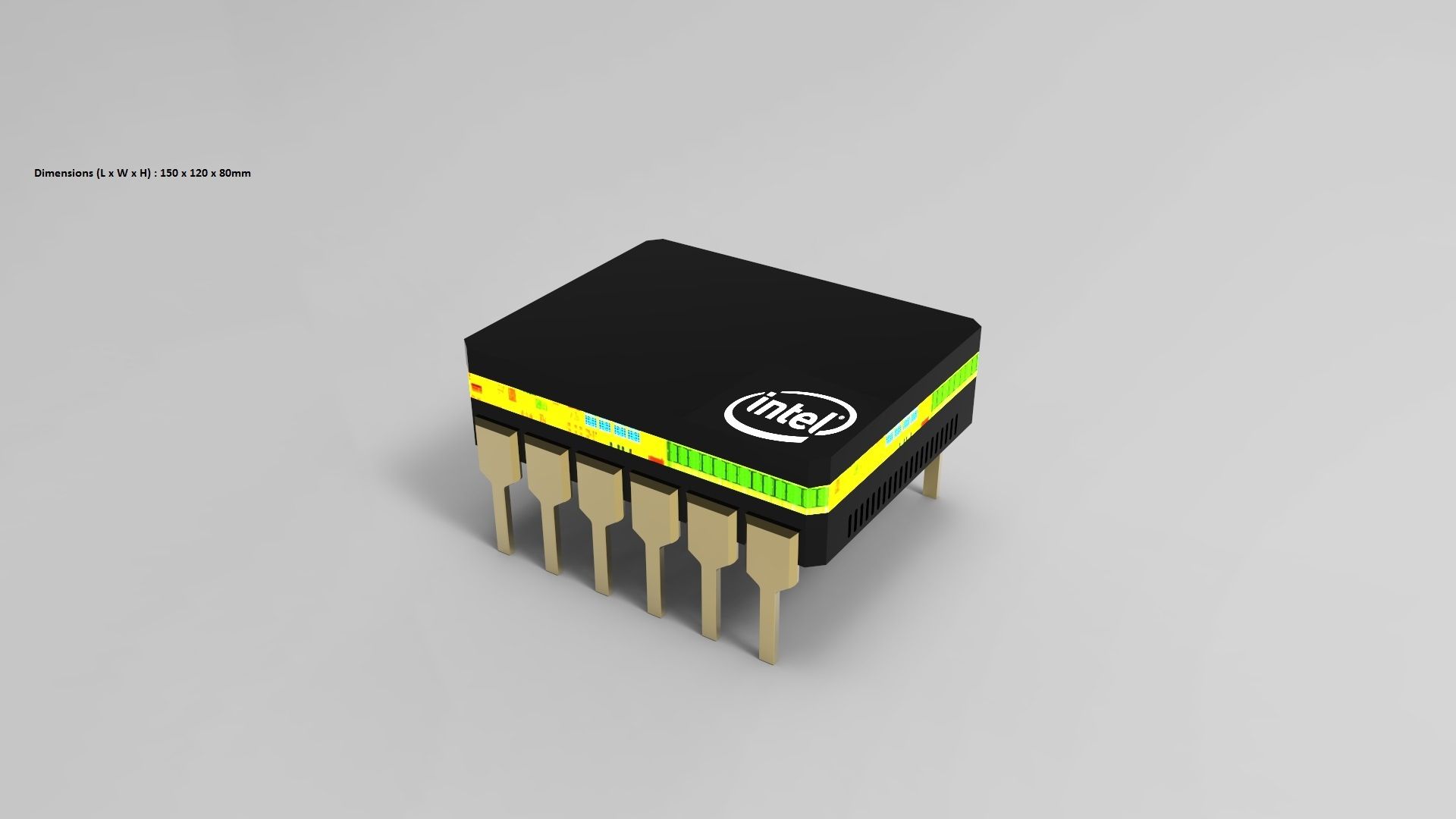

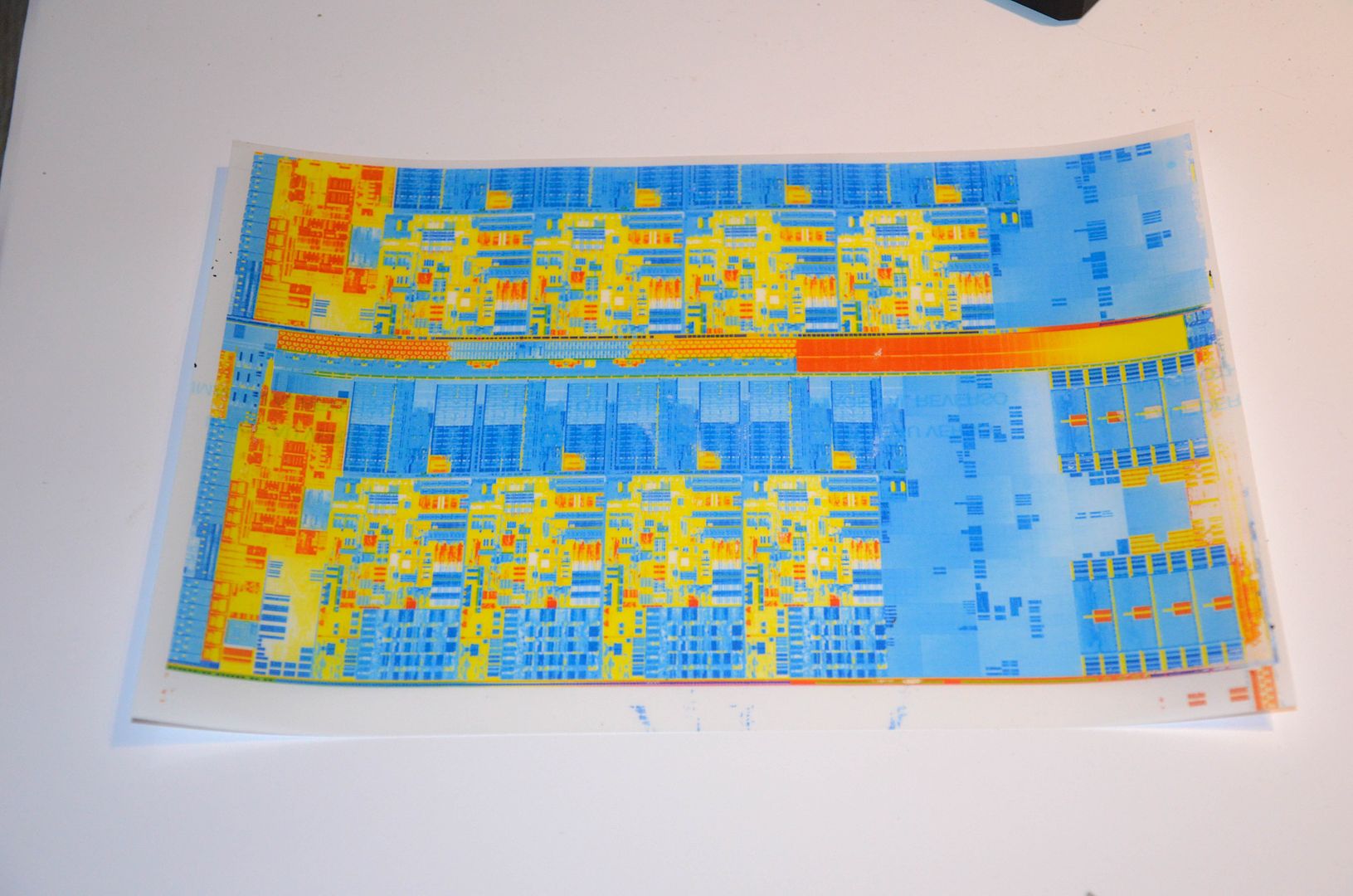

This is the design i sent in for the competition. It has changed quite a bit but i don't have any better ones.

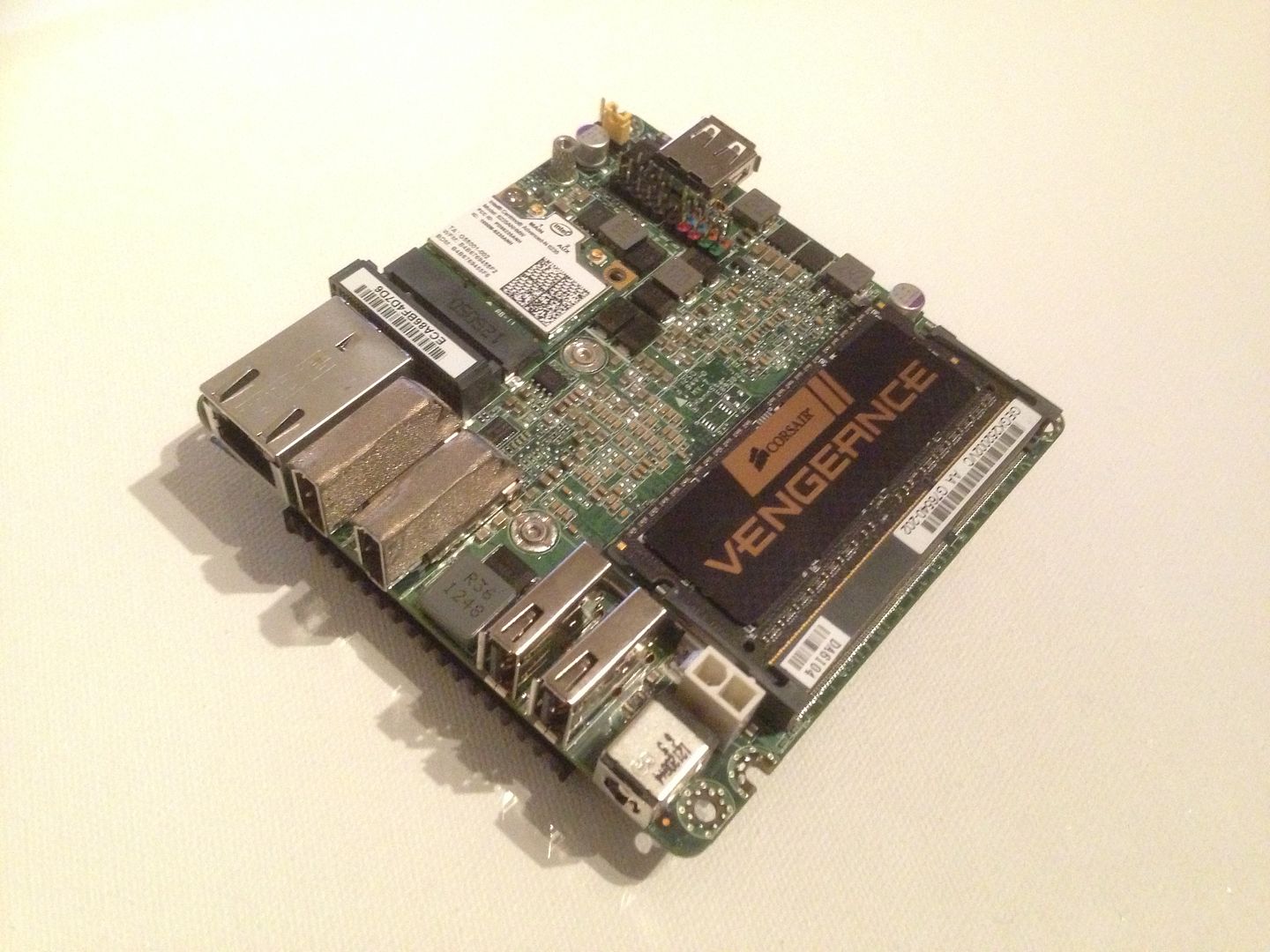

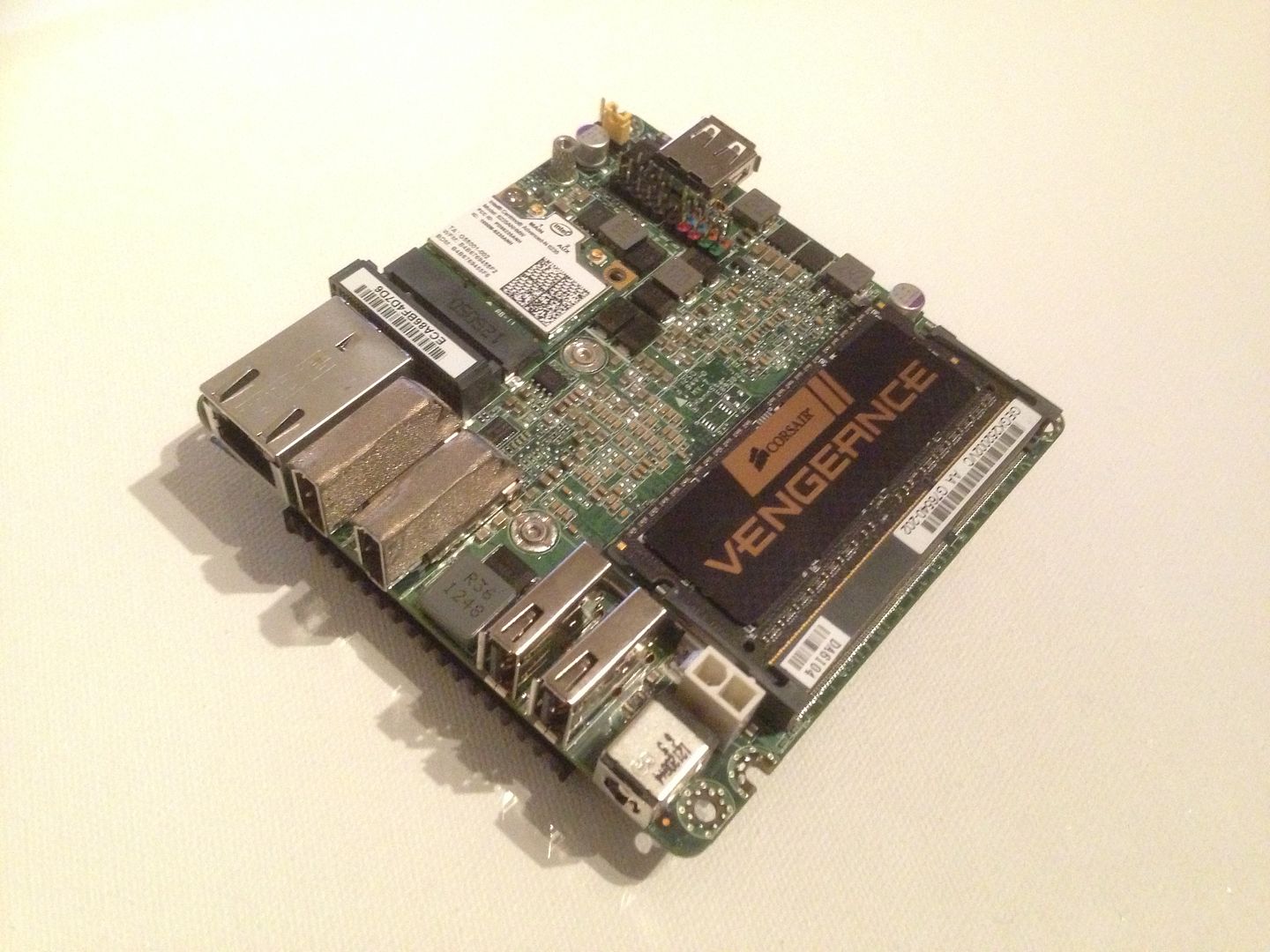

Decided on a different version (still an i3) but with an wired network and no thunderbolt as i have no need for thunderbolt as of now and it was a bit cheaper

