You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Project NoName

- Thread starter KiNgPiN83

- Start date

More options

View all postsYo OCUK'ers. First of all, sorry for the extreme lack of updates.  I know how frustrating it is to be watching a project and it go quiet... However things have been very busy recently and life has been getting in the way of all my fun things like this. However i have a small update:

I know how frustrating it is to be watching a project and it go quiet... However things have been very busy recently and life has been getting in the way of all my fun things like this. However i have a small update:

I finished masking and primering for the first two levels of the case:

And then set to work on spraying the final colour:

The photo really doesn't do it justice. Paint wise i went for a dark grey stone flecked paint from PlastiKote. This gives a nice textured finish and also means i don't have to worry about glossing and subsequent polishing/wetsanding etc. Lol!

Here are another couple of photos with the masking tape removed:

This brings me on to why the next update is taking a while... I'm currently designing the Mobo level which will sit on top of these two finished levels. What is taking the time is that i'm self taught with this whole design stuff in illustrator and i struggle to visualise my flat drawing on the screen into how it will look cut in the real world. (Everything is designed in Illustrator in 2D and then converted to a .dxf which the laser understands.) So with that in mind i can kind of see what i want in 3D in my head but then i have try and realise this in a 2D design whilst bearing in mind how this 2D design translates to the real world. If that makes sense... Haha! Needless to say i'm slowly getting there and once designed the updates will come thick and fast as i'm able to cut, build and then paint etc. So please bear with me.

I just hope i can do my minds designs justice. But even if i don't quite get there this process has taught me a lot with regards to the design aspect of things plus i can take all this and use it in the next project!

Thanks for reading/looking.

Andy

I know how frustrating it is to be watching a project and it go quiet... However things have been very busy recently and life has been getting in the way of all my fun things like this. However i have a small update:

I know how frustrating it is to be watching a project and it go quiet... However things have been very busy recently and life has been getting in the way of all my fun things like this. However i have a small update:I finished masking and primering for the first two levels of the case:

And then set to work on spraying the final colour:

The photo really doesn't do it justice. Paint wise i went for a dark grey stone flecked paint from PlastiKote. This gives a nice textured finish and also means i don't have to worry about glossing and subsequent polishing/wetsanding etc. Lol!

Here are another couple of photos with the masking tape removed:

This brings me on to why the next update is taking a while... I'm currently designing the Mobo level which will sit on top of these two finished levels. What is taking the time is that i'm self taught with this whole design stuff in illustrator and i struggle to visualise my flat drawing on the screen into how it will look cut in the real world. (Everything is designed in Illustrator in 2D and then converted to a .dxf which the laser understands.) So with that in mind i can kind of see what i want in 3D in my head but then i have try and realise this in a 2D design whilst bearing in mind how this 2D design translates to the real world. If that makes sense... Haha! Needless to say i'm slowly getting there and once designed the updates will come thick and fast as i'm able to cut, build and then paint etc. So please bear with me.

I just hope i can do my minds designs justice. But even if i don't quite get there this process has taught me a lot with regards to the design aspect of things plus i can take all this and use it in the next project!

Thanks for reading/looking.

Andy

Funnily enough I've been really getting into my carpentry at the moment too and contemplating getting a CNC to go with the laser to open up new ideas. (Obviously its another software but still, haha!) I know these are pretty basic but I've made these recently too:

Projector screen holder:

Racing seat: (Needs sanding/painting) (Also excuse the mess.. Lol!)

Projector screen holder:

Racing seat: (Needs sanding/painting) (Also excuse the mess.. Lol!)

Nice to see an updateThese ambitious projects always take their time.

I'm pretty confident working with 2D and 3D relationships and dimensions, thanks to previous experience with fine carpentry and similar. My partner bought a laser so I've been tinkering occasionally. I've had some good successes! My main weakness is definitely the software - I can visualise the parts, and draw them on paper, but no idea how to draw much more than a square!

Keep at it, as you say, the design skills are very much reusable for other projects.

Exactly. When i started out i could pretty much only cut out shapes like hearts and things, so I've come quite far already.

A little update for you guys...

