Midlag Crisis

Story behind the name, my main current project is called Lean & Green or LAG for short, I was midway through & I had a hissy fit over something stupid which made my progress come to an emergency stop so had a little timeout to regain my sense, or at least some of it

my main current project is called Lean & Green or LAG for short, I was midway through & I had a hissy fit over something stupid which made my progress come to an emergency stop so had a little timeout to regain my sense, or at least some of it  could call the project anything since I never have it in writing on my projects, great story...

could call the project anything since I never have it in writing on my projects, great story...

But I’m using this one to get me right back in motion to continue LAG straight after this.

It’s a small practical HTPC I'm making for my dad as a present, he's in Australia until the 8th of February & I aim to have this project completed well before then.

It holds an SFX PSU, mini-ITX mobo with support for regular height expansion card, Internal IR receiver, Internal 3.5" e-sata HDD dock which can be switched on/off & 1 3.5" HDD & 1 SSD & 1 140mm custom fan, 1 of the parts of the custom frame is the front panel too, got all the hardware covered already & this is my first rig without an optical drive.

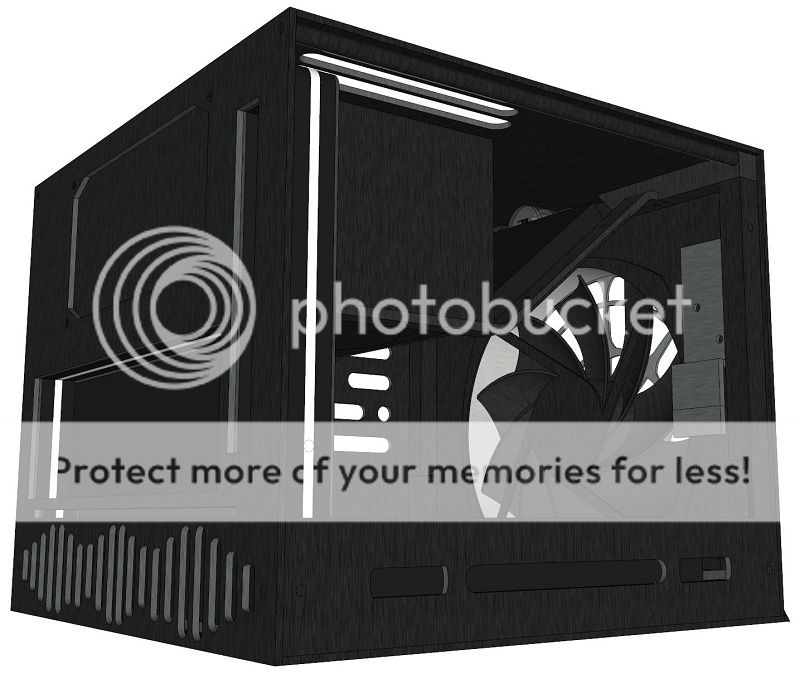

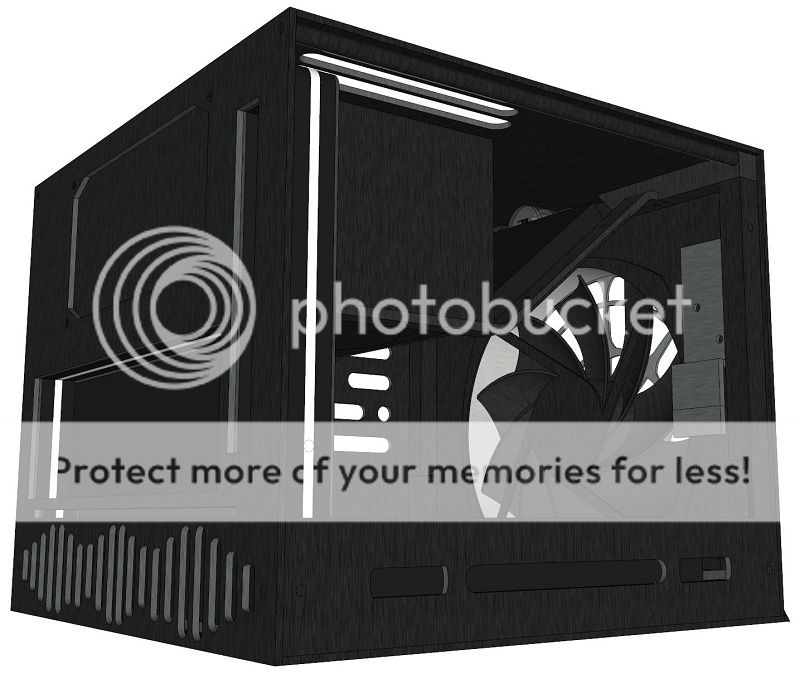

Some concept shots.