Nuc, 8GB of vengence 1600 ram and a wireless & BT card from Intel

120GB Kingston SSD

Now that that is over lets start with the build pictures

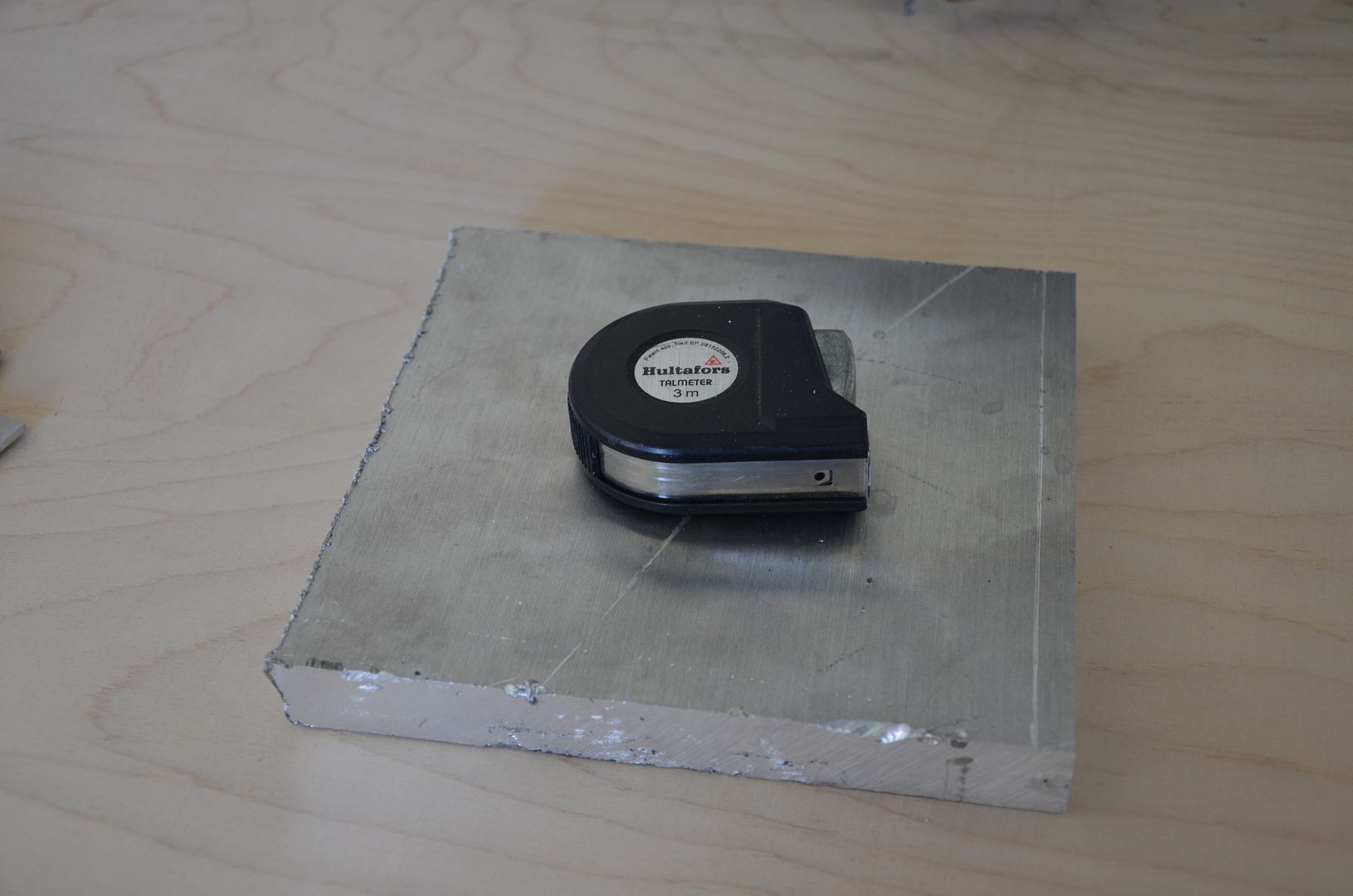

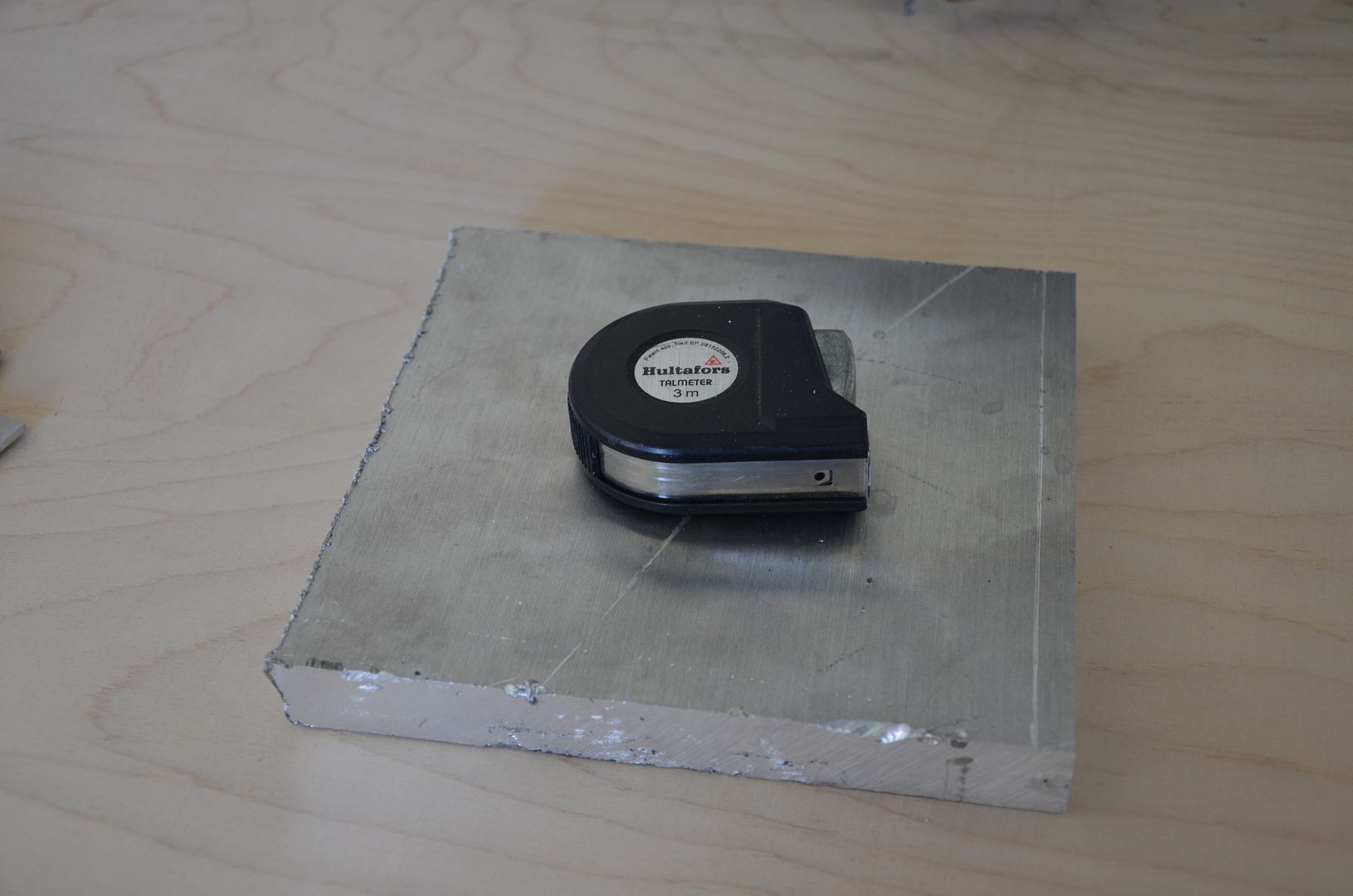

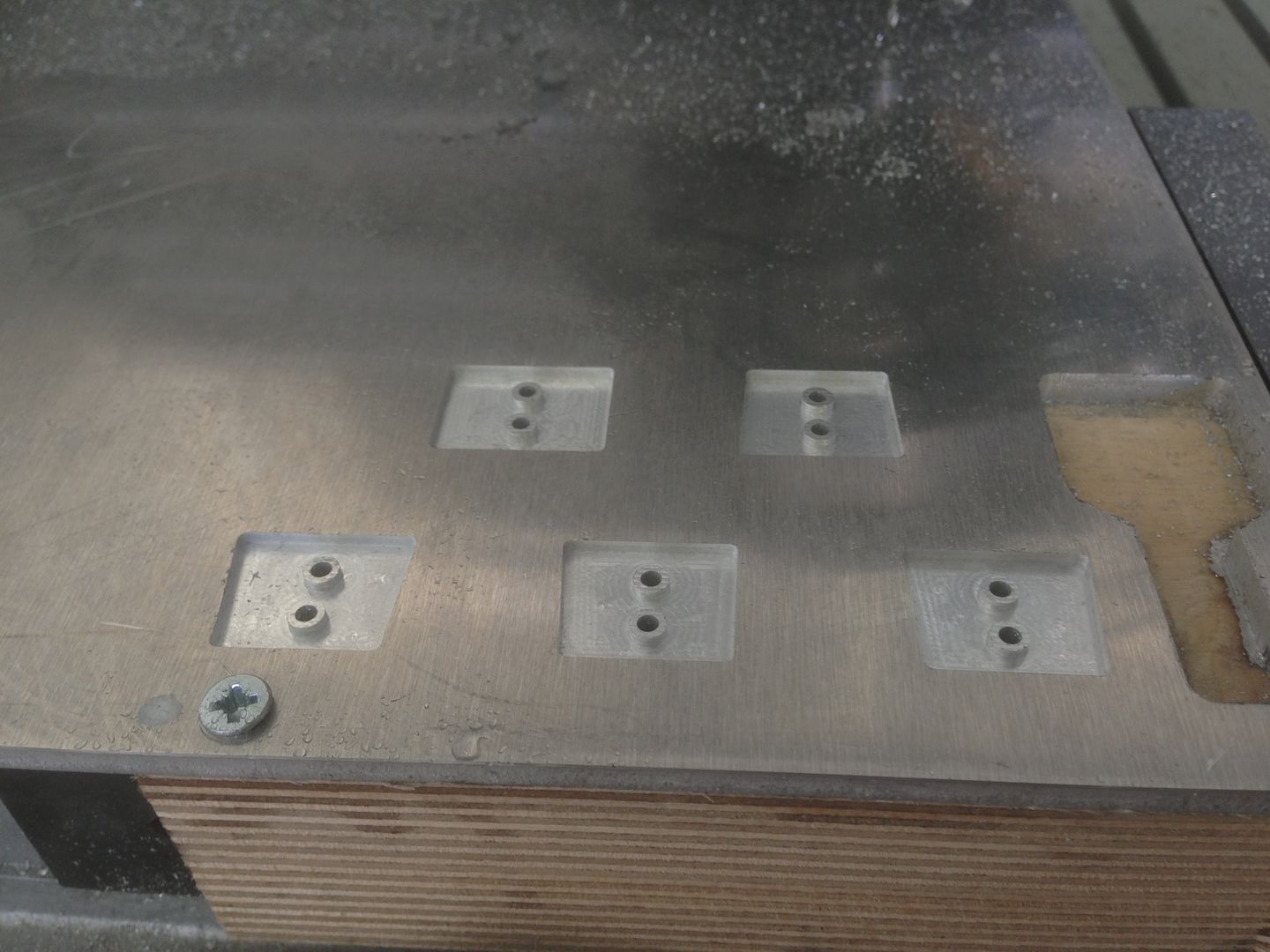

