Group A rear beam mounts fitted. Good!

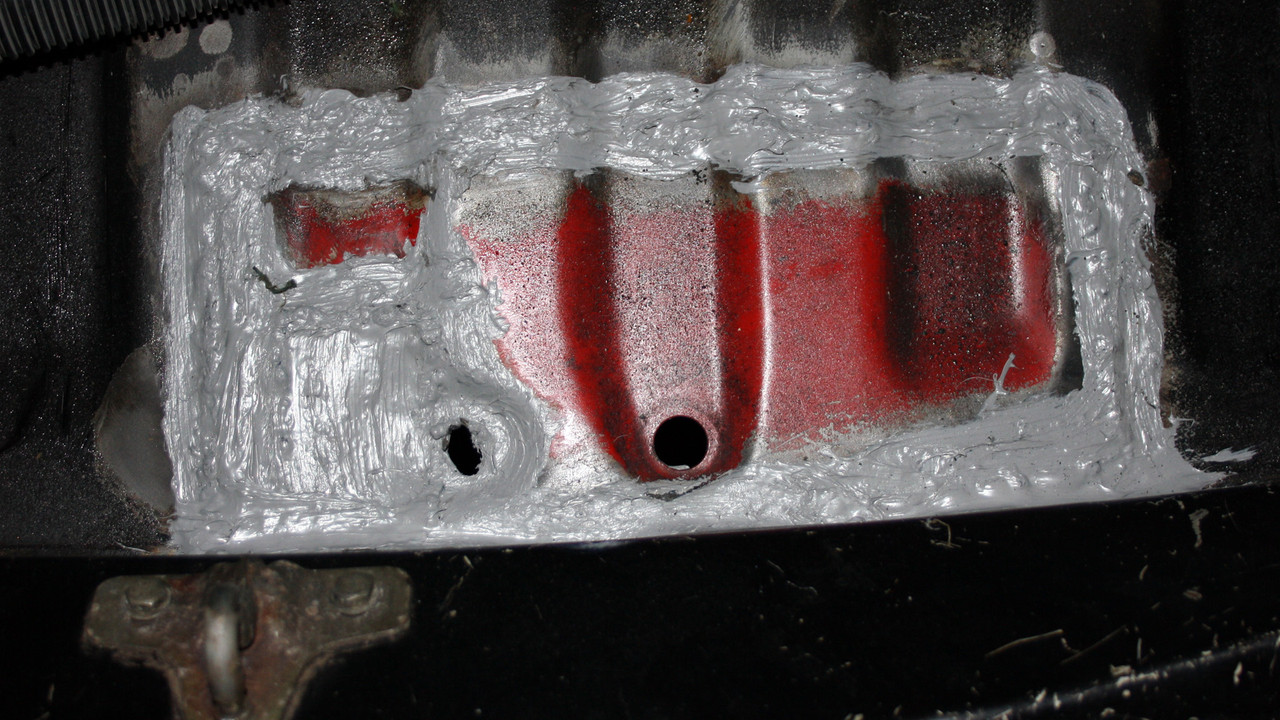

Bloody great hole in the crossmember that appeared when I dropped the spare wheel cage. Bad!

That's my next Saturday morning accounted for then

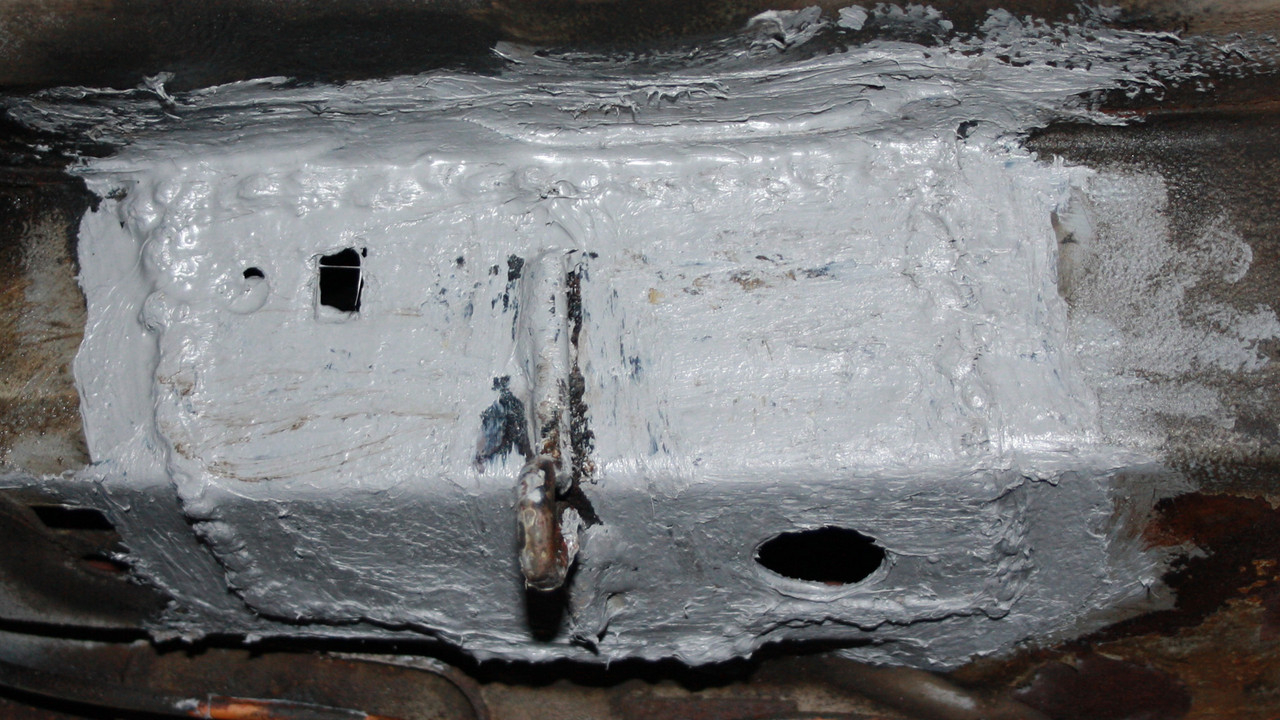

The rear crossmember where the beam mounts sit doesn't look in brilliant health either, but I've given it a thorough prodding and it's not even close to perforating. Still needs a good clean and paint to prevent further rot. I swear this thing was parked under the sea or something.

Bloody great hole in the crossmember that appeared when I dropped the spare wheel cage. Bad!

That's my next Saturday morning accounted for then

The rear crossmember where the beam mounts sit doesn't look in brilliant health either, but I've given it a thorough prodding and it's not even close to perforating. Still needs a good clean and paint to prevent further rot. I swear this thing was parked under the sea or something.

Last edited: