After spending the best part of our day working on APIS it's starting to really come together and the detailed and thorough planning seems to be paying off. Despite a few moments of tension an elegant solution was quickly found to most of the little issues that arose.

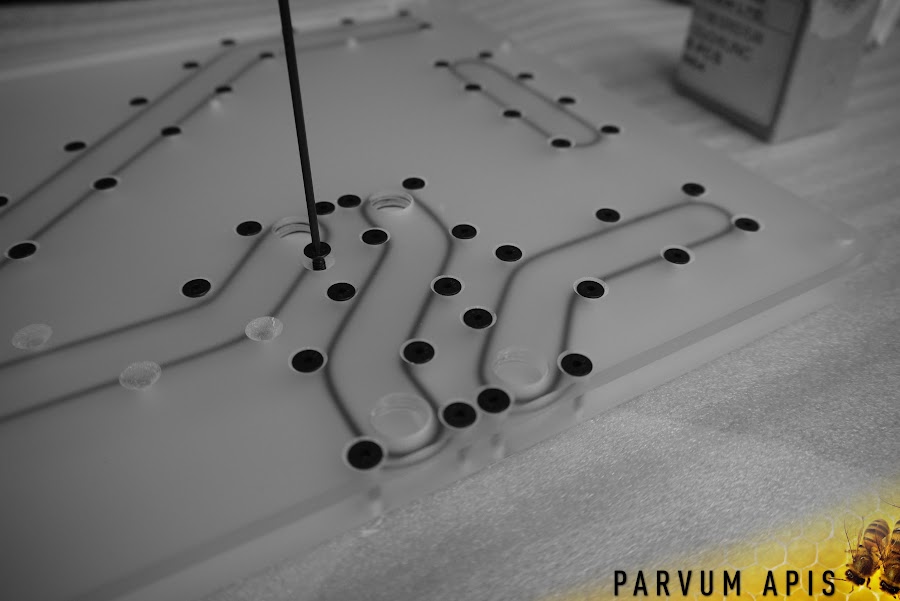

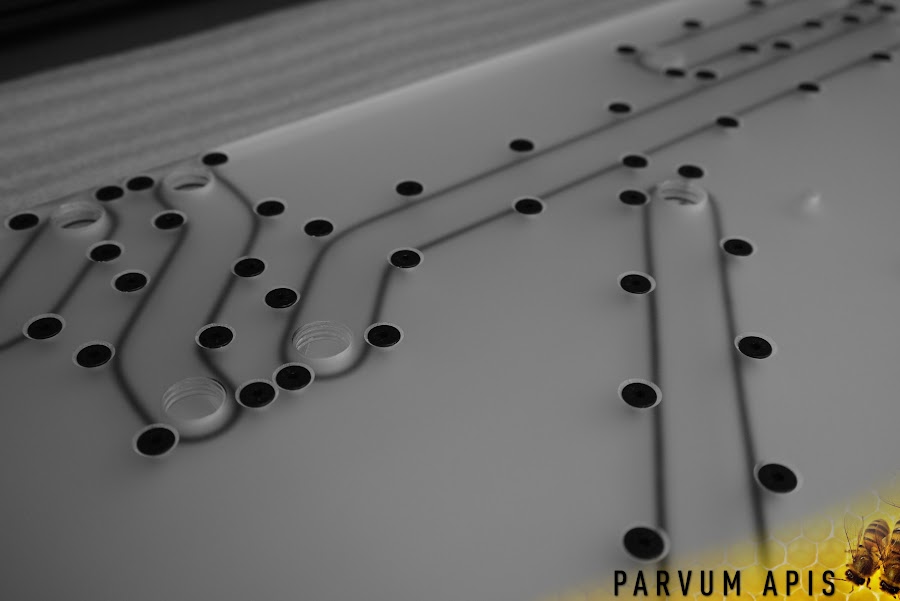

The first task was to tap the 1/4" BSP holes in the acrylic pass through components.