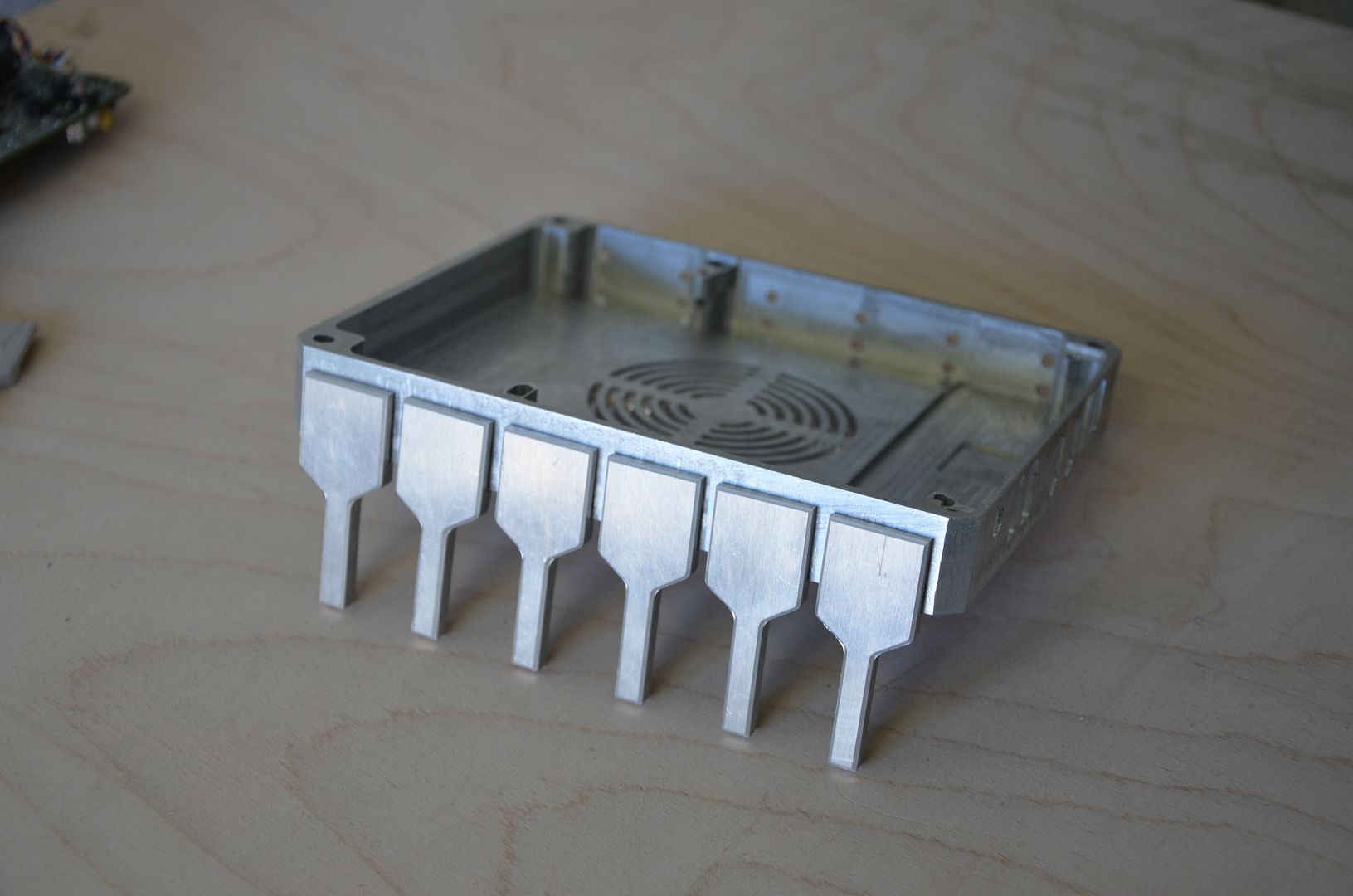

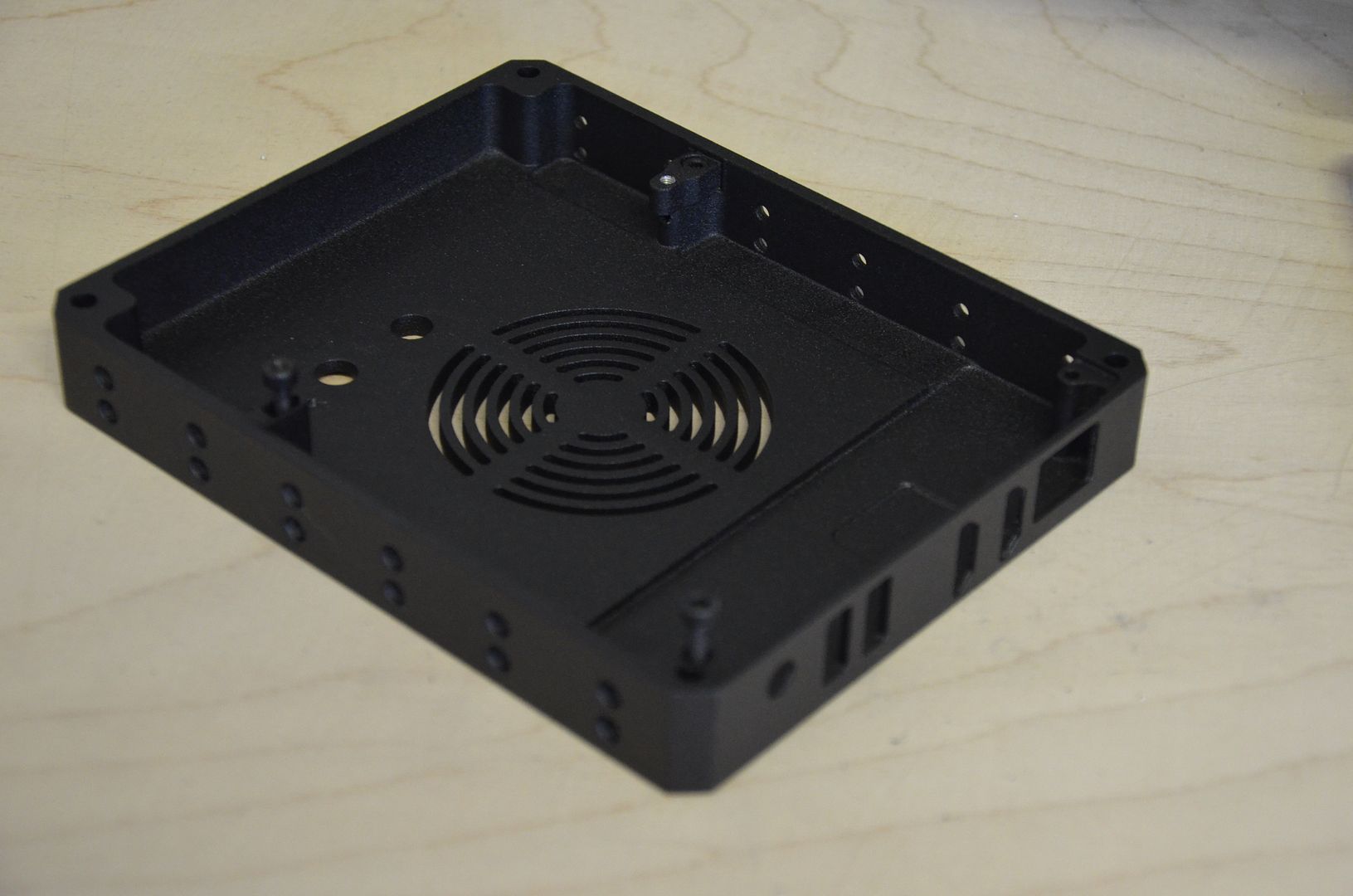

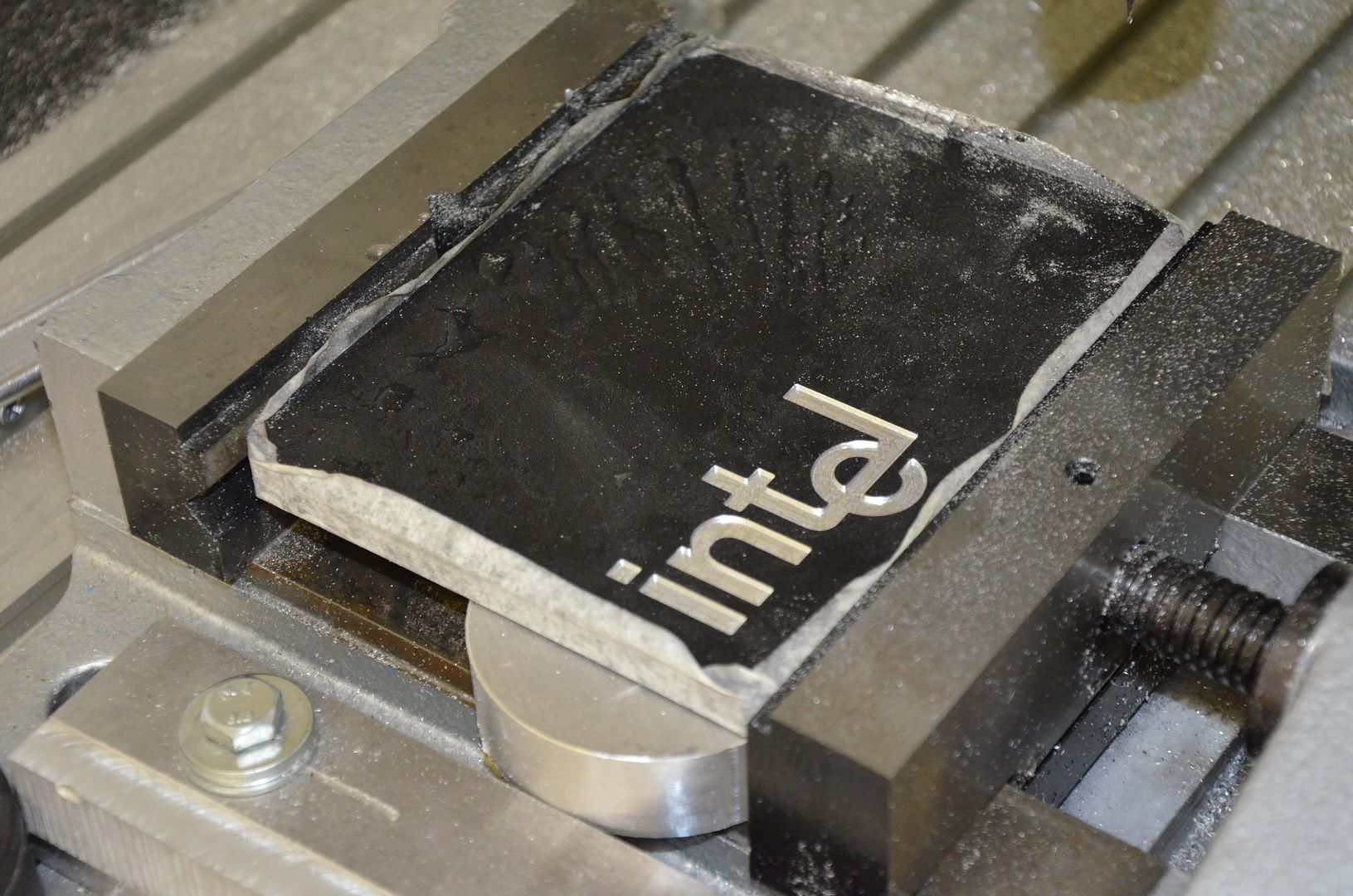

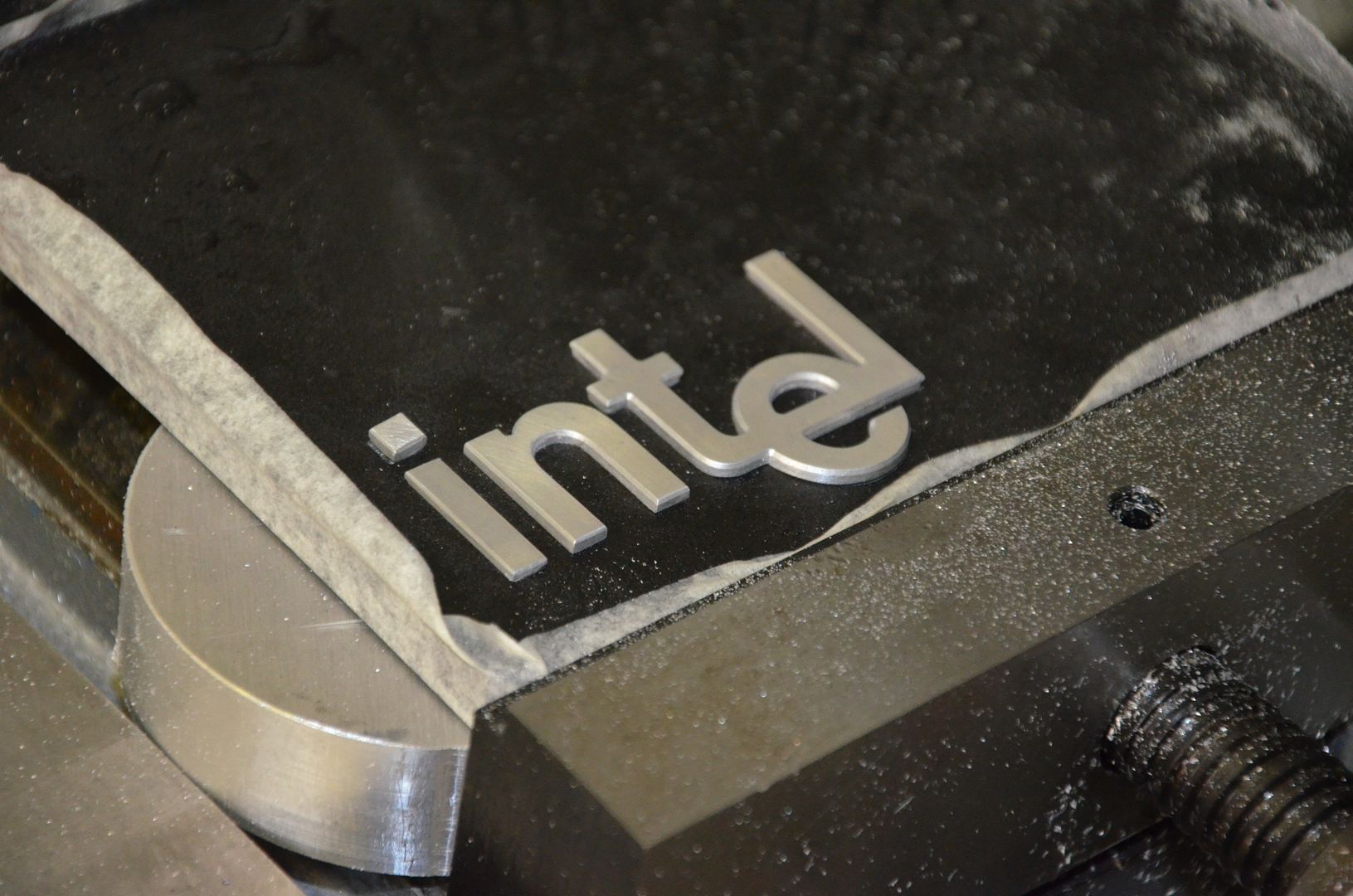

200x200x20mm piece of aluminum cut with a circular saw, worked a lot better than i thought it would.

