Associate

Hi all

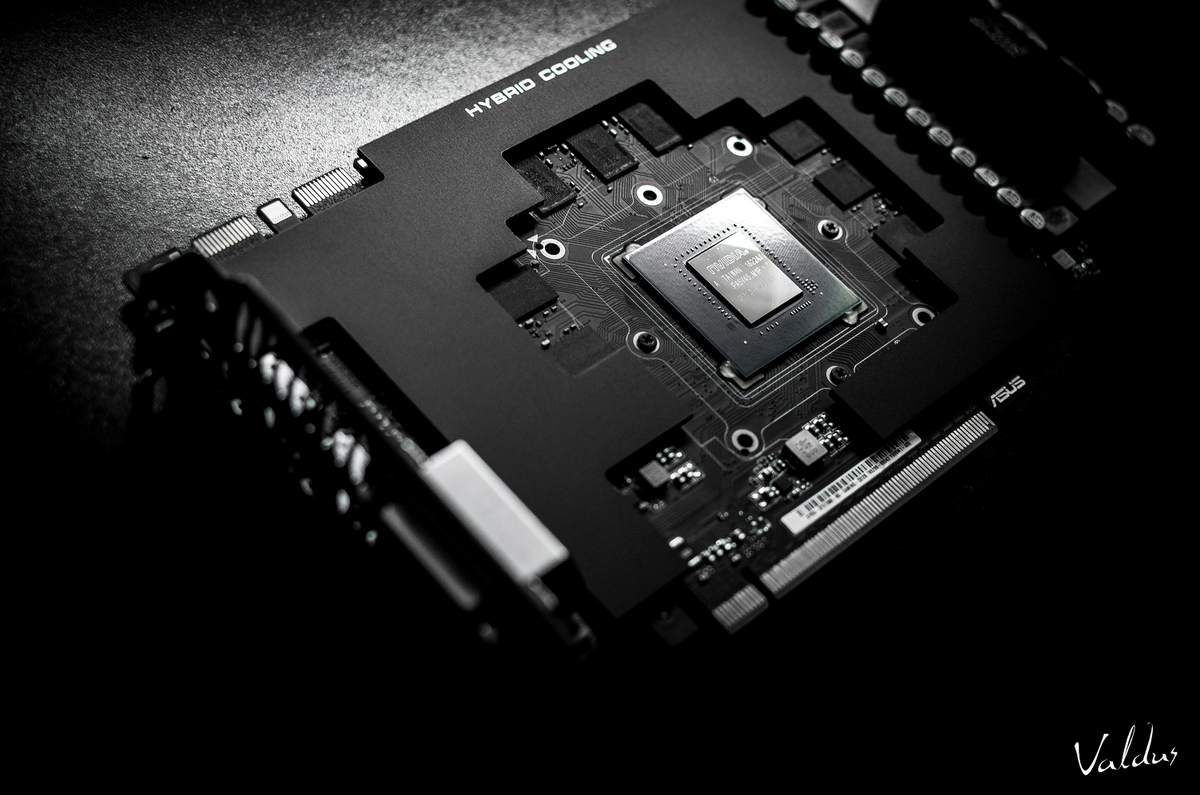

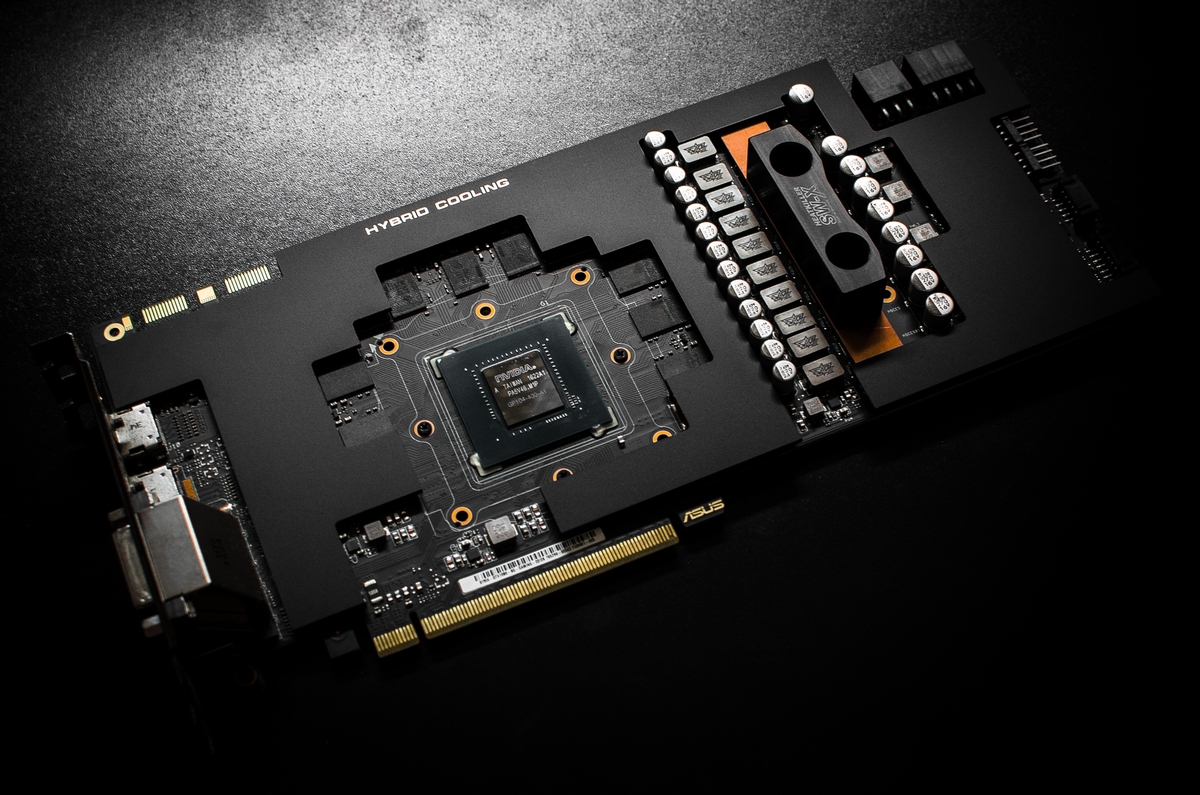

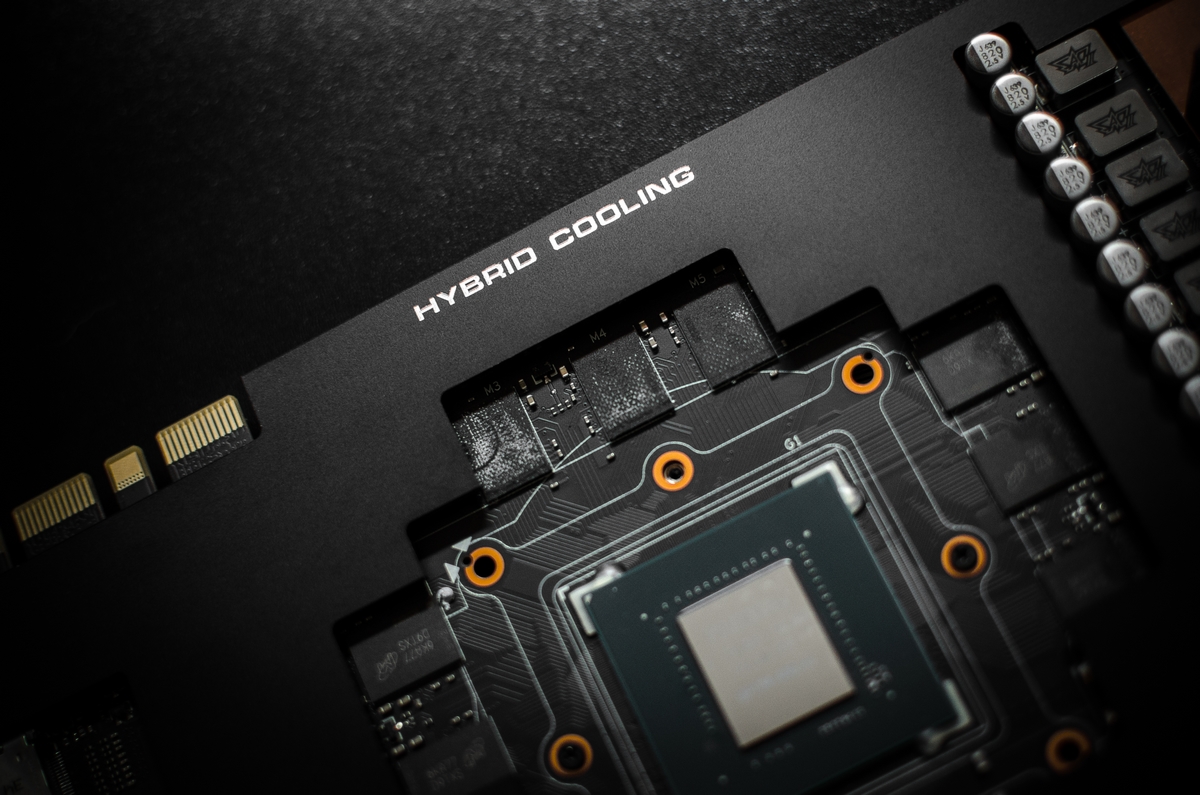

I introduce myself, Valdus, I make a hybrid system for graphics card since... 2014.

(Sorry for my bad English, I'm french)

I started hybrid systems on the Gtx 780 in 2014 and for the Gtx 980 in 2015/2016, and now, I'm making a new version. Best and one made professional.

I use a large numbers of machine (milling machine for example) and 3D software for the design.

Website:

http://valdus.free.fr/

Facebook:

https://www.facebook.com/HybridCoolingModding/

review performance for V2 (Gtx 980):

http://valdus.free.fr/Bench.html

http://valdus.free.fr/generic2.html

Already a few months I started working on this version 3, so I make you a quick summary, date-by-date of what has already been.

-------------------------------------------------------------------------------------

25-07-2016 : Received a GTX 1080 Strix (gaming version)

03-08-2016 : First plans for the Backplate (3ds max 2016).

07-08-2016 : 3D renderings (substance painter)

28-08-2016 : 3D renderings (complete kit)

14-09-2016 :

waterblock HeatKiller for the Gtx 1080 Vrm

)

)

)

)

Very tiring that!

Very tiring that!