Associate

- Joined

- 4 Jan 2007

- Posts

- 197

- Location

- Stoke

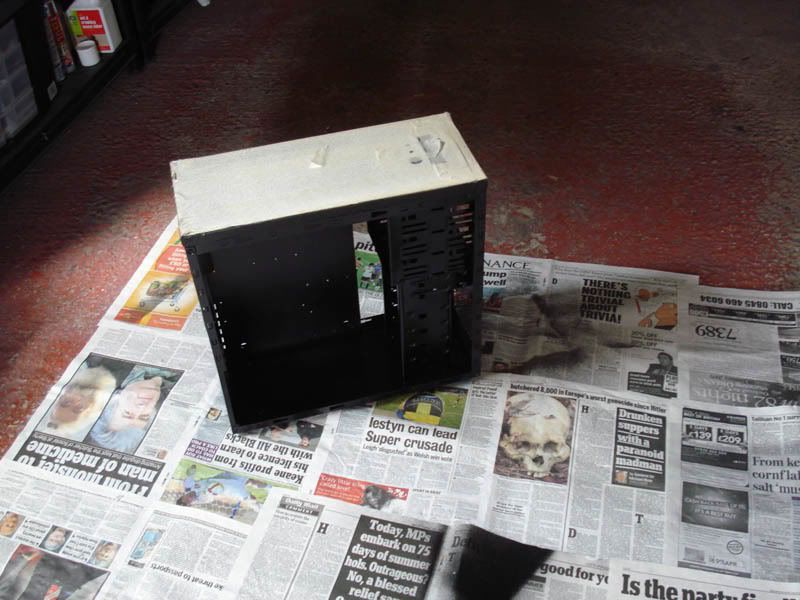

I'm back with a brand new project! Last time I painted the inside of my case black so I'm going for something a bit more adventurous this time.

Basically I'm helping my friend mod a case to take to uni with her. We're both pretty big into computers and she's always complaining about the lack of "nice, girly" cases. So we decided to make our own

When we started the plans were to paint the inside and outside, cut out a window, do something to the front panel to make it clean and simple, possibly put the power buttons on the top, and look into making a fan controller. We didn't have concrete plans but we've just sort of felt our way along.

I did start to post some pictures of this before but I didn't get very far and we hadn't worked on the case for a while. I thought I'd start a new thread and start again now that we've done a lot more work on it.

Pictures to follow in the next post!

Basically I'm helping my friend mod a case to take to uni with her. We're both pretty big into computers and she's always complaining about the lack of "nice, girly" cases. So we decided to make our own

When we started the plans were to paint the inside and outside, cut out a window, do something to the front panel to make it clean and simple, possibly put the power buttons on the top, and look into making a fan controller. We didn't have concrete plans but we've just sort of felt our way along.

I did start to post some pictures of this before but I didn't get very far and we hadn't worked on the case for a while. I thought I'd start a new thread and start again now that we've done a lot more work on it.

Pictures to follow in the next post!

should be good when it's done

should be good when it's done