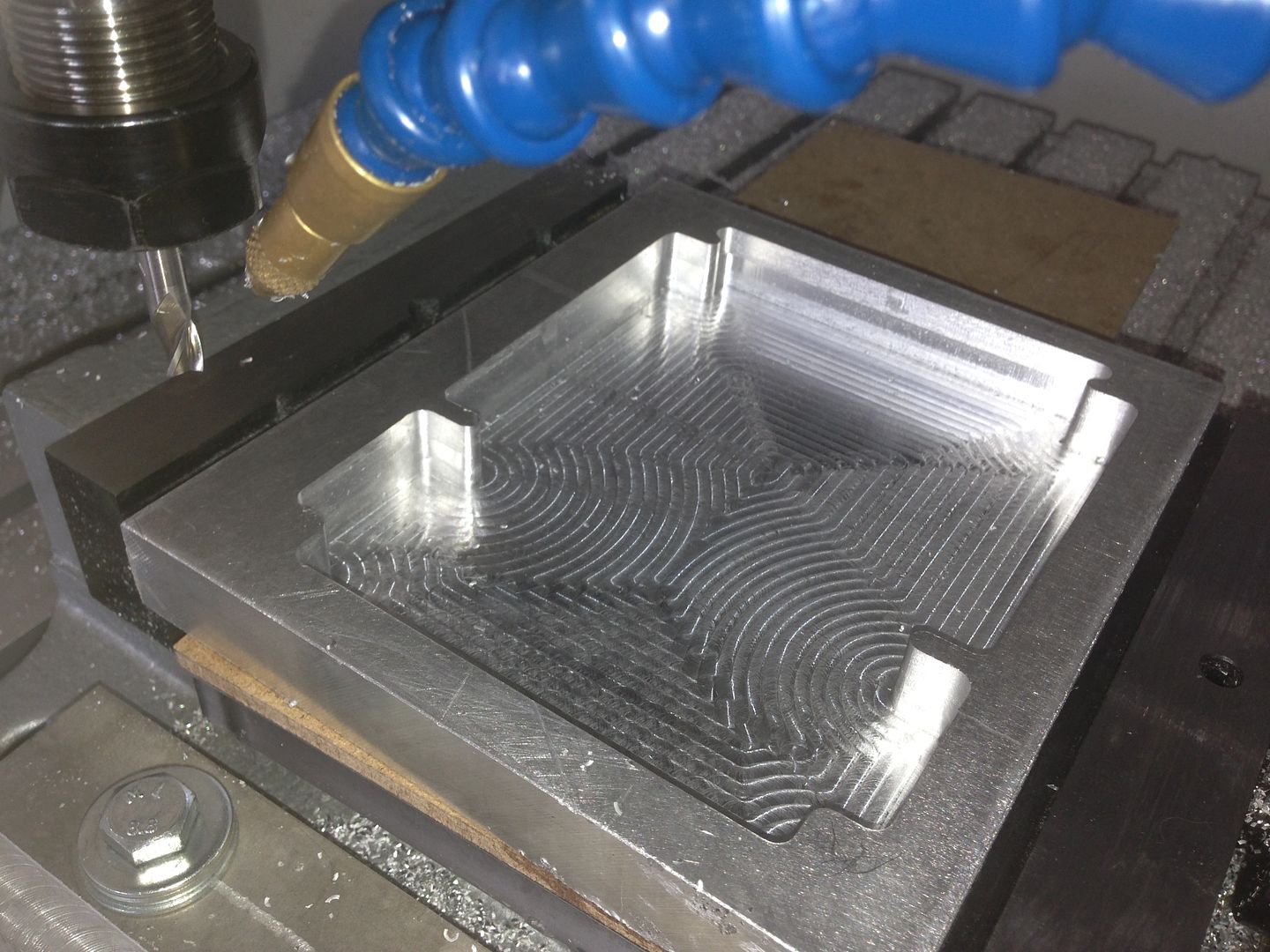

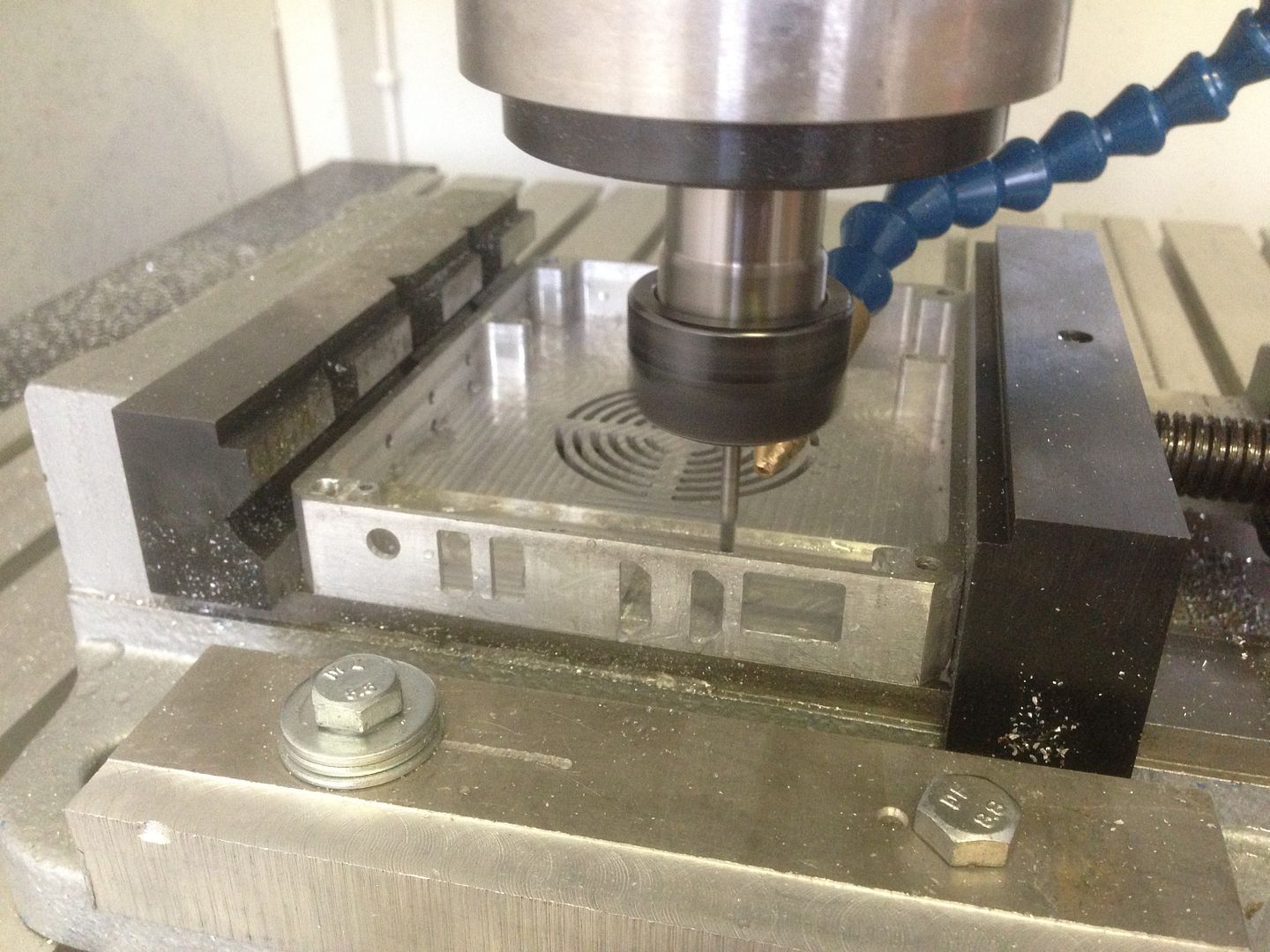

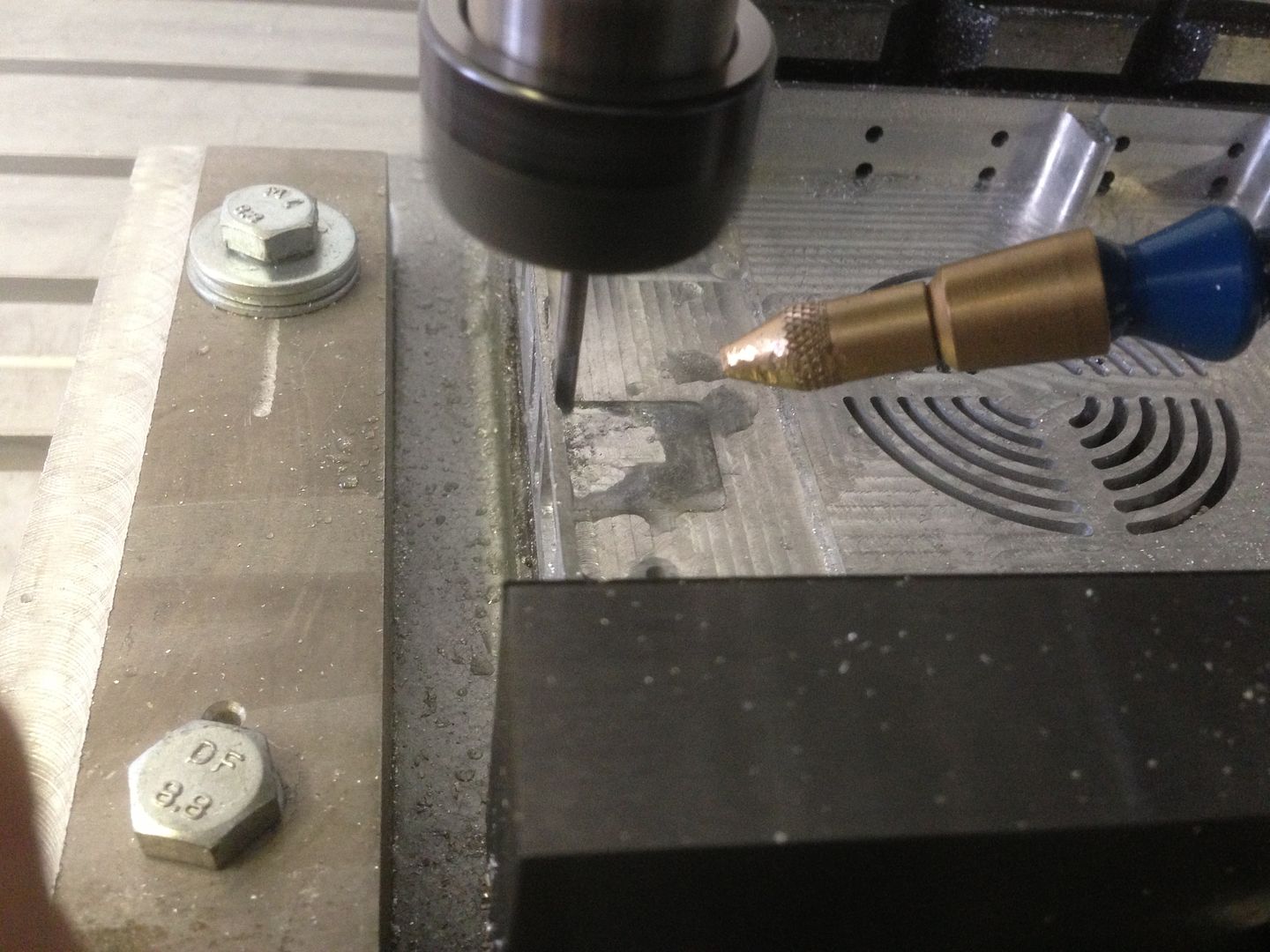

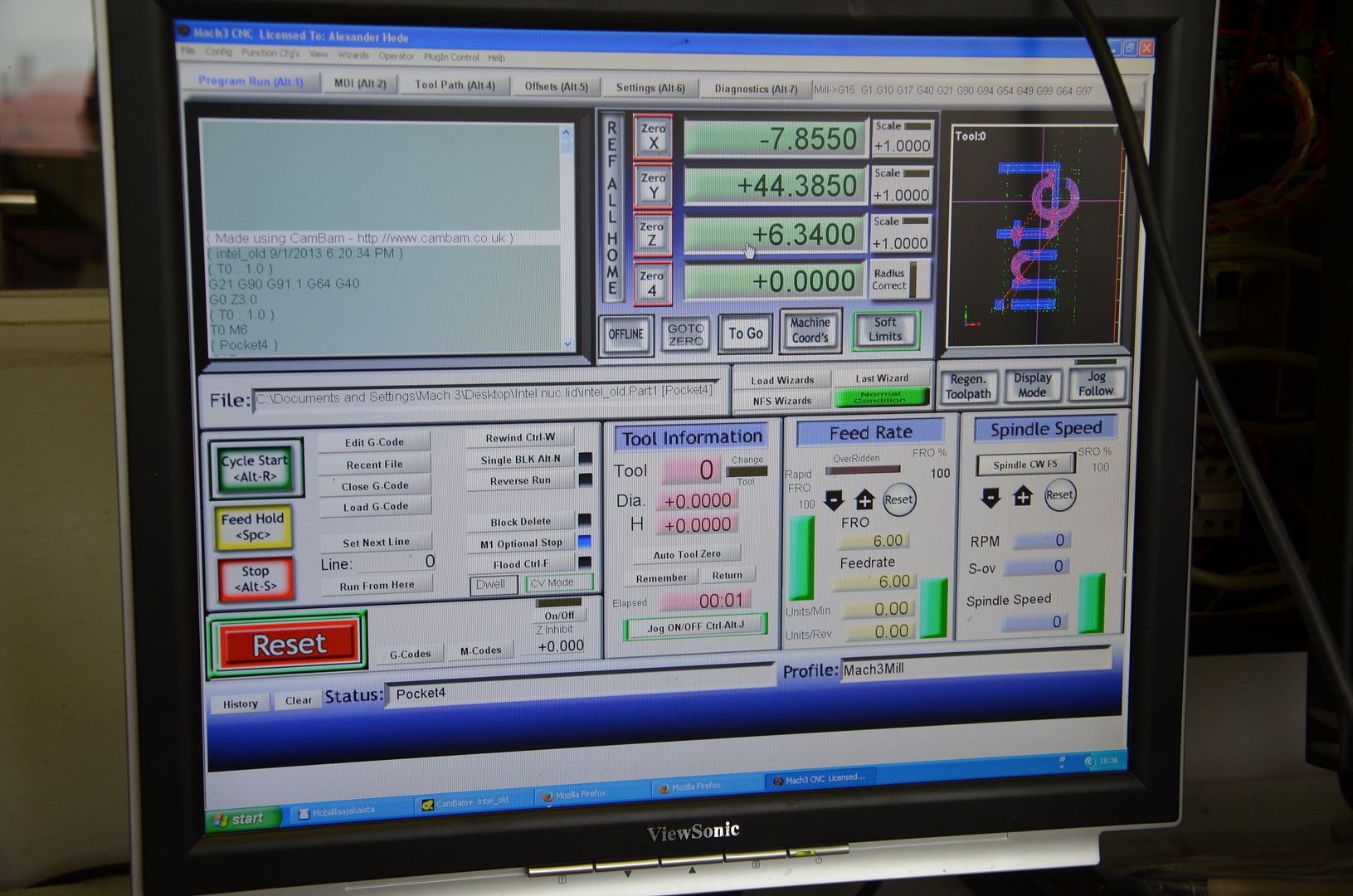

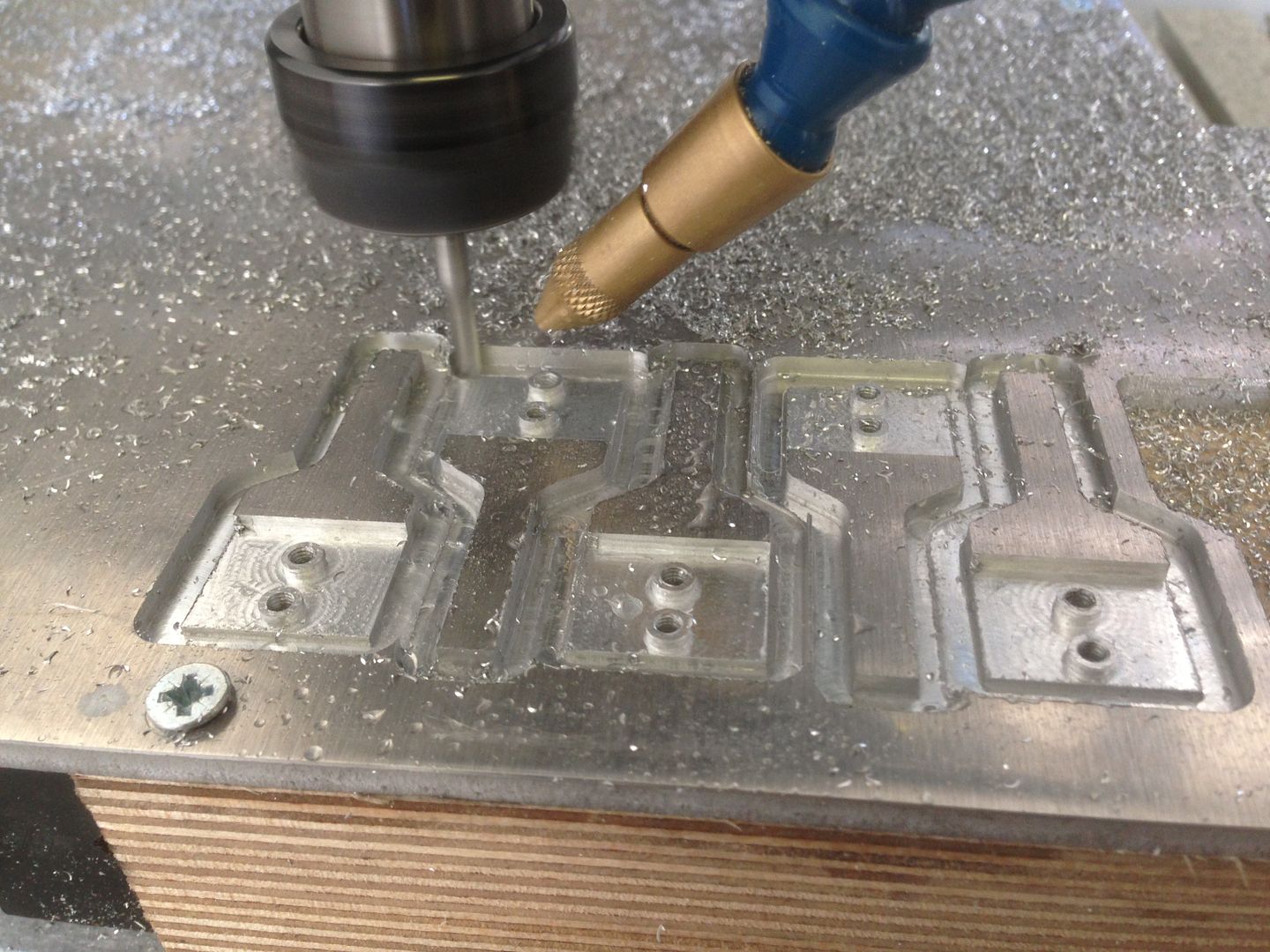

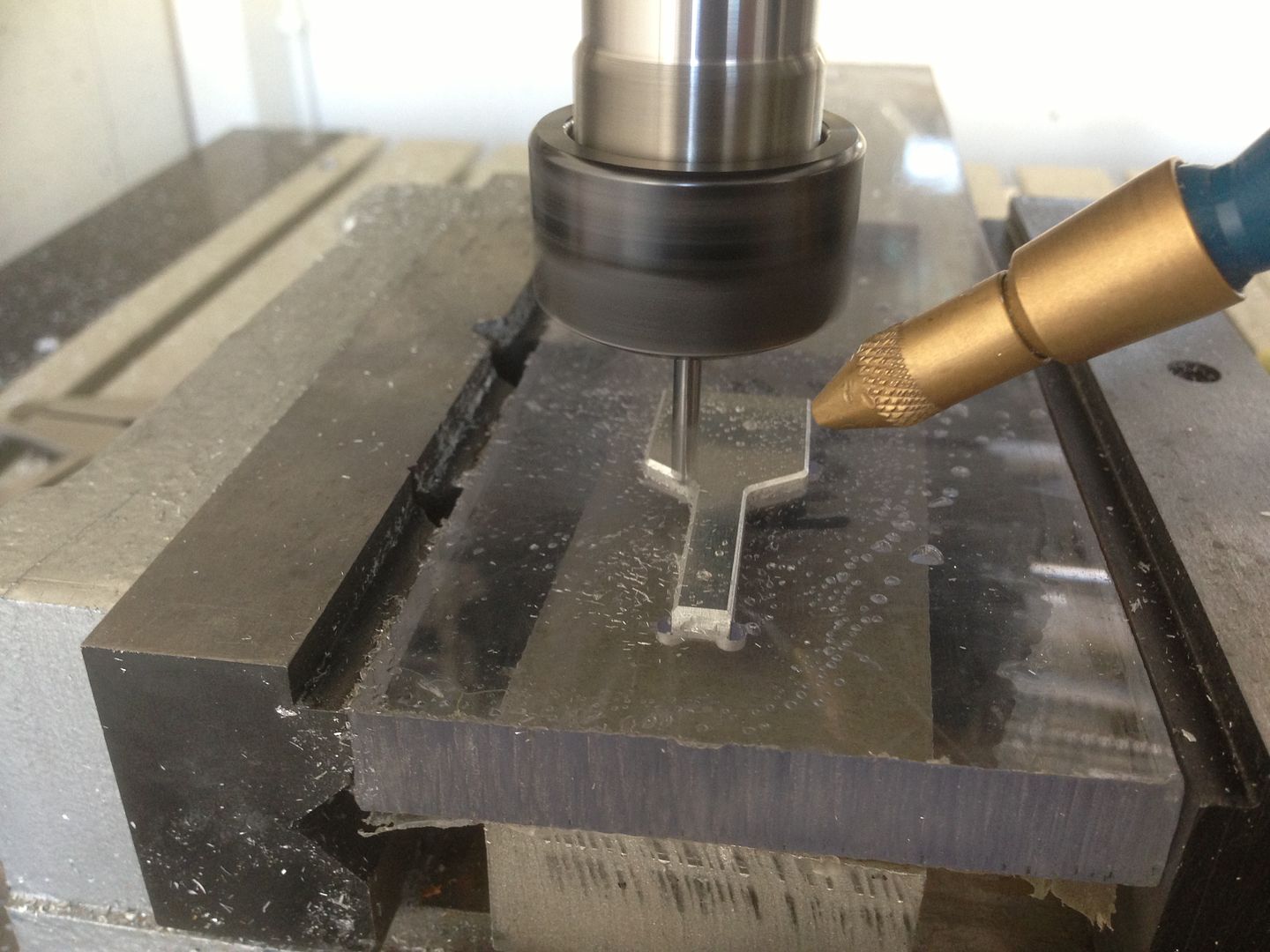

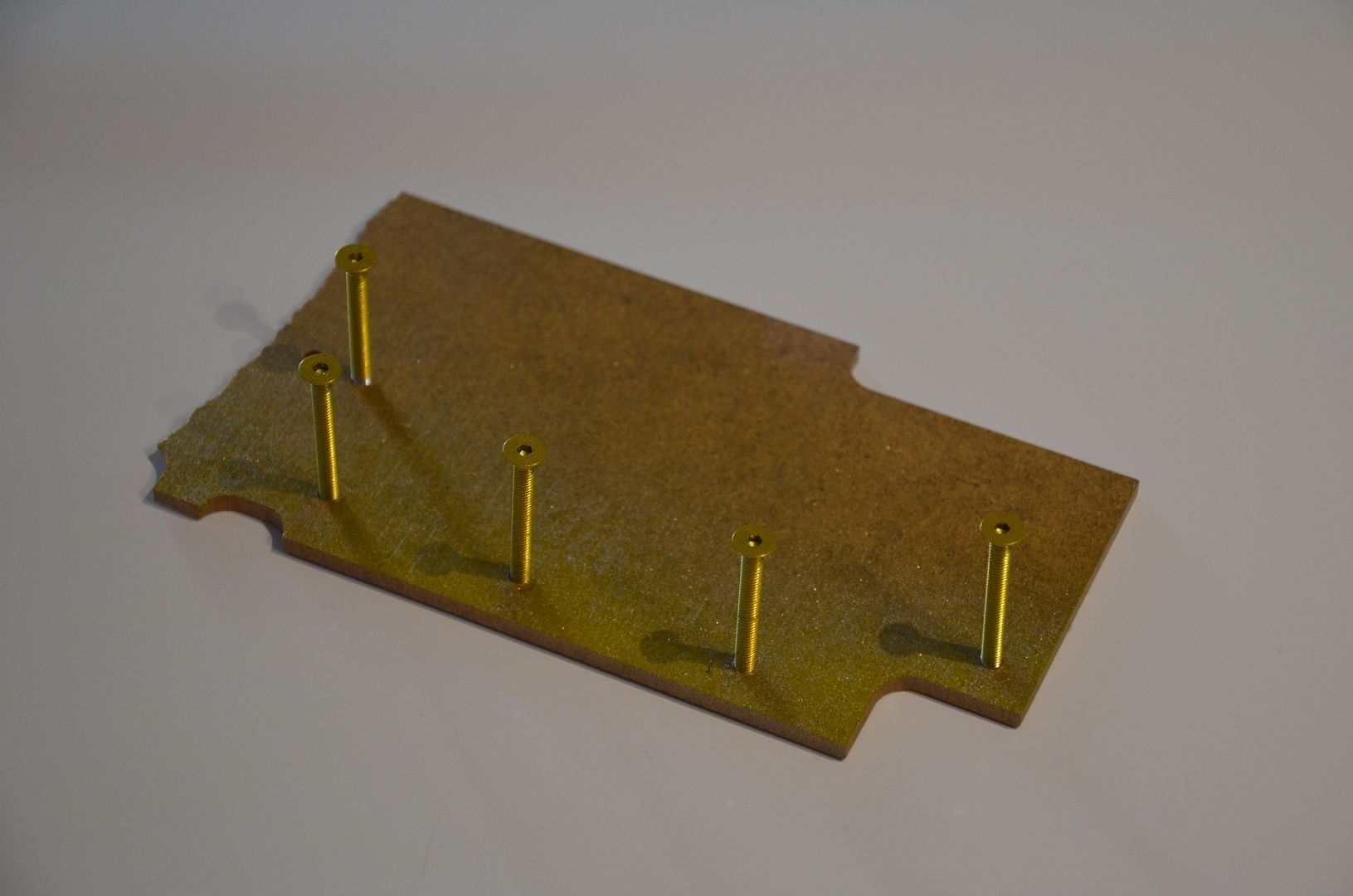

As i recently finished upgrading my homebuilt CNC mill/router