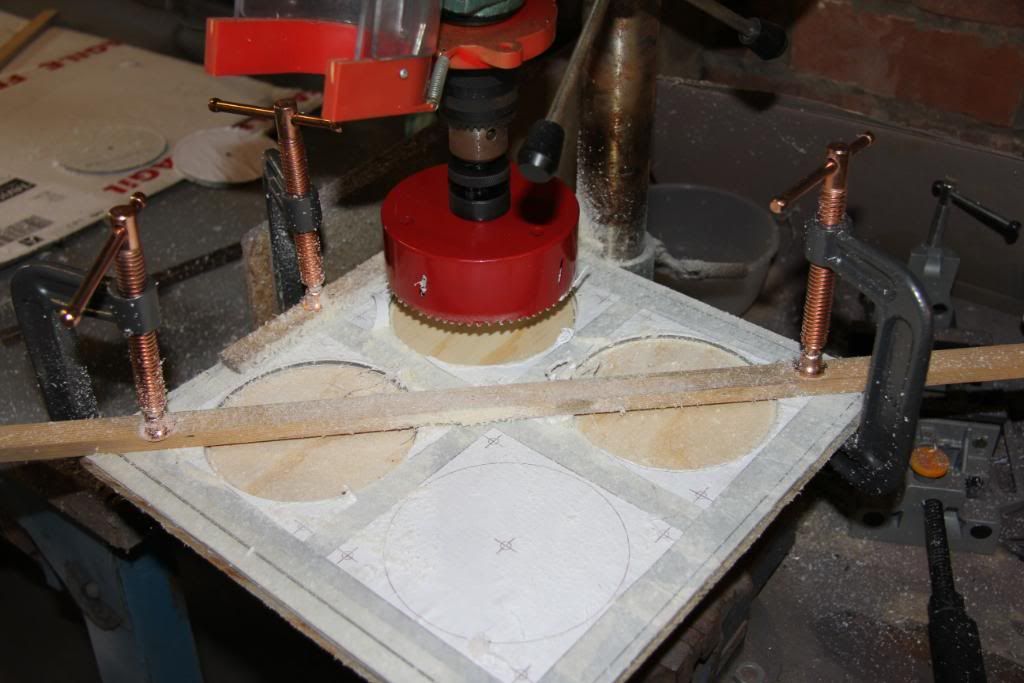

Today saw my first ever use of a hole saw. Man it's a scary bit of kit. Very prone to vibration, and there's just no way holding the job with the hand is going to work.

Still I learned a new set of skills, albeit at a very basic level.

I also learned to take the chuck key out of the drill press before turning it on.

Nearly winged me on the way past and took me a good 20 minutes to find the little git.

