UPDATE 1.0 - IT'S ABOUT DAMN TIME!

Sure feels like its been a while, the last three builds have felt the same. It's getting harder and harder to find the time, organise and pull everything together. I'm closer to 40 than ever (funny how that works), married, two kids (under 3), a dog, a mortgage and a job to keep it all moving forwards. I adore PC hardware, its the one constant that has stayed with me my whole life. It's an absolute pleasure and a true privilege to have the support of these industry titans! It's been six years since I started modding under the MODZERO name and truly, I don't take any of this support for granted. I enjoy the process more than the result and without these sponsors, I'd get to build maybe one PC every 5 years. Each project is a labour of love, I don't go to the extreme and believe that a 'PC' should look like a PC. For me, it's all about clean lines, custom cables, sexy hardware and water cooling. With that in mind, come along for the ride.

I'm not sure when I first mentioned I'd be doing a 0-11D build but I'm pretty sure Lian Li sent me the case well over a year ago!

So where to begin, erm... Lian Li got in touch (I was honoured) and asked if I'd like to work with their Razer Edition 0-11D. I said I would and a couple of weeks later it arrived on my door from OCUK. I reached out to Gigabyte UK and they hooked me with some hardware goodies (I'll cover those in the next update). I then reached out to AMD UK and they sent me over some silicon loveliness (Thanks AMD, it's such a buzz having your support). Then, thinking this build was turning into something rather epic I reached out to Silverstone Tech (I'd not previously been sponsored by them). Side note - I've only ever used Silverstone PSUs (on my own builds), simply put, I believe they produce the best PSUs on the market. Certainly, others make great PSUs but for me, the simple design aesthetic and great cable pinouts make Silverstone my 1st choice.

Anyway, they hooked me up with a couple of options (more in the next update). EK then sent me a message as they were working on their 0-11d distro at the time (showing this builds age). The OG plan had been I'd build this around that, demo their distro glory early release style.

But a number of things went '**** up' and everything got delayed...

Life can be a bummer.

THE CASE!

...

...

...

...

It's your standard 0-11d with some added RGB and a Razer etched logo. Oh! and some green USB ports. To be honest, I love it! There is a reason this case is so popular, it looks amazing! I like Razer, I've used their products off and on since their inception and the green flare of the ports with the effect the etched logo will give once the RGB does its thing is all good news in my books.

So what to do first...

...

Yup! dismantle it!

...

Which turned out to be a PIA. The price point on this case is awesome and I guess you gotta keep them costs low somehow huh... pressed steel and rivets it is then. But never mind, my wife treated me to a new drill (fancy) and I got to work hunting them down. Like this cheeky ****** hiding behind a black tape I'll not be able to replace.

...

A lot of rivets later, the case was down to a frame. But why I hear you cry (cried no one) well, I'll get to that in a moment.

...

The front IO and rear panel were difficult, well, a pain. That front IO panel doesn't want to come off and they integrated an RGB strip into the panel which needed to come out in a sequence. The back was a fight too, it seemed as though the order in which the frame would have been first assembled would call for top/bottom panel to be removed before the back would come away. I opted to drill out the mid-wall rivets on the bottom panel which provided enough flex for the rear panel to come away.

So front, rear, top, back and feet are all off for some painting love.

...

Oh, a couple of rads too! If you're on Instagram check me out, with this build as I've been doing certain bits documented as stories. I pulled apart the SE360 and PE360 rads with ease. EK have you mind with those rads. four hex screws, slide the ends across and the sides pull off.

So, the case and rads in bits, they got packed up and sent on their jollies.

This is where this one gets fun. Some time prior, I was watching Top Gear and the lads are ragging a McLaren 600LT around the track.

...

This, McLaren 600LT!!!!.. in THAT green, with THOSE yellow callipers, forged alloy wheels, carbon panelling and a touch of orange in the model name stitching.

THAT'S WHAT I WANT!

Not the car! but the paint, the whole colour scheme. That's my 0-11D build in car form.

As it turned out, getting that green wasn't gonna happen. McLaren doesn't list the colour on their website (not that I could find) and 3rd party colours without a reference were gonna be difficult.

Very difficult.

Still, I sent some emails and PM'd a few people.

...

That's it! That is Luminaire green, a sample from Mclaren! Not that Mclaren knows that. I'll link the company that made it happen when I finish the build cos you really need the light to show off this paint! It has a metallic pearlescence to the hue (ponce)! it's three shade of green with a sparkle up close and wow do the panels look awesome!

Yup, sorry... moving on. I'll show it off when it's done and the guy that did the paint is happy to provide the service to others (granted, it cost me three times the value of the case to get it painted) but compared to other sprayers I'd had quotes from he is reasonable, reliable, great communication and genuinely takes pride in his work.

...

RIVETS! counter-sunk Lian Li black rivets... These I picked up from MDPC-X along with all my cable sleeve, connectors, crimps, wire, combs and terminals. They ship worldwide and only offer the best. #nocompromise again, more on this in a future update.

...

Putting them in is so much easier than taking them out. Once you remember how to re-assemble the case that is! I got a panic on fearing I'd have to drill the rivets back out and mark the paintwork in the process.

But alas...

...

Oddly, I was left with 4 stubby thumb screws and a small piece of foam (which now, having written it down reminded me it was a pressure fit wedge to hold the LED strip from wiggling) Oops.

...

I'm jumping ahead a little, but I bought the Phanteks vertical GPU bracket. I'd intended to hold out for the EK one they announced during the EK EXPO and if the ribbon on this gives me any grief I'll be sure to go back and place my order.

I went with Phanteks for two reasons, it seems to have a smaller footprint and it positions the GPU further forward (closer to the side panel) than the Lain Li vertical bracket (oh yeah, that's the other one I was looking at..).

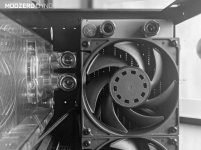

Annoyingly I didn't get a photo but fitted there wasn't the clearance required to put the SE rad + a 25mm fan underneath. Which ticked me off as I'm sure I'd seen it used in another 0-11d build on reddit. But not to worry.. break out the old Dremel and touchup paint.

...

Sorted.

That'll do for now. I'll be back with UPDATE 2.0 perhaps at the weekend. I want to share the hardware I'll be using and maybe get some photos of all the EK glory they sent me!!!! I mean, WOW! They spoilt me. <3 those guys.

Thanks for checking this out, I appreciate I write a lot and maybe you just came for the photos (hey, we look at pron), either way, thanks.

J.

I'll only be attaching a HD 6670 to it (to be revealed in the coming months, hopefully) so I don't need serious speed

I'll only be attaching a HD 6670 to it (to be revealed in the coming months, hopefully) so I don't need serious speed  and don't fully fancy shelling out 30 notes "just" for a rehomed web server.

and don't fully fancy shelling out 30 notes "just" for a rehomed web server.