Lets plan the Fans!

So I have decided to add an additional 240 Rad in the basement of the case. I have an improvement to the top Rad planned (more on that in a post coming up) however with the plan to add a GTX 1070 down the road, I felt it would be prudent to upgrade my radiator surface area. There is loads of room to add this without getting in the way and it’s not like I’m going to use the basement area for anything else!

So after giving it some thought i have settled on the following fan configuration:

The two front 140mm fans will pull cool air into the case

The rear 140 will exhsaust air out of the case

The 3 120mm fans on the top Rad are configured in PUSH, pushing cool air into the case, not ideal but due to Rad thickness this was the only possible configuration.

the 2 120mm fas on the bottom rad will be configgered in PULL to exhaust air out of the cast

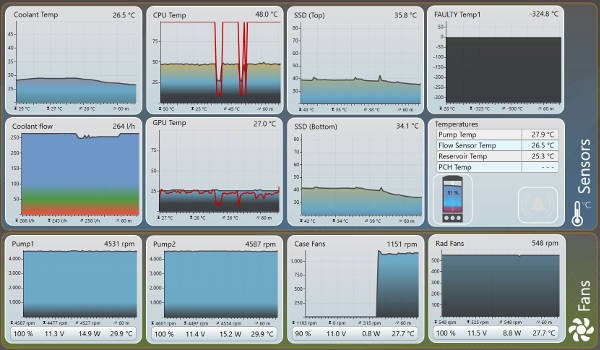

this gives me a reasonably balanced setting, favouring slightly on the positive side. the rad fans normal spin slower than the case fans the way I have them configured.

I have a 6 way PWM splitter coming so I can run them all off the same header and run them off the same speed curve. I have also switched over to controlling the pump and Rad fan’s via water temperature after some testing which is much easier on the ears.