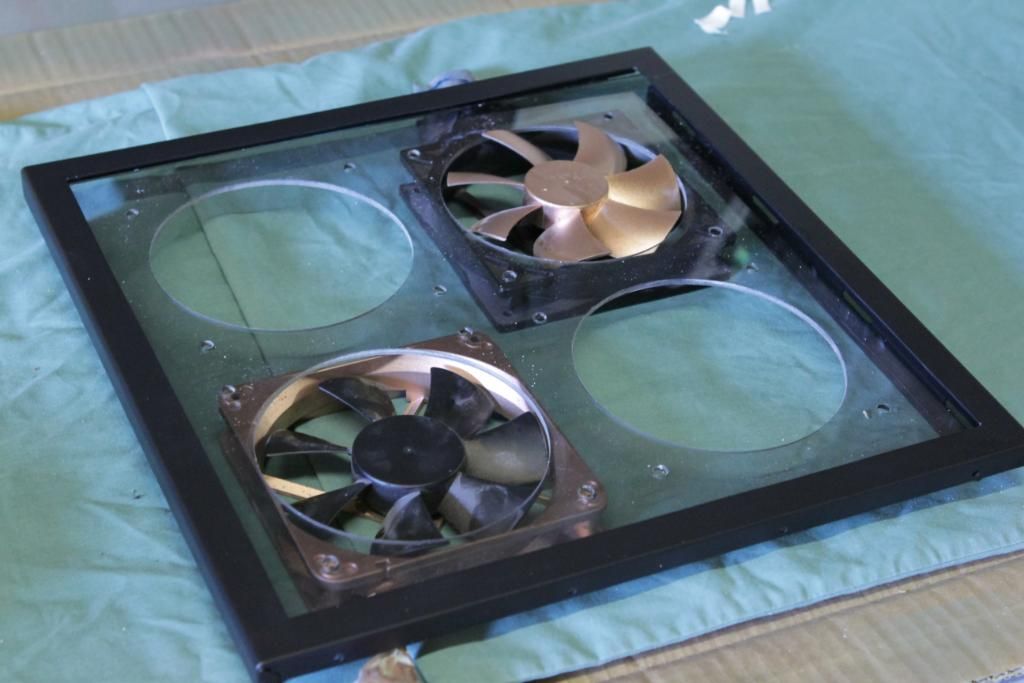

Disaster averted i've managed to cut 4 fan holes in the piece of roof acrylic.

I've actually got 2 pieces of acrylic, this is the lighter of the 2 and I figured as I probably want to use the darker i'd start with the lighter and make my mistakes there.

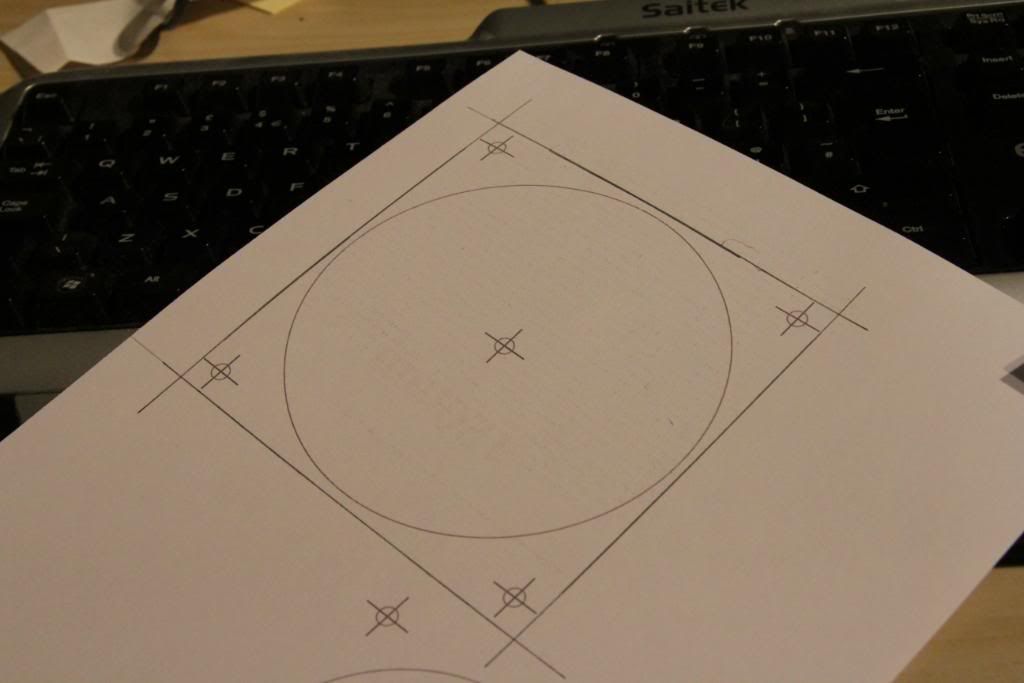

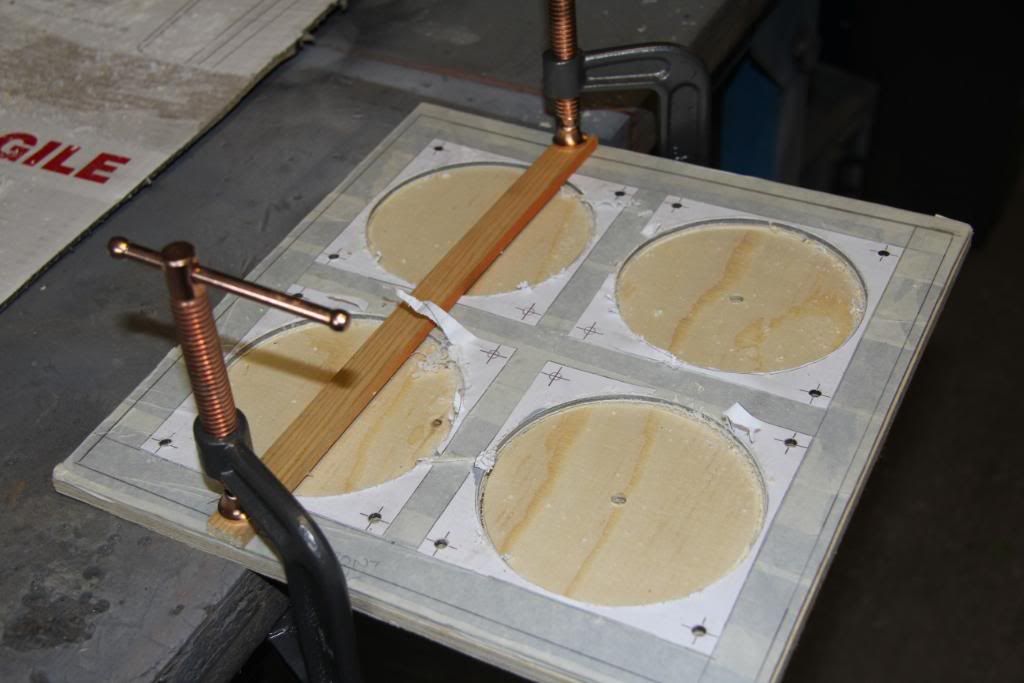

First thing was to make a mask of a 120mm fan.

Like so.