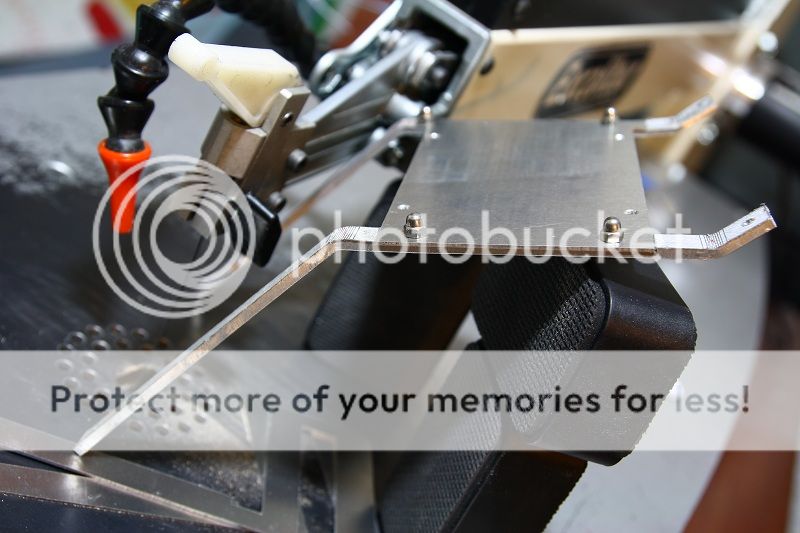

The internal custom e-sata HDD dock has a sliding piece which 3 rods guide it so it goes forward/back nice & straight that has enough room to free the drive & then the HDD clips in/out of place with it's own little side panel for quick access.

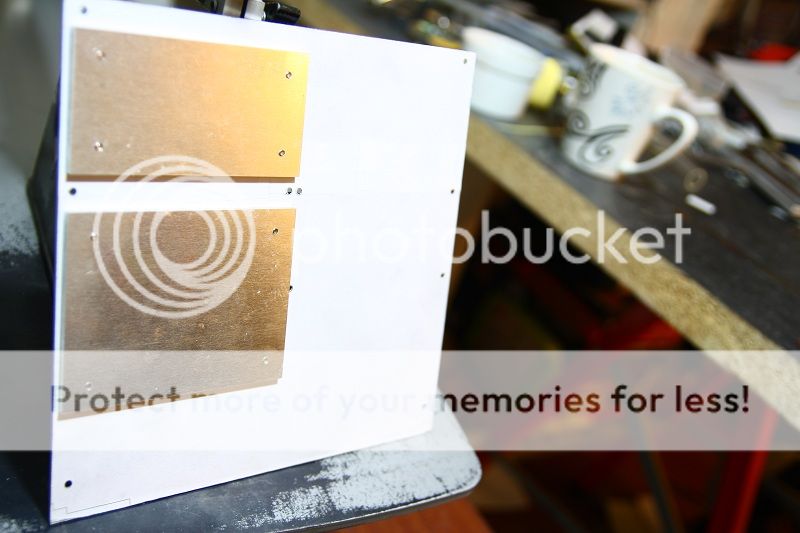

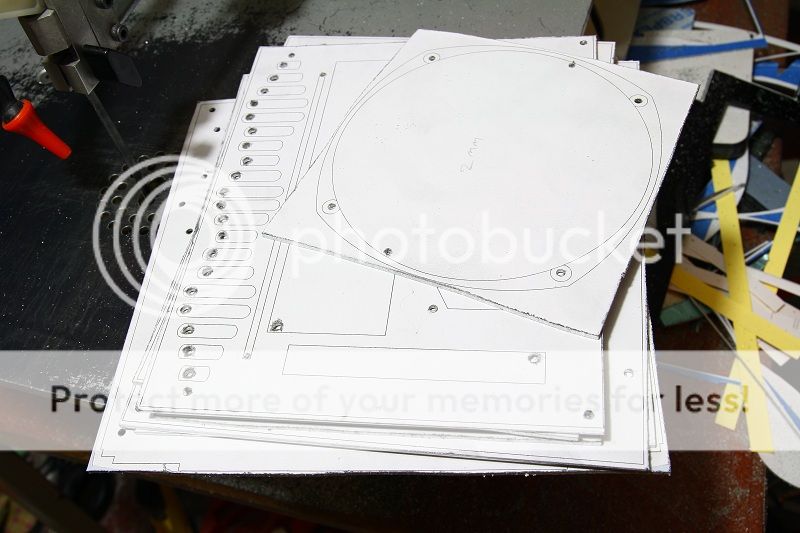

After making it all printer ready.

