You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nuts PC build

- Thread starter Stupot_

- Start date

More options

Thread starter's postsWhat he has acheived isn't that difficult given the workshop he's in, the tools he has at his disposal makes the job pretty straight forward. Watching what he does, bending, drilling, sanding, cutting, welding etc is very basic fabrication with a mind to working sums for the design.

The end result looks great don't get me wrong, but it isn't what I'd call difficult given what he has at his disposal and the brand new tool selection which appears in virtually every shot even down to the clamps...

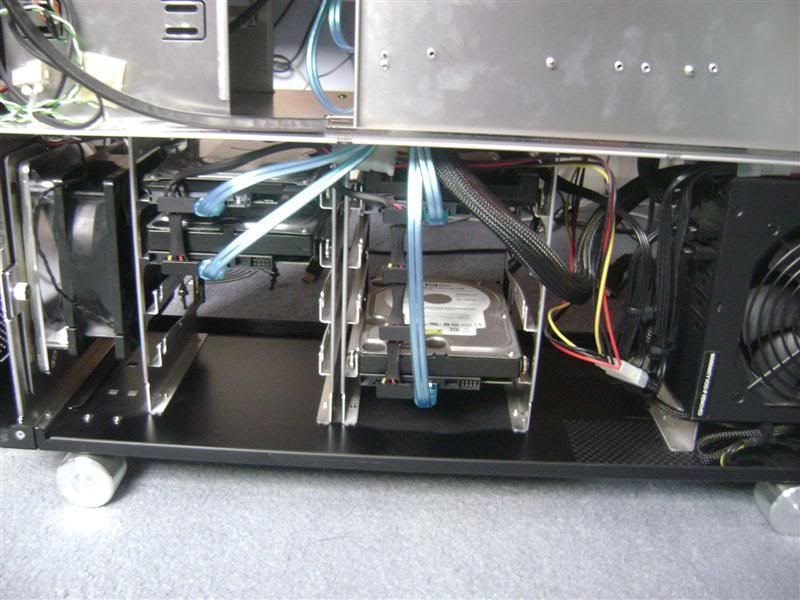

I find it similar to those that spend possibly £1000's on parts for a PC, build it in their shiny new case, take some pics and go ' look at my rig '..yes it looks nice, but it's hardly difficult what you did. However the guy who spends his saturday trying to cut holes in his case with a hacksaw, pliers and any tool he can find in his dad's shed just to make a fan fit is going to get my appreciation a lot more.

Anyway, it looks good

What you on mate? lol.. Having good tools doesn't make the job easyer (watch your missus with an electric drill) What it does do is make the process much quicker. If you wanted to cut a peace of steal and you had a hack saw or a band saw, what would you choose?

I'm a mechanical engineer and use cnc machine tools. I can do the same jobs on old mechanical machine tools ie laves, millers it just takes me much longer.

Credit to the bloke, he has skills...

What you on mate? lol..

Having good tools doesn't make the job easyer (watch your missus with an electric drill) What it does do is make the process much quicker.

That's not entirely true, yes it does make it quicker and it makes the job an awful lot easier, try and bend aluminium without a press or drill it without a pillar drill, how about the spot welding? perhaps he could have cut small brackets with his hacksaw and bent them with a hammer and block, my point is it makes the job a hell of a lot easier.

If you wanted to cut a peace of steal and you had a hack saw or a band saw, what would you choose?

see my point above.

I'm a mechanical engineer and use cnc machine tools. I can do the same jobs on old mechanical machine tools ie laves, millers it just takes me much longer.

Again using a cnc machine is a damn sight easier than hand craft engineering, you load the bit, work out your design, press the start button and off you go, whether it's cutters, drilling, lathing etc, it's all the same, and the reason it becomes easier and quicker is down to the way we work these days, it's based on time on limited knowledge ( if the company employing can get away with it ). a lot of engineering companies have a two tier work force, those that sit in the office and program the cnc and those that work on the shop floor....and let's be honest a lot of those in the office wouldn't have a clue which router bit went where, or the pressure valve for the water cutters.

Credit to the bloke, he has skills...