i thought i would put it to the test during this build

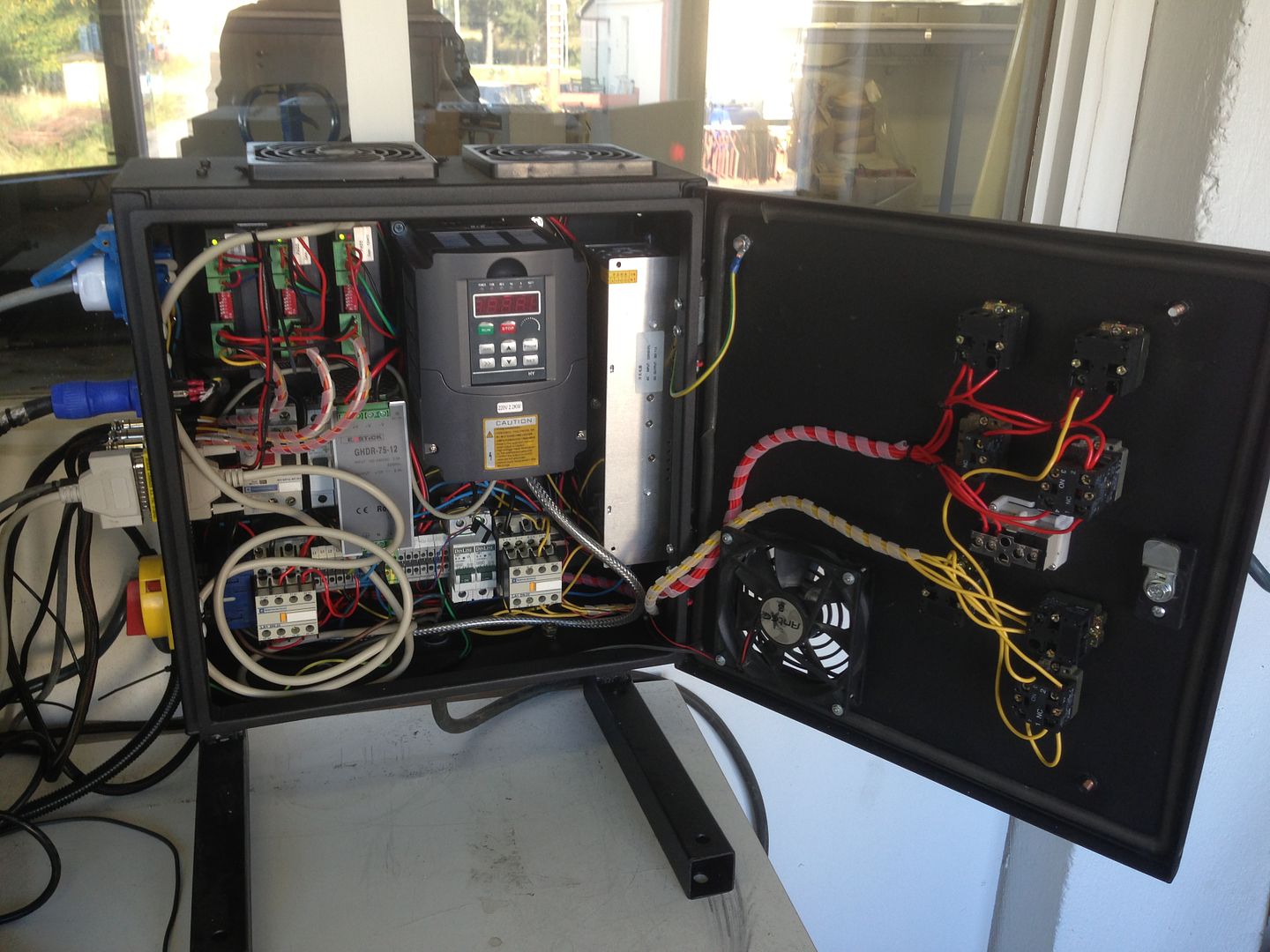

The Mill

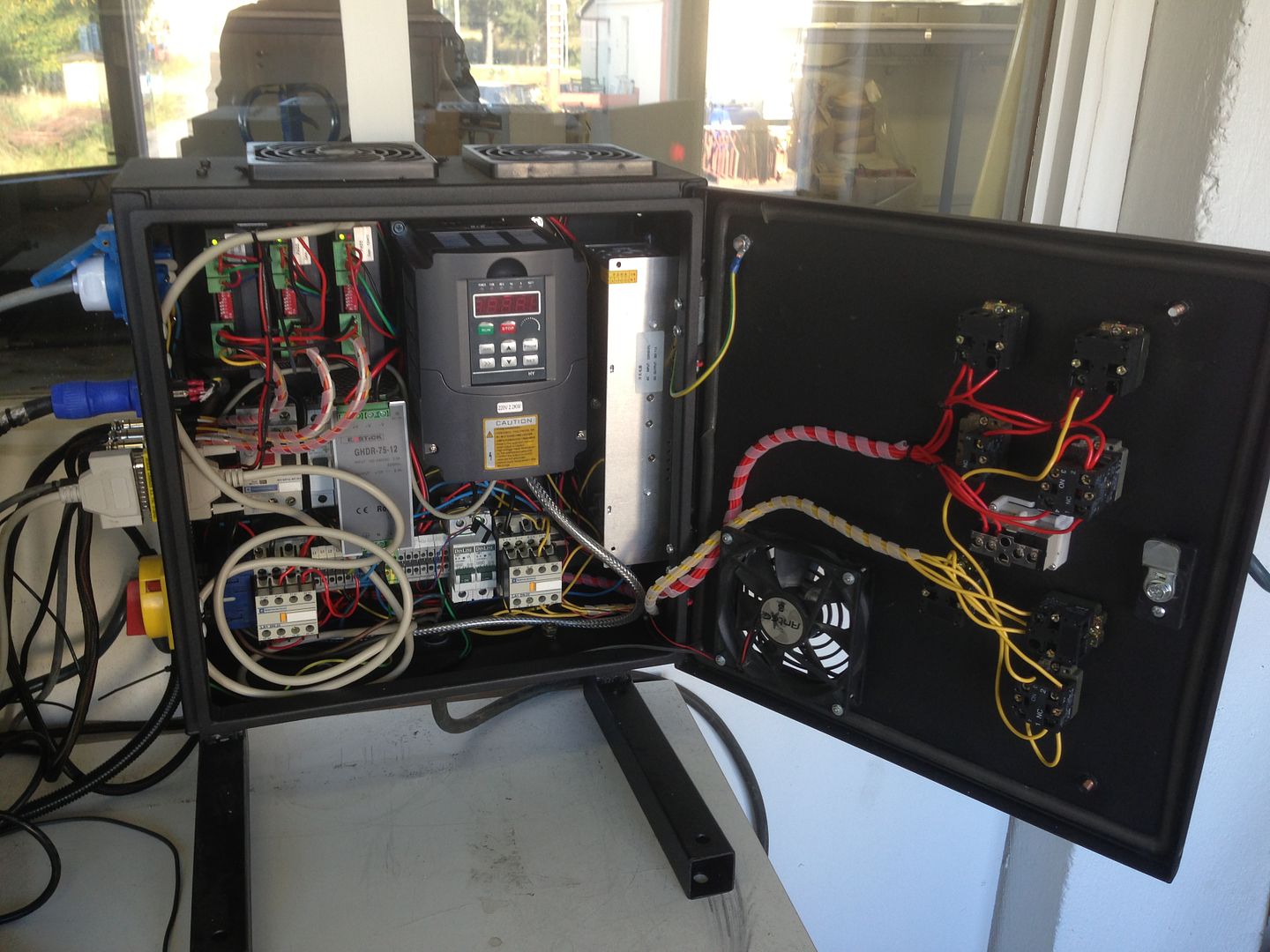

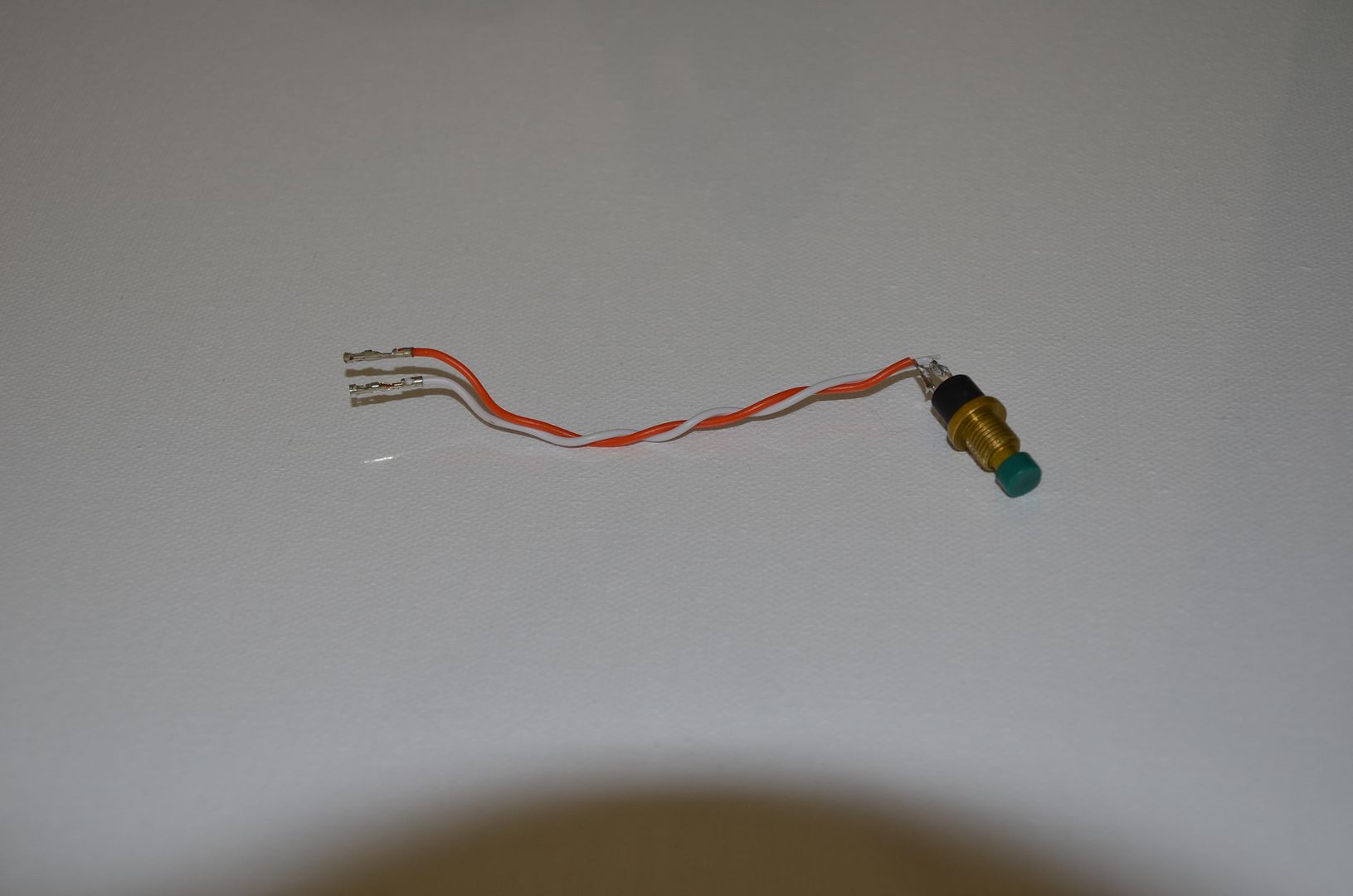

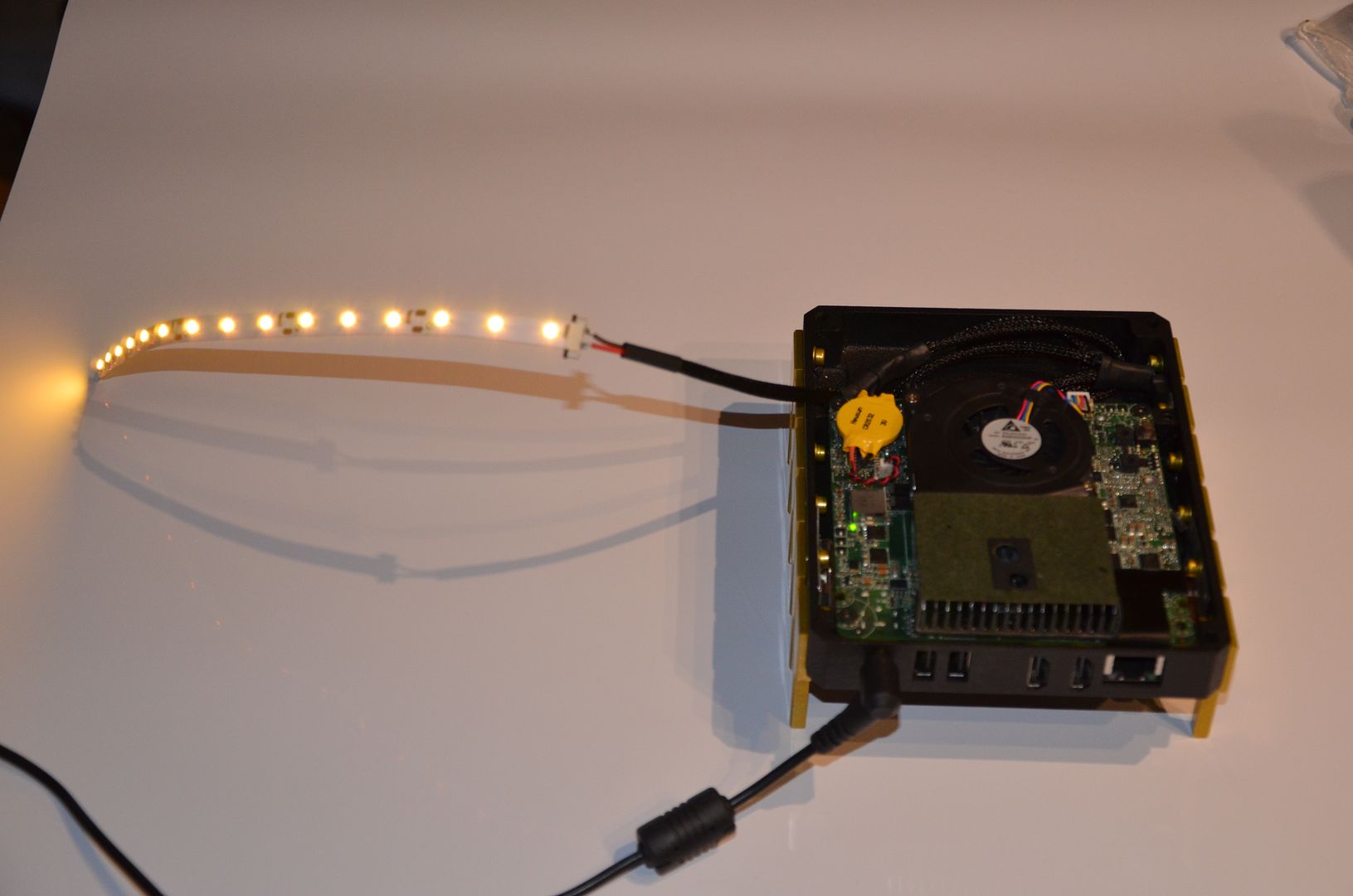

Took me a while with the electronics since im no electrician and don't have a lot of skills with it, luckily no smoke