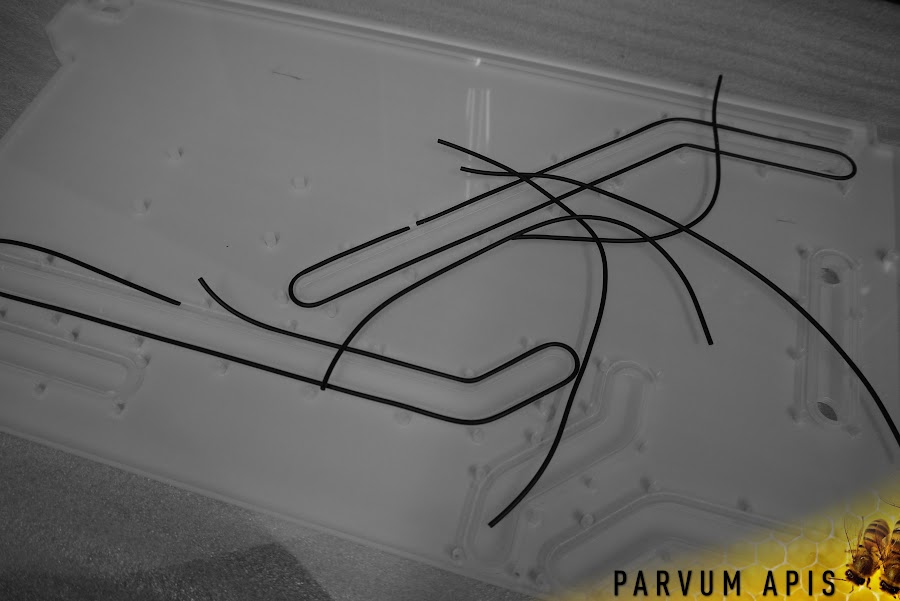

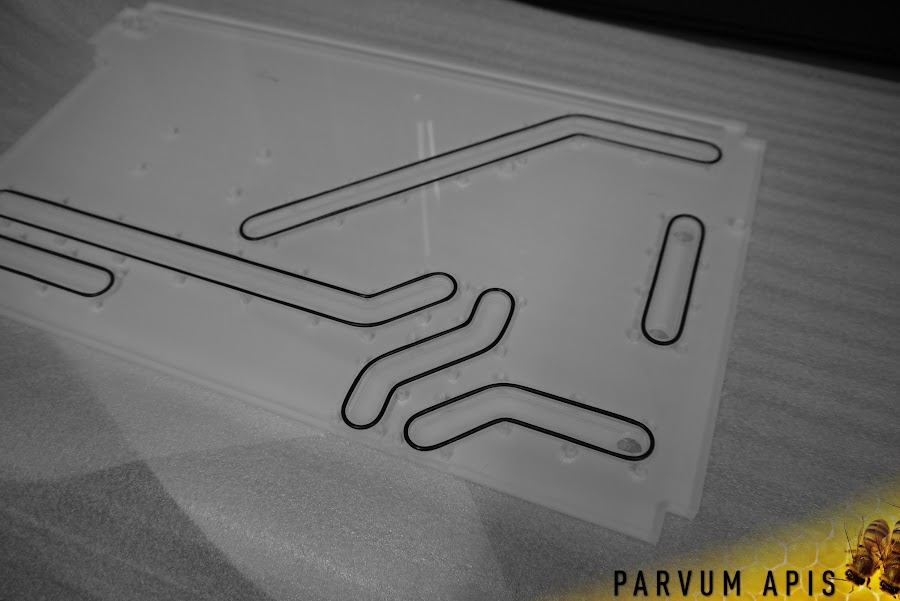

With that out of the way it was straight on to cutting and bonding o-rings from nitrile cord.

Then A LOT of screws.

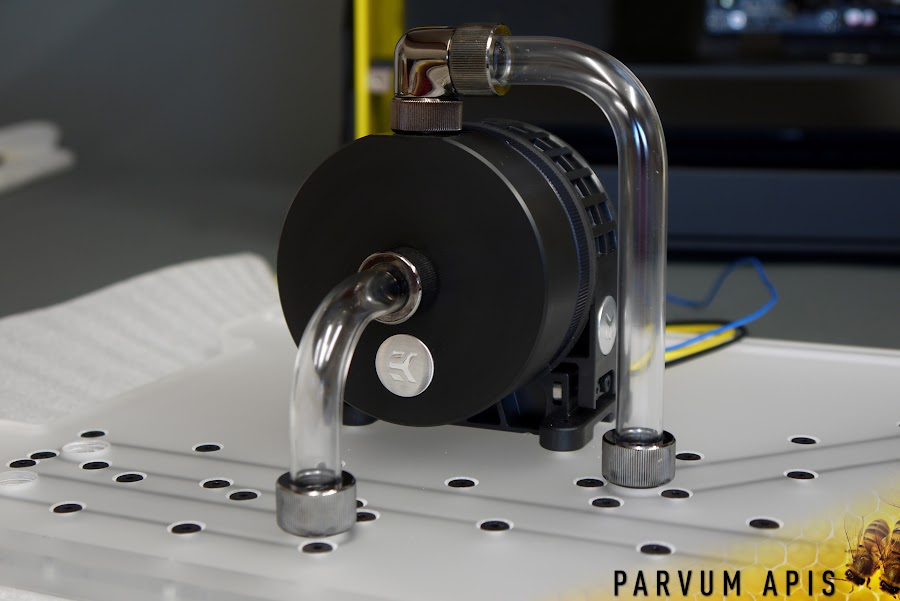

After that I went on to bend some tubing...

...completing the pass-through assembly with all of the push in fittings as well as sleeving the D5 with a Corsair peripheral connector.