So i'd been stuck into the design aspect of various parts and got myself to the point where i could do a lot of cutting in bulk and guess what happens? Yep, the laser had died.. Well, the PSU had. 2 weeks later i finally get the new psu, fit it and we are back up and running again. So here are the updates:

So here are the updates:

Measuring up how the mobo will fit with regards to the sides:

Made a few calculations based on this so the hole in the side will hopefully line up with the mobo...

Had to cut a new lid as the one in my hand had no holes in it for things to go through: (It also doubles up as a mechanism to position the motherboard section that will sit on top. i.e. the panel supporting the back of the mobo will sit in this recess.)

The mobo support/base of the mobo section being glued together. As you can see i've moved on from random tins of paint and now use weights instead! Haha!

And lastly all the panels cut for the mobo box as it were. We have intake fans on the back and exit fans on the roof. These roof ones will also be where the radiator for the AIO will be mounted. On preparing this post i've noticed i missed a piece which is a shroud for mounting the fans on the radiator. I'll cut this tomorrow when i go to assemble it all.

I was also thinking of mounting a touch screen TFT in the front but i cant afford it at the moment and it doesn't really add too much other than looking cool i guess. (And saving monitor space?) However it could always be added later.

I'm hoping to have another update tomorrow of this lot being assembled and the mobo added. Then i can look at priming and painting it to match the other two levels.

So i'd been stuck into the design aspect of various parts and got myself to the point where i could do a lot of cutting in bulk and guess what happens? Yep, the laser had died.. Well, the PSU had. 2 weeks later i finally get the new psu, fit it and we are back up and running again.

So here are the updates:

So here are the updates:Measuring up how the mobo will fit with regards to the sides:

Made a few calculations based on this so the hole in the side will hopefully line up with the mobo...

Had to cut a new lid as the one in my hand had no holes in it for things to go through: (It also doubles up as a mechanism to position the motherboard section that will sit on top. i.e. the panel supporting the back of the mobo will sit in this recess.)

The mobo support/base of the mobo section being glued together. As you can see i've moved on from random tins of paint and now use weights instead! Haha!

And lastly all the panels cut for the mobo box as it were. We have intake fans on the back and exit fans on the roof. These roof ones will also be where the radiator for the AIO will be mounted. On preparing this post i've noticed i missed a piece which is a shroud for mounting the fans on the radiator. I'll cut this tomorrow when i go to assemble it all.

I was also thinking of mounting a touch screen TFT in the front but i cant afford it at the moment and it doesn't really add too much other than looking cool i guess. (And saving monitor space?) However it could always be added later.

I'm hoping to have another update tomorrow of this lot being assembled and the mobo added. Then i can look at priming and painting it to match the other two levels.

Final update of the evening. (Decided to glue the base to the other bits as i guess it had pretty much dried itself..)

All the panels together:

Base in situ on the lid below:

All the panels glued together:

Hopefully i can start mocking up the bits tomorrow and see where it is before priming/painting this level.

All the panels together:

Base in situ on the lid below:

All the panels glued together:

Hopefully i can start mocking up the bits tomorrow and see where it is before priming/painting this level.

Damn, only thing I could do of this sort is try to assemble basic ikea desk. Great work.

Thanks.

I've basically taught myself how to do the designing and stuff over the last 3 years. Its not too difficult once you get used to it although i still struggle with designing the pieces and imagining how they are going to fit together although i am getting better at this.

I've basically taught myself how to do the designing and stuff over the last 3 years. Its not too difficult once you get used to it although i still struggle with designing the pieces and imagining how they are going to fit together although i am getting better at this.So another little update for you guys. Test fitted the motherboard to see how the ports lined up:

It isn't perfect but its good enough. I may tweak the design so that if i ever cut it out again it will be better. Looks like it could do with moving 1mm to the right and maybe .5 down? Probably down to the 3mm wood not always being 3mm.

I then placed this on top of the other levels to see where we are:

So around 580mm tall right now.

And some other views of it:

I then decided to take it all apart.. Lol! I was never going to paint the insides of the boxes/levels as it wouldn't really be seen and theres nothing exciting like cable management or RGB to show off. However i had a think and thought that maybe it would be best to at least varnish them to make dust removal easier as it seems to get stuck on all the little wood fibres and splinters. So i gave them all a light sand inside and then put a coat of varnish on them:

The wood seems to have soaked this first coat in quite well so i think it may take another coat or two for a nice soft finish. Next coat at 17:00. I've also ordered some more plywood as i was running low and theres still a lot more to cut.

