Right, back with another one.

So for this one it's not about spending money. I want to build a very small LAN rig I can take on holiday with me and hook up for our LAN night. As such it doesn't need to be terribly powerful either.

All of the work here will be on the case, not the internals. I will probably change the cables to orange and white, we will see.

Many years ago (like, 10) I built my first ITX rig. For nothing more than the fact I was bored. It was a silly idea, as I had all of my cash tied up in the big PC, but I did it any way. Well this PC ended up going to my aunt sans the Titan Black which I sold to Sam (Jinq). Since then she has daily driven it.

It looked like this when I gave it to her.

And this inside.

Only with a Quadro in there the same as a GTX 480. I am now getting it back.

The board in there is one of these.

So I shamelessly stole @Arboreal 's idea and called it Orange Crush. The RAM in there is faulty and has to be underclocked, and besides it is only 4gb dual channel. So two 2gb sticks. Not good enough. Thankfully my mate sent me some 1866 DDR3 down last year (Vengeance) and it is 16gb, more than good enough. The CPU in it is also poo, a Pentium anniversary edition. So that is coming out, and.

It will also get a 980Ti I got from Tree also, with a 1080Ti cooler on (FE). Again, more than enough.

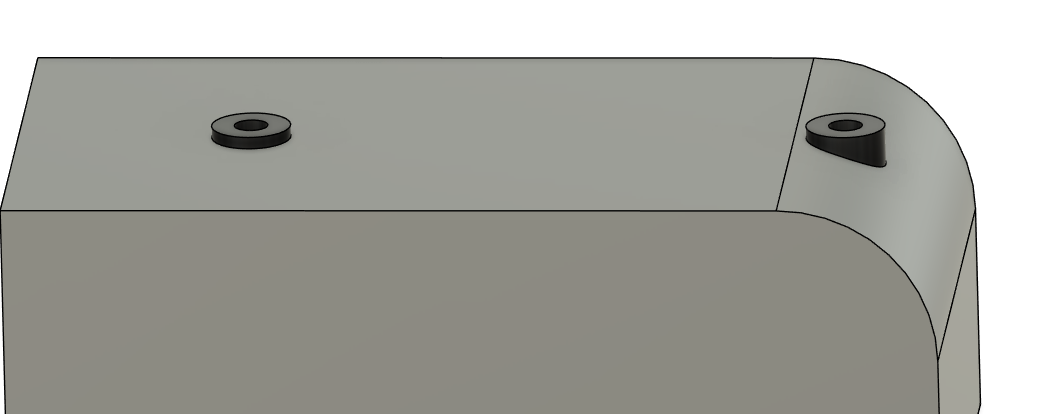

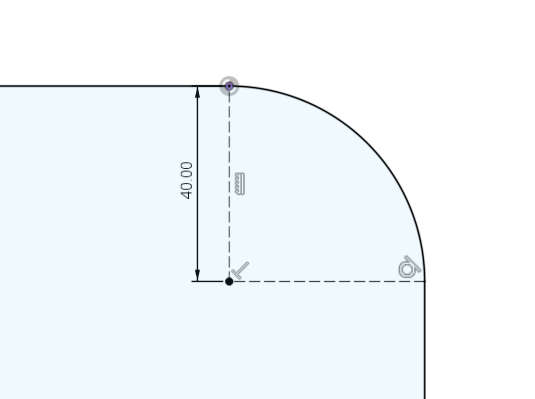

The case has already been quite extensively modded.

I know I know, I cut the fan wire hole in the wrong side. It has a plastic cover on I made, so I will paint that. Talking of paint. That will be 99% of the work here. I am going to go mental, with a full blown custom paint finish that will require lots of stages.

I am going to remove the Mayhem fan grille on the side that did not go to original plan, and put that on the fans at the bottom. This will stop me getting smashed in the fingers by fan blades when I move the rig around, something I remember being really annoying. That will leave a gaping hole in the side, and so.

The 240 Radguard is what I have in mind. It is lovely polished silver anno. So to match that I got a handle. I went with 9" (that is what she said) in brushed stainless.

The look I am going for? think 1950s cooler. Paint scheme is in my head, but I CBA drawing it so you will just have to bear with me.

So for this one it's not about spending money. I want to build a very small LAN rig I can take on holiday with me and hook up for our LAN night. As such it doesn't need to be terribly powerful either.

All of the work here will be on the case, not the internals. I will probably change the cables to orange and white, we will see.

Many years ago (like, 10) I built my first ITX rig. For nothing more than the fact I was bored. It was a silly idea, as I had all of my cash tied up in the big PC, but I did it any way. Well this PC ended up going to my aunt sans the Titan Black which I sold to Sam (Jinq). Since then she has daily driven it.

It looked like this when I gave it to her.

And this inside.

Only with a Quadro in there the same as a GTX 480. I am now getting it back.

The board in there is one of these.

So I shamelessly stole @Arboreal 's idea and called it Orange Crush. The RAM in there is faulty and has to be underclocked, and besides it is only 4gb dual channel. So two 2gb sticks. Not good enough. Thankfully my mate sent me some 1866 DDR3 down last year (Vengeance) and it is 16gb, more than good enough. The CPU in it is also poo, a Pentium anniversary edition. So that is coming out, and.

It will also get a 980Ti I got from Tree also, with a 1080Ti cooler on (FE). Again, more than enough.

The case has already been quite extensively modded.

I know I know, I cut the fan wire hole in the wrong side. It has a plastic cover on I made, so I will paint that. Talking of paint. That will be 99% of the work here. I am going to go mental, with a full blown custom paint finish that will require lots of stages.

I am going to remove the Mayhem fan grille on the side that did not go to original plan, and put that on the fans at the bottom. This will stop me getting smashed in the fingers by fan blades when I move the rig around, something I remember being really annoying. That will leave a gaping hole in the side, and so.

The 240 Radguard is what I have in mind. It is lovely polished silver anno. So to match that I got a handle. I went with 9" (that is what she said) in brushed stainless.

The look I am going for? think 1950s cooler. Paint scheme is in my head, but I CBA drawing it so you will just have to bear with me.