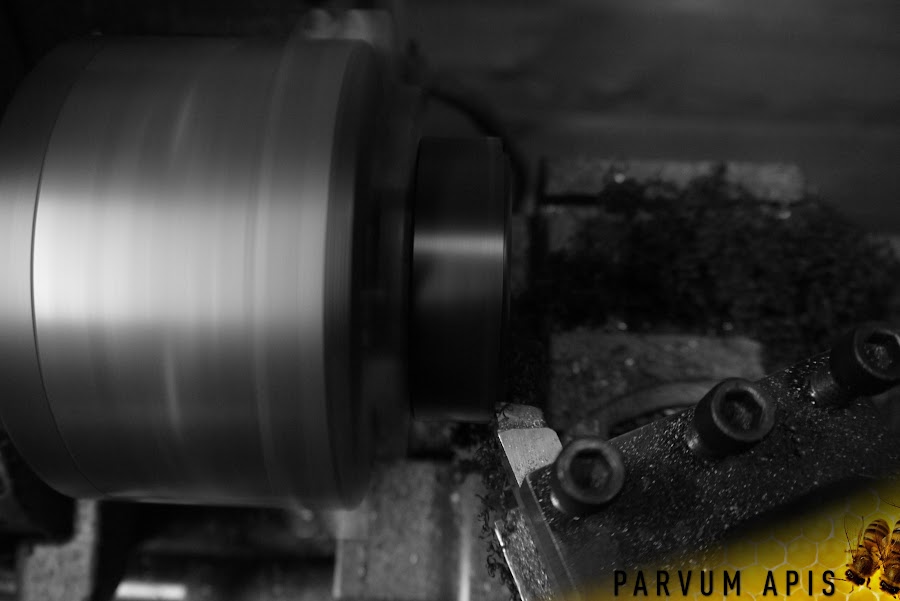

Now for one of the slightly more dramatic moments, unfortunately the reservoir was very slightly too tall for what we had planned. Easily rectified with a little lathe action.

It was only a subtle difference, facing ~2mm off the top and extending the counter-bore which encompasses the recessed stop plug.

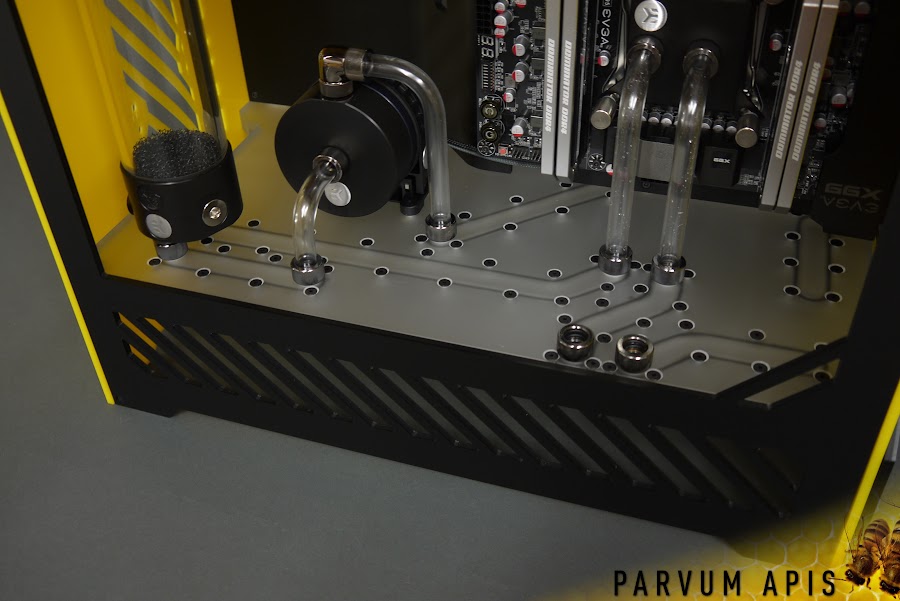

But once in position it was perfect, perhaps even more elegant than if the res had been shorter. The sharp edge blending seamlessly into the case.

If that didn't give away how I chose to mount the reservoir then i'm sure this will. The top is inlaid into the accent of the case and the bottom sitting directly over a pair of push in fittings. The res simply drops through the roof and is trapped in position by the outer black layer of the roof.

I also bored out the recessed holes in the bottom part of the reservoir to accept normal fittings rather than EK's 8mm extenders.

We are extremely pleased with how the loop is taking shape and the contrast of materials and colours on show. Tomorrow we plan to fit the graphics cards, tube those, then assemble the pedestal section with radiators, fans, cables and tubing. The top of the case should simply drop over it and hopefully if there are no major problems we will see how this all looks with some coolant!

JR

Its obvious that you love building these systems and you guys are always trying out new ideas. This is why I'll be buying cases and accessories from Parvum.

Its obvious that you love building these systems and you guys are always trying out new ideas. This is why I'll be buying cases and accessories from Parvum.