I've also ordered some more plywood as i was running low and theres still a lot more to cut.

It isn't perfect but its good enough. I may tweak the design so that if i ever cut it out again it will be better. Looks like it could do with moving 1mm to the right and maybe .5 down? Probably down to the 3mm wood not always being 3mm.

I then placed this on top of the other levels to see where we are:

So around 580mm tall right now.

And some other views of it:

I then decided to take it all apart.. Lol! I was never going to paint the insides of the boxes/levels as it wouldn't really be seen and theres nothing exciting like cable management or RGB to show off. However i had a think and thought that maybe it would be best to at least varnish them to make dust removal easier as it seems to get stuck on all the little wood fibres and splinters. So i gave them all a light sand inside and then put a coat of varnish on them:

The wood seems to have soaked this first coat in quite well so i think it may take another coat or two for a nice soft finish. Next coat at 17:00.

I've also ordered some more plywood as i was running low and theres still a lot more to cut.

I've also ordered some more plywood as i was running low and theres still a lot more to cut.

Looking nice! Love a good laser cut project.

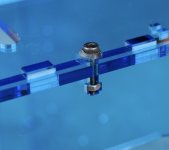

If you’ve not seen them before these joints are cool..

If you overlap the top edge so the slot is closed it will make the whole thing much stronger and also way easier to assemble as it won’t fall apart when you’re trying to put the panels together! The slot for the nut is just tiny bit bigger than the bolt across its flats so it’s held captive.

Also check out living hinges for laser cutting, they really extend the possibilities of the projects you can create with 2D sheets.

Took my eyes a moment to work out that photo but that’s a pretty good idea! I’ve not really done much with living hinges myself although there is a part of this that could probably really benefit from it so I might try it out. I have some designs from other people with living hinges so I may cut one of those to see how my wood copes with it.

I think I’ll try that bolt idea out though as the gluing of all the tabs can be a right pain. Lol

Living hinges will definitely work with that material. For ultra tight radius’ cut out slots (~1.5mm width) with a radius at the ends, you’ll be able to get it to go round a 10p piece. I have some designs if you get stuck.

For that acrylic design above you’ll make life way easier if you have an overhang at the ends so you can make the edge slots closed rather than open. I can send a pic if that doesn’t make sense!

Nice one! That’s good to know.

Have you been lasering long?

Have you been lasering long?I’m sure those can be incorporated into the design to make them less obvious too. Plus they have the benefit of being removable too. I still need to try acrylic. I have some sheets but still have reservations that my 40w laser will cut through it as I’m having to do multiple passes on 3mm plywood at the moment as it is! Really need to upgrade to a bigger machine at some point.

Nice worki like the racing seat.

Sorry, I missed this! Thanks, it replaced my chair/bean bag and is quite comfortable just using it as a seat.

I teach DT/engineering in a secondary school so we use the laser all the time, probably been using one for about 10yrs. 40w should be more than capable of 3mm ply, might be worth checking your mirrors and lens are clean and aligned to make sure the power isn’t being wasted. 3mm acrylic will usually cut better than ply. We’ve just got a new one from HPC that can cut through 15mm acrylic and 9mm ply in one pass. I’ve just bought the old one from the school to use at home and that is quite old but it will cut through 3mm ply and acrylic no problem, managed to get it for £100 as it overheats when you do a long job, hopefully I can have a play and improve it slightly

That’s cool. Not sure I could handle the kids though but that’s probably my three year olds fault. I guess the older ones might not be as bad. Haha! I did clean them when I fit the new psu a week or so ago. (Also changed the tube but the other seems doa which is annoying) i’ll give them another check later and check the head one as that’s always a pain to get to so could be a bit dirty. Do you have much experience of tube life? Could by existing tube be giving up if I’m still having problems? Wow that new one sounds like a beast! I was going to go HPC but chose these other guys instead and they’ve now gone under.. however my next one may come from them I think. That’s a bargain for you with the old one too! I take it it’s not water cooled? Mine uses the cw3000 which seems to be the standard for entry level water cooled lasers. Even on long photo engravings/cutting sections I only just about see 30 degrees I think. Hopefully you can get it fixed.