The only material I had to buy was the 2mm panel & an acrylic tube with 16mm ID for the marble power button, everything else is scraps.

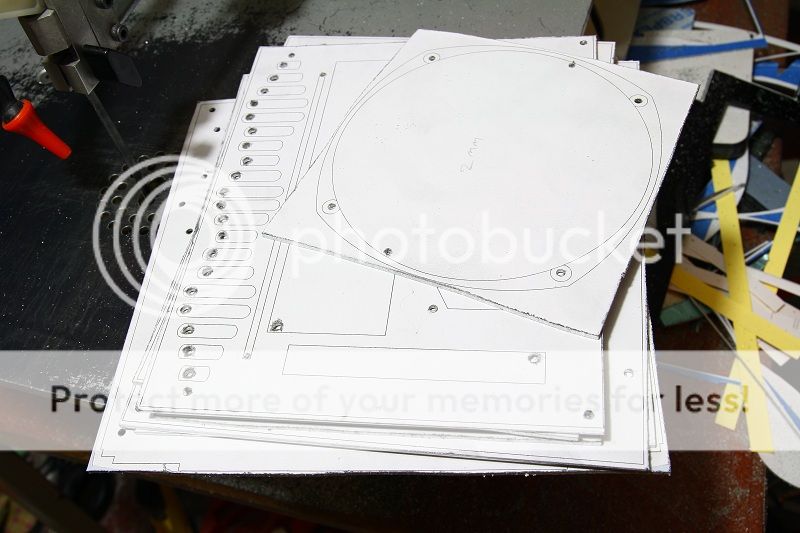

Cut into manageable pieces.

Drilled.

Cut & undressed after a nicely productive 10 hours, so that's the front, back, top, bottom, both sides, mobo tray & most of the HDD dock pieces & back IO piece but all the acyrlic bits need the adhesive before I can complete them.

Also cut some acrylic pieces but I can't find my tensol 12 adhesive so I'll have to order a new bottle & get it on Tuesday but this lets me complete everything else in the meantime.

This project should be a quickie.

Feels good to have done some modding after such a big timeout, I'll do more tomorrow.

Story behind the name,

my main current project is called Lean & Green or LAG for short, I was midway through & I had a hissy fit over something stupid which made my progress come to an emergency stop so had a little timeout to regain my sense, or at least some of it

my main current project is called Lean & Green or LAG for short, I was midway through & I had a hissy fit over something stupid which made my progress come to an emergency stop so had a little timeout to regain my sense, or at least some of it  could call the project anything since I never have it in writing on my projects, great story...

could call the project anything since I never have it in writing on my projects, great story...

But I’m using this one to get me right back in motion to continue LAG straight after this.

It’s a small practical HTPC I'm making for my dad as a present, he's in Australia until the 8th of February & I aim to have this project completed well before then.

It holds an SFX PSU, mini-ITX mobo with support for regular height expansion card, Internal IR receiver, Internal 3.5" e-sata HDD dock which can be switched on/off & 1 3.5" HDD & 1 SSD & 1 140mm custom fan, 1 of the parts of the custom frame is the front panel too, got all the hardware covered already & this is my first rig without an optical drive.

Some concept shots.

The internal custom e-sata HDD dock has a sliding piece which 3 rods guide it so it goes forward/back nice & straight that has enough room to free the drive & then the HDD clips in/out of place with it's own little side panel for quick access.

After making it all printer ready.

The only material I had to buy was the 2mm panel & an acrylic tube with 16mm ID for the marble power button, everything else is scraps.

Cut into manageable pieces.

Drilled.

Cut & undressed after a nicely productive 10 hours, so that's the front, back, top, bottom, both sides, mobo tray & most of the HDD dock pieces & back IO piece but all the acyrlic bits need the adhesive before I can complete them.

Also cut some acrylic pieces but I can't find my tensol 12 adhesive so I'll have to order a new bottle & get it on Tuesday but this lets me complete everything else in the meantime.

This project should be a quickie.

Feels good to have done some modding after such a big timeout, I'll do more tomorrow.

you always have fantastic projects, looking forward to seeing this one come to fruition

you always have fantastic projects, looking forward to seeing this one come to fruition