Just a small thingy.

I managed to find a US retailer with EVGA X99 Micro, who actually ships stuff to Europe.

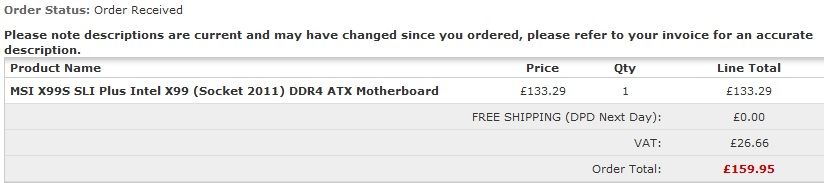

I paid a bit more than I planned, but I think it will be worth it - or so I hope.

At least I will be able to tell you guys if EVGA fixed their early BIOS issues.

I managed to find a US retailer with EVGA X99 Micro, who actually ships stuff to Europe.

I paid a bit more than I planned, but I think it will be worth it - or so I hope.

At least I will be able to tell you guys if EVGA fixed their early BIOS issues.