Should also have another update tonight. Ran out of paint and then had to use a different primer and now my colour matching is a bit rubbish. I’m hoping I’ve just fixed that but need to wait for it to dry.

Little update.

So here is where i ended up after the different primer issues:

As you can see the colour is way off...

So i tried another primer which i believed was the right one and went straight over the top of it. (I know, i know that is horrible but i really couldn't bring myself to sanding it all back as its really textured and full of flecks so it would've taken ages...) Once that primer dried i whacked another coat of the finish over the top and we are now here:

Its not hugely obvious but i'm afraid we have now gone the other way and the top is now lighter than the two original boxes/levels... It was at this point that i was really really learning my lesson. "Though shall not be impatient and paint bits separately and forget what primers they are using."

It was at this point that i was really really learning my lesson. "Though shall not be impatient and paint bits separately and forget what primers they are using."

We are now here in the "Spray Booth" (En suite to man room. Luckily my wife doesnt really go in there. Haha!)

Just waiting for the primer to dry on the bottom two levels then another top coat and they should all look the same. Luckily i don't think i have any other bits that need to be this colour/finish. However, I've learnt a painting lesson so its all good.

So here is where i ended up after the different primer issues:

As you can see the colour is way off...

So i tried another primer which i believed was the right one and went straight over the top of it. (I know, i know that is horrible but i really couldn't bring myself to sanding it all back as its really textured and full of flecks so it would've taken ages...) Once that primer dried i whacked another coat of the finish over the top and we are now here:

Its not hugely obvious but i'm afraid we have now gone the other way and the top is now lighter than the two original boxes/levels...

It was at this point that i was really really learning my lesson. "Though shall not be impatient and paint bits separately and forget what primers they are using."

It was at this point that i was really really learning my lesson. "Though shall not be impatient and paint bits separately and forget what primers they are using."We are now here in the "Spray Booth" (En suite to man room. Luckily my wife doesnt really go in there. Haha!)

Just waiting for the primer to dry on the bottom two levels then another top coat and they should all look the same. Luckily i don't think i have any other bits that need to be this colour/finish. However, I've learnt a painting lesson so its all good.

Much better:

Will leave it to dry fully until the morning and work on some other stuff for the rest of the night. Also ordered the screws for the doors and some other bits earlier so should be ready to start some assembly and test running within the next week or so i think. I was going to use rivets but i think they'll destroy the wood which wont be enjoyable. Lol!

Will leave it to dry fully until the morning and work on some other stuff for the rest of the night. Also ordered the screws for the doors and some other bits earlier so should be ready to start some assembly and test running within the next week or so i think. I was going to use rivets but i think they'll destroy the wood which wont be enjoyable. Lol!

Another little update. Started putting the hardware in and connecting it as i dont think i'm going to have anymore painting required on the bits i've already done. Here is how it stands:

PSU went in really nicely and seems quite stable.

Motherboard in place and cables fed through to where they need to be. That was a job in itself though and just about manageable with the doors i put in the sides. One cable hole wasn't big enough for the small motherboard PSU connector so i fed it through the GPU power cable(s) hole instead which is ok. It would've been nice to have had a modular PSU but i really can't afford it at the moment plus these are all old components anyway so i'd rather just keep them together as they were.

Views inside the doors at the state of the cables:

This is probably it for today although i may mount the AIO on the CPU as i can at least then power it up and see whats what.

PSU went in really nicely and seems quite stable.

Motherboard in place and cables fed through to where they need to be. That was a job in itself though and just about manageable with the doors i put in the sides. One cable hole wasn't big enough for the small motherboard PSU connector so i fed it through the GPU power cable(s) hole instead which is ok. It would've been nice to have had a modular PSU but i really can't afford it at the moment plus these are all old components anyway so i'd rather just keep them together as they were.

Views inside the doors at the state of the cables:

This is probably it for today although i may mount the AIO on the CPU as i can at least then power it up and see whats what.

Small update today. Fitted the power/reset buttons and LED's:

Just need to add the buttons themselves(They are currently being painted) and a small surround to make it look a bit neater.

Also prepped the graphics cards. Needed to replace the thermal pads for the RAM and while i was there reapply compound to GPU's. Also gave one of the cards a dust with a paintbrush as i'd seemingly forgotten to before. Just need to do a bit more work to actually mount them in the case as they aren't being mounted in a standard fashion...