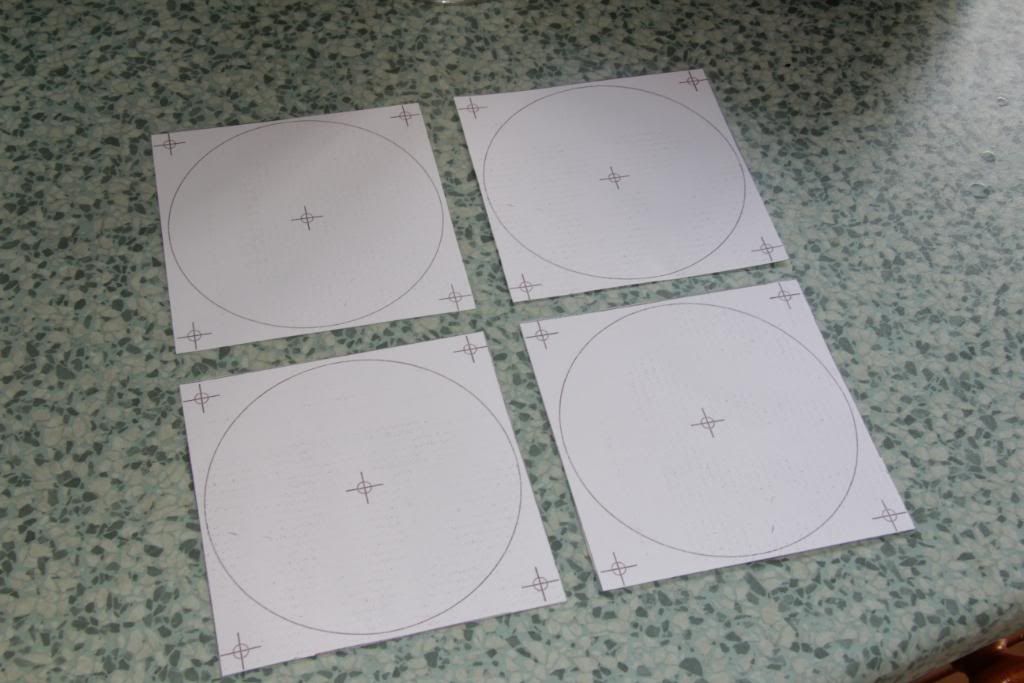

Then make 3 more

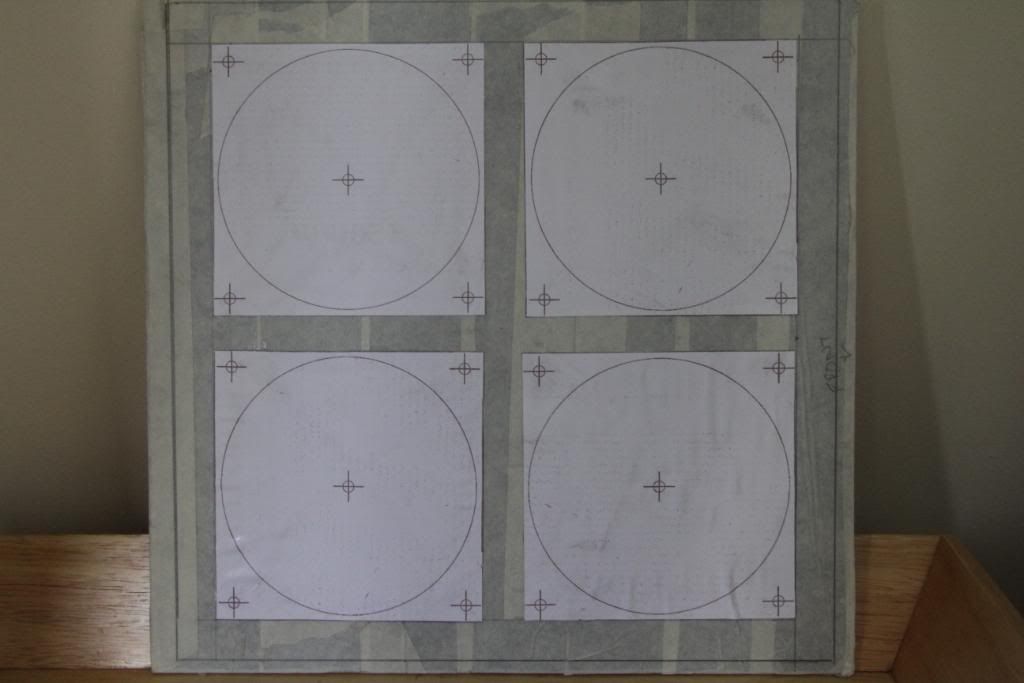

Work out the spacing and then glue them onto the piece of acrylic

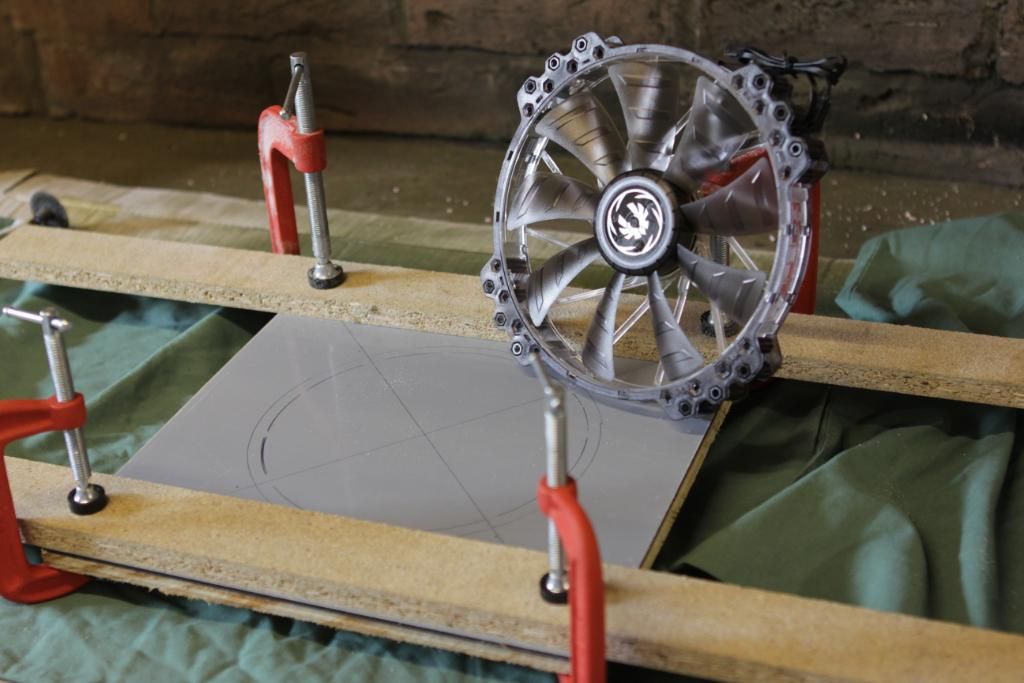

Then get everything clamped down.

Getting everything lined up perfectly

The acrylic drills quite easily, but heck does it make a mess

Last one to go

Then just the fan mounting holes. These were also countersunk.