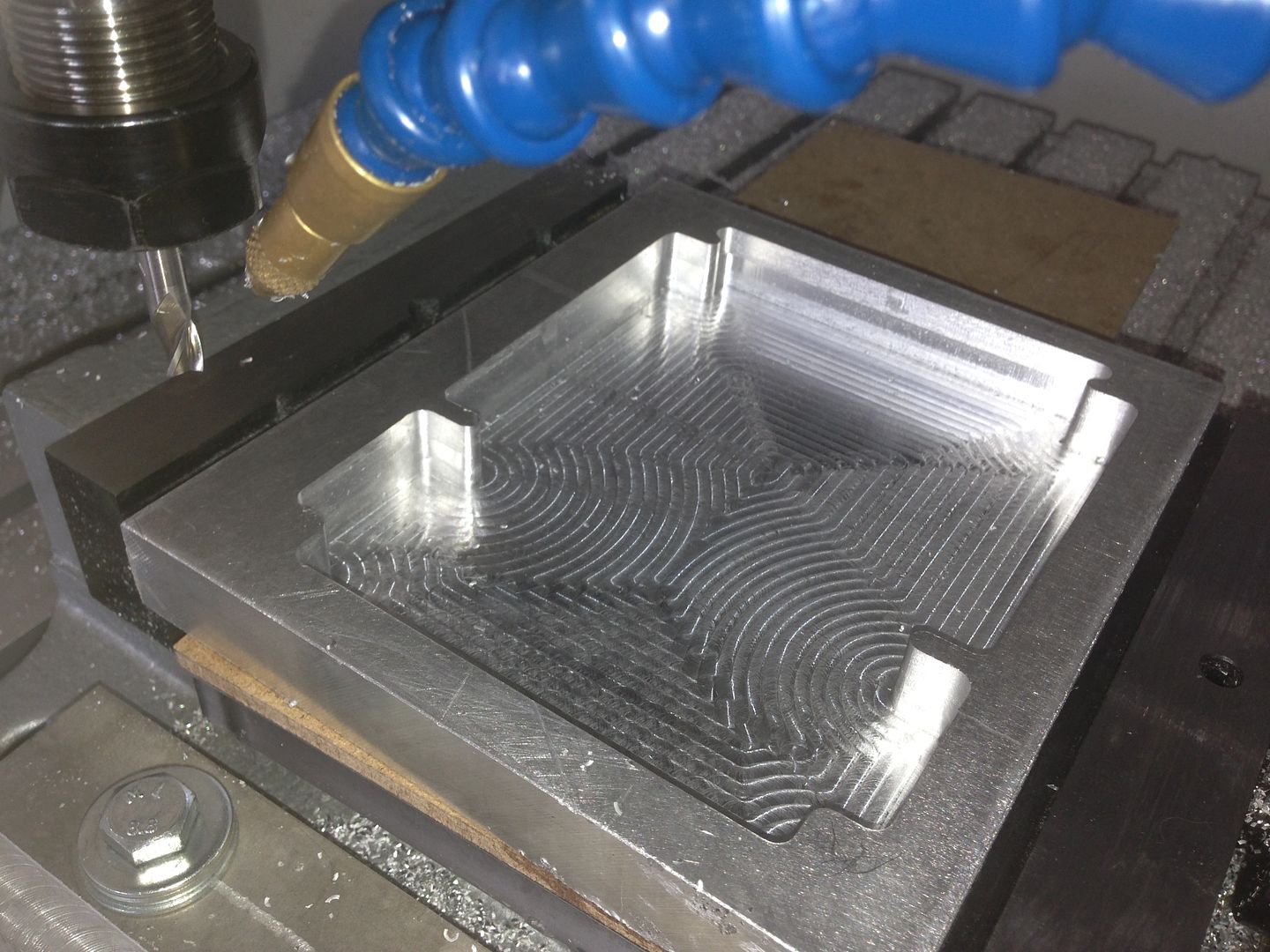

A bit of roughing with a 6mm endmill

More pictures soon as i have gotten a bit further than this.

Hope you like it and please drop a comment

For a long time i've been wanting to make a small pc for the tv so when i saw the announcement of the Intel NUC/Bit-tech competition i thought i would send in a design and see how it goes. Sadly I didn't get picked for the competition but in the true spirit of modding i bought all the parts instead so i can still make a case.

Background:

When i first saw the Intel NUC and its small size i knew it would be perfect for my needs. When thinking of a design for the competition i started looking at Intel's old microprocessors and what they meant for the general public back in the days. These nuc motherboards are a bit of the same in my mind seeing they are quite powerful for their very small form factor. Anyways, enough of that

This is the design i sent in for the competition. It has changed quite a bit but i don't have any better ones.

Decided on a different version (still an i3) but with an wired network and no thunderbolt as i have no need for thunderbolt as of now and it was a bit cheaper

Nuc, 8GB of vengence 1600 ram and a wireless & BT card from Intel

120GB Kingston SSD

Now that that is over lets start with the build pictures

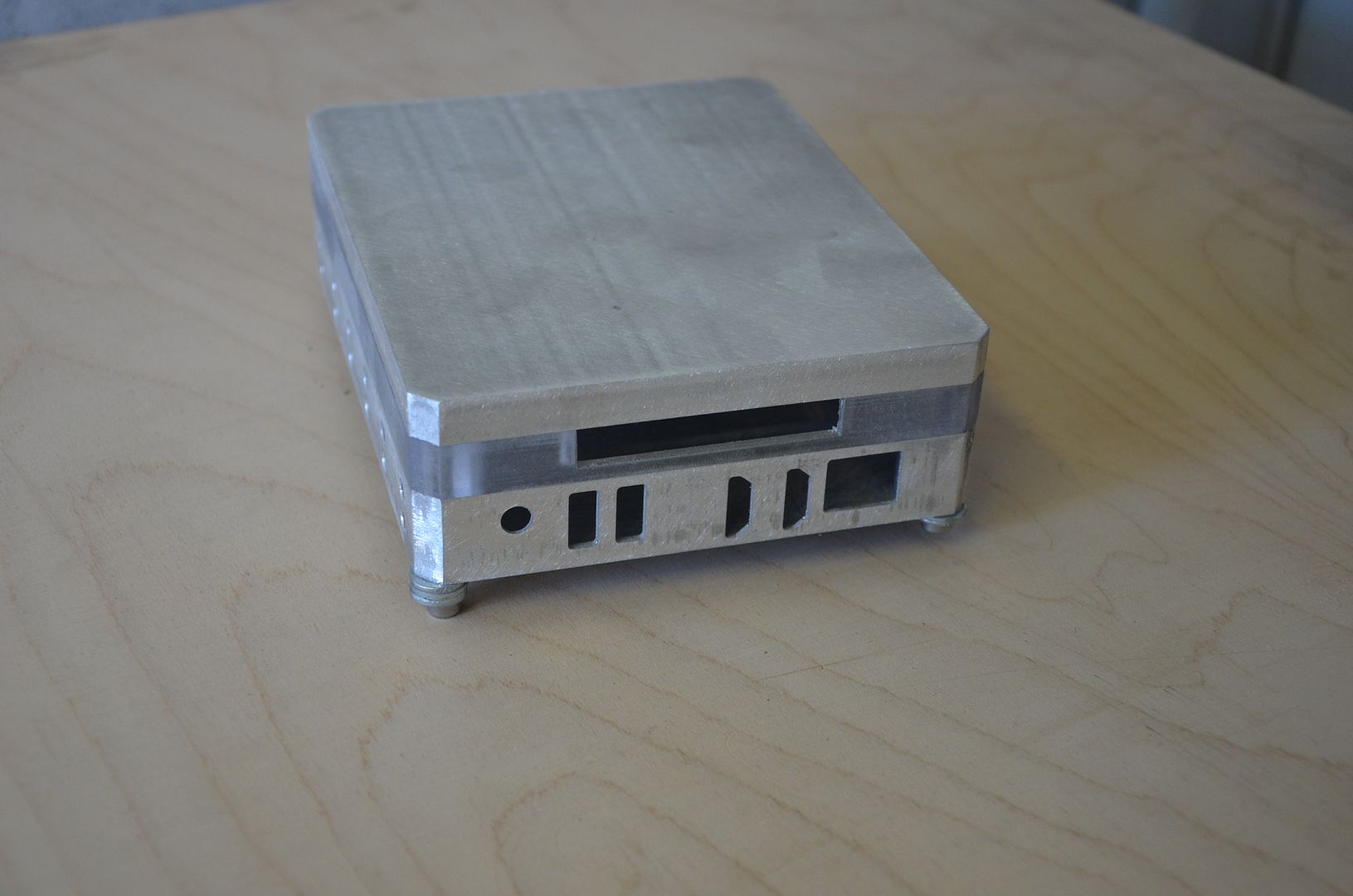

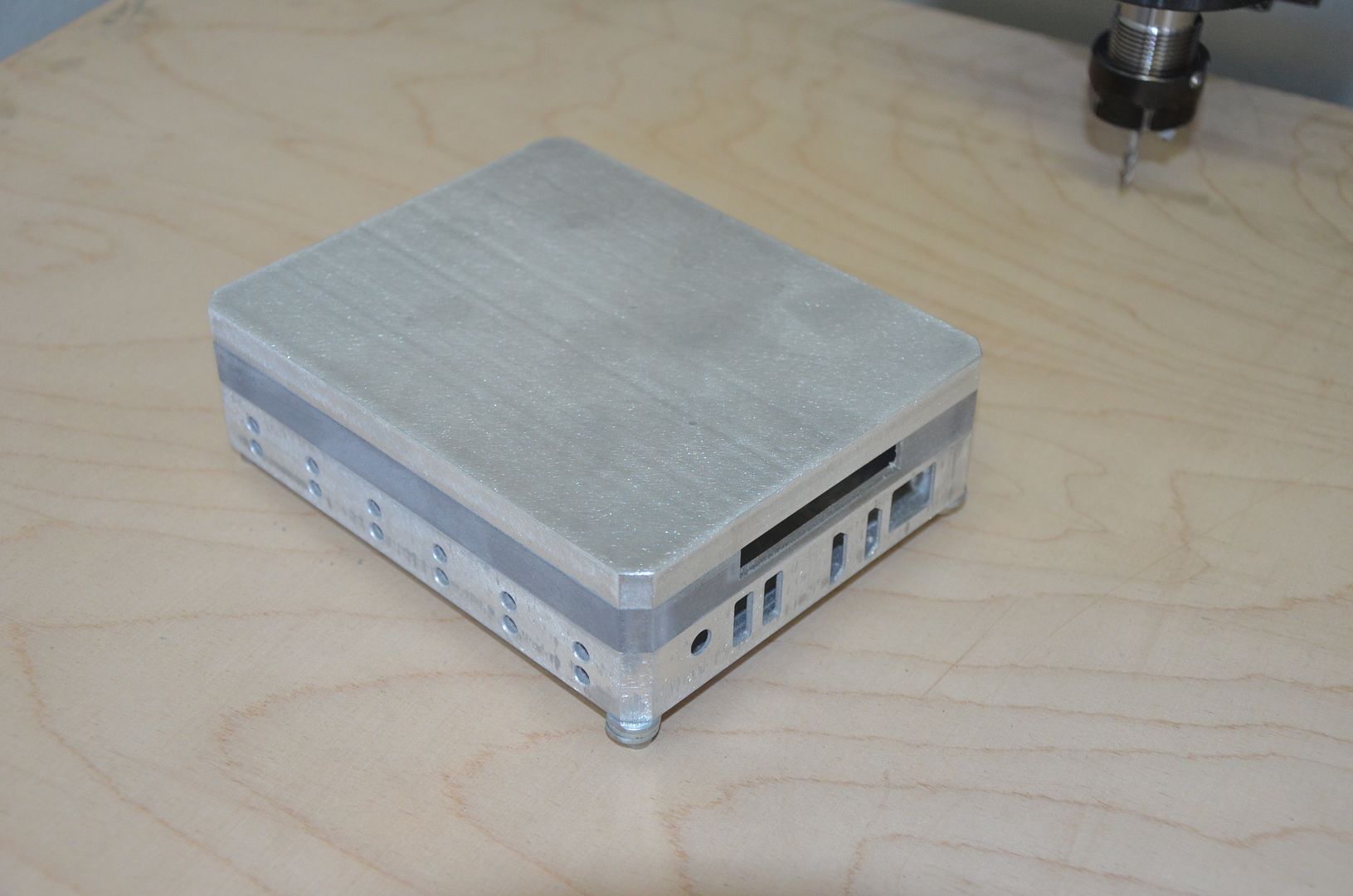

200x200x20mm piece of aluminum cut with a circular saw, worked a lot better than i thought it would.

As i recently finished upgrading my homebuilt CNC mill/router i thought i would put it to the test during this build

The Mill

Took me a while with the electronics since im no electrician and don't have a lot of skills with it, luckily no smoke

A bit of roughing with a 6mm endmill

More pictures soon as i have gotten a bit further than this.