Naked card.

New pads:

Dusty:

Clean:

And now we have two GPU's ready to go. I have got some other updates but i'm holding them back as i want to show them complete rather than in stages. Although i'll post them as stages if that makes sense? It kind of gives away the theme of the build if i do it now.

I have got some other updates but i'm holding them back as i want to show them complete rather than in stages. Although i'll post them as stages if that makes sense? It kind of gives away the theme of the build if i do it now.

Just need to add the buttons themselves(They are currently being painted) and a small surround to make it look a bit neater.

Also prepped the graphics cards. Needed to replace the thermal pads for the RAM and while i was there reapply compound to GPU's. Also gave one of the cards a dust with a paintbrush as i'd seemingly forgotten to before. Just need to do a bit more work to actually mount them in the case as they aren't being mounted in a standard fashion...

Naked card.

New pads:

Dusty:

Clean:

And now we have two GPU's ready to go.

I have got some other updates but i'm holding them back as i want to show them complete rather than in stages. Although i'll post them as stages if that makes sense? It kind of gives away the theme of the build if i do it now.

I have got some other updates but i'm holding them back as i want to show them complete rather than in stages. Although i'll post them as stages if that makes sense? It kind of gives away the theme of the build if i do it now.

Have you finished it now? any more photos? Build looks very good - them joints are perfect. Like others I have wondered about building in a drawer but others have had issues like with earthing - does yours work well.

Not quite. Been painting some bits today and trying to figure out how to mount the GPU’s as the way I planned and designed, didn’t actually fit. At this point I probably should’ve redesigned but I’d already used a few sheets of wood and glued bits so I’m persevering.. It should be ok though.

I probably could’ve hidden the joints a bit better with filler as there are some small gaps but this is my first go at a case so I wasn’t too bothered to be honest. I don’t think i’ll Have any issues as the motherboard is mounted properly on standoffs etc but I guess we’ll see in the next week or so.

I probably could’ve hidden the joints a bit better with filler as there are some small gaps but this is my first go at a case so I wasn’t too bothered to be honest. I don’t think i’ll Have any issues as the motherboard is mounted properly on standoffs etc but I guess we’ll see in the next week or so.I've been having a nightmare with some parts of the design. However i have made a bit of progress:

Chiselled off some bits that i forgot would come into contact with the roof when i was designing it...

As you can see before that was chiselled off it stopped the roof fitting flush. Once these bits were removed however...

Relatively impressed that it doesn't look terrible:

Power/reset buttons painted and stuck to their appropriate switches. The rest button seems a bit stiff though.. Nothing a bit of sandpaper wont fix...

Also i had to remove the heat sink from the GPU and noticed that the pads between RAM and heat sink were too thick and the GPU wasn't making contact with the heat sink!! So i ordered thinner pads and will make sure this wont happen again as i dont really want to burn the GPU out. Lol!

So i ordered thinner pads and will make sure this wont happen again as i dont really want to burn the GPU out. Lol!

Going back to the design issues this involves the mounting of the GPU's. (Even designing new mounts/shrouds for the GPU's fans to replace the shroud/fan that came with them!!) Think i'm almost there though... Although i'm on holiday for the next two weeks so the update may be a bit slow i'm afraid.

Chiselled off some bits that i forgot would come into contact with the roof when i was designing it...

As you can see before that was chiselled off it stopped the roof fitting flush. Once these bits were removed however...

Relatively impressed that it doesn't look terrible:

Power/reset buttons painted and stuck to their appropriate switches. The rest button seems a bit stiff though.. Nothing a bit of sandpaper wont fix...

Also i had to remove the heat sink from the GPU and noticed that the pads between RAM and heat sink were too thick and the GPU wasn't making contact with the heat sink!!

So i ordered thinner pads and will make sure this wont happen again as i dont really want to burn the GPU out. Lol!

So i ordered thinner pads and will make sure this wont happen again as i dont really want to burn the GPU out. Lol!Going back to the design issues this involves the mounting of the GPU's. (Even designing new mounts/shrouds for the GPU's fans to replace the shroud/fan that came with them!!) Think i'm almost there though... Although i'm on holiday for the next two weeks so the update may be a bit slow i'm afraid.