Without looking at his other work i can't comment fully on that, what he achieved in this video wasn't something that anyone on here ( with a week on those machines ) and a good idea for a model could do.

As a mechanical Engineer, i would have thought you would have recognised the basic tooling and building work he was doing to achieve the result.

Overall i like what he's done and i've said that several times now, I'm just not as enthusiastic about it, there are plenty of mods shown on this site that have taken more to do and deserve, i feel, a lot more praise for their work( for instance the Hush mod)

Cheers

Associate

- Joined

- 15 Jul 2004

- Posts

- 2,437

- Location

- Norway...maybe...

I want his worksop

http://maps.google.co.uk/maps?f=q&s...sop,+Nottinghamshire,+United+Kingdom&t=h&z=13

I'm sorry, I couldn't help myself. I think this is my first post in Case Central, and I make a sarcastic comment. Sorry about that.

That case is epic, and I'm truly envious of both his workshop, and his obvious level of skill

I made typo on purpose

I can kinda see what you are getting at re: skill level, perceived and actual.

In some ways you could make that case as a GCSE DT project...

I agree in that respect but I am always wary of becoming a nay-sayer, with a quote from Roosevelt saying;

'It is not the critic who counts; not the man who points out how the strong man stumbles, or where the doer of deeds could have done them better. The credit belongs to the man who is actually in the arena, whose face is marred by dust and sweat and blood; who strives valiantly; who errs, who comes short again and again, because there is no effort without error and shortcoming; but who does actually strive to do the deeds; who knows great enthusiasms, the great devotions; who spends himself in a worthy cause; who at the best knows in the end the triumph of high achievement, and who at the worst, if he fails, at least fails while daring greatly, so that his place shall never be with those cold and timid souls who neither know victory nor defeat.'

I can kinda see what you are getting at re: skill level, perceived and actual.

In some ways you could make that case as a GCSE DT project...

I agree in that respect but I am always wary of becoming a nay-sayer, with a quote from Roosevelt saying;

'It is not the critic who counts; not the man who points out how the strong man stumbles, or where the doer of deeds could have done them better. The credit belongs to the man who is actually in the arena, whose face is marred by dust and sweat and blood; who strives valiantly; who errs, who comes short again and again, because there is no effort without error and shortcoming; but who does actually strive to do the deeds; who knows great enthusiasms, the great devotions; who spends himself in a worthy cause; who at the best knows in the end the triumph of high achievement, and who at the worst, if he fails, at least fails while daring greatly, so that his place shall never be with those cold and timid souls who neither know victory nor defeat.'

Soldato

- Joined

- 3 Aug 2008

- Posts

- 10,477

- Location

- Bath, England

http://maps.google.co.uk/maps?f=q&s...sop,+Nottinghamshire,+United+Kingdom&t=h&z=13

I'm sorry, I couldn't help myself. I think this is my first post in Case Central, and I make a sarcastic comment. Sorry about that.

That case is epic, and I'm truly envious of both his workshop, and his obvious level of skill

thought you were stalking the chap in the vids for a second

Don't know if you've had any luck yet, but I couldn't find them either. I ended up getting some right angled SATA power extension cables off the bay (like these) and bodging them into this:Good find, if anyone knows where to get those SATA power plugs from that he uses to make his own SATA power cable, PLEASE tell me where they're from, I've been looking for some for ages.

Google search has been fruitless, I think I may have the name of them wrong though?

They have a cap on the back of them to protect where the cable slots into them and you just have to pop it off and pull the cables out to get the bare connector. Makes things much neater!

Associate

- Joined

- 13 Jan 2010

- Posts

- 2,032

- Location

- A box in the Astral Plane

Overall i like what he's done and i've said that several times now, I'm just not as enthusiastic about it, there are plenty of mods shown on this site that have taken more to do and deserve, i feel, a lot more praise for their work( for instance the Hush mod)

Cheers

I agree with everything you've said

A friend of mine has done a few projects

A friend of mine has done a few projectssimilar to this and Project Hush, hopefully with his consent I can post them here

for all to see. Credit to the man who made this case, but there are a lot of others

as good as or better imo, who don't have the same tools that he has at his disposal

!

!