Hope you like it and please drop a comment

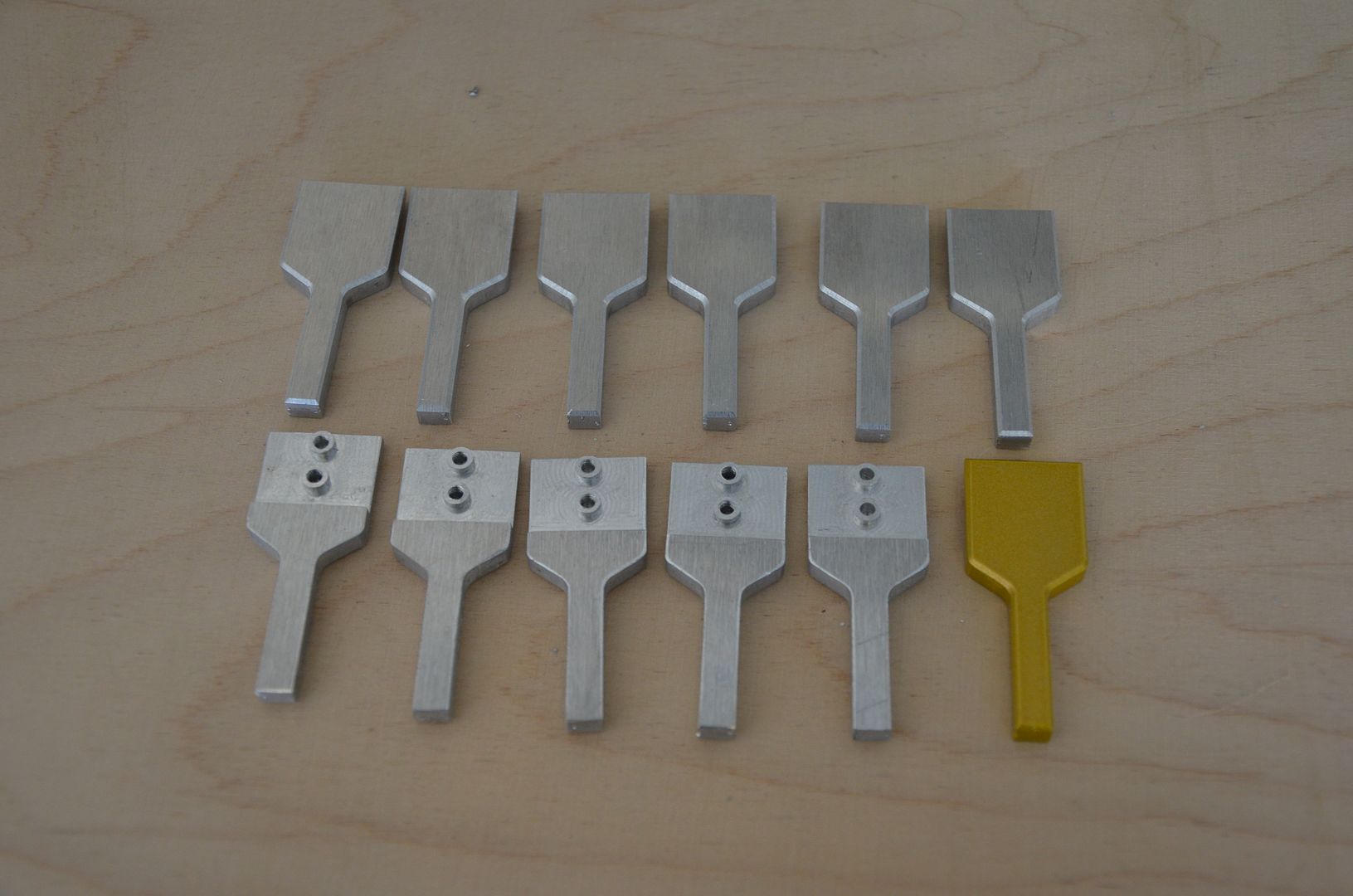

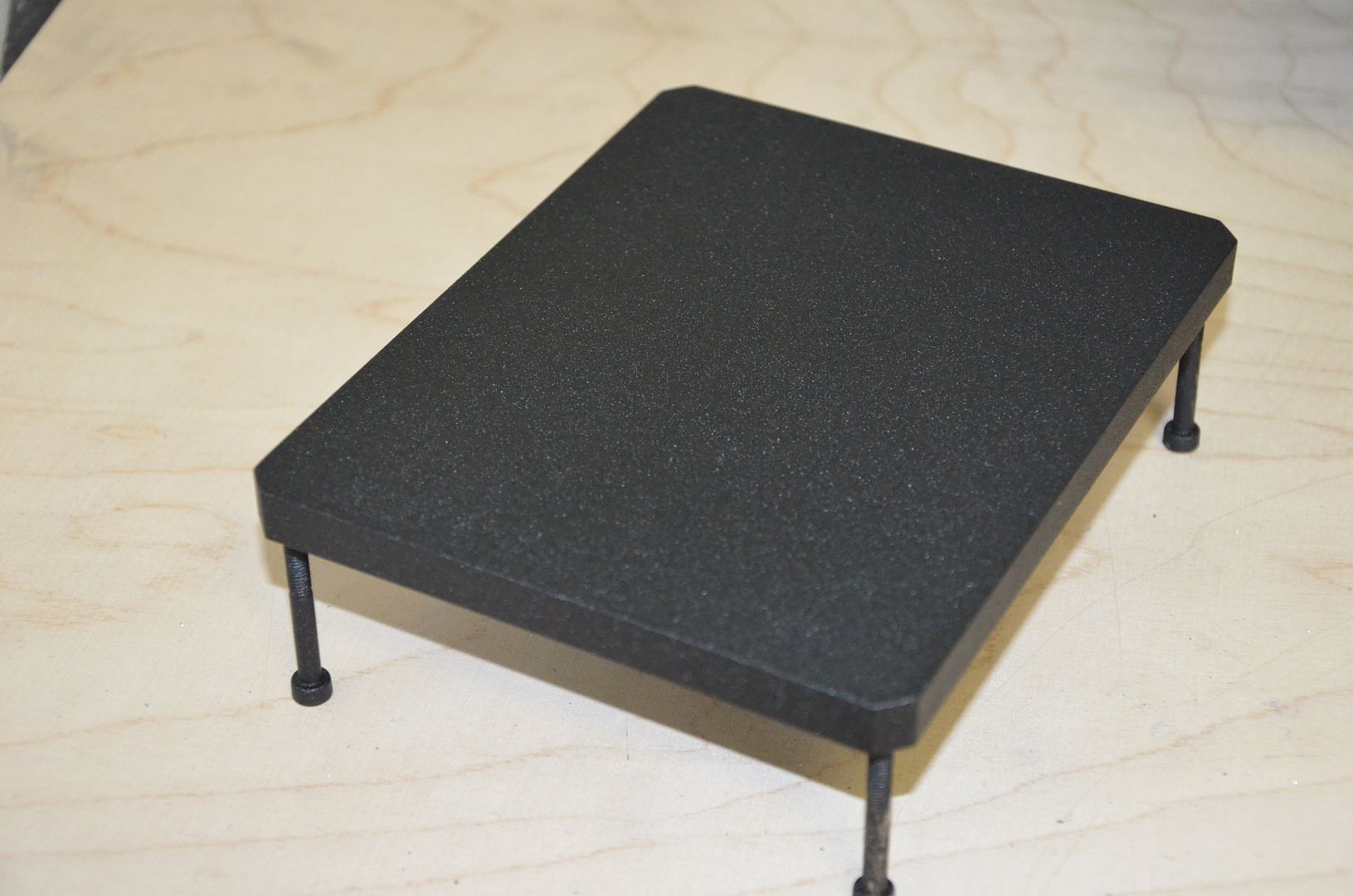

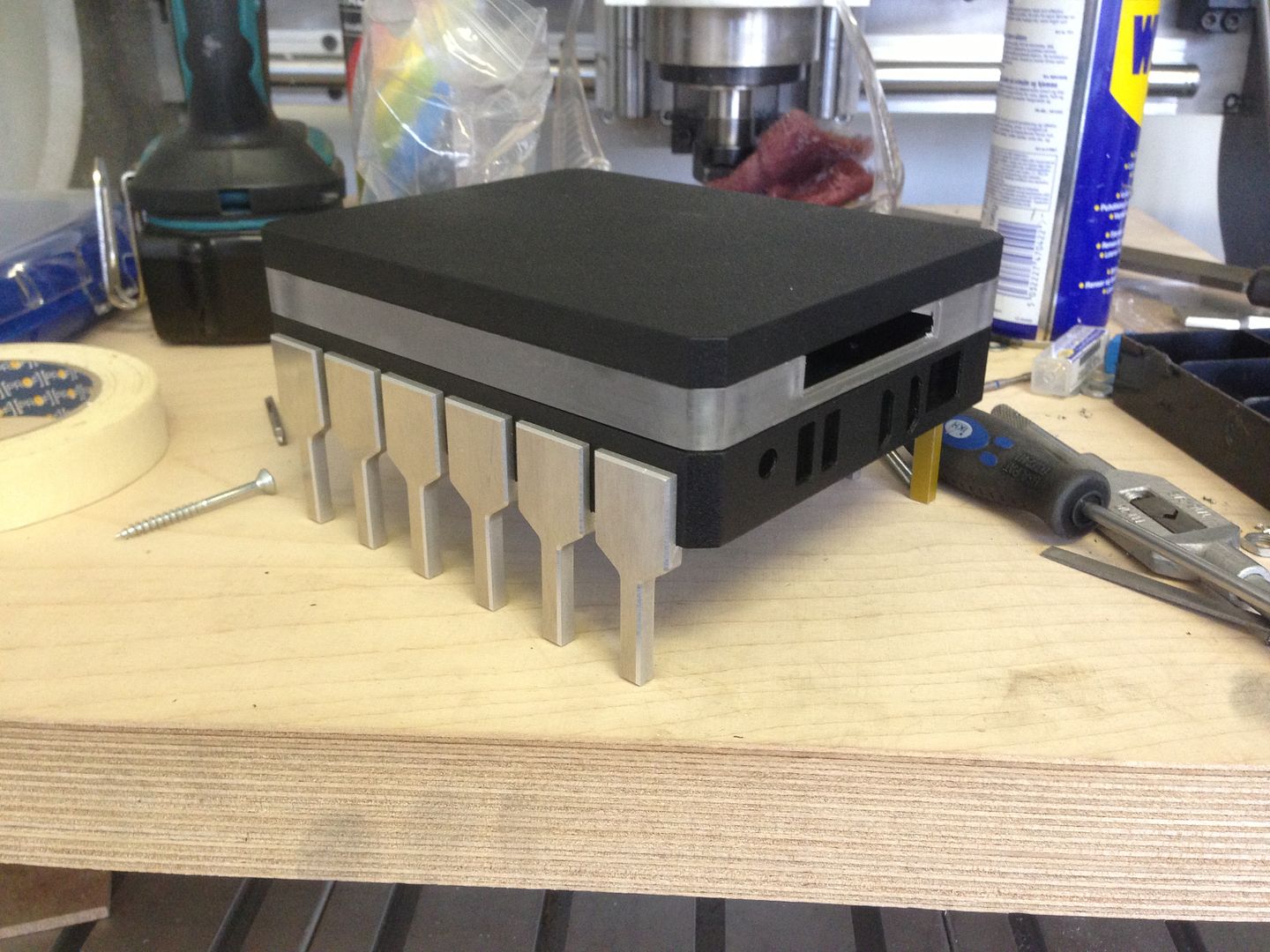

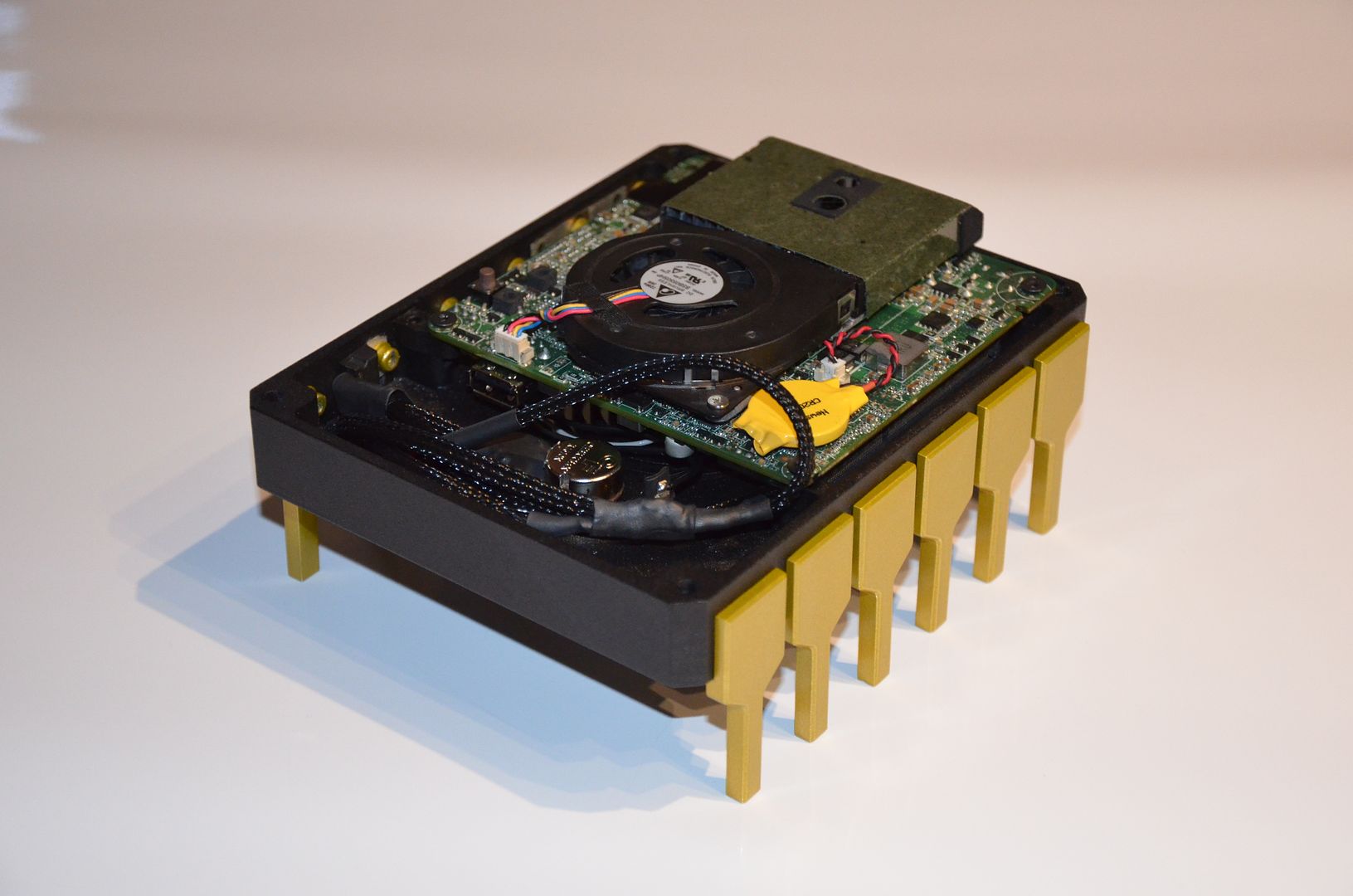

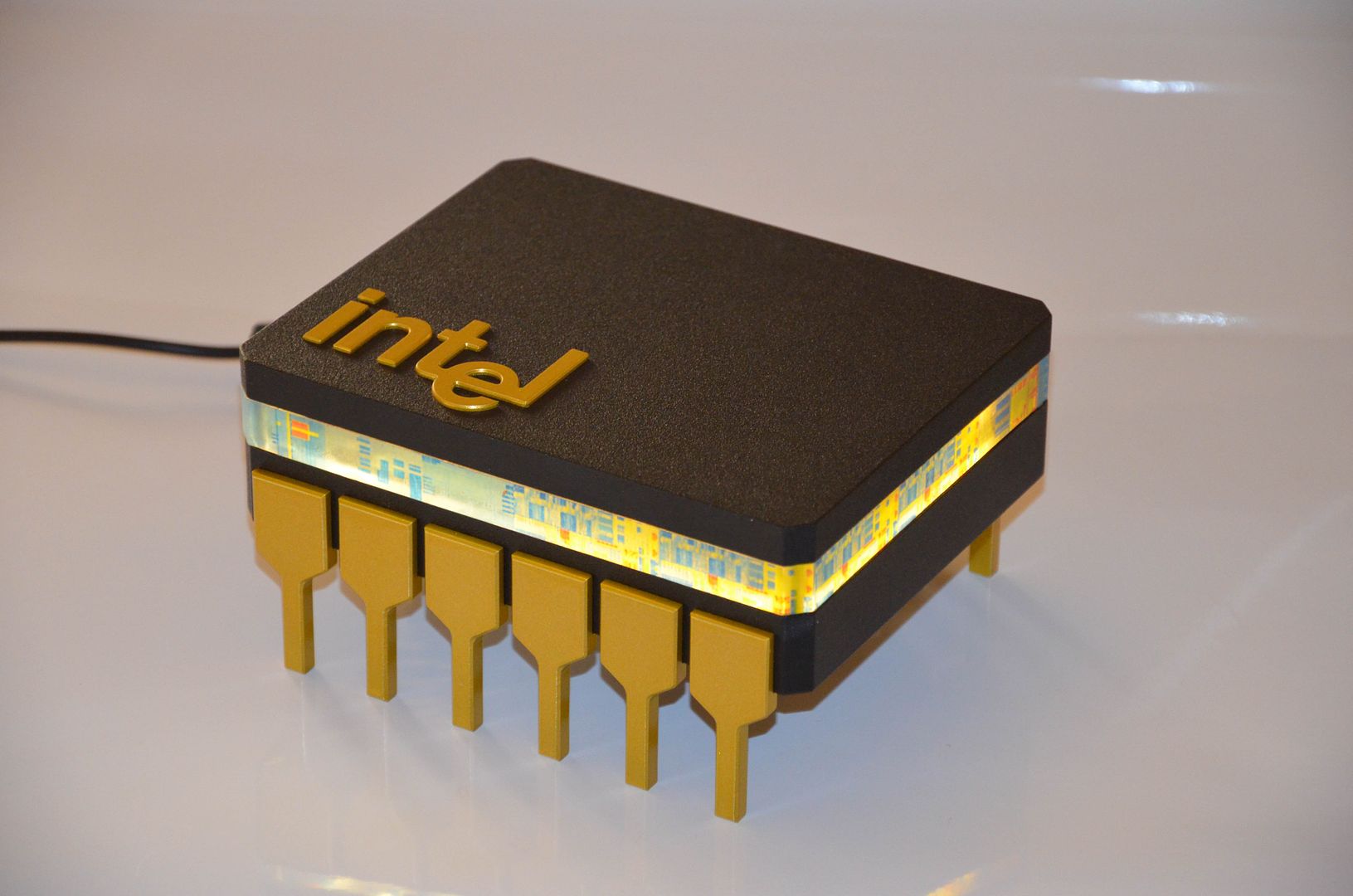

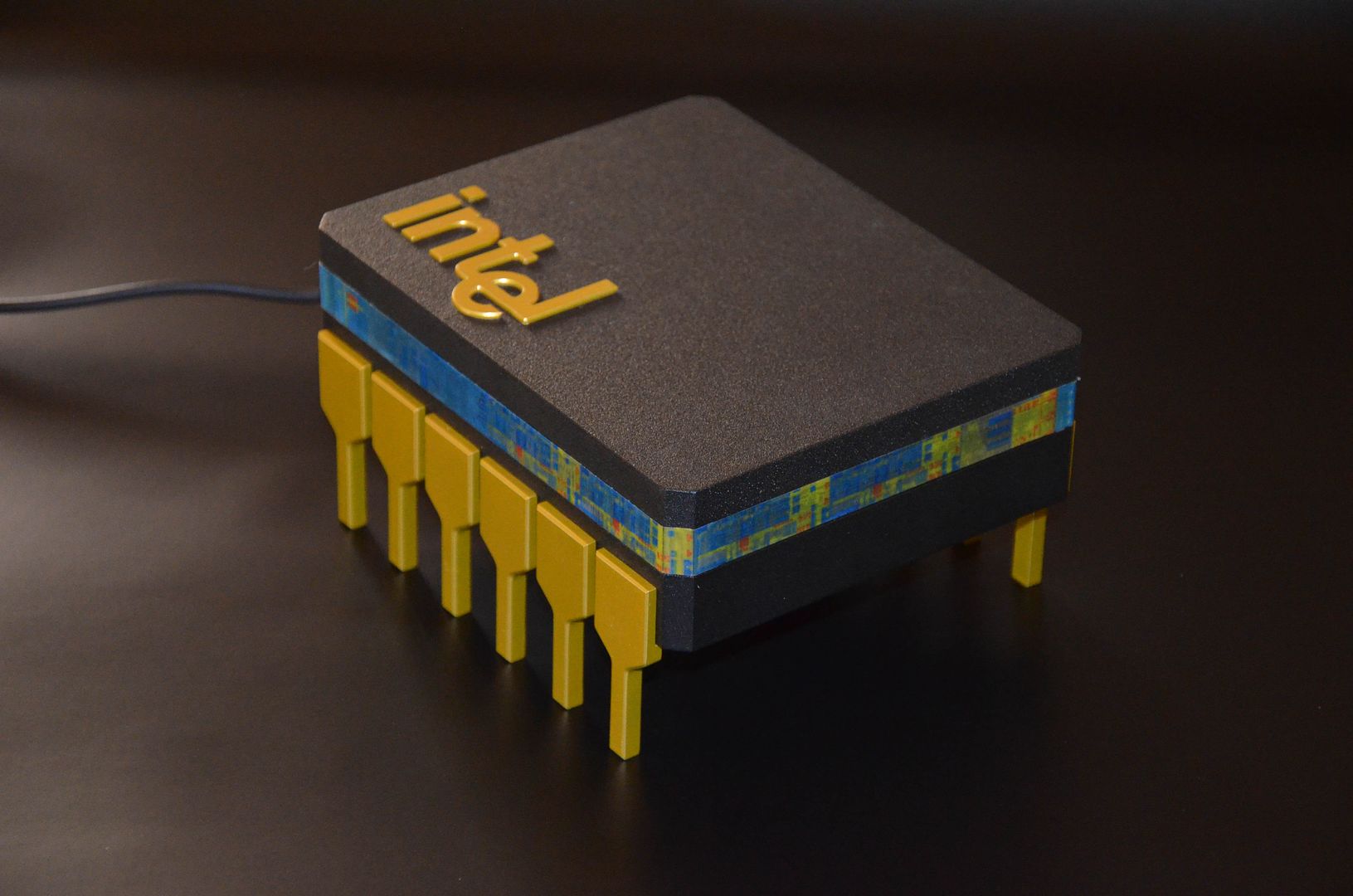

This is looking even better in the metal than in the CAD drawings, and those legs/Chip Pins look absolutely superb. What paint did the paint the surface of the actual chip with (the black) as the texture and finish looks spot on

This is looking even better in the metal than in the CAD drawings, and those legs/Chip Pins look absolutely superb. What paint did the paint the surface of the actual chip with (the black) as the texture and finish looks spot on

)

)

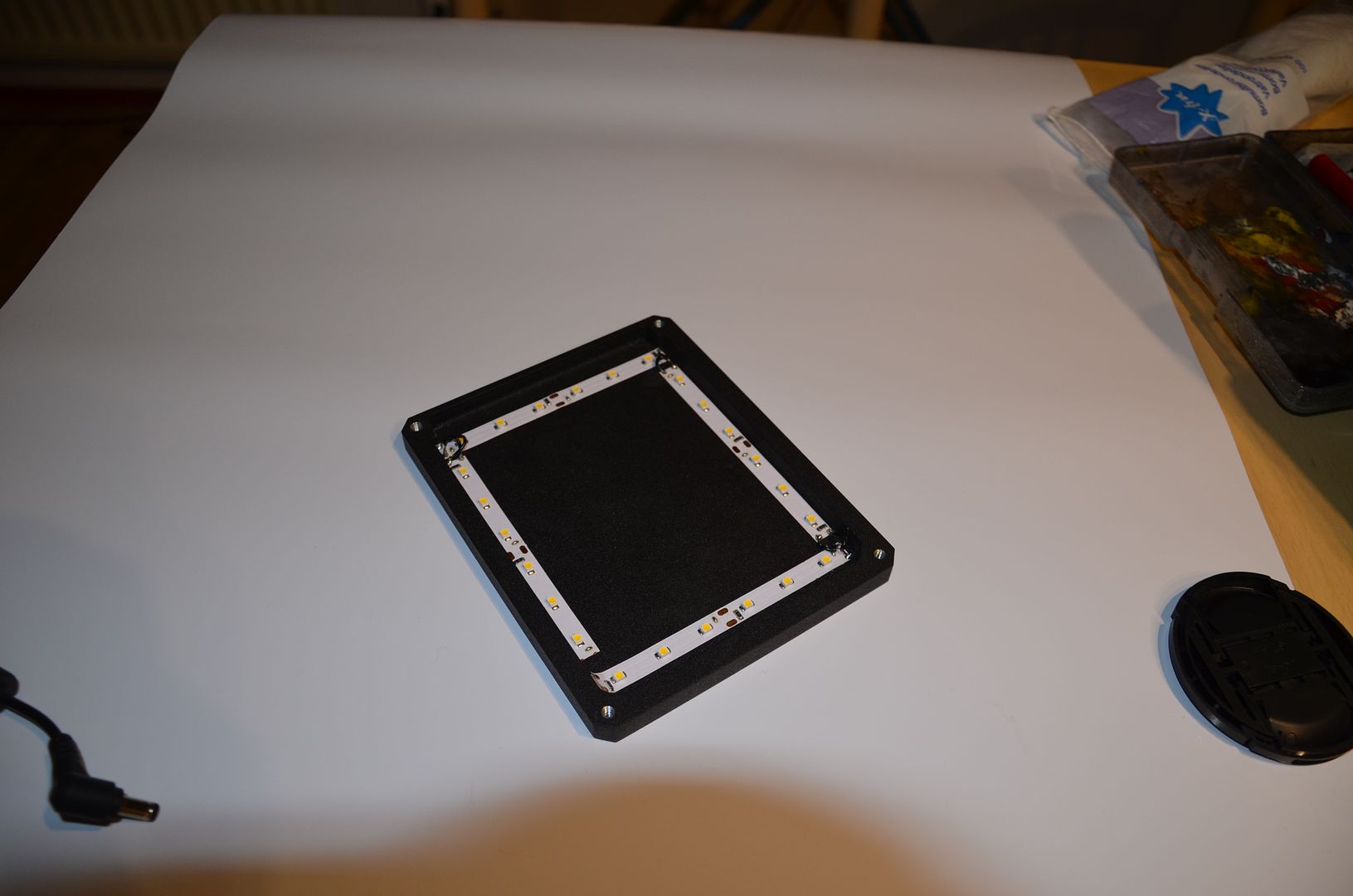

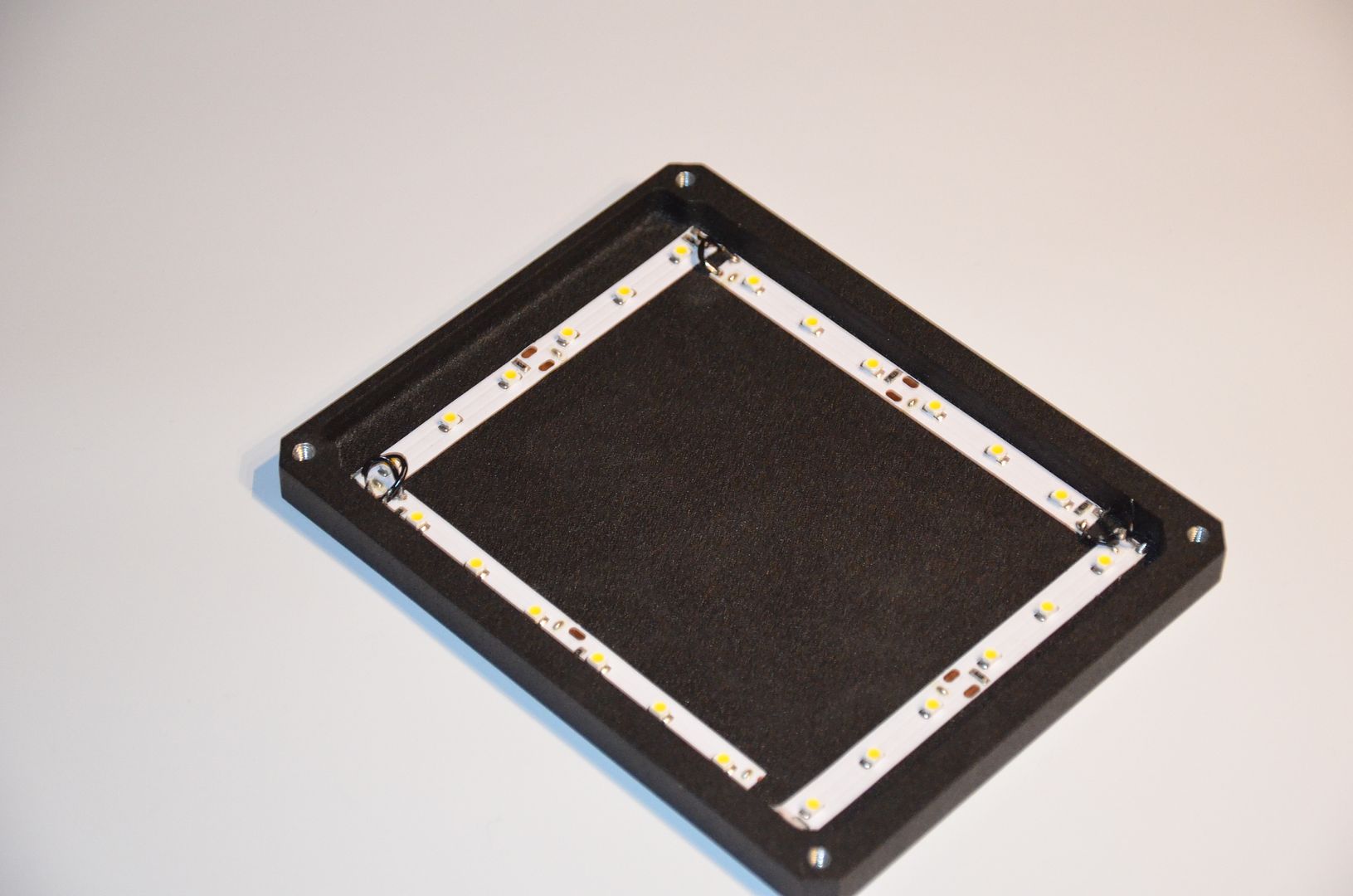

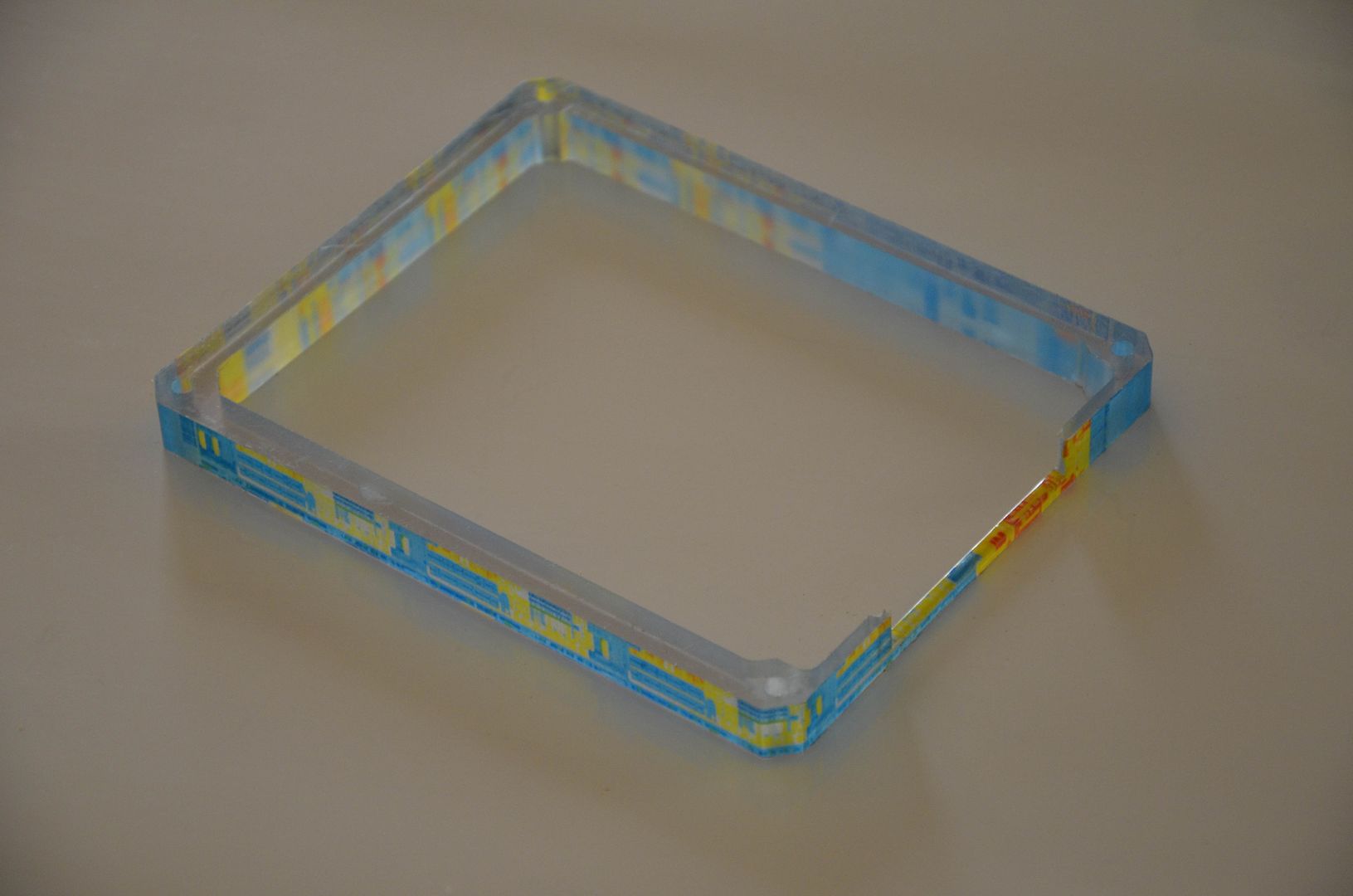

But will do it this way instead

